A grid printing forming machine

A molding machine and grid technology, applied in the direction of electrode carrier/collector, etc., can solve the problems of low automation and high labor intensity, and achieve the effect of improving standardization and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

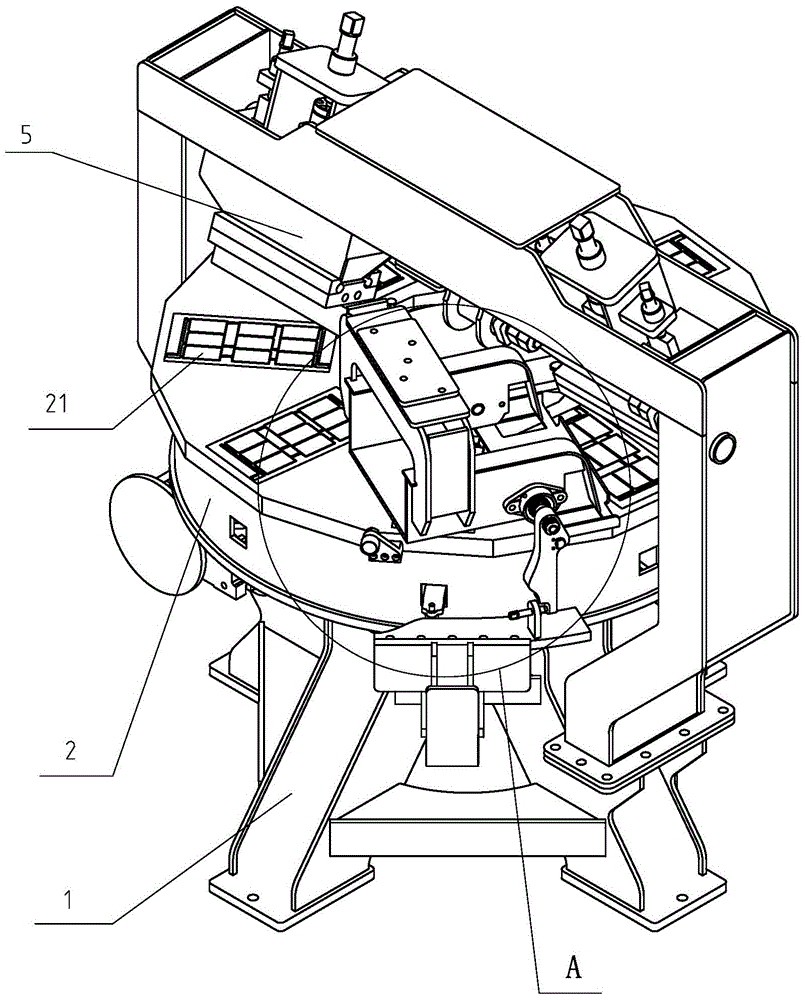

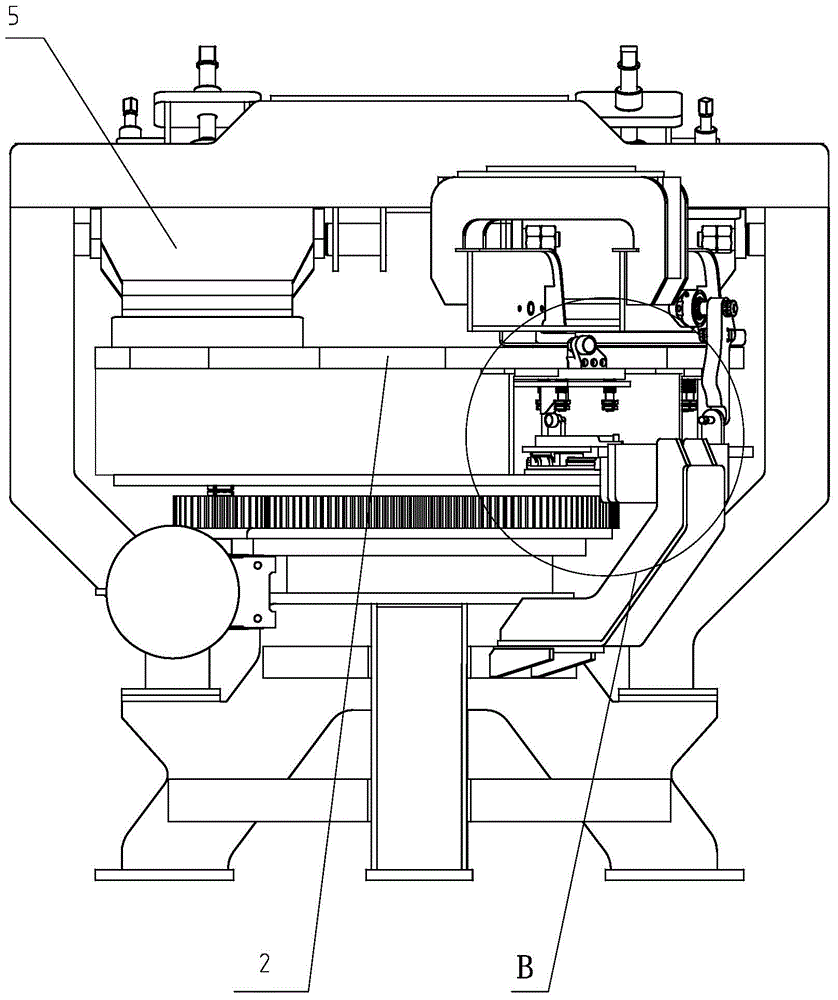

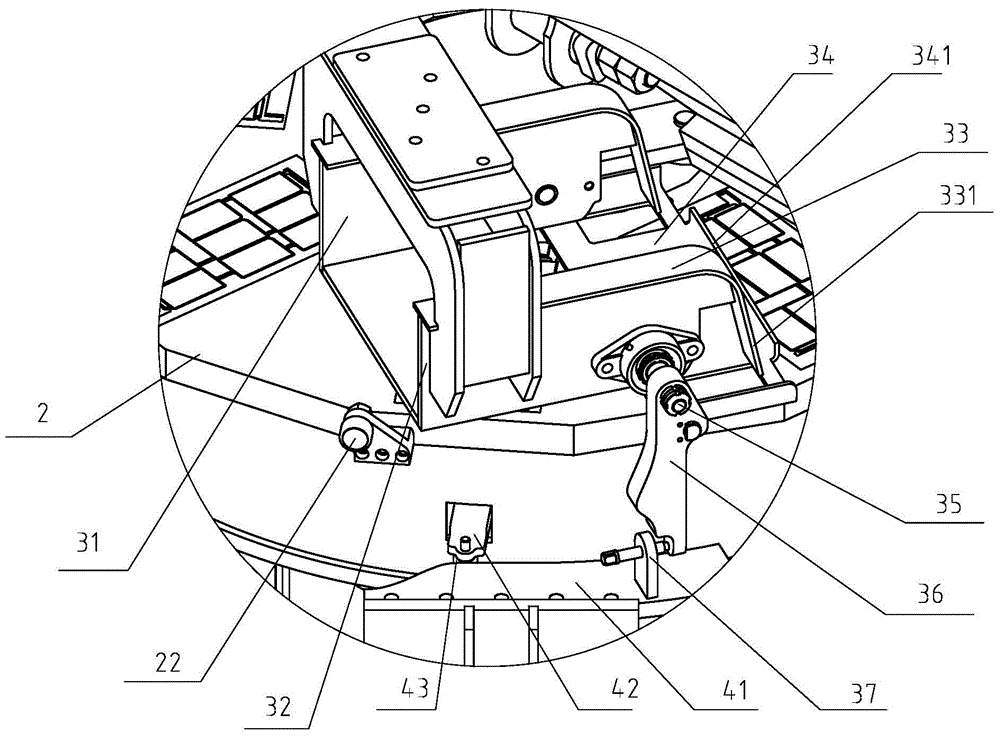

[0025] The invention provides a grid printing forming machine, which includes a frame, on which a turntable and a driving member for driving the turntable are arranged, a plurality of grid forming grooves are arranged at intervals on the turntable, and an ejector device is connected to the bottom of the turntable, along which The rotation direction of the turntable is provided with a printing device and a discharge device in turn. The printing device includes a printing bucket connected to the frame and a brush plate connected to the bottom of the printing bucket. A liquid inlet pipe is connected to the printing bucket, and the bottom surface of the brush plate is a slope , the discharge device includes a left support plate and a right support plate oppositely arranged, and guide rails are provided on the tops of the left support plate and the right support plate, and a curved section that bends downward is provided at the end of the guide rail toward the rotation direction of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com