Tensioning device for coil winder and controller for hysteresis braker

A technology of hysteresis brake and tensioning device, which is applied in the control of electromechanical brakes, coil manufacturing, control systems, etc., can solve the problems of inability to control the braking force, the braking force cannot be reduced to the target value, and the residual magnetic force cannot be completely eliminated. The effect of over-adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

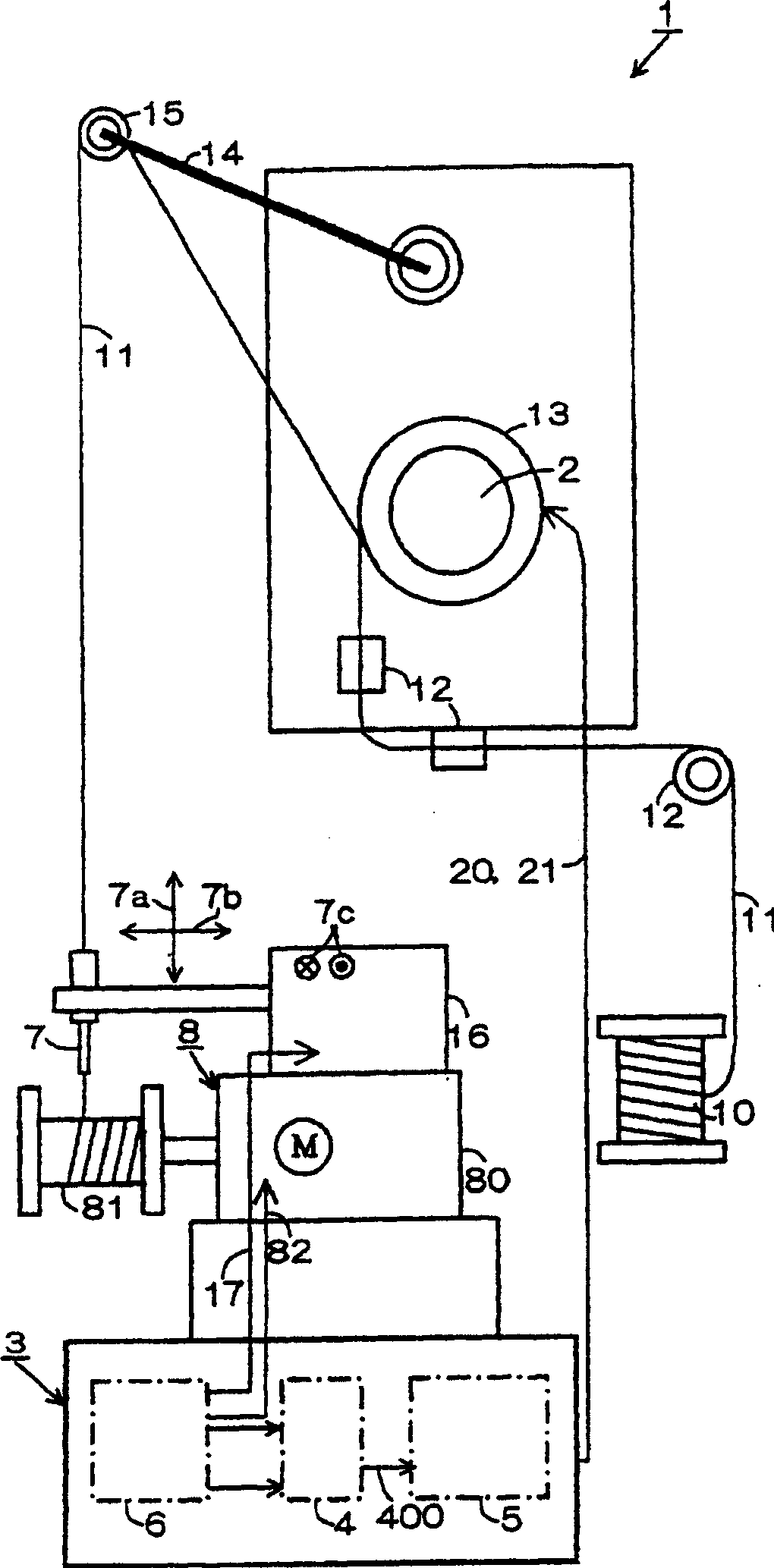

[0041] Hereinafter, for Embodiment 1 of the winding machine tensioning device of the present invention, according to figure 1 Go to FIG. 6 for description. In addition, the same code|symbol is attached|subjected to the member with the same meaning as a conventional example, and detailed description is abbreviate|omitted.

