Clamping device for magnetic disk

A technology for clamping devices and magnetic disks, which is applied in the fields of recording information storage, instruments, etc., can solve the problems of increasing manufacturing costs, complicated assembly processes, etc., and achieves the effect of firm suspension and prevention of falling off.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] Embodiments of the present invention will be described below in conjunction with the accompanying drawings.

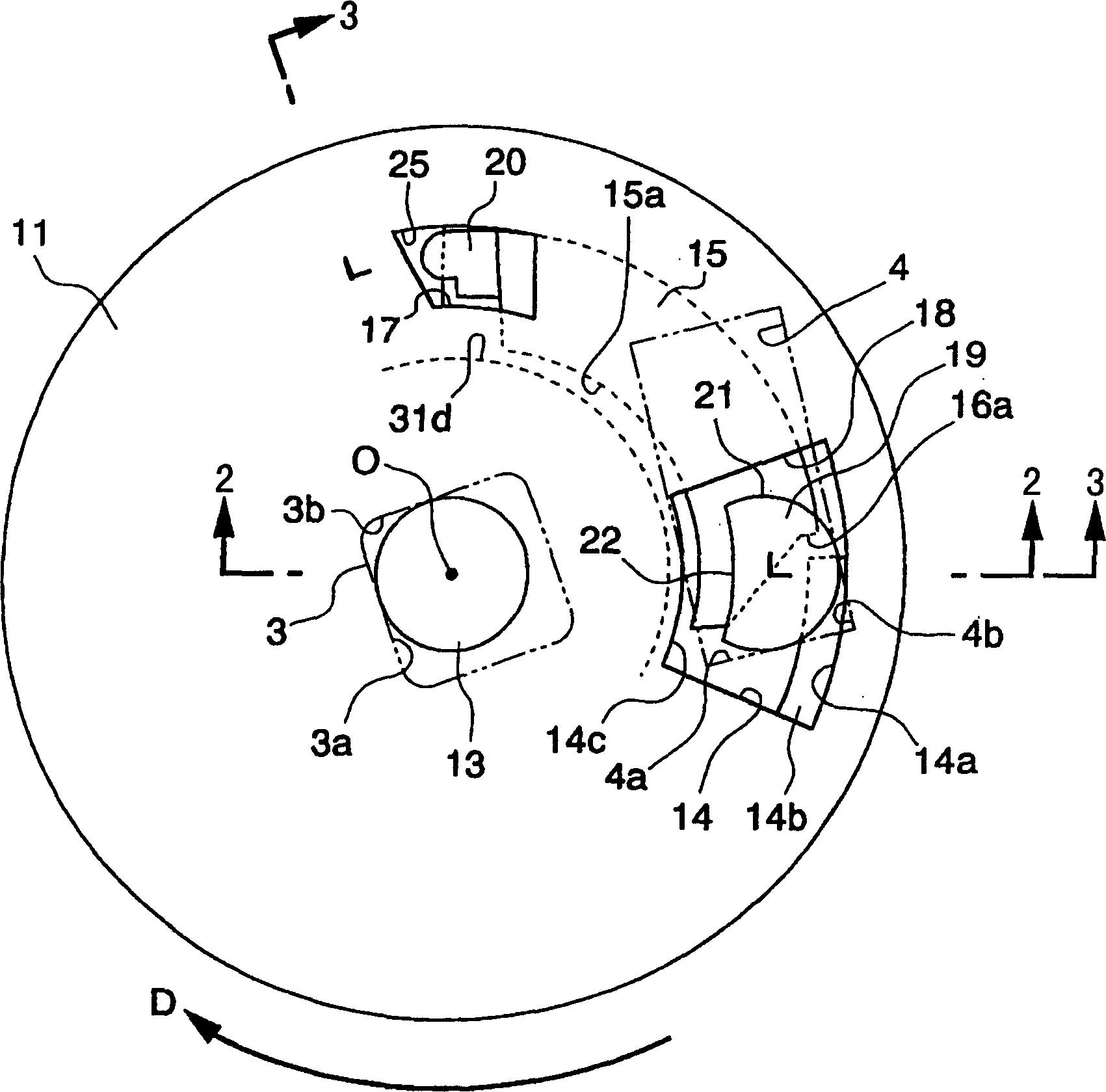

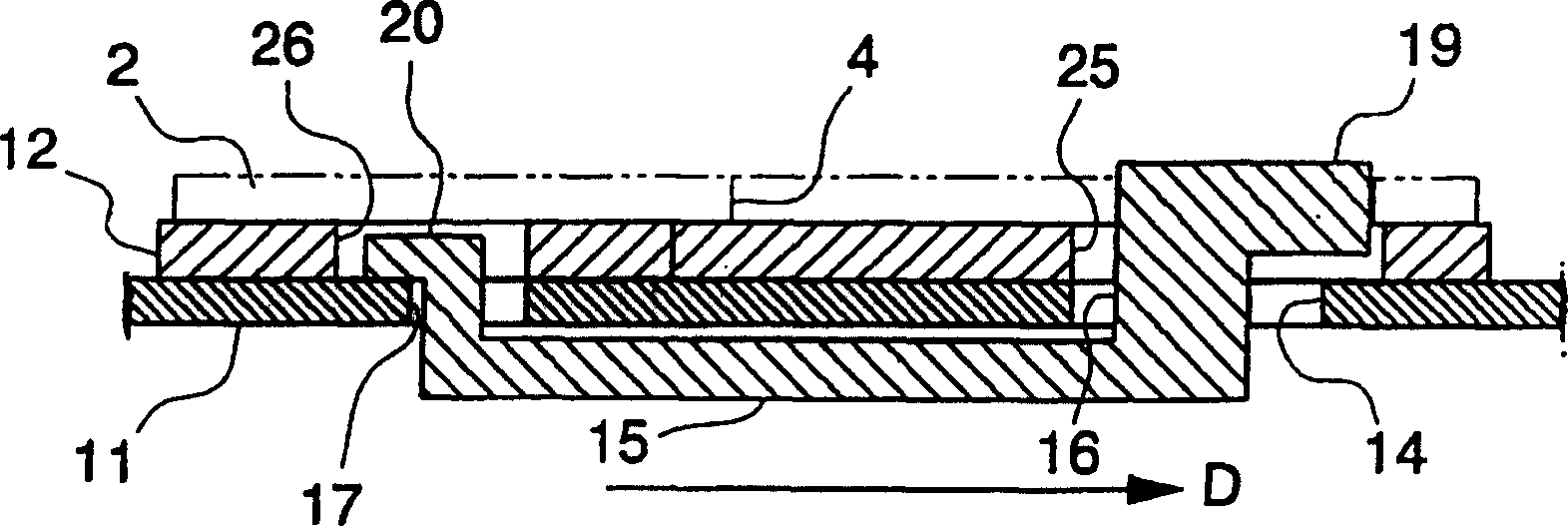

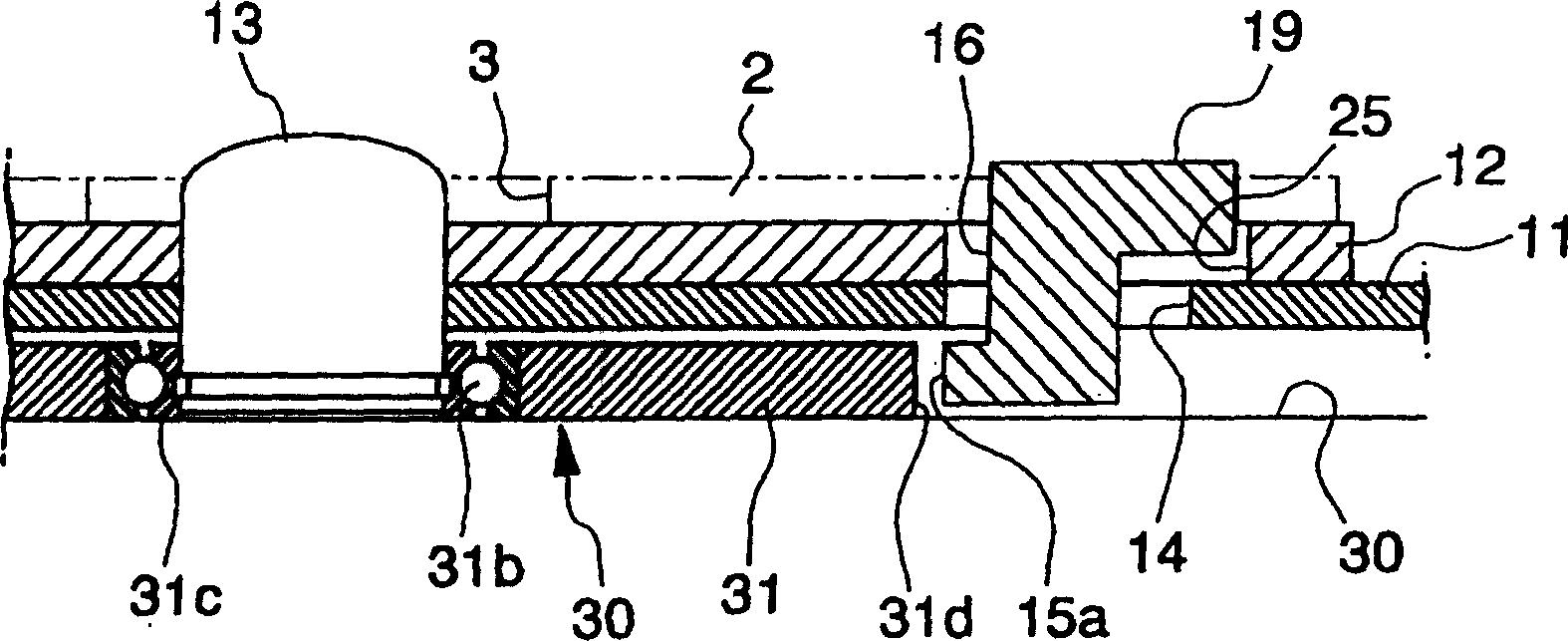

[0069] Figure 1 to Figure 3 A part of a magnetic disk drive device provided with a chucking device for a magnetic disk according to the present invention is shown. figure 1 is the plan view of the clamping device for the magnetic disk, figure 2 is along figure 1 A sectional view of the 2-2 line, image 3 is along figure 1 The 3-3 line profile.

[0070] For illustrative purposes, figure 1 removed from figure 2 The magnetic disc 12 is shown. Also in the description below for the Figure 7 , 8 The same symbols are used for the same structure of the conventional components described in , and the descriptions of these components are omitted or simplified.

[0071] exist Figure 1 to Figure 3 Among them, this disk drive device has a rotor yoke 11 composed of a ferromagnetic metal disk, which is driven to rotate in the D direction by a motor not shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com