Buckle

A technology of components and strips, which is applied in the field of buckles, can solve the problems of insufficient clamping force of the belt, inability to reliably prevent the movement of the belt, and the decline of the fixing function, so as to achieve easy fixing and moving operations, less damage, and prevent the fixing function Falling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be described below with reference to the drawings.

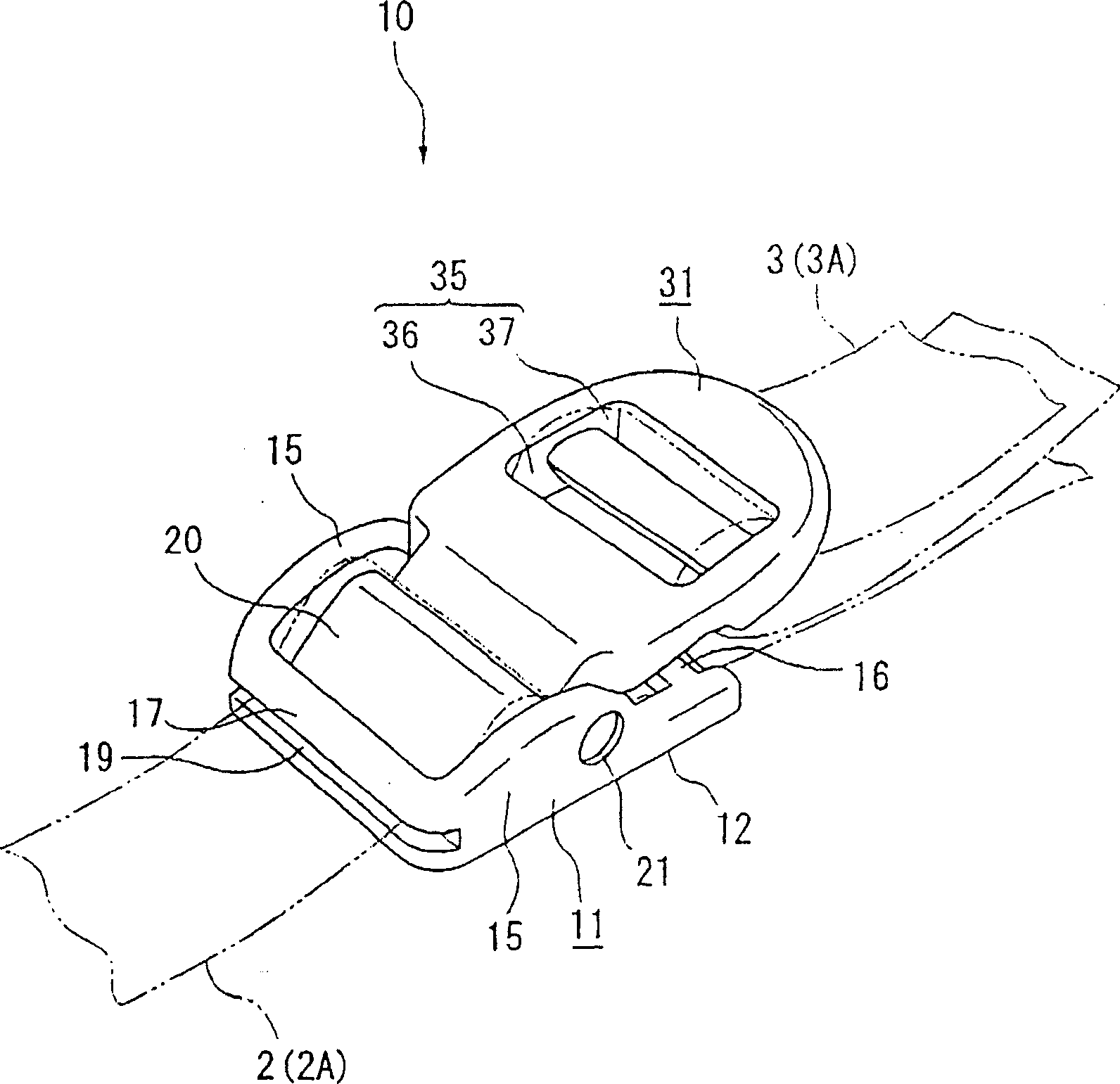

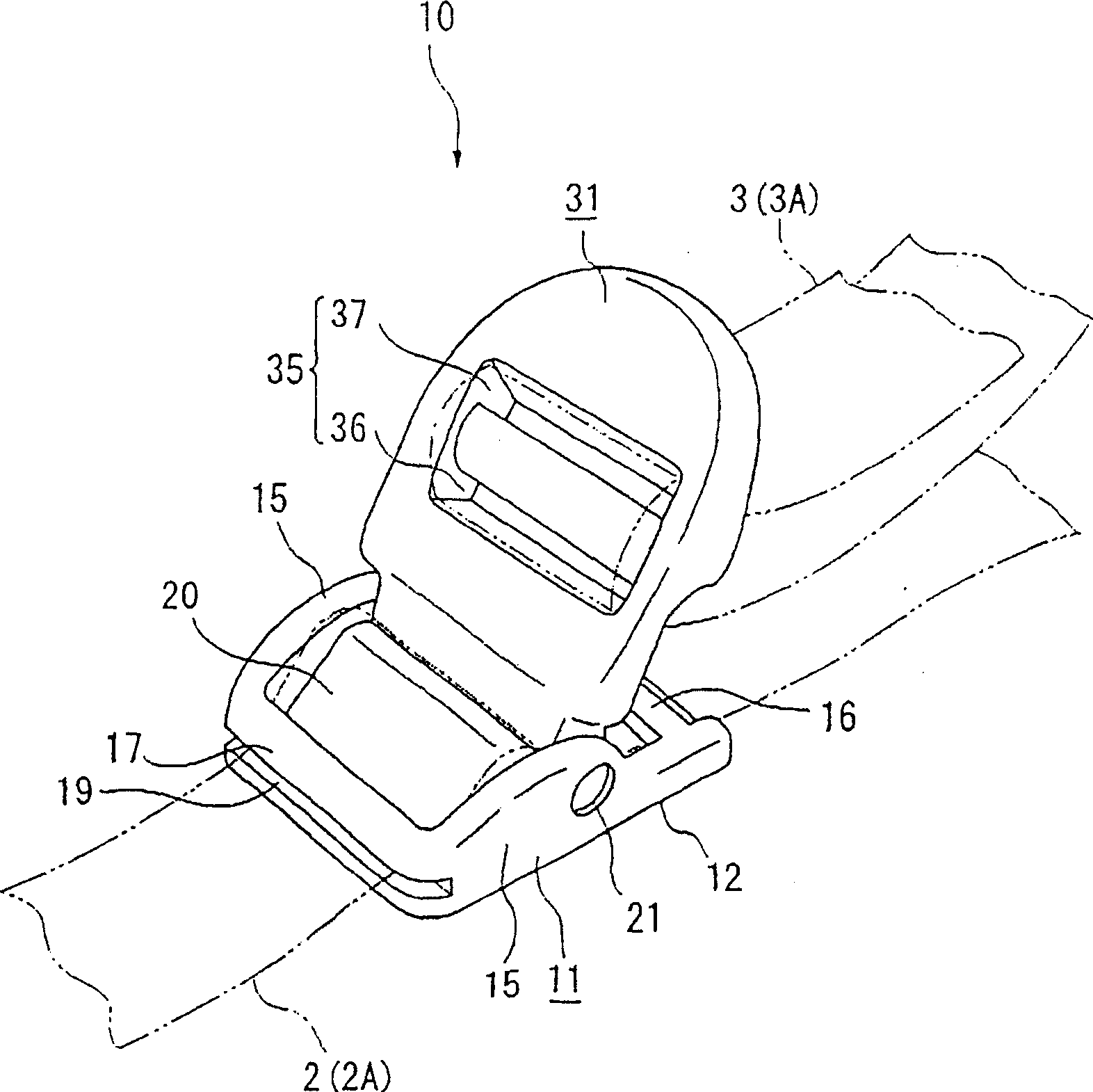

[0046] figure 1 and figure 2 The clasp (fixed state and unfixed state) 10 of this embodiment is shown. The buckle 10 in the above Figure 8 and Figure 9 In the structure of the rucksack, it is suitable for the position of the connector 3D, and has the function of moving the belt 2 (2A) as a belt in the length direction and can be fixed at any position and can adjust the belt 3 ( 3A) Function of length. The belts 2 and 3 are synthetic resin yarns made of plain weave, mountain cedar weave, grosgrain weave, basket weave, deformed basket weave, etc., which have a certain degree of body (rigidity) and are formed into a predetermined width. Ribbon.

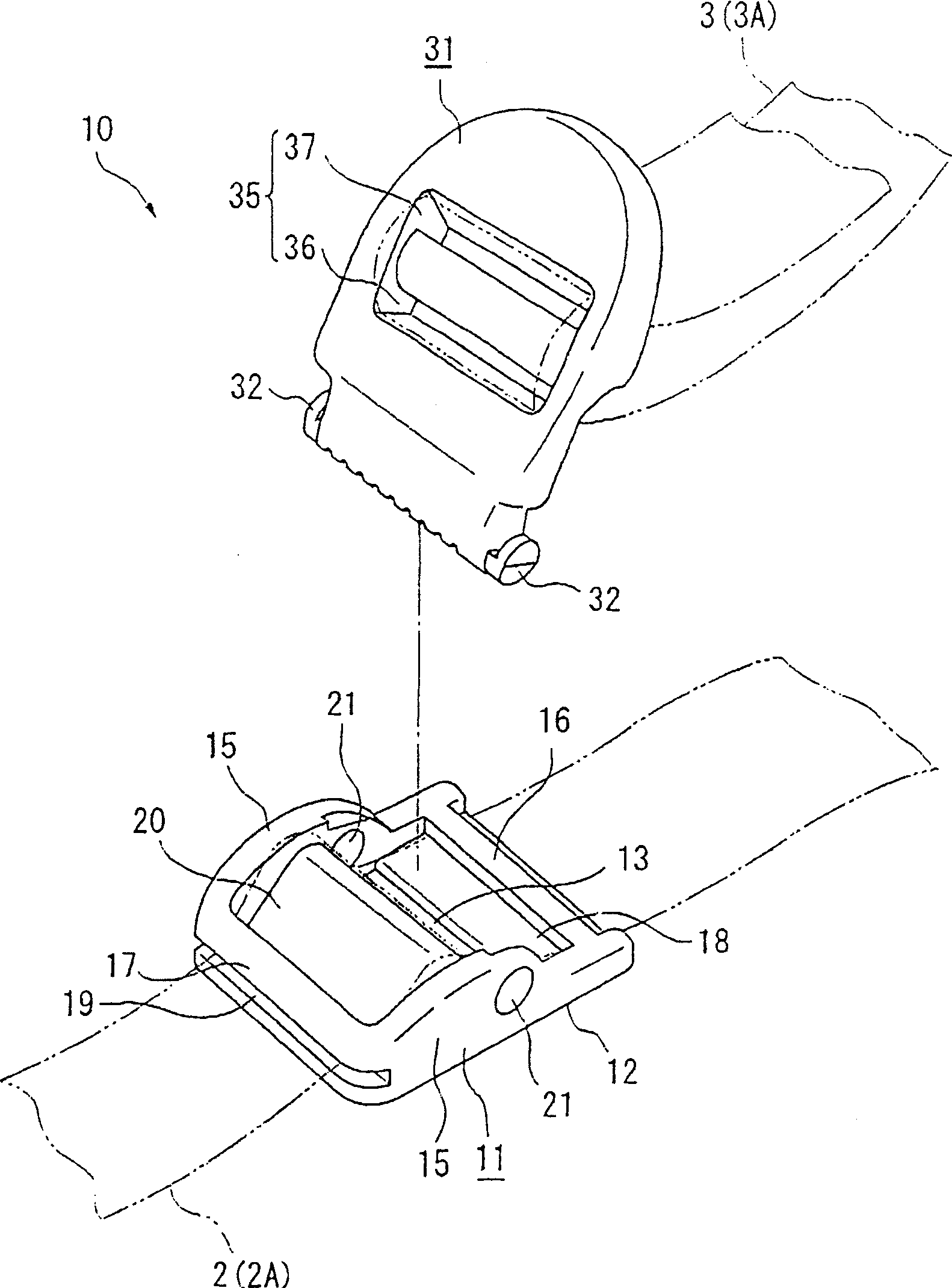

[0047] The buckle 10 of this implementation form is as image 3 and Figure 4 As shown, there is a buckle body 11 as a first member made by injection molding of synthetic resin, and an engaging member 31 as a second member pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com