Sleeve flashover characteristic measuring device considering humidity influence

A flashover characteristic and measuring device technology, which is applied in the field of casing flashover characteristic measuring devices, can solve the problems of complicated and complicated operation, low detection efficiency, condensation residue, etc., so as to improve detection efficiency, simplify operation steps, and promote accelerated vaporization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

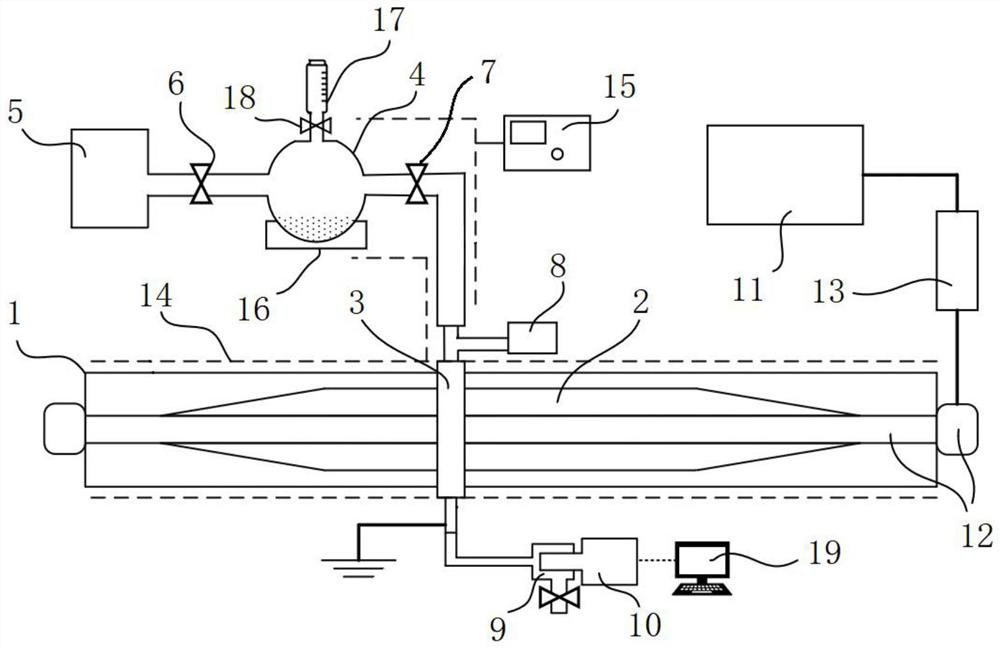

[0029] like figure 1 As shown, this embodiment provides a casing flashover characteristic measurement device considering the influence of humidity, including a high-voltage casing, a humidity adjustment device, a suction device 8, a humidity detection device, a power supply device, and a temperature control device;

[0030] The high-voltage bushing includes a capacitor core 2, an outer casing 1 and a casing flange 3. The capacitor core 2 is arranged inside the outer casing 1, the casing flange 3 is installed on the outer casing 1, and the casing flange 3 is provided with There is an air inlet and an air outlet communicated with the inner cavity of the outer casing 1;

[0031] The humidity adjustment device includes a moisture addition chamber 4 and a gas addition chamber 5, the moisture addition chamber 4 is provided with a first channel and a second channel, the first channel is connected with the gas addition chamber 5, and the second channel is connected with the inlet on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com