Intelligent electric execution device with stable adjustment performance

An electric execution and intelligent technology, which is applied in the direction of electromechanical devices, valve operation/release devices, valve devices, etc., can solve the problems that the reduction gear cannot be adjusted, cannot be adjusted, and the valve is damaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

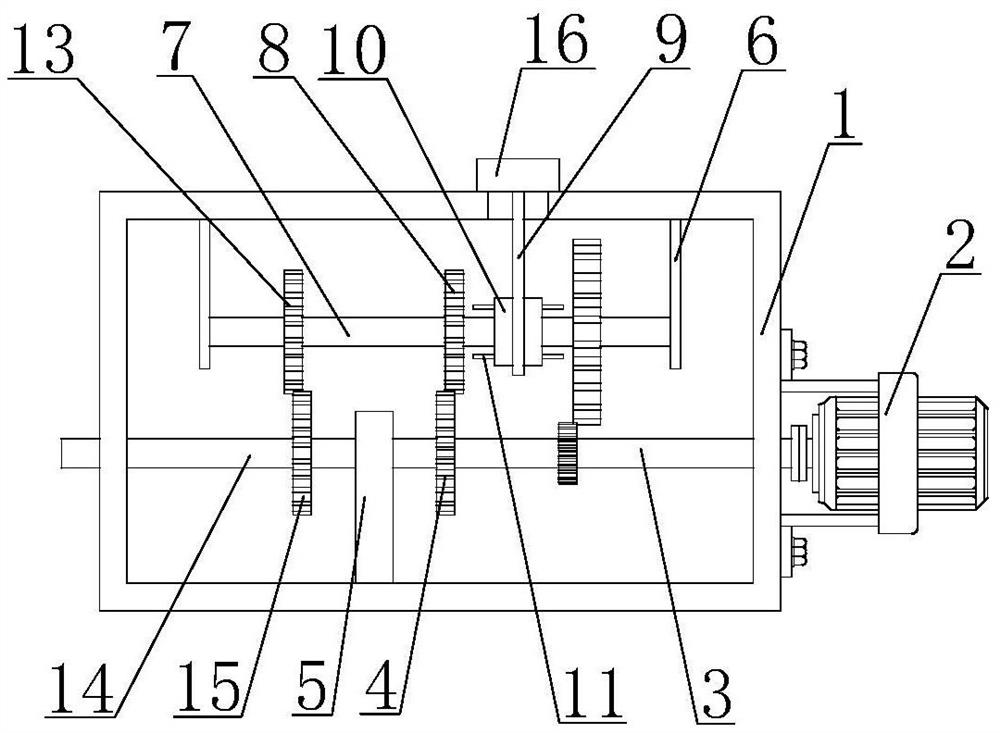

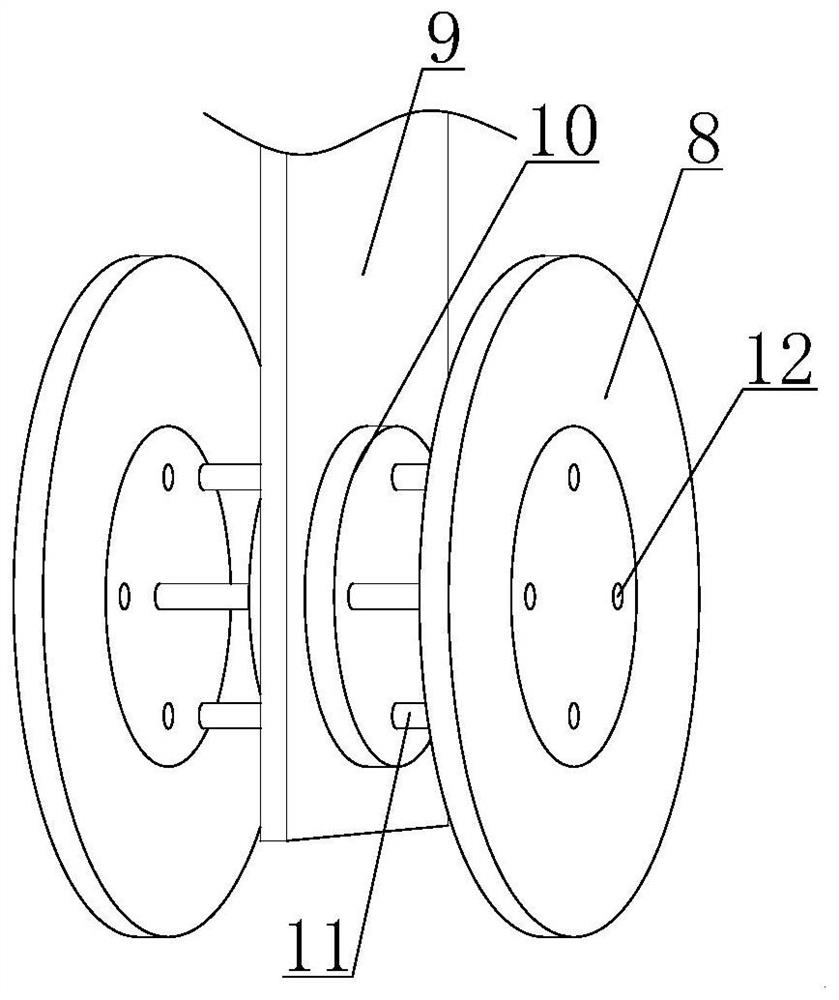

[0023] like figure 1 and image 3 As shown, this specific embodiment adopts the following technical solutions: an intelligent electric actuator with stable adjustment performance, comprising a casing 1, one end of the casing 1 is fixedly connected with a motor 2, and the output end of the motor 2 extends to the casing The inside of the body 1 is fixedly connected with a No. 1 transmission rod 3, the rod wall of the No. 1 transmission rod 3 is fixedly connected with a No. 1 gear set 4, the No. 1 gear set 4 is meshed with a No. 2 gear set 8, and the inner sleeve of the No. 2 gear set 8 is connected There is a No. 2 transmission rod 7, the two ends of the No. 2 transmission rod 7 are inserted with a No. 2 support plate 6, the No. 2 support plate 6 is fixedly connected with the inner wall of the housing 1, and the gears of the No. 2 gear set 8 are connected. Sleeve 10, the connecting sleeve 10 is fixedly connected with the No. 2 transmission rod 7, both ends of the connecting sle...

