Iron with self-cleaning sole plate

A soleplate and iron technology, applied in the field of irons, can solve the problems of not explaining the method of preventing dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

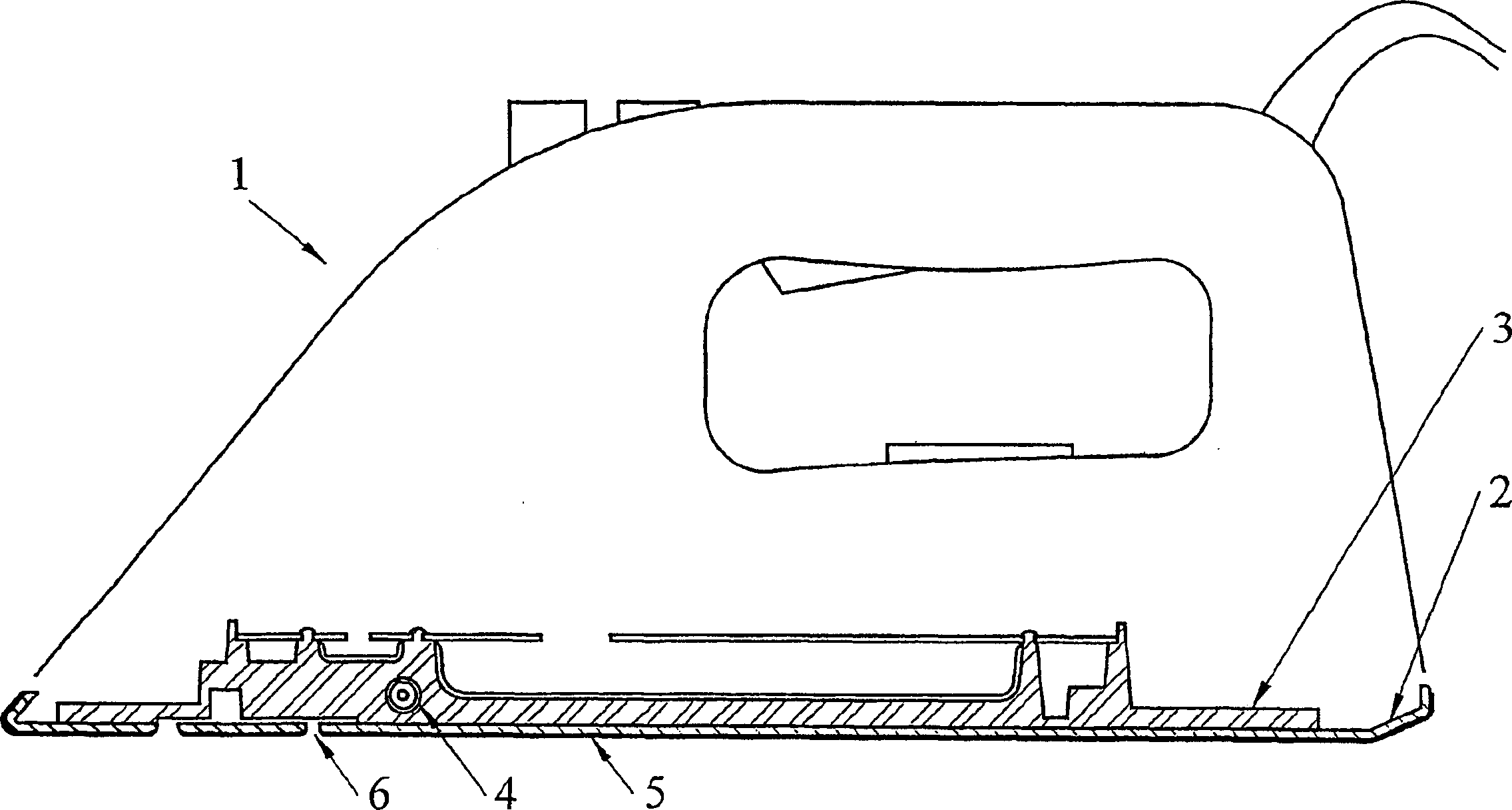

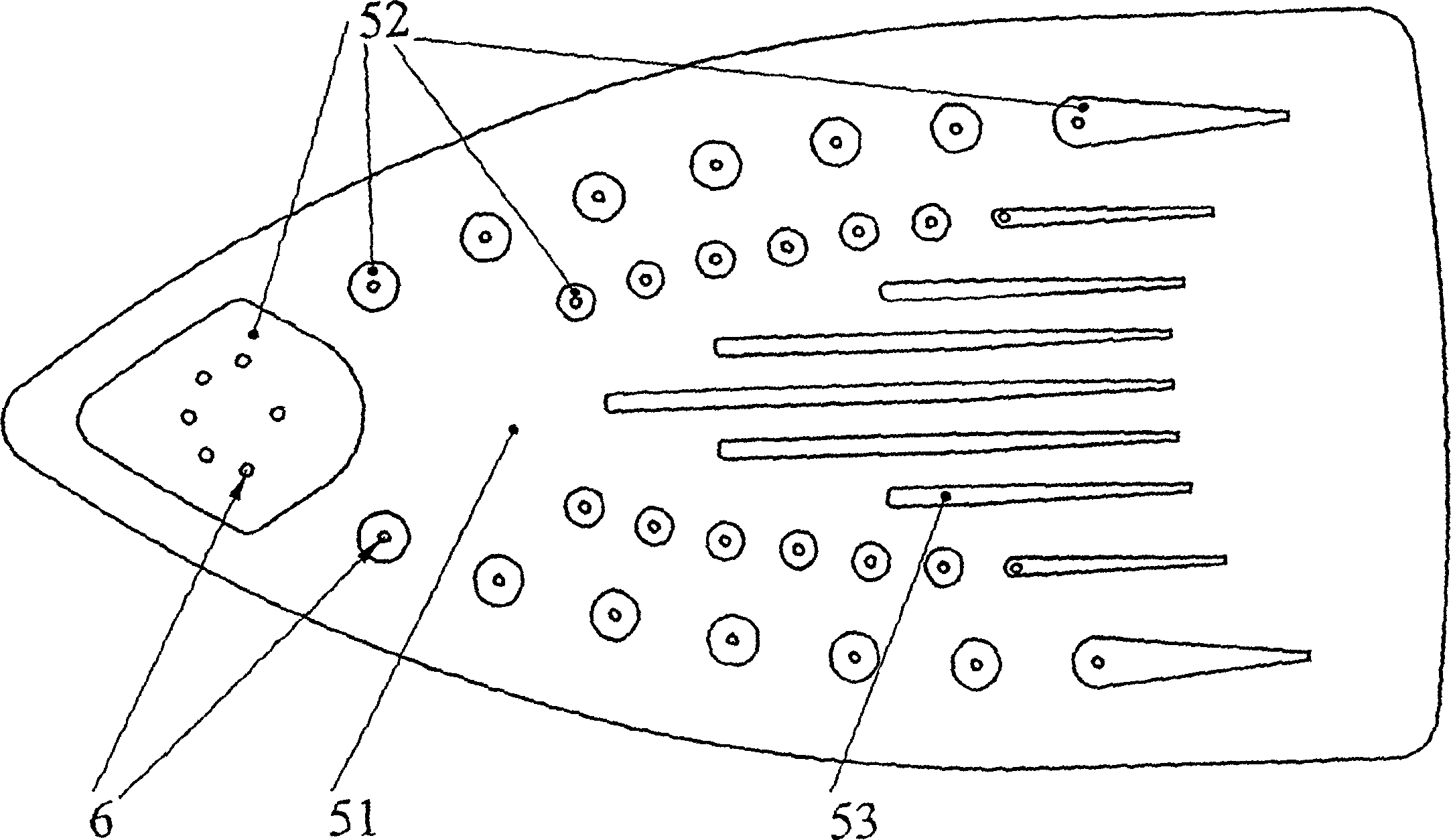

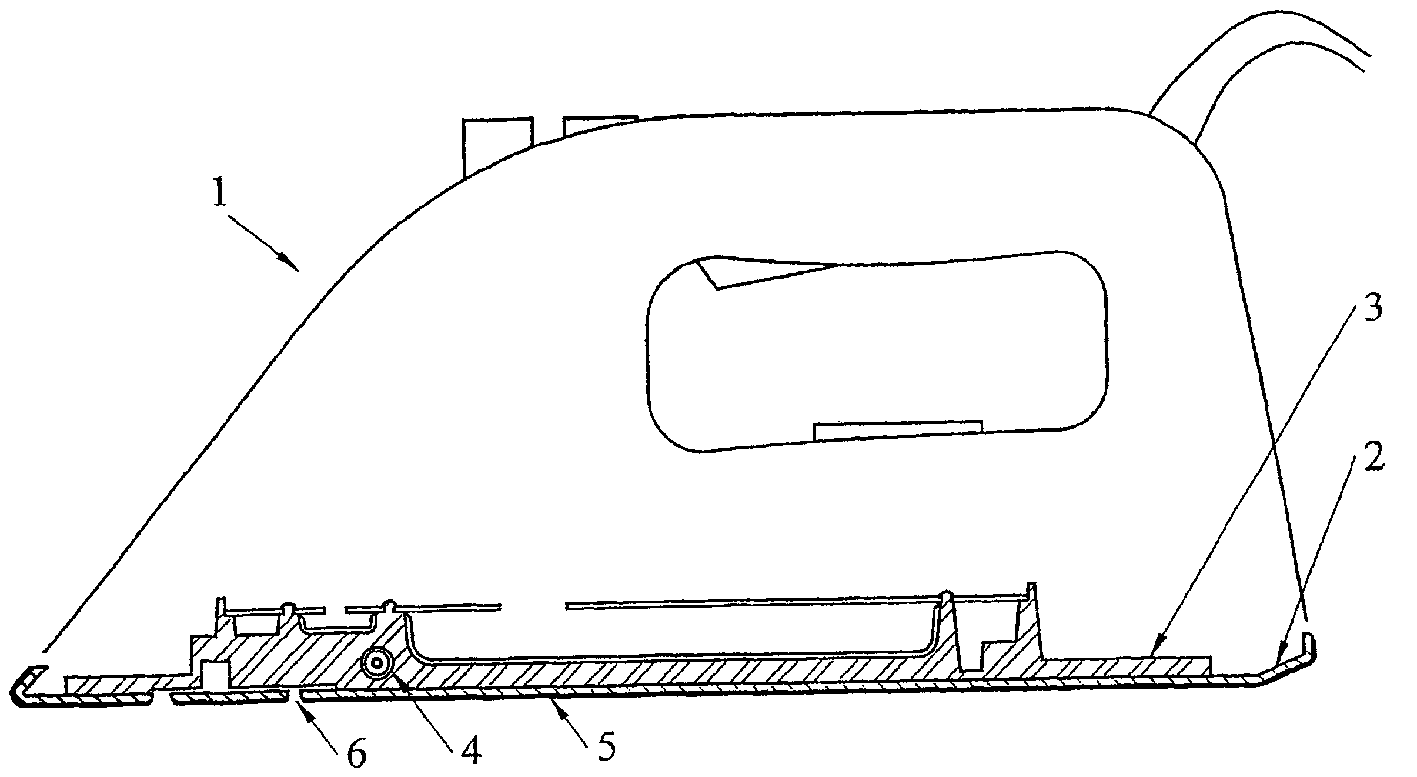

[0048] In the first embodiment, such as figure 1 The iron 1 shown includes an aluminum soleplate 2 which is connected to a heating base 3 which is cast from aluminum and has a heating element 4. in figure 2 As can be seen more clearly, the bottom plate 2 is covered on its outer surface 5 with a glaze known to improve ironing quality. The catalyst or oxidation catalyst is provided on the outer surface in a very thin layer. The outer surface 5 includes an ironing surface 51 in the strict sense and hollow portions 52, 53 surrounding the steam outlet 6, for example.

[0049] To this end, the outer surface is subjected to a mild acid etching with a solvent such as citric acid or nitric acid to obtain a grease removal treatment and be