Door mirror assembly for vehicle

A technology for a rearview mirror assembly and a vehicle, which is applied to vehicle components, optical observation devices, transportation and packaging, etc., can solve the problems of reducing the comfort of the cabin, insufficient fixing strength, and reducing the visibility of the driver, so as to reduce the production cost. , the effect of high fixing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

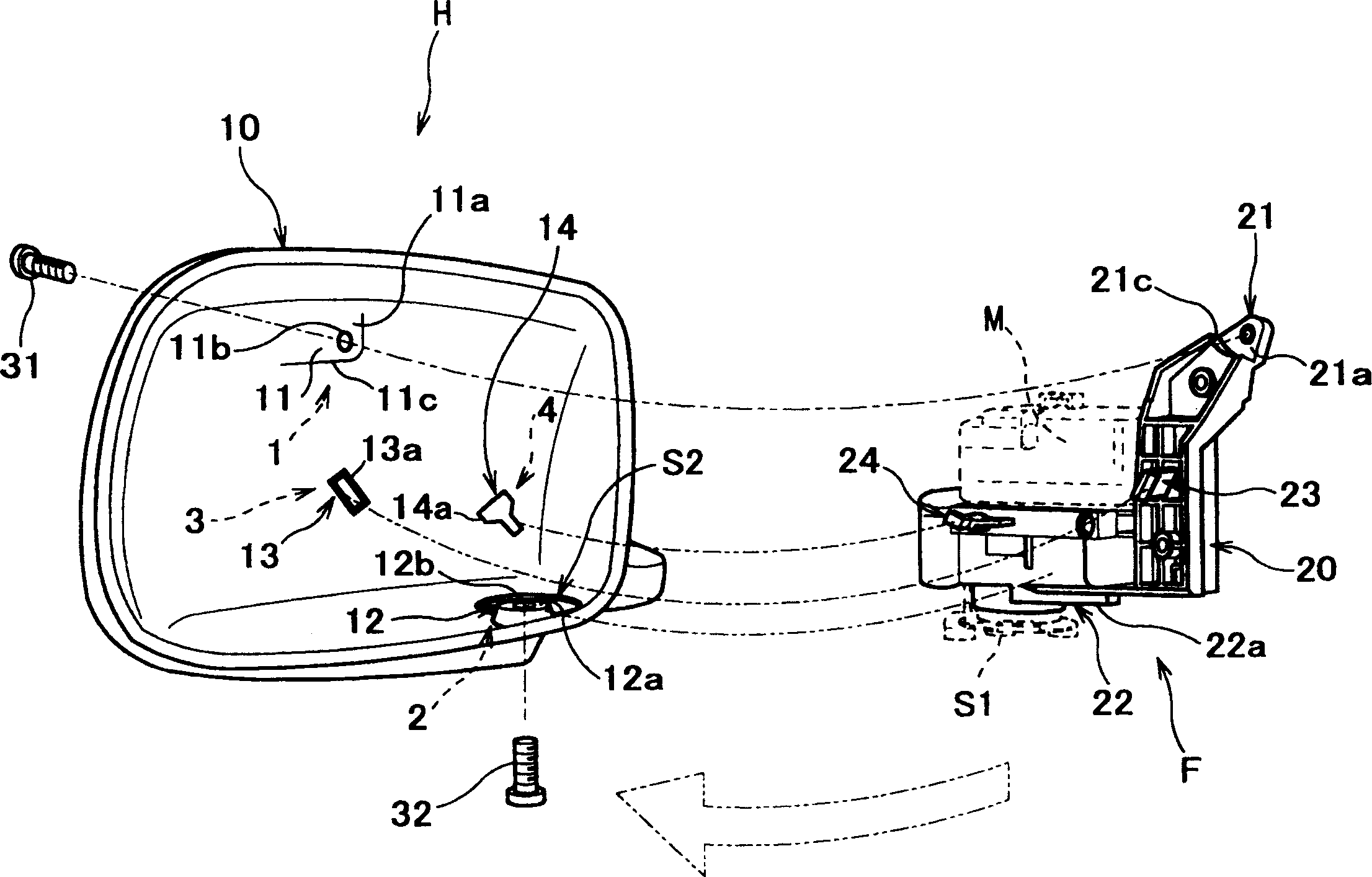

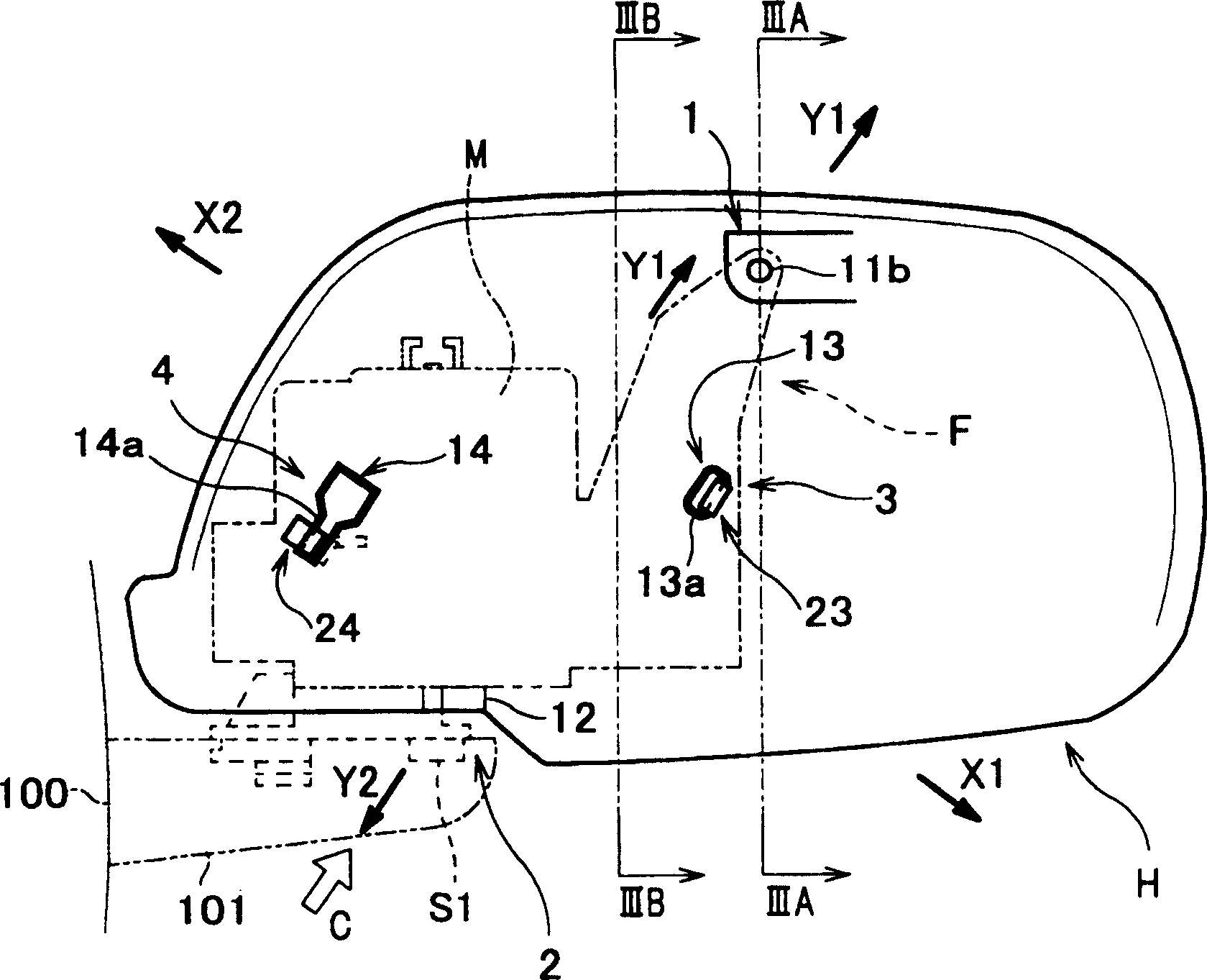

