Fractionation of soybean 7s globulin and 11S globulin and process for producing the same

一种分级分离、大豆蛋白的技术,应用在化学仪器和方法、植物肽、肽源等方向,能够解决不能加快7S球蛋白和11S球蛋白分级分离等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

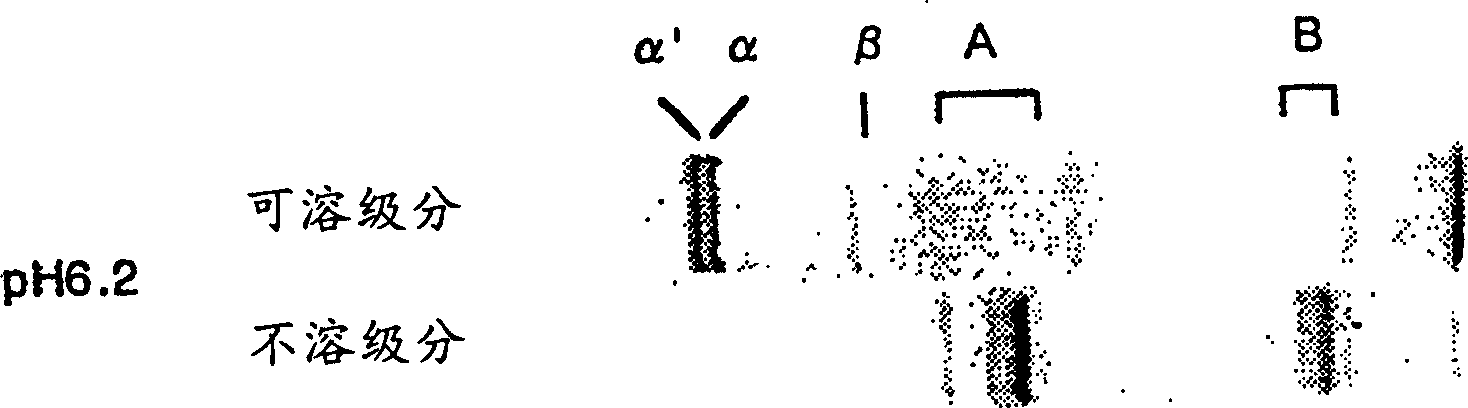

[0031] Soybeans were shaved into flakes, and the oil was extracted using n-hexane as an extraction solvent. The oil was separated and removed to obtain almost non-denatured defatted soybean protein (1 wt., NSI 91), to which water (7 wt.) was added. protein. The mixture was extracted at pH 1 at room temperature for 1 hour, and then centrifuged to obtain defatted soybean milk. The pH of this soybean milk was adjusted to 6.2 with hydrochloric acid, and heated to 40°C, in this solution (phytic acid content: 2.20% protein weight; TCA solubility: 8.6%) was added phytase ("phytase NOVOL ", produced by NOVO company), the addition is 8 units of protein per part of weight, and the enzyme treatment is carried out for 30 minutes. After the reaction, the mixture (phytic acid content 0.05% / protein weight; TCA solubilization: substantially the same as before the reaction) with the enzyme-treated mixture does not need to change the pH, and it is still 6.2, which is to use a batch type centri...

Embodiment 2

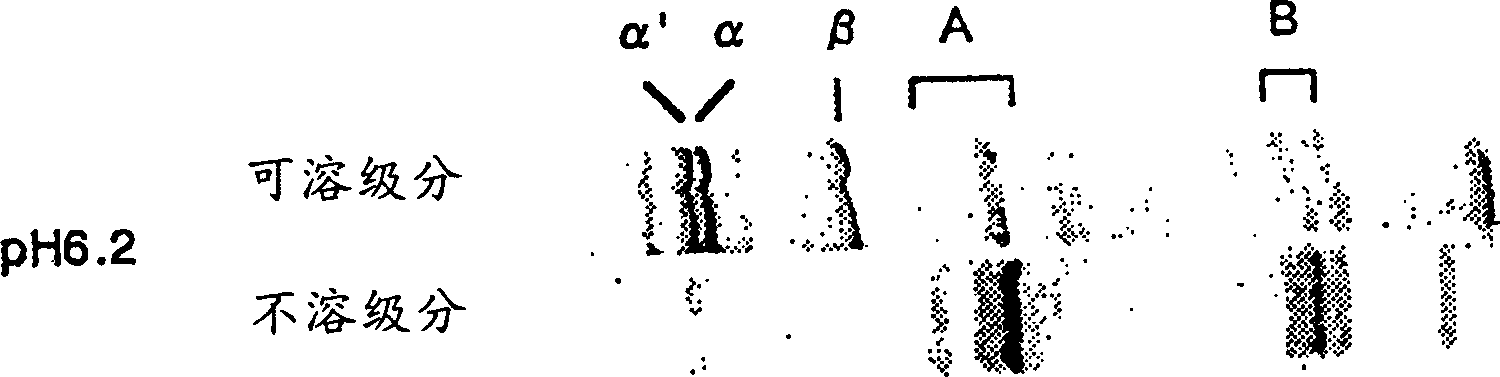

[0053] Extraction was carried out in the same manner as described in Example 1 to obtain defatted soybean milk, which was adjusted to pH 5.9 or 6.4 with hydrochloric acid and heated to 40°C. Phytase ("Phytase NOVOL", produced by NOVO Company) was added to the solution in an amount equal to 8 units by protein weight, and the enzyme treatment was carried out for 30 minutes. After the reaction, without changing the pH, the mixture treated with the enzyme was centrifuged (3,000G) with a batch type centrifuge to obtain an insoluble fraction and a soluble fraction.

[0054] In the same manner as described in Example 1, the contents of 7S and 11S globulin in the insoluble and soluble fractions of Example 2 were calculated. The results are shown in Table 5 and Table 6.

[0055] Soluble Fraction Insoluble Fraction

[0056] Soluble Fraction Insoluble Fraction

[0057] From the above results, it can be seen that the pH during centrifugation, that is, the pH of fracti...

Embodiment 3

[0059] Extract in the same manner as described in Example 1 to obtain defatted soybean milk, adjust its pH to 4.0 or 7.0 with hydrochloric acid, and heat to 40°C. Phytase ("Phytase NOVOL", produced by NOVO Company) was added to the solution in an amount equal to 8 units by protein weight, and the enzyme treatment was carried out for 30 minutes. After the reaction, the mixture with pH 4.0 (phytic acid content: 0.05% / weight of protein) was adjusted to pH 6.2 with sodium hydroxide, and the mixture with pH 7.0 (phytic acid content: 0.08% / weight of protein) Adjust the pH to 6.2 with hydrochloric acid. Then, each mixture was centrifuged with a batch type centrifugal separator (3,000G) to obtain an insoluble fraction and a soluble fraction.

[0060] In the same manner as described in Example 1, the contents of 7S and 11S globulin in the insoluble and soluble fractions of Example 3 were calculated. The results are shown in Table 7 and Table 8.

[0061] Soluble Fraction Ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com