Sealed container

A technology for sealing containers and container lids, which is applied to containers, rigid containers, food heating containers, etc., and can solve problems such as insufficient loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

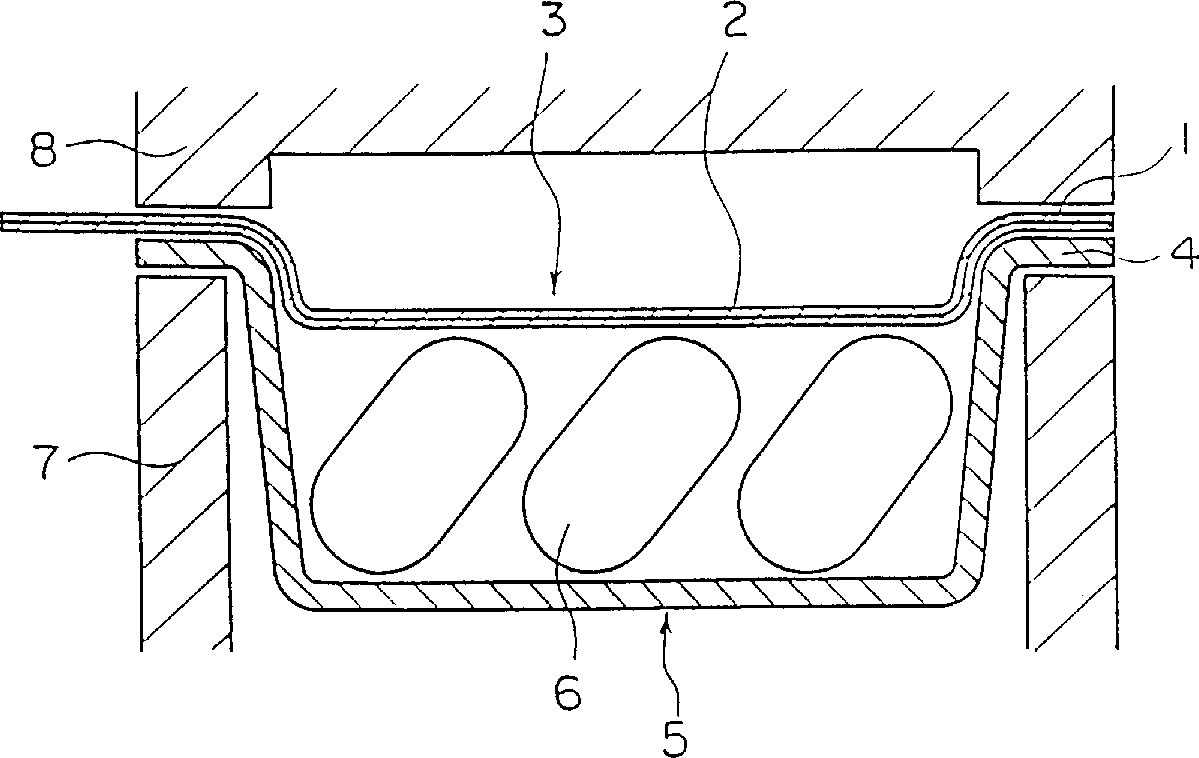

example 1

[0041] A double-layered sheet having a polycarbonate outer layer with a thickness of 0.25 mm and an inner layer of polypropylene and polystyrene mixed resin with a thickness of 0.05 mm was made into a container cover with a cut-off diameter of 70 mm by vacuum molding. Head cone, convex part with a height of 10 mm and a flange part with a width of 6 mm and a fitting. The container body was molded from a polypropylene sheet having a thickness of 0.8 mm, the container body having a frusto-conical body having a depth of 50 mm, a diameter of 70 mm, a volume of 200 ml and a flange portion having a width of 5 mm.

[0042] 210g of cooked vegetables including 50ml of soup are put into the prepared container main body, and the container cover is matched with the container main body in a state where the matching part on the periphery of the flange part of the container cover is engaged with the flange part of the container main body. The top of the cooked vegetables placed in the contain...