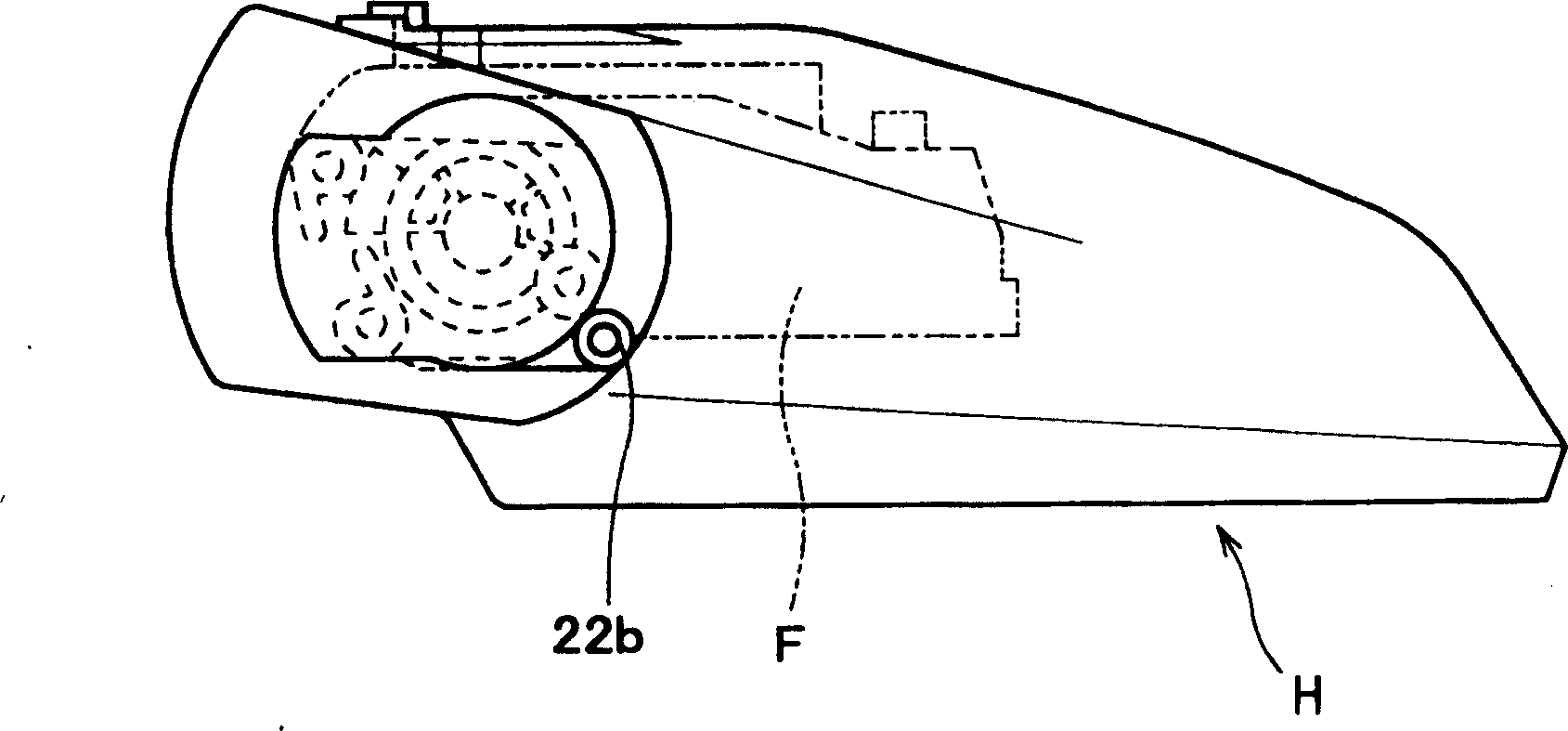

[0026] Embodiments of the present invention will now be described with reference to the accompanying drawings.

[0027] Such as figure 1 , 2A As shown in and 2B, the rearview mirror assembly for a vehicle according to the present invention includes: a rearview mirror cover (hereinafter referred to as cover H); a bracket F supporting the cover H inside. Such as Figure 2A As shown, the rear view mirror assembly is mounted on a rear view mirror base 101 provided on the side of the vehicle body 100 . The rear view mirror assembly also includes a mirror (not shown) mounted in the front opening of the housing H and houses a control subassembly (not shown) for controlling the angle of the mirror within the housing H.

[0028] Such as figure 1 As shown, the cover H includes a case 10 made of synthetic resin, upper and lower fixing openings 11 and 12 formed on the inner surface of the case 10, first and second joint openings 13 and 13 integrally formed with the housing 10. 14. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com