Lotus root-shaped porous metal finite element analysis method based on reverse reconstruction

A lotus-shaped porous, analysis method technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as complex structure, different length of pores, irregular shape of pores, etc., and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

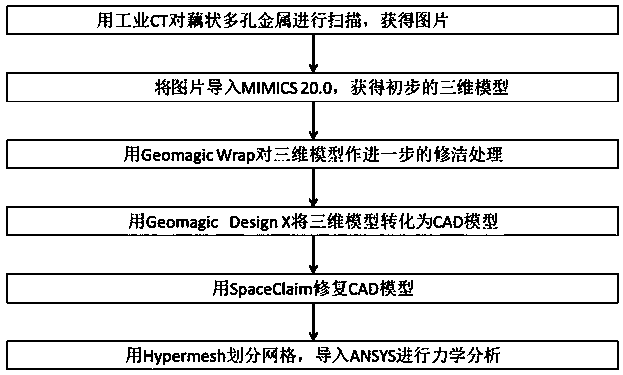

[0026] A finite element analysis method for lotus-shaped porous metal based on inverse reconstruction, the compression performance simulation of lotus-shaped porous copper, specifically includes the following steps:

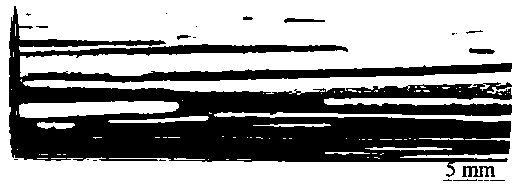

[0027] (1) Preparation of lotus root-shaped porous metal by directional solidification of gas-metal eutectic: In this example, high-purity copper (99.99%, mass fraction) is used. First, the weighed copper is put into a melting crucible, and vacuumized to After 1Pa, heat slowly until the metal melts, fill it with high-purity hydrogen to 0.6MPa, and keep it at 1573K for 10 minutes, then turn on the pull-down system, and the copper liquid will flow out and solidify in the mold, driven by the pull rod with a pulling speed of 30mm / min Gradually pull out the lotus-shaped porous copper;

[0028] (2) Use industrial CT to scan the sample, scan a picture at an interval of 10 microns, obtain multiple consecutive micron-level pictures and number them sequentially;

[0029] ...

Embodiment 2

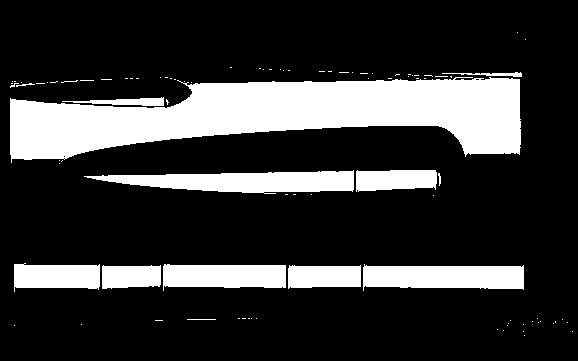

[0038] A finite element analysis method for lotus-shaped porous metals based on inverse reconstruction, the tensile performance simulation of lotus-shaped porous Cu-0.3Cr, specifically includes the following steps:

[0039] (1) Preparation of lotus-shaped porous metal by directional solidification of gas-metal eutectic: In this example, high-purity copper (99.99%, mass fraction) and Cu-10%Cr (mass fraction) alloy are used, according to Cu-0.3Cr For the stoichiometric ratio of the alloy, put the weighed metal into the melting crucible, evacuate to 1Pa, then slowly heat until the metal melts, fill in high-purity hydrogen to 0.6MPa, and keep it at 1573K for 15 minutes, then turn on the pull-down system, the alloy The liquid flows out and solidifies in the mold, and the lotus-shaped porous copper Cu-0.3Cr is gradually drawn under the drive of the draw bar with a pulling speed of 20mm / min;

[0040] (2) Use industrial CT to scan the sample, scan a picture at an interval of 10 micron...

Embodiment 3

[0050] A finite element analysis method for lotus-shaped porous metals based on inverse reconstruction, the tensile performance simulation of lotus-shaped porous Cu-0.8Cr, specifically includes the following steps:

[0051] (1) Preparation of lotus-shaped porous metal by directional solidification of gas-metal eutectic: This example uses high-purity copper (99.99%, mass fraction) and Cu-10%Cr (mass fraction) alloy, according to Cu-0.8Cr For the stoichiometric ratio of the alloy, put the weighed metal into the melting crucible, evacuate to 1Pa, then slowly heat until the metal melts, fill in high-purity hydrogen to 0.6MPa, and keep it at 1573K for 5 minutes, then turn on the pull-down system, the alloy The liquid flows out and solidifies in the mold, and the lotus-shaped porous Cu-0.8Cr is gradually drawn under the drive of the drawbar with a pulling speed of 25mm / min;

[0052] (2) Use industrial CT to scan the sample, scan a picture at an interval of 10 microns, obtain multipl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com