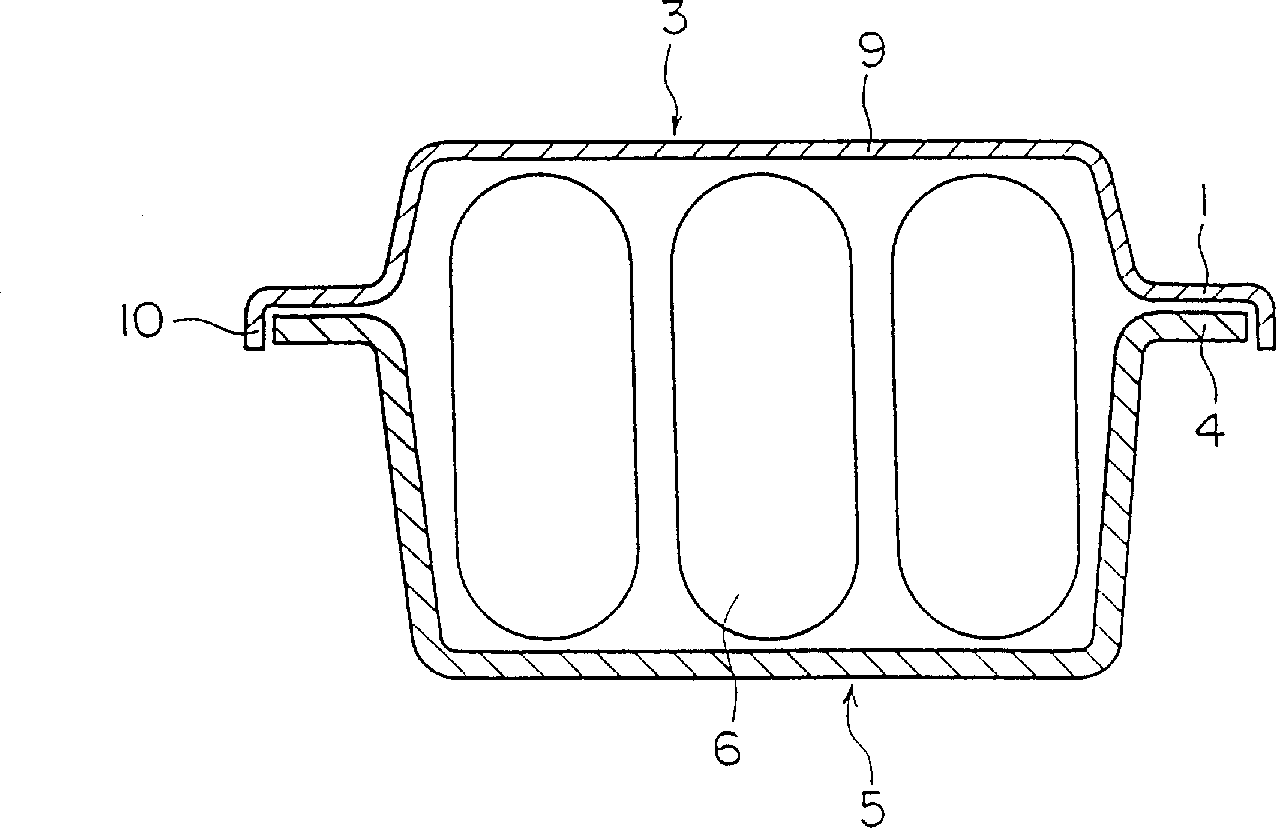

example 2

[0045] The container lid is made by vacuum molding of a multi-layer board consisting of a layer of polycarbonate with a thickness of 0.06mm, a layer of polypropylene with a thickness of 0.1mm, and a layer of polystyrene with a thickness of 0.015mm. Dichloroethylene and a layer of polypropylene and high-density polyethylene mixed resin with a thickness of 0.05mm are laminated in this order from the outermost layer to the innermost layer with a thickness of 0.18mm. The container cover has A flange portion with a width of 7 mm and a fitting portion and a convex portion with a length of 80 mm, a width of 100 mm, and a height of 10 mm. The main body of the container with a volume of 200ml, a length of 80mm, a width of 100mm, and a depth of 25mm is made by vacuum molding of a co-extruded multilayer board consisting of a layer of 0.38mm thick Polypropylene, a layer of ethylene and vinyl acetate saponified copolymer with a thickness of 0.04mm and a layer of polypropylene with a thickn...

