Calibration method for tyre uniformity test

A calibration method and uniformity technology, applied in the field of grades, can solve problems such as tire unevenness, uneven density, geometric deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

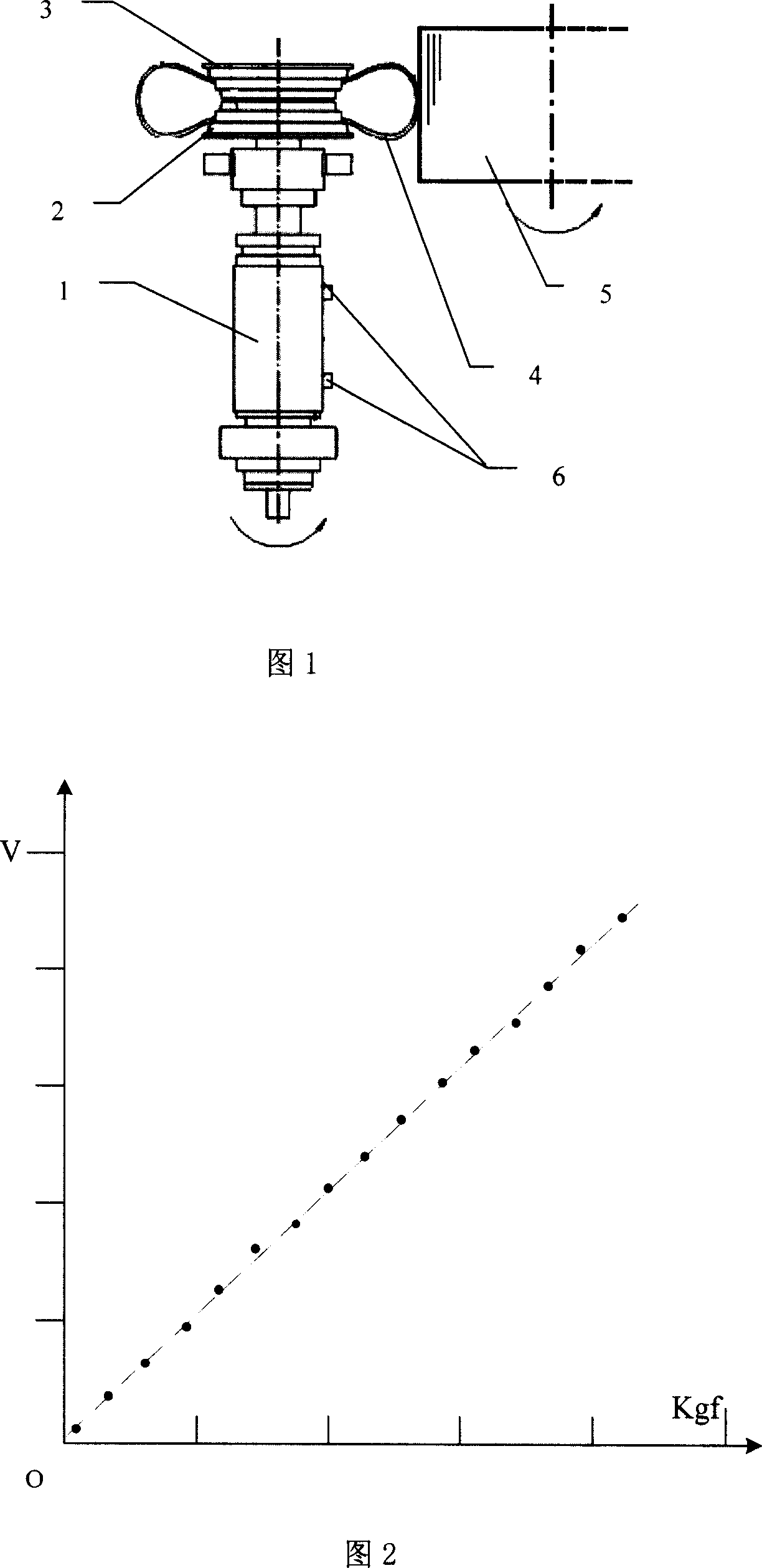

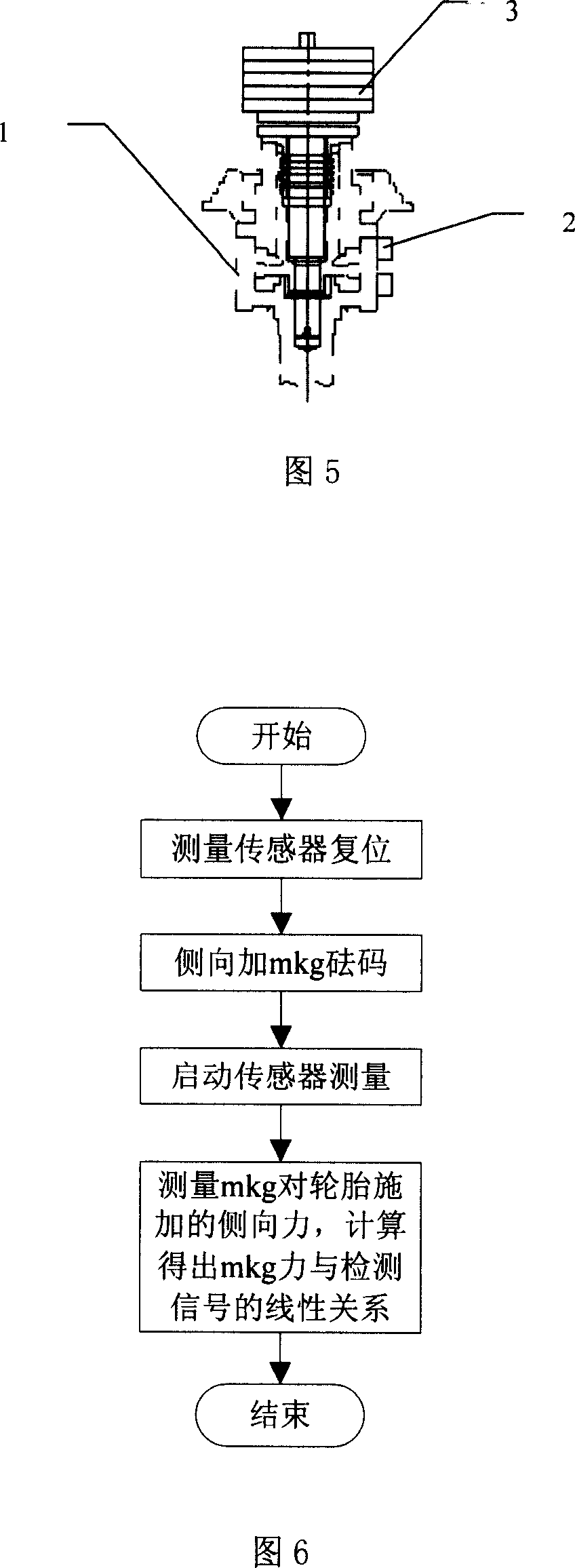

[0028] Embodiment 1, as shown in Figures 2 to 6, the calibration method applied to the tire uniformity test according to the present invention is to use the test device shown in Figure 1 to carry out the uniformity test on the tire before the load cell The linear relationship between the measured voltage value and the radial force and lateral force of the tire is used for calibration.