Embodiment 2

[0029] like Figure 2-5 As shown, this specific embodiment adopts the following technical solutions:

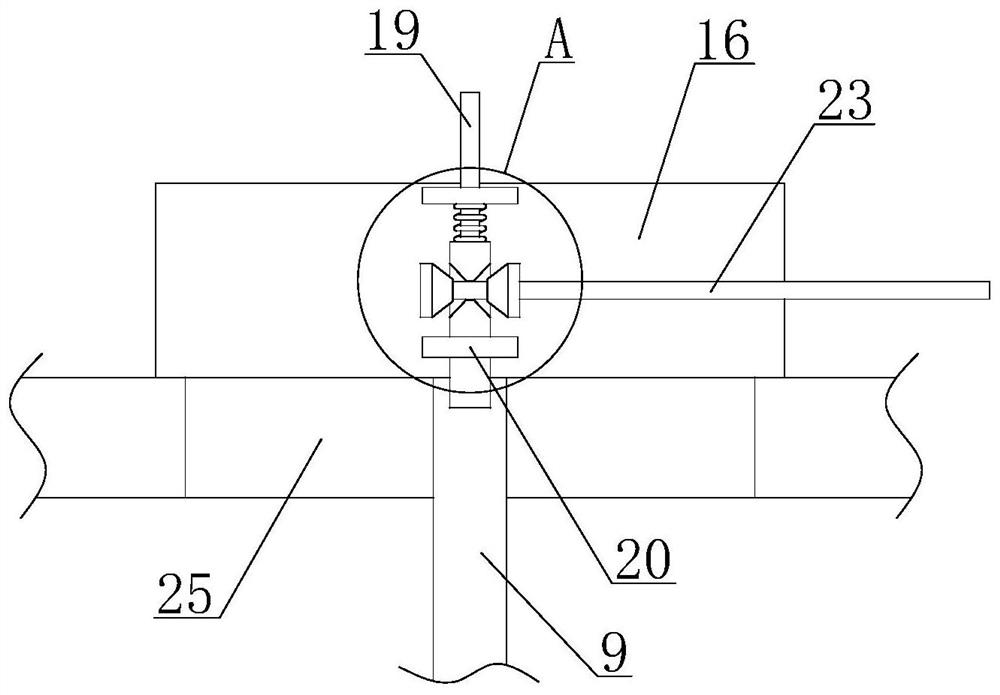

[0030] The top of the transmission block 16 close to the limit rod 21 is fixedly connected with a limit plate 17 , the middle of the limit plate 17 is inserted into the limit rod 19 , and the bottom of the limit rod 19 is fixed with the limit rod 21 The transmission block 16 is located below the No. 1 limit plate 17 and is fixedly connected with the No. 2 limit board 20. The limit rod 21 is inserted into the No. 2 limit board 20, and the top of the limit rod 21 is connected to the No. 1 limit board. A spring 18 is fixedly connected between 17 .

[0031] The upper end of the limit rod 21 is drilled with a No. 1 through hole 22 , a transmission rod 23 is inserted into the inside of the No. 1 through hole 22 , and a trapezoidal limit block 24 is fixedly connected to both sides of the transmission rod 23 located in the No. 1 through hole 22 . , both ends of the No. 1 through ho...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap