Permanent magnet type rotary motor and compressor using same

A rotating motor and permanent magnet technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve problems such as reducing pulsating torque, and achieve the effect of reducing torque and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

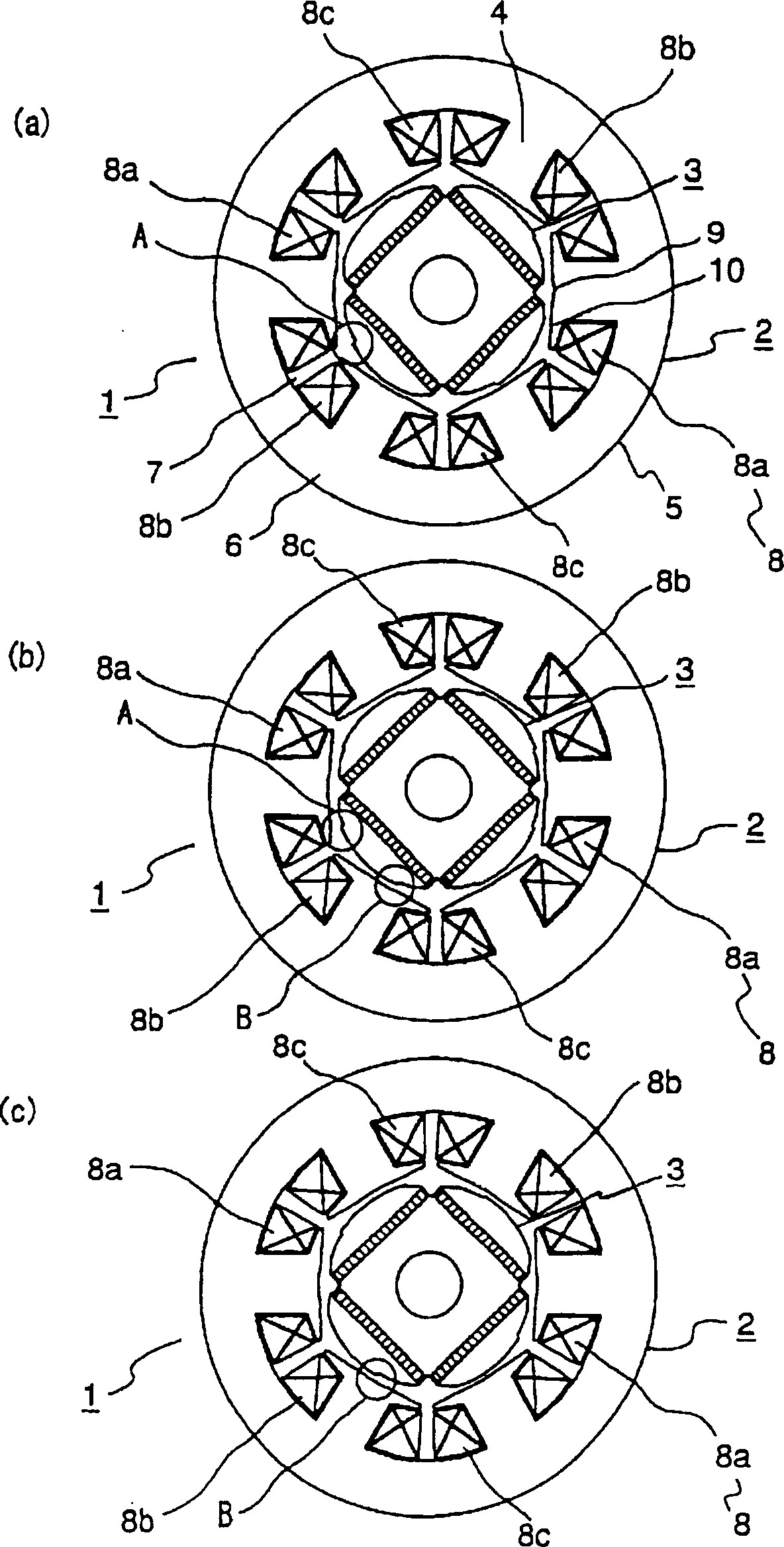

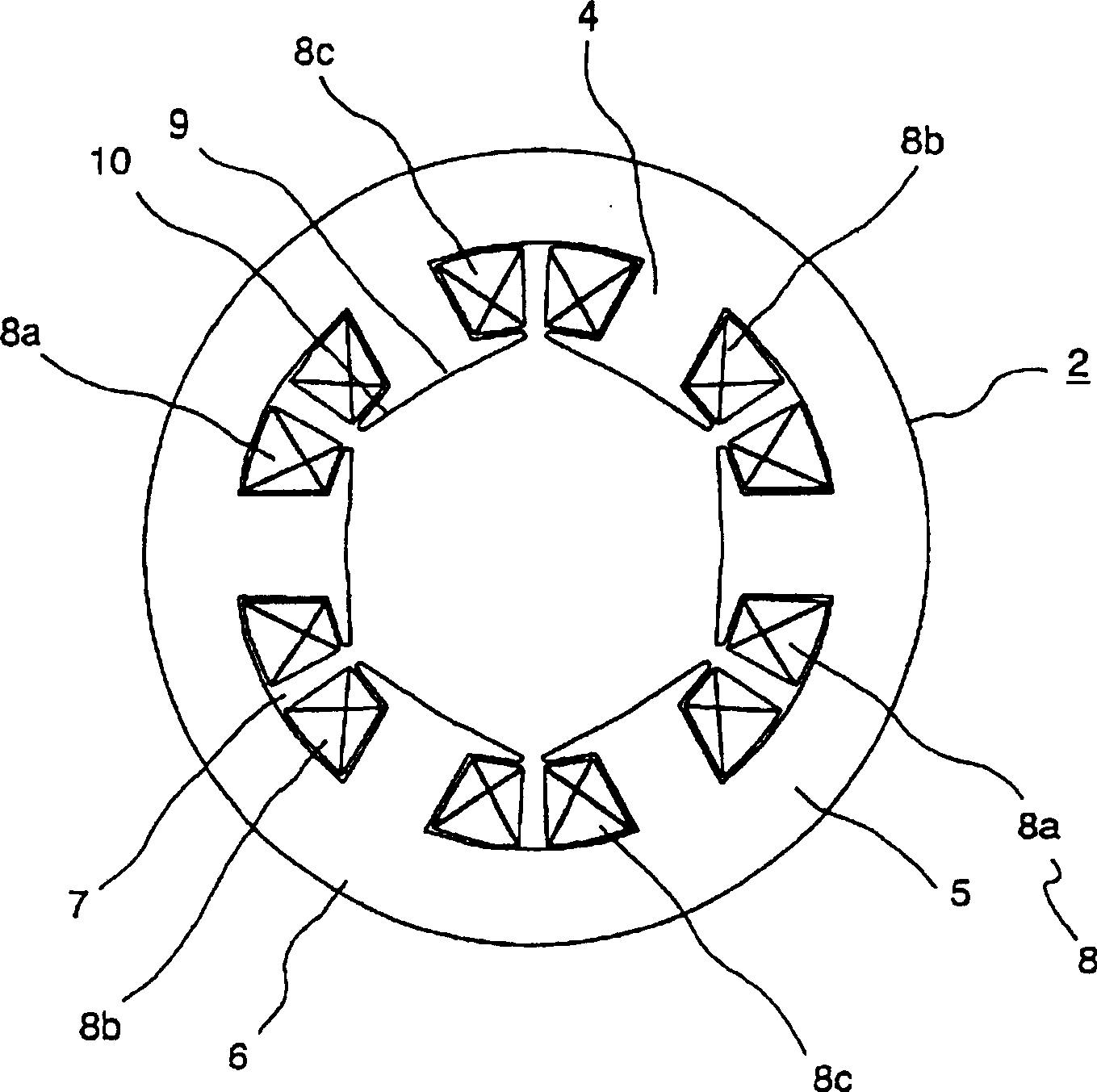

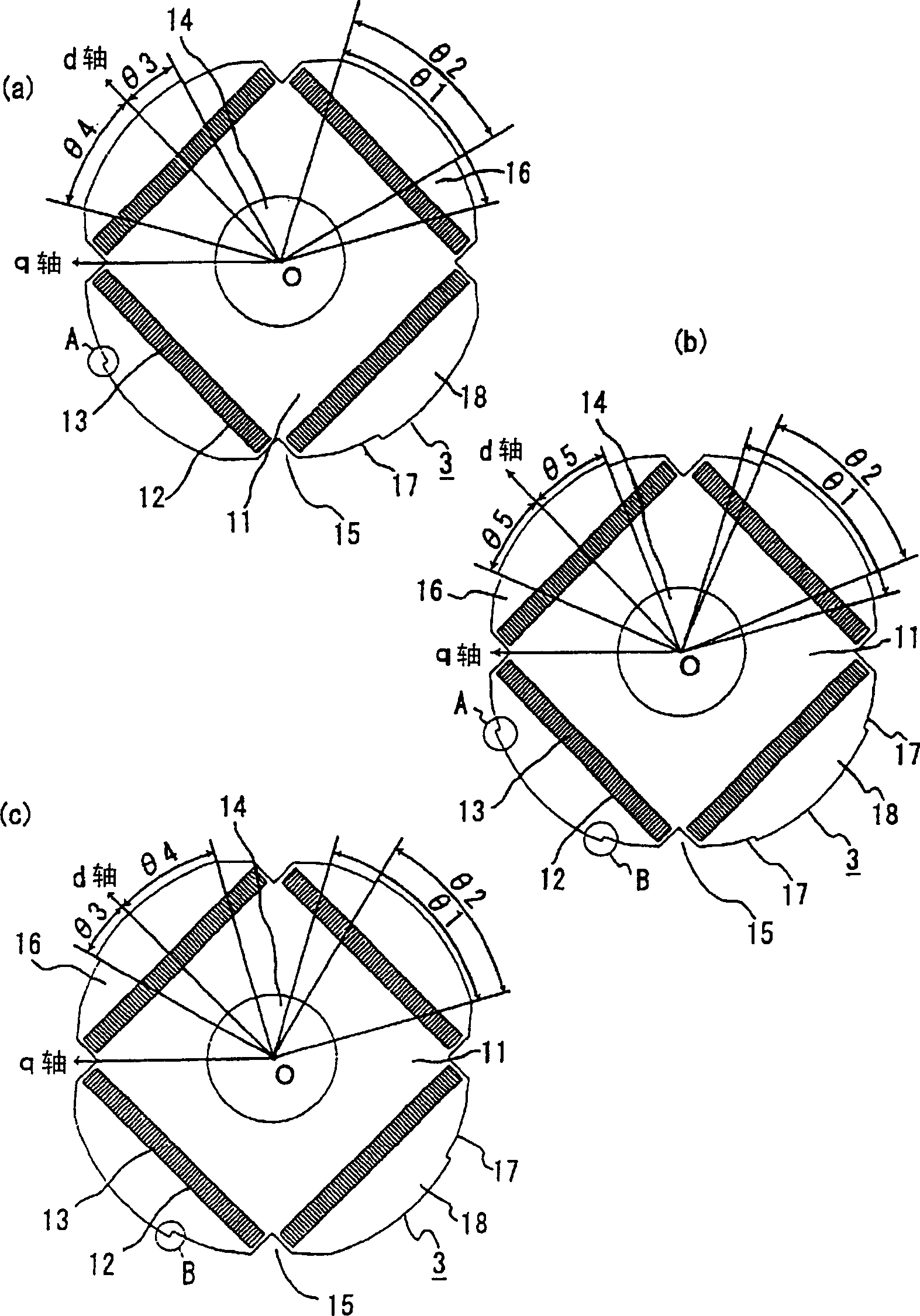

[0050] The axial cross section of the stator 2 in the first embodiment is the same at any position, but the axial cross section of the rotor 3 differs depending on the position. Figure 4 A perspective view of a rotor according to Embodiment 1 of the present invention is shown. exist Figure 4 Among them, the inline permanent magnets 13 are accommodated in the permanent magnet insertion holes 12 which are continuous at the same position along the axial direction, and only the circumferential position of the magnetic pole portion 18 is different according to the axial direction. In other words, the positions of the pole cores of the rotor are shifted in a stepwise manner with respect to the axial direction.

[0051] However, in the permanent magnet type rotating electrical machine 1 for driving a compressor which is the object of the present invention, there is always a problem of noise generation. The ripple torque is a main factor that increases the noise of the permanent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com