[0042]The structure of the take-up device 1 for a winding machine of the present invention is to include a take-up roller 13 for winding a wire 11, a hysteresis brake 2 for supplying rotation resistance to the take-up roller, and a wire 11 pulled out from a wire storehouse 10 to pass through the guide roller 13. The device 12 is wound on the take-up roller 13 of the hysteresis brake 2, passes through the roller 15 at the front end of the take-up arm 14, and is wound on the bobbin 81 driven by the motor 80 of the winding machine main body 8 through the nozzle 7 .

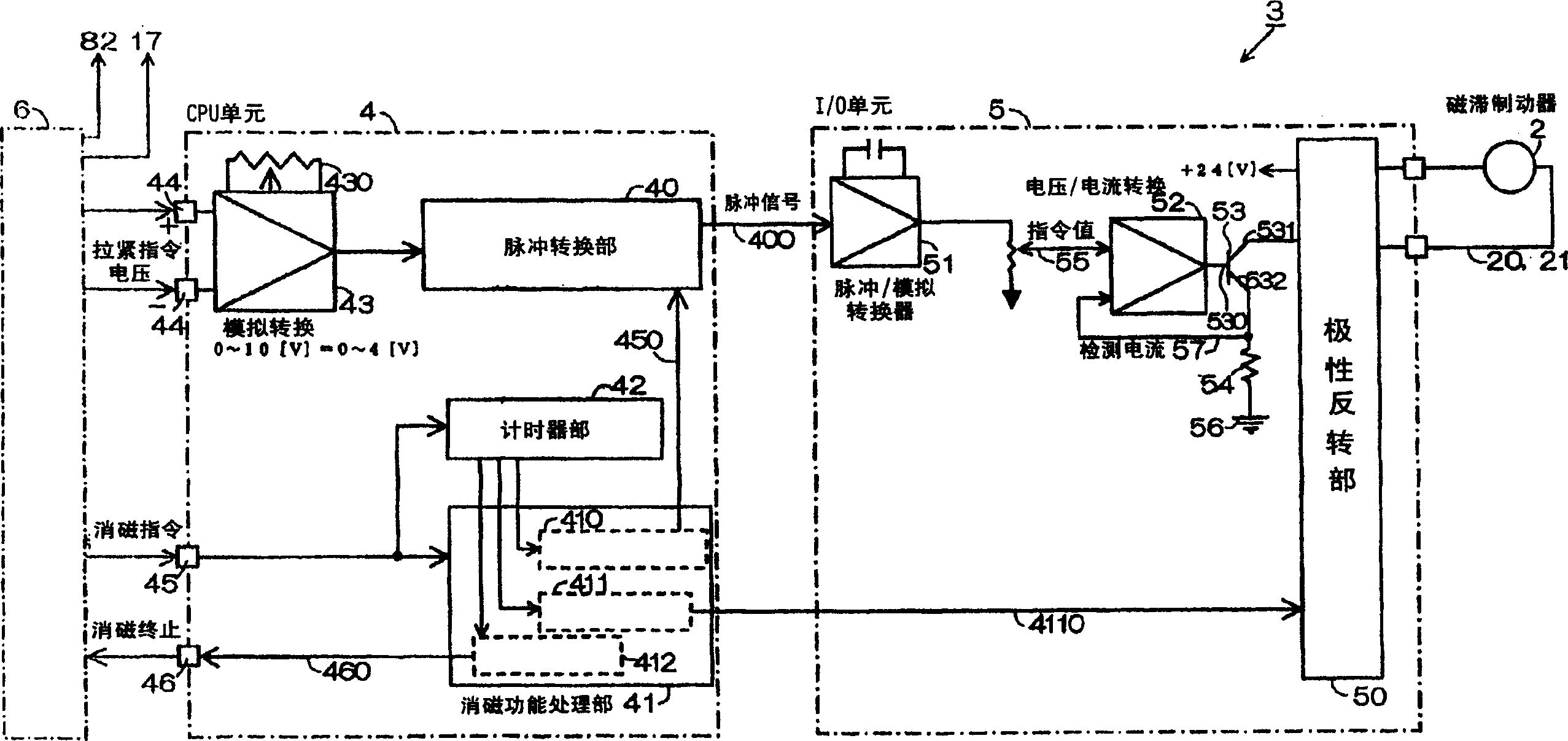

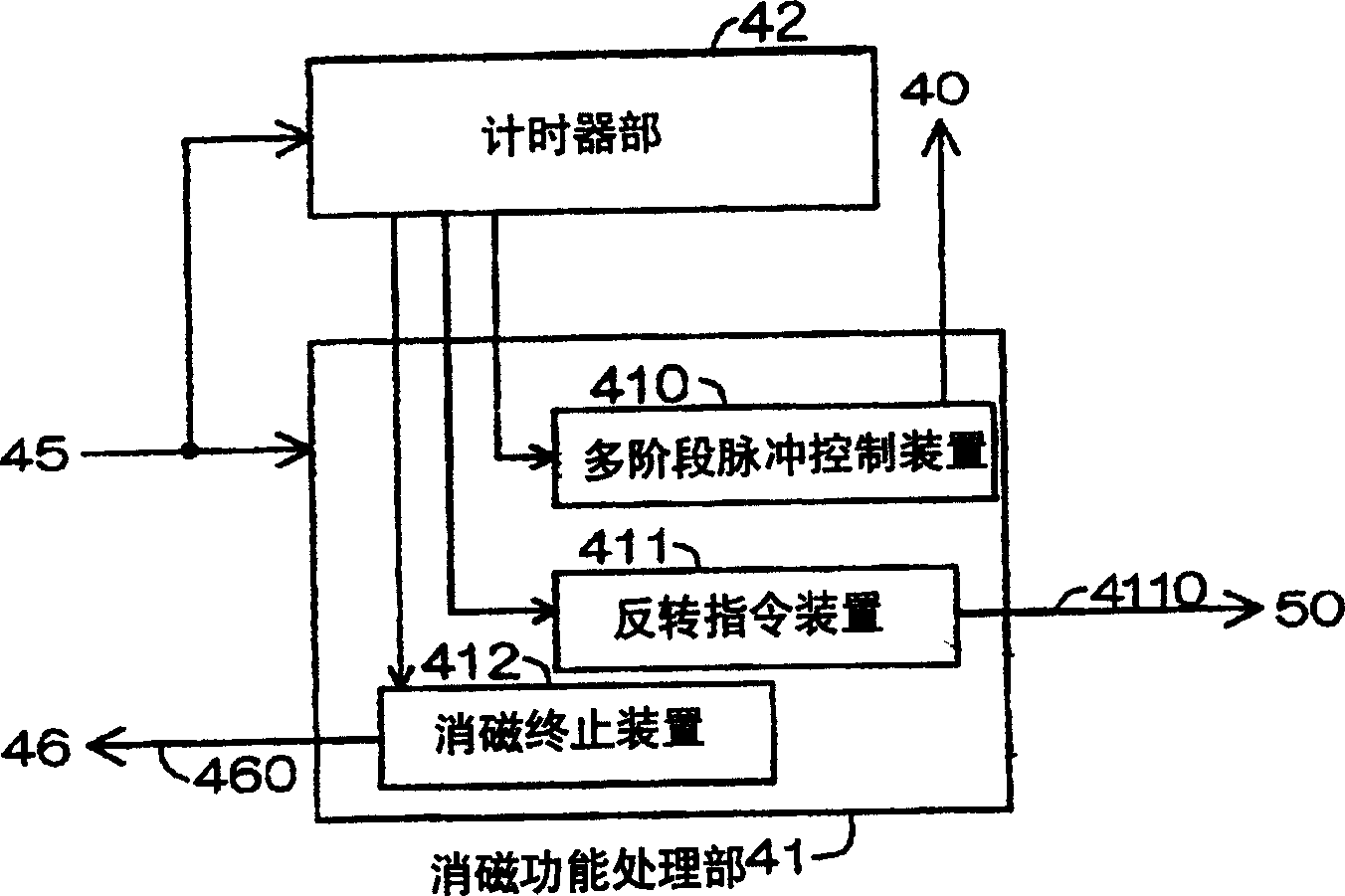

[0043] In addition, a control device 3 for controlling the hysteresis brake 2 and making the...

Embodiment 2

[0076] Hereinafter, Embodiment 2 to which the tensioning device of the wire winding machine of Embodiment 1 is applied will be described, and descriptions that are the same as those in Embodiment 1 will be given the same symbols and detailed descriptions will be omitted.

[0077] The tensioning device 1 of the wire winding machine of the second embodiment has the control device 3 for controlling the hysteresis brake 2a and forming a fixed tensioning corresponding to the winding state similarly to the first embodiment.

[0078] The control device 3 includes an NC control device 6 , a CPU unit 4 , and an I / O unit 5 .

[0079] The CPU unit 4 has the same configuration, control method, etc. as those in Embodiment 1, and therefore description thereof will be omitted.

[0080] The I / O unit 5 is configured such that a hysteresis brake selection unit 58 is connected to the output side of the pulse / analog conversion circuit 51 , and a voltage / current converter 52 is connected to the ou...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap