Electrical machine particular for electric or hybrid motor vehicle

A technology of motor unit and torque, applied in the direction of electrical components, electric components, electromechanical devices, etc., can solve the problems of low stability, easy interference, insufficient shielding, etc., and achieve the effect of minimizing wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

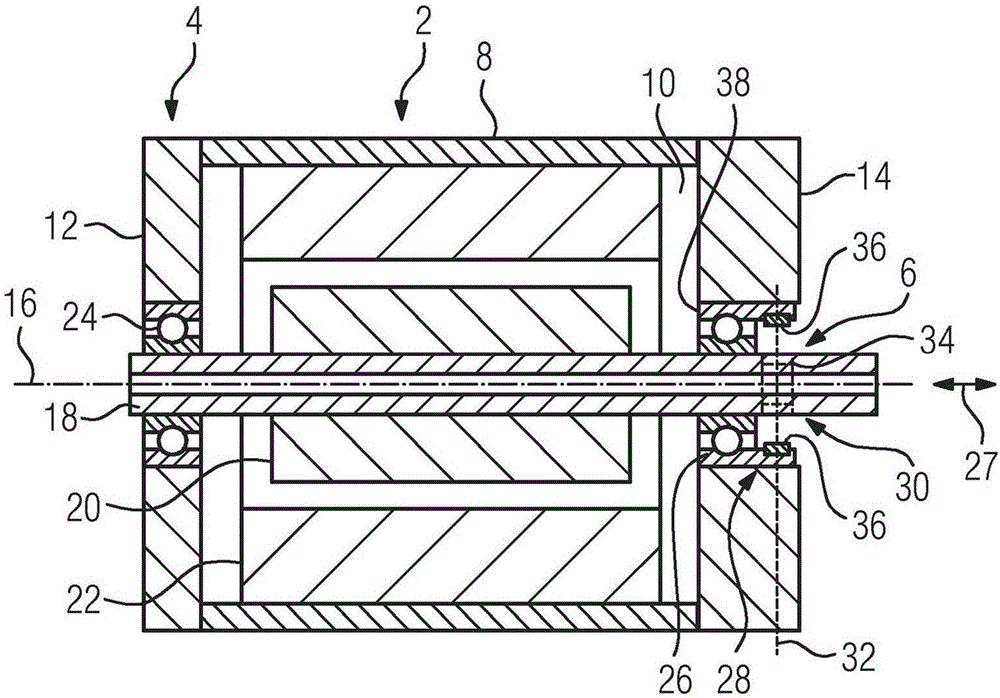

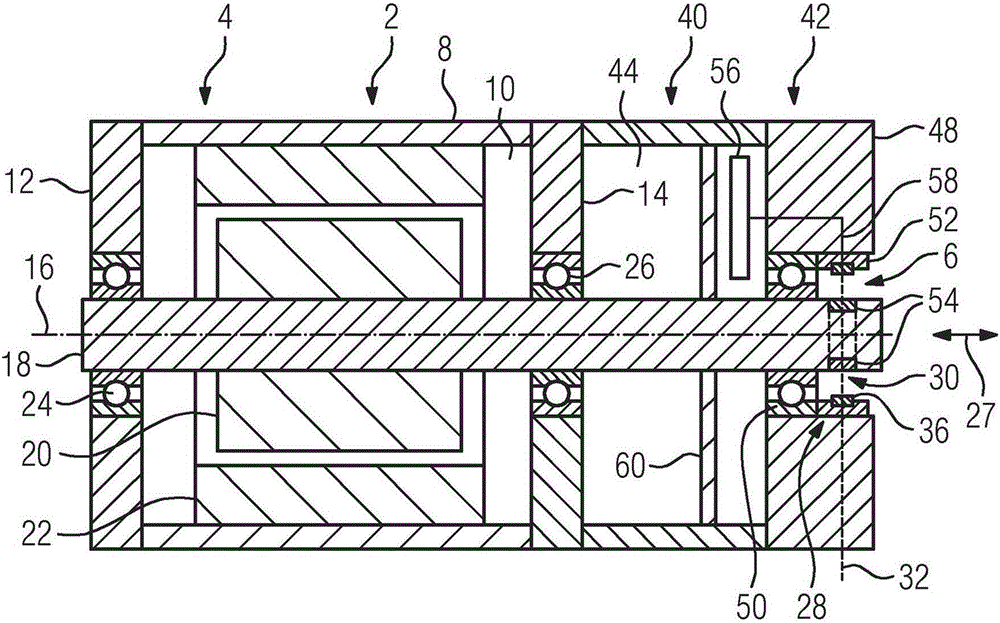

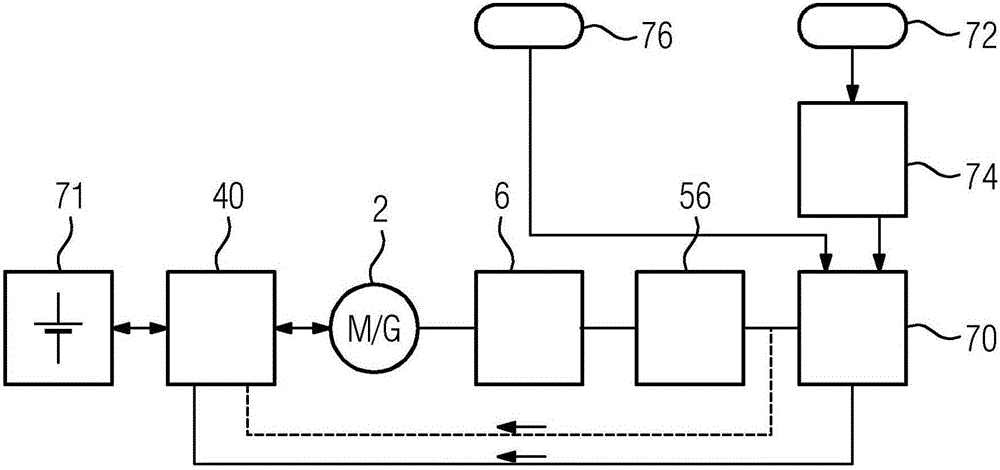

[0026] Before describing the illustrated embodiment in detail, a brief introduction to the known mechanical working background between torsional forces and rotational moments or torques is provided.

[0027]When a turning moment causes a twist (torsion force) of a rod, beam or shaft, it is called a torque. Torque acts on both ends of a twisted object as action and reaction. In a shaft with a constant cross section, the elastic torsion is proportional to the magnitude of the torque. Similar to in control, only shear or torsional stress occurs in torsion. The torsional stress is defined as the ratio of the torque acting when an object is twisted to the resistive moment. The respective currently acting rotational torque can be detected via the measurement of the respective current torque force or twist.

[0028] However, several boundary conditions must be taken care of in practical applications. Only relatively small torsion angles should therefore occur in a reversible or e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com