Ink jet head drive circuit and ink jet recording device

A technology for driving circuits and inkjet heads, applied in printing and other directions, can solve the problems of poor characteristic deviation, waveform error, and high cost, and achieve the effects of stable voltage waveform, low cost, and high utilization possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] best practice

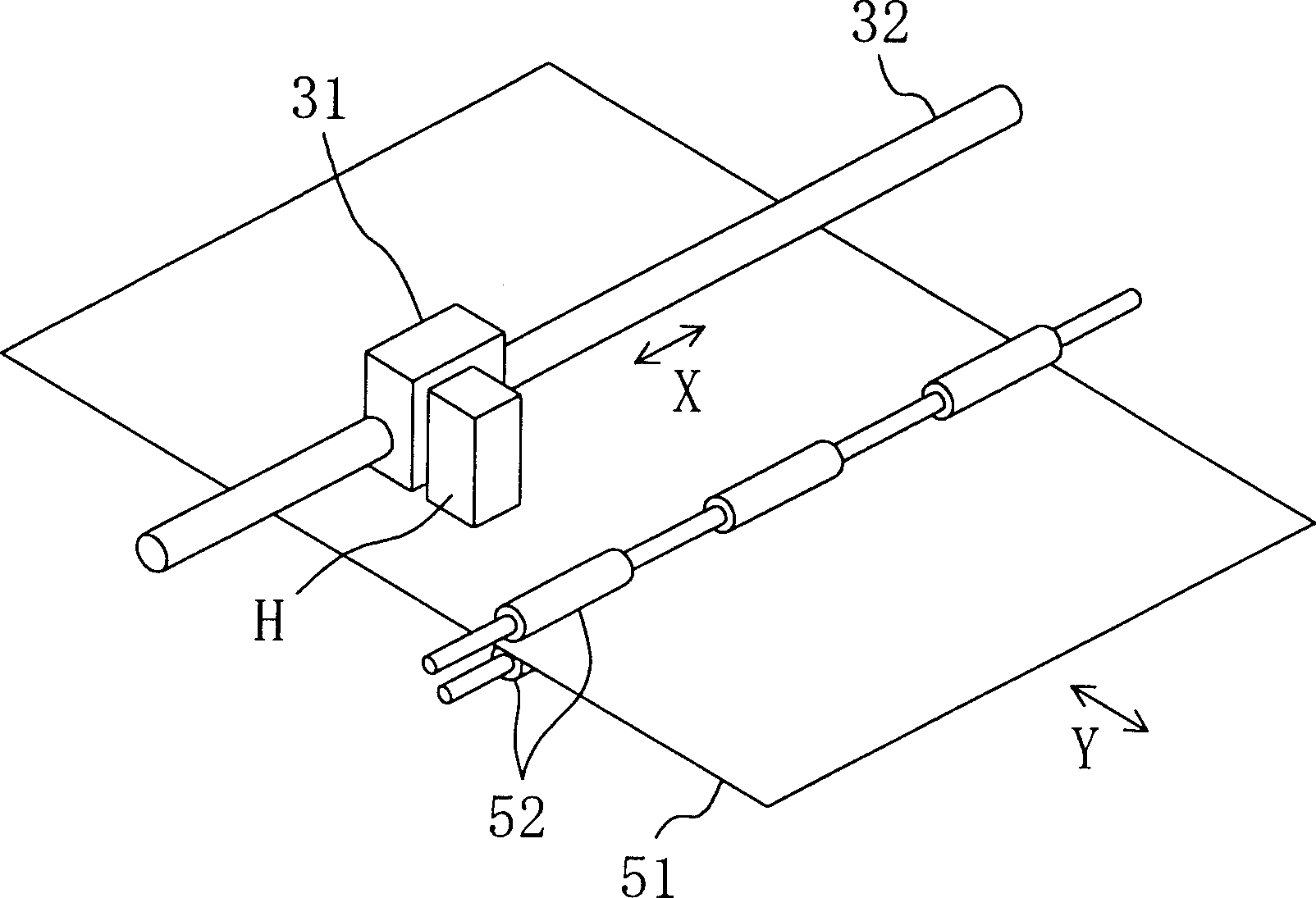

[0036] figure 1 The inkjet head type recording apparatus according to the embodiment of the present invention is shown as a schematic diagram. This inkjet head type recording device has an inkjet head H that ejects ink onto recording paper 51 as a recording medium, as will be described later. The inkjet head H is fixed and supported by the carriage 31; the carriage 31 is provided with a carriage motor, not shown; utilizing the carriage motor, the figure 1 The carriage shaft 32 extending in the X direction) makes the inkjet head H and the carriage 31 reciprocate along this direction. The carriage 31 , the carriage shaft 32 , and the carriage motor constitute a relative moving member that relatively moves the inkjet head H and the recording paper 51 .

[0037] The above-mentioned recording paper 51 is sandwiched between two conveying rollers 52 rotationally driven by a conveying motor not shown, and by the conveying motor and each conveying roller 52,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com