Tampon applicator tube having apertured finger grip

A finger and tampon technology, applied in the field of tubular insertion devices, can solve the problems of inability to provide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

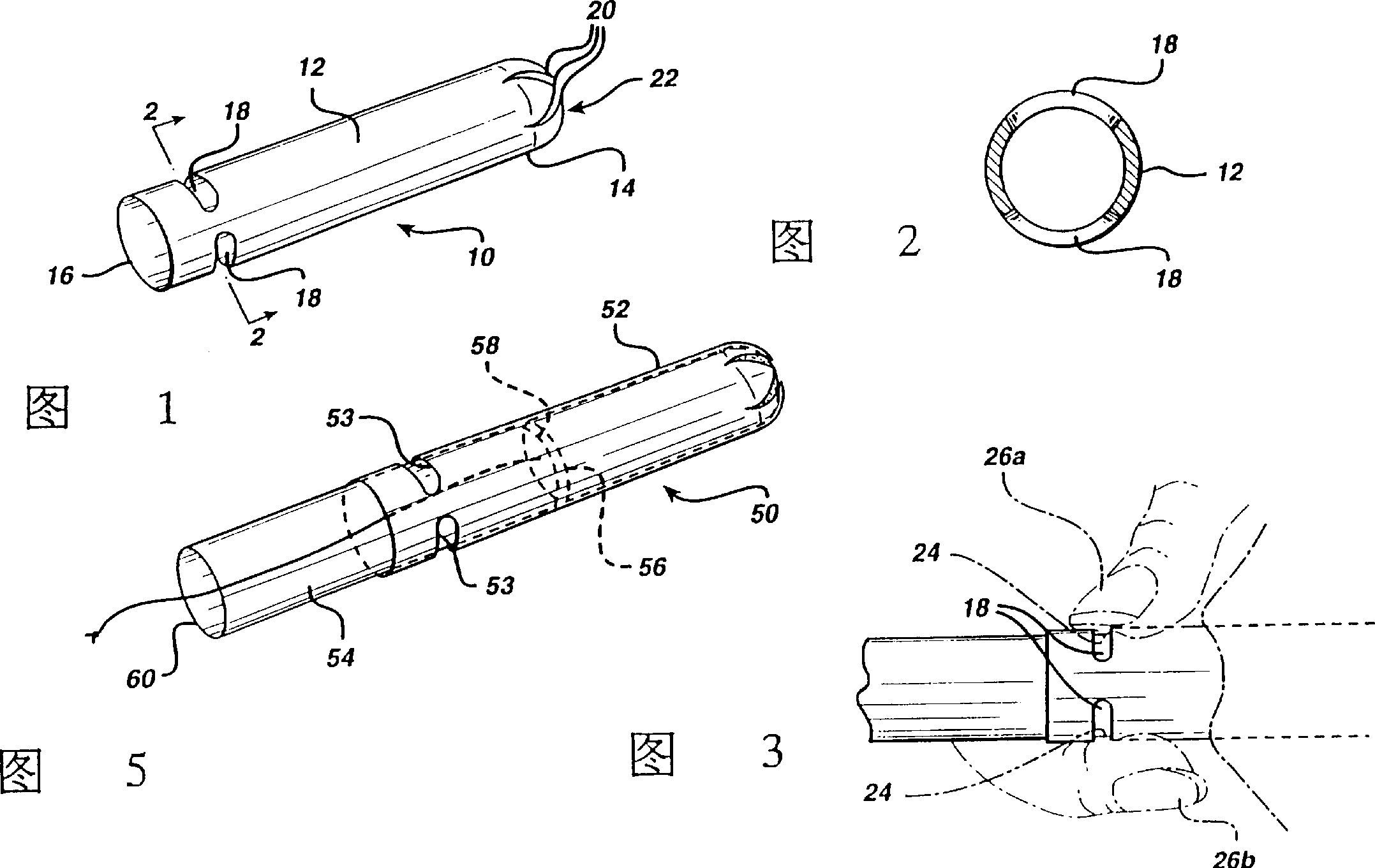

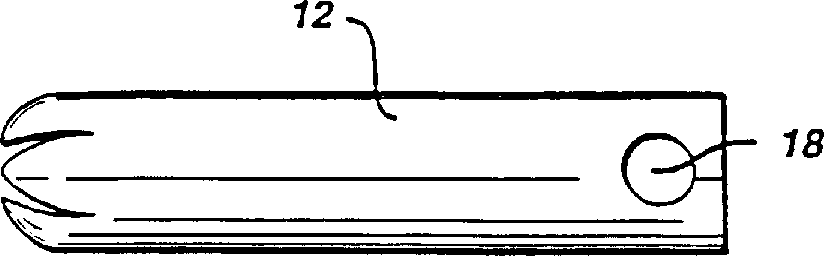

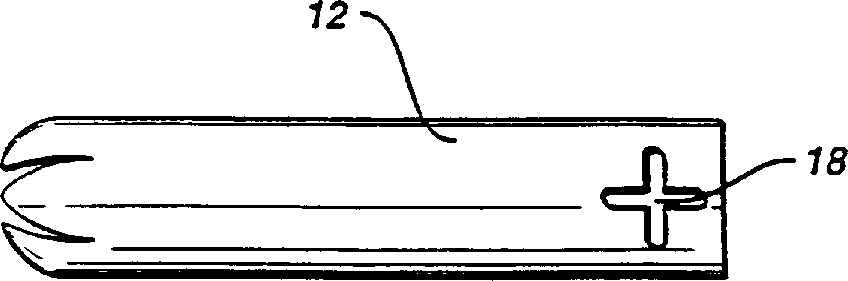

[0019] Referring to FIGS. 1-3 , one embodiment of the present invention relates to a tampon applicator tube 10 forming a tubular member 12 having an insertion end 14 and a gripping end 16 . Gripping end 16 has a plurality of finger receiving holes 18 . Insertion end 14 has a plurality of inwardly curved lobes 20 to form a generally closed dome.

[0020] The finger-receiving aperture 18 at the gripping end is sized to receive a portion 24 of a user's finger 26 . Experimentation has shown that the useful longitudinal dimension of the aperture 18 can vary from 1 mm or less to greater than 10 mm. The useful circumferential dimension of the bore 18 varies from about 1 mm to greater than 20 mm. Preferably the longitudinal dimension is from about 1 mm to about 10 mm, more preferably from about 6 mm to about 8 mm. Preferably the circumferential dimension is from about 3mm to about 20mm, more preferably from about 8mm to about 16mm. If the hole size is too long, the tube loses the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com