Rapid downshift control device for electric vehicles

A technology for electric vehicles and control devices, applied in control devices, electric vehicles, electric vehicles, etc., can solve problems such as prolonged shifting time and large delay

- Summary

- Abstract

- Description

- Claims

- Application Information

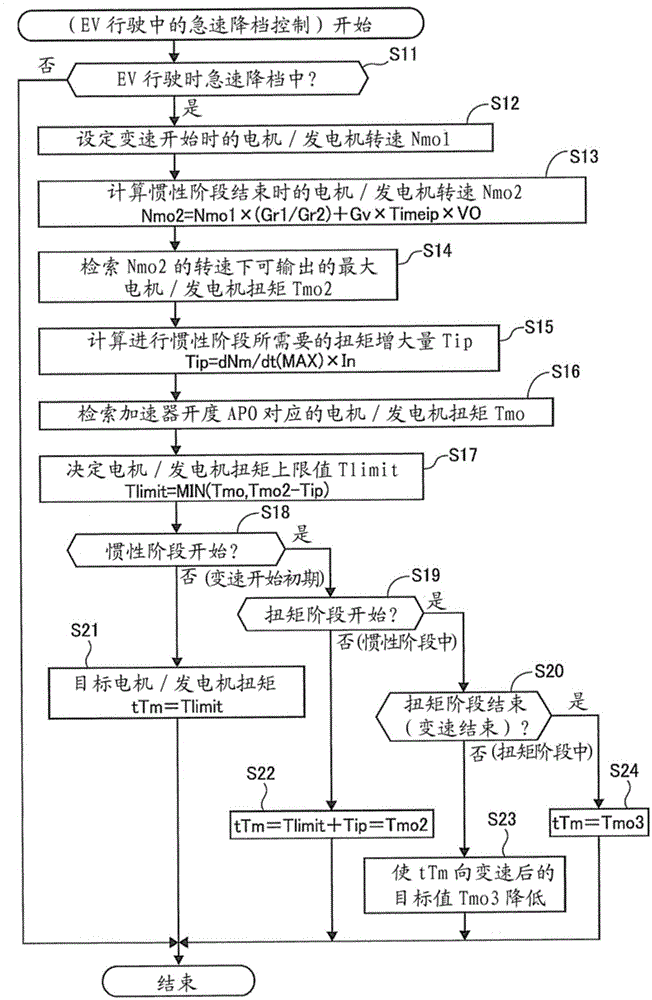

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

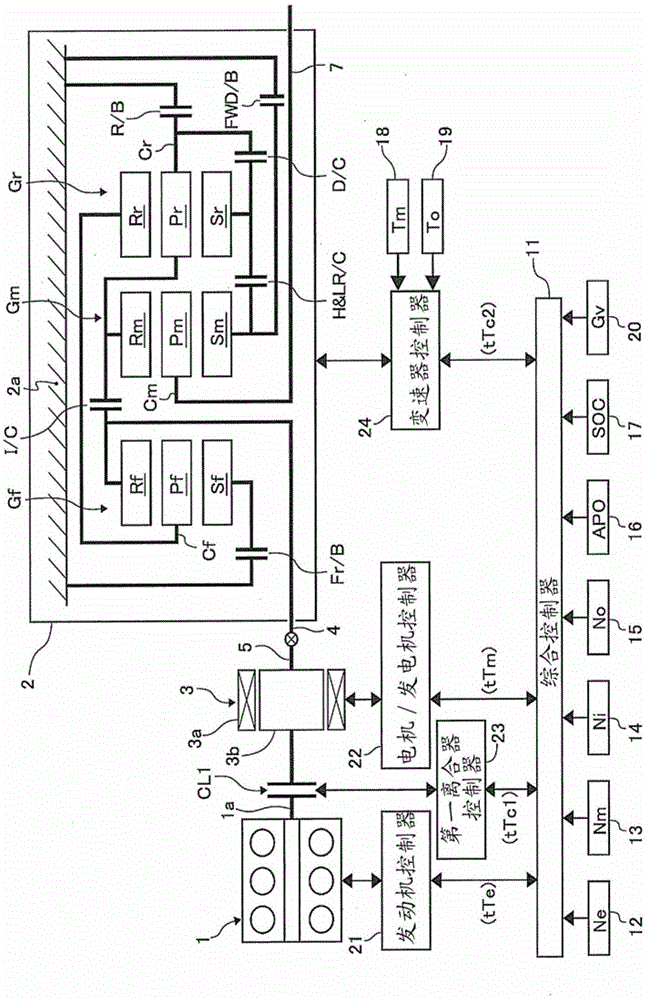

[0028] Hereinafter, embodiments of the present invention will be described in detail based on examples shown in the drawings.

[0029] (Constitution of the embodiment)

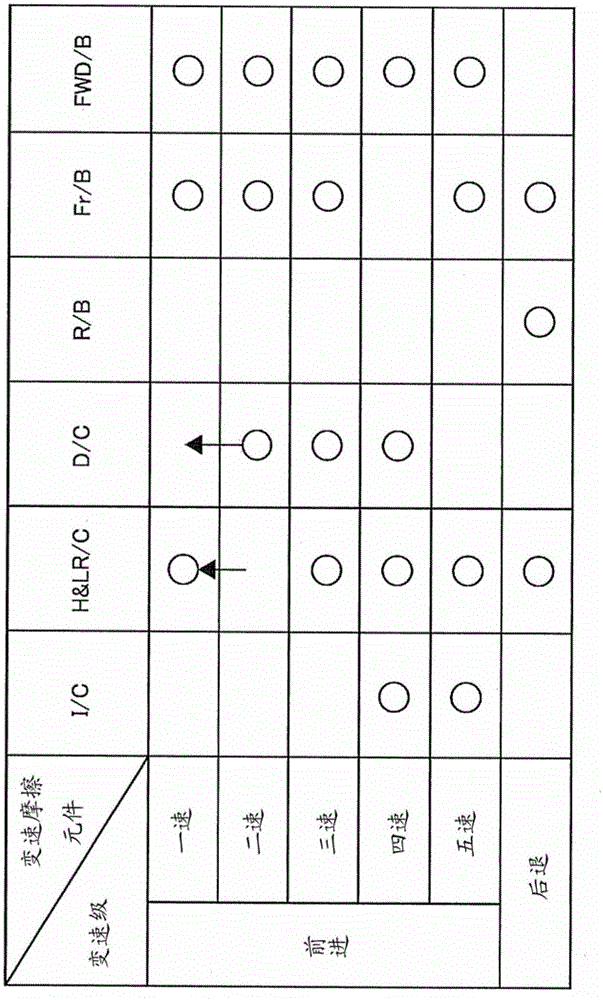

[0030] figure 1 A front engine, a rear-wheel-drive hybrid vehicle powertrain and its control system of a hybrid drive device equipped with a kick-down control device according to an embodiment of the present invention are shown together, and 1 is one of the powertrains. 2 is the engine of the source, 2 is the automatic transmission, and 3 is the motor / generator as another power source.

[0031] exist figure 1 In the power train of the hybrid vehicle shown, as in a normal rear-wheel drive vehicle, the automatic transmission 2 is arranged in series behind the engine 1 in the vehicle front-rear direction, and the power from the engine 1 (specifically, the crankshaft 1a) is connected to the engine 1. A motor / generator 3 is provided in conjunction with a shaft 5 that transmits rotation to an input shaft 4 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com