Hypersonic liquid jet generator

A liquid jet, supersonic technology, applied in the direction of liquid injection devices, injection devices, etc., can solve the problems of damage, waste, nozzle deformation, etc., and achieve the effect of convenient use and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

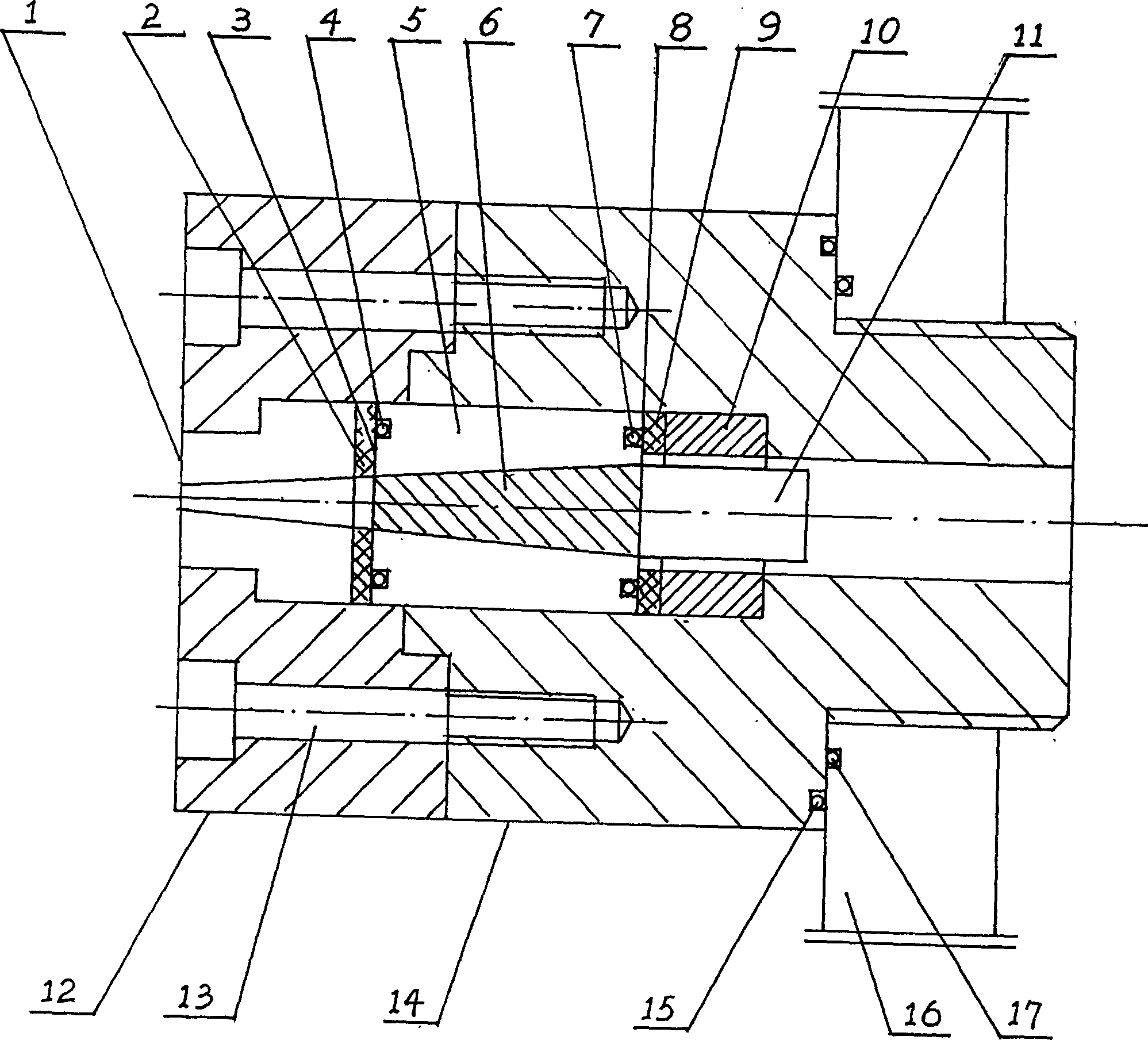

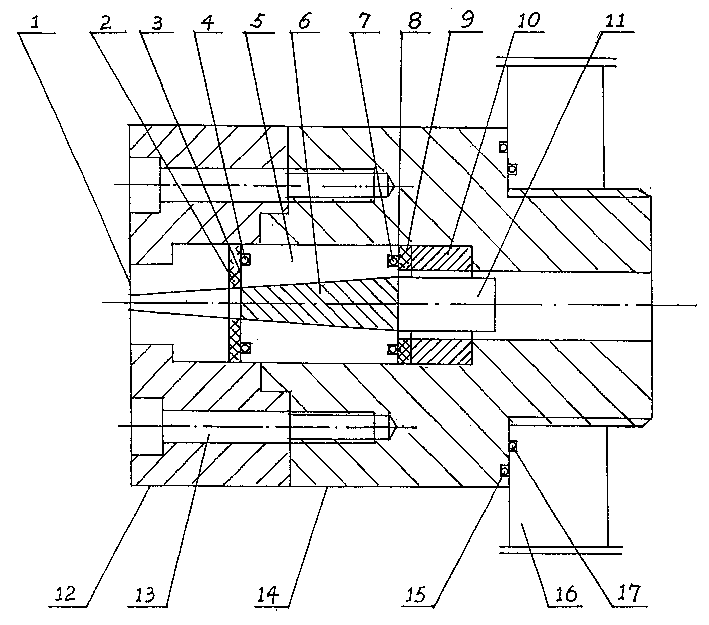

[0007] The hypersonic liquid jet generating device has an outer chamber 14, in which a free piston 11, an adjustment ring 10, a rubber gasket 9, a diaphragm 8, an O-ring 7, a liquid chamber 5, and an O-ring are sequentially arranged. 4. Diaphragm 3, rubber gasket 2, nozzle 1, there is an annular step outside the nozzle 1 and a matching top flange 12, the top flange 12 and the outer chamber 14 are fixed with hexagon socket head cap screws 13, and the outer chamber 14 is threaded It is fixed on the supporting flange 16, and the outer side of the rear end of the outer chamber 14 is provided with an external thread interface, which is connected with the inner thread of the supporting flange 16, and the contact surface between the outer chamber 14 and the supporting flange 16 is provided with an O-shaped seal Circles 15 and 17.

[0008] Said liquid chamber 5 is conical, and liquid 6 is arranged in the liquid chamber 5 .

[0009] The hypersonic liquid jet generating device has an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com