activated. Prepare an oxidation catalyst precursor, for example, dissolve palladium nitrate with 2 grams of palladium nitrate in one liter of water. In addition, many companies, such as PCAS of Longjumeau, France, provide precursors for further processing...

Embodiment 2

[0053] In the second embodiment, the glazed bottom plate is heated to 300°C. By mixing 4 grams of tetraethyl silicate into 96 grams of nitric acid diluted to 0.6%, and adding 12.8 grams of "DISPERSALS" to it, a solution containing suspended alumina was prepared. "DISPERSALS" is an alumina-based product provided by CONDEA. Spray this 10-fold diluted solution on the bottom plate. The bottom plate was kept at 300°C for one hour. The spray was adjusted so as to obtain a solid deposited layer of alumina-based oxidation catalyst support about 10 microns thick. Then, an aqueous solution of palladium nitrate was sprayed and subjected to baking at 300°C for one hour.

[0054] Compared with the above example, the activity of the same catalytically active surface sample is increased to 175×10 per hour. -6 Moles of carbon dioxide gas.

Embodiment 3

[0056] In the third embodiment, the iron includes an aluminum soleplate. The ironing surface is cleaned by alkaline etching, then neutralized and rinsed. The bottom plate was oxidized in an oven at 560°C for 30 minutes and then coated by spraying 2 grams of palladium nitrate solution per liter. After firing at 300°C for one hour, a catalytically active or oxidation catalytic surface layer with a thickness of about 30 nanometers is obtained.

[0057] We can get a smoothness that is basically close to that of aluminum. The advantage of this embodiment is that the activity obtained by manufacturing economy is that for a sample of a catalytically active surface of 10 square centimeters, about 112×10 per hour can be produced. -6 Moles of carbon dioxide gas.

[0058] In a variation of this embodiment, the oxidation catalyst is added to the surface layer of the Ormosil type as the carrier. This word is the abbreviation of the English phrase "Organic Modified Silicate", as described by Jo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap