Washing machine

A technology of washing machine and shunt chamber, which is applied in the field of washing machines, can solve problems such as out of control, inability to use, and inability to drain water, etc., and achieve the effect of simplifying the switching structure, simple and reliable structure, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is an embodiment of the present invention, which is a fully automatic washing machine with up and down drainage and three working modes of stirring wing washing, centrifugal washing and centrifugal dehydration.

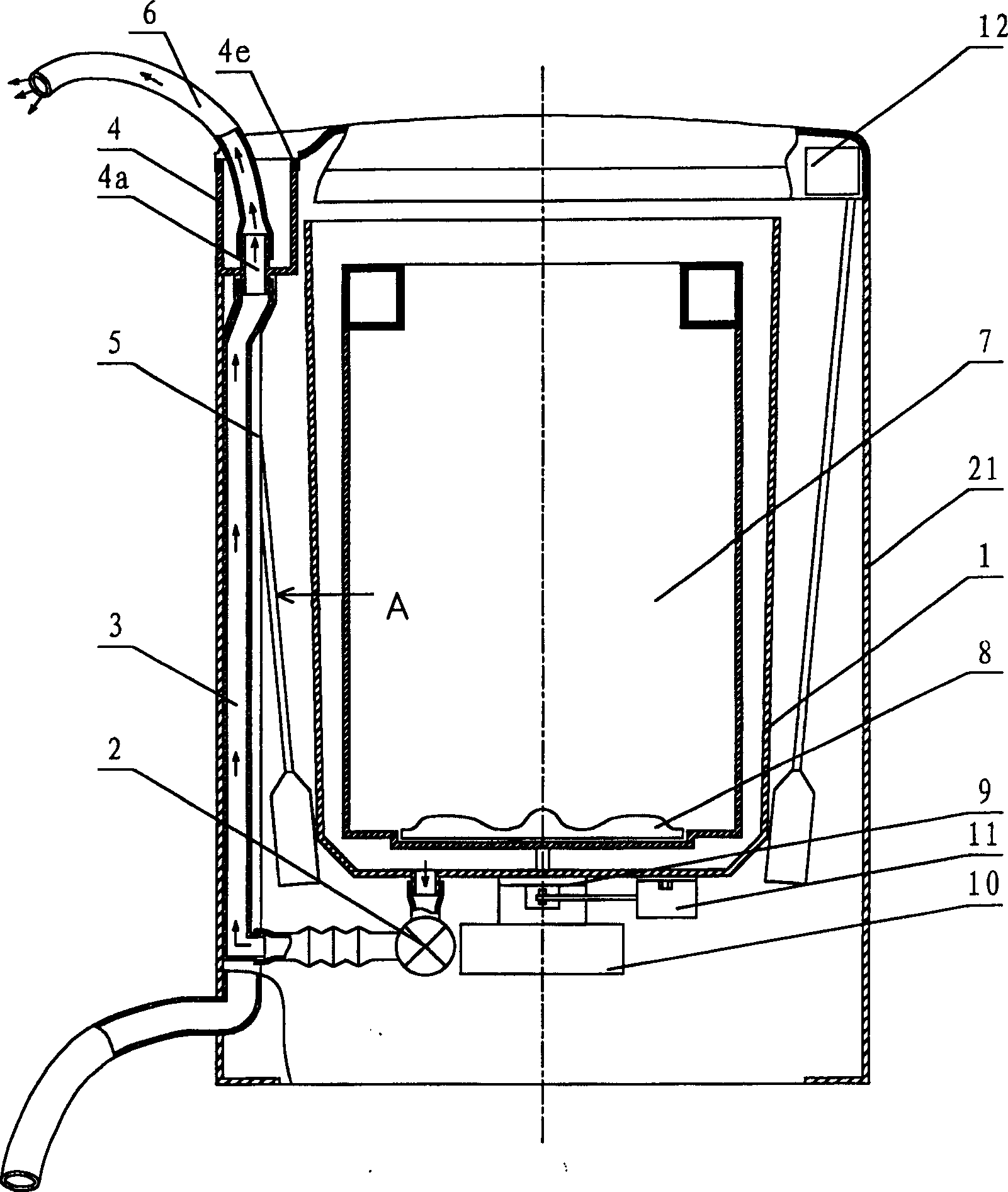

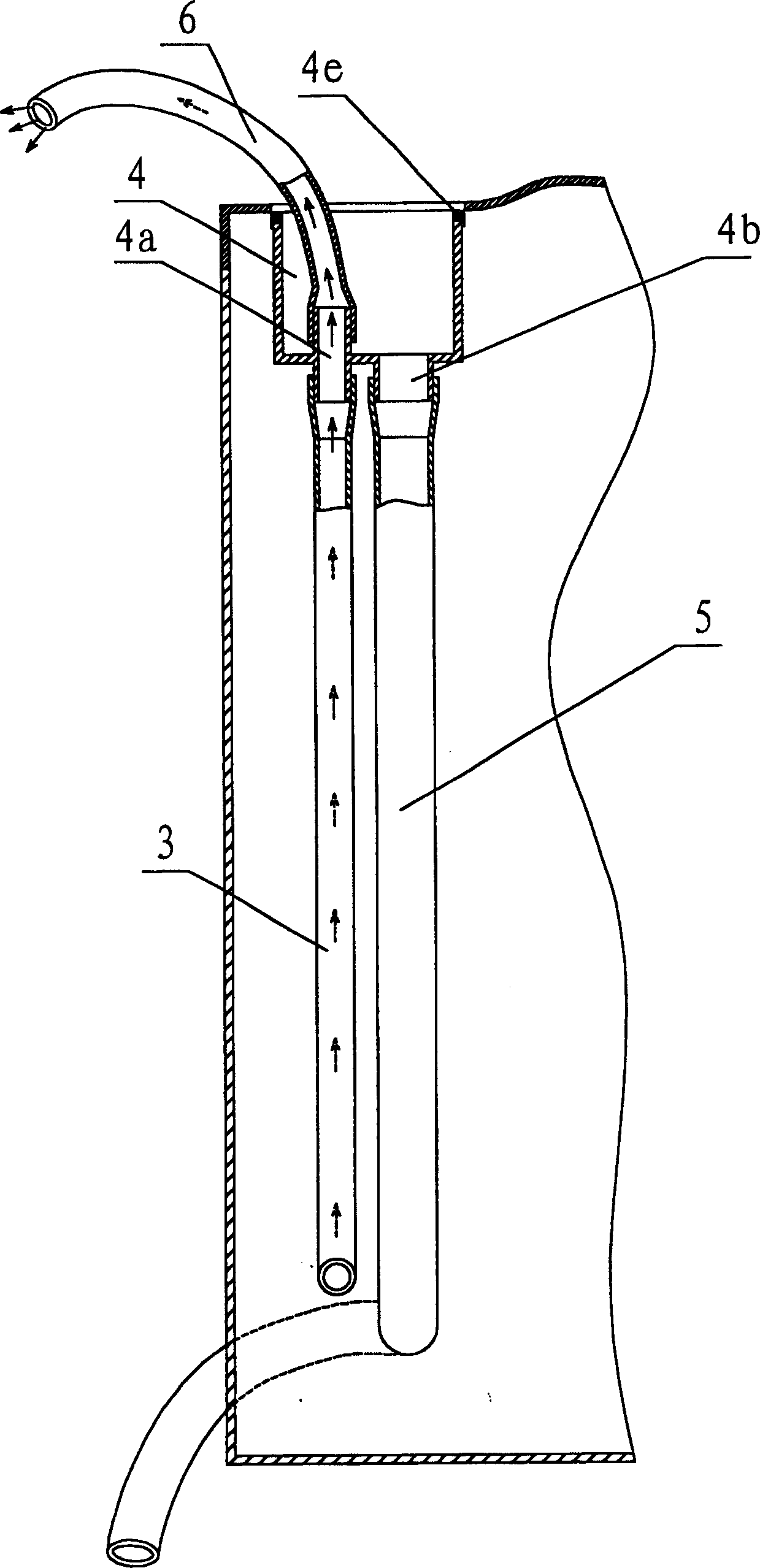

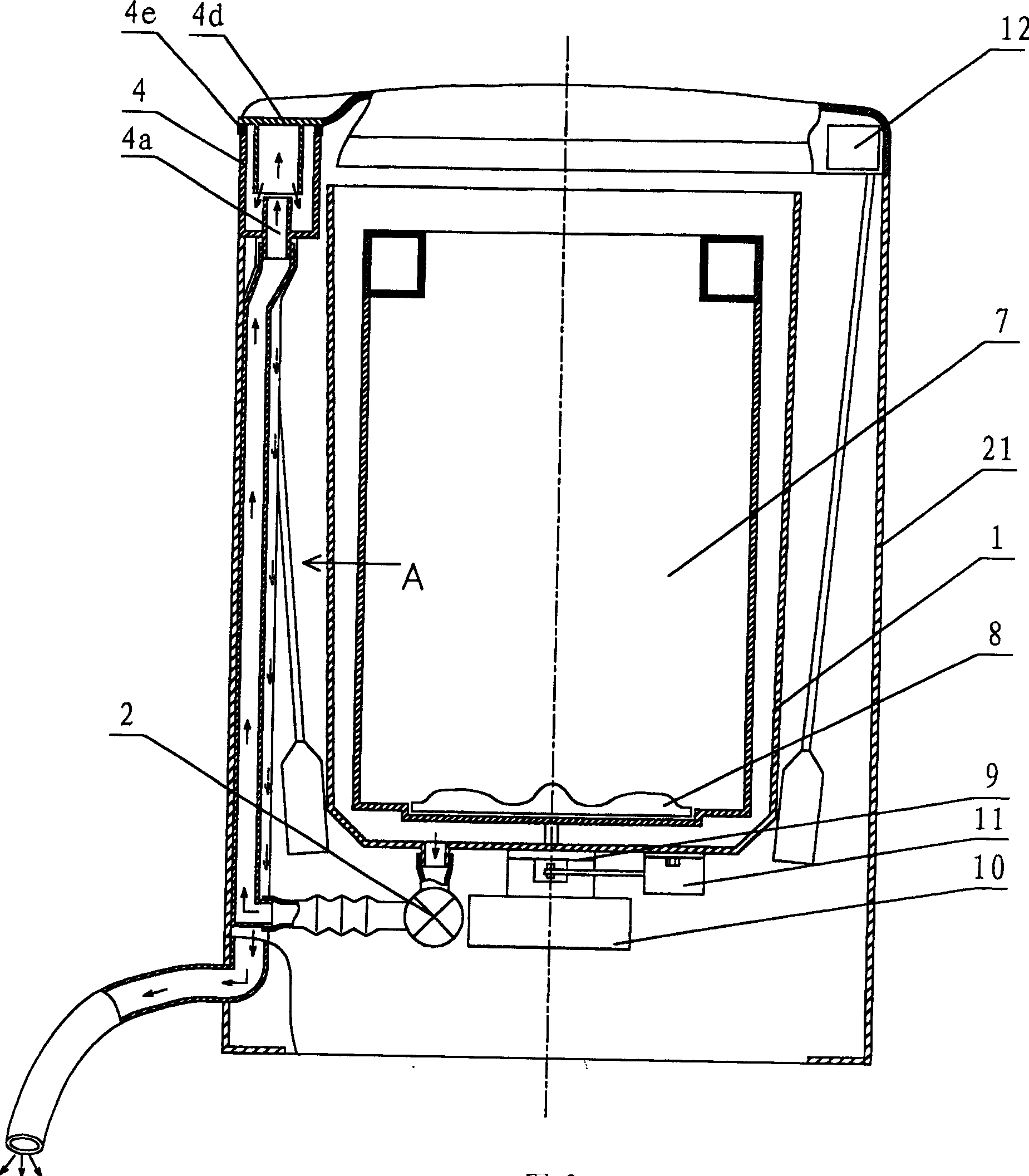

[0031] Such as figure 1 or image 3 as shown ( figure 1 or image 3 Zoom in on the local structure figure 2 , Figure 4 with Figure 5 ), the bucket 1 of the washing machine according to the present invention is suspended in the casing 21, the drain hole of the bucket 1 is connected to the water inlet of the drainage pump 2, and the water outlet of the drainage pump 2 is connected to the water inlet of the riser pipe 3 , the water outlet of the riser pipe 3 is connected to the water inlet 4a of the distribution chamber 4, and the water outlet 4b of the distribution chamber 4 is connected to the water inlet of the lower drain pipe 5, and the lower drain pipe 5 leads out of the casing 21. The above parts can be directly connected, or connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com