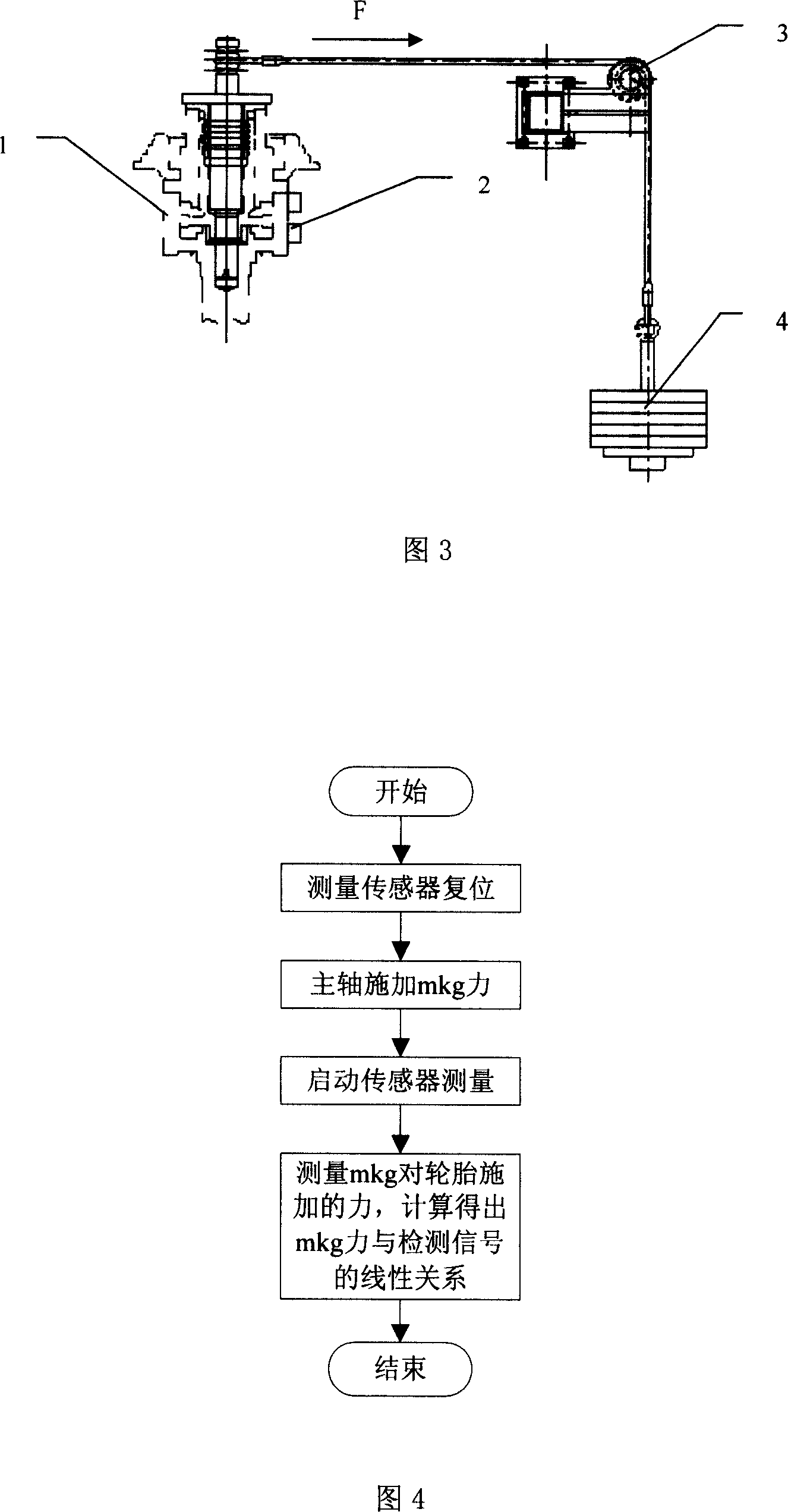

[0029] Taking any measurement of radial force or lateral force as an example, as shown in Figure 2, the abscissa in the figure represents the force value of the tire under test conditions, and the ordinate represents the value measured and output by the sensor. voltage value.

[0030] Through the actual measured data, it can be observed that in the coordinate system, the voltage signal output by the sensor is linearly related to the pressure value of the actual tire, and a linear curve can be obtained through fitting.

[0031] The calibration method of the uniformity test is to determine the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com