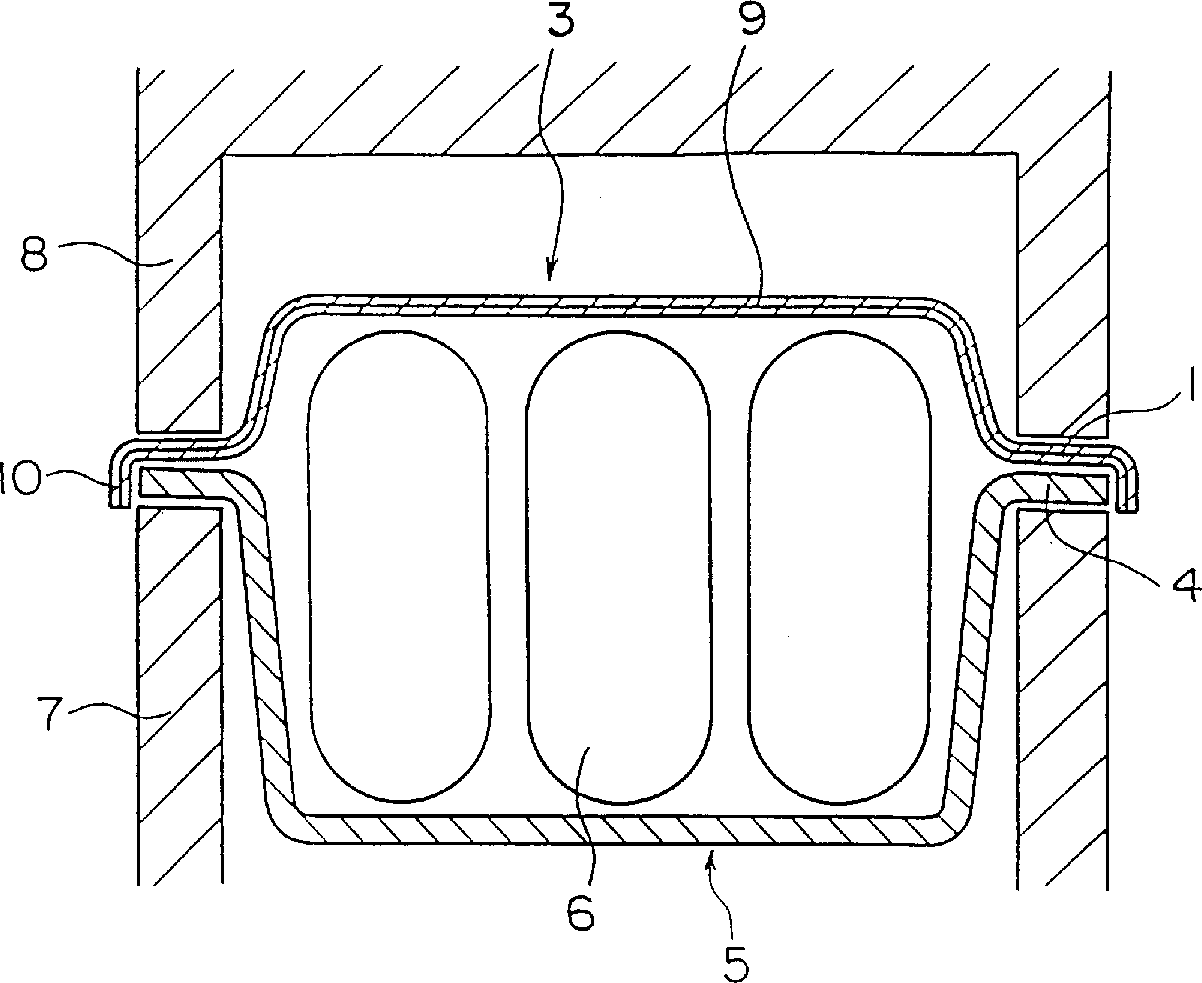

example 3

[0049] The container lid in this example has the same shape as the container lid in Example 2, and is formed by vacuum molding from the same double-layer sheet as that used in Example 1, that is, the double-layer sheet has a thickness of 0.25mm polycarbonate outer layer and 0.05mm thick polypropylene and polystyrene hybrid resin inner layer. The container body in this example has the same flange portion as the container body in Example 2, and the length, width and depth of the container body are also the same, and it is made of the same 0.8 mm thick polypropylene as used in Example 1. The plate was formed by vacuum molding, and as shown in FIG. 6( a ), at the bottom of the main body of the container, there was an elliptical concave portion with a major axis of 70 mm and a minor axis of 50 mm and a depth of 7 mm.

[0050] 210g of cooked vegetables including 50ml of soup are put into the prepared container main body, and the container cover is matched with the container main bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com