Liquid crystal polyester resin compson. and its moulded products

一种树脂组合物、液晶聚酯的技术,应用在液晶材料、化学仪器和方法等方向,能够解决液晶聚酯粘度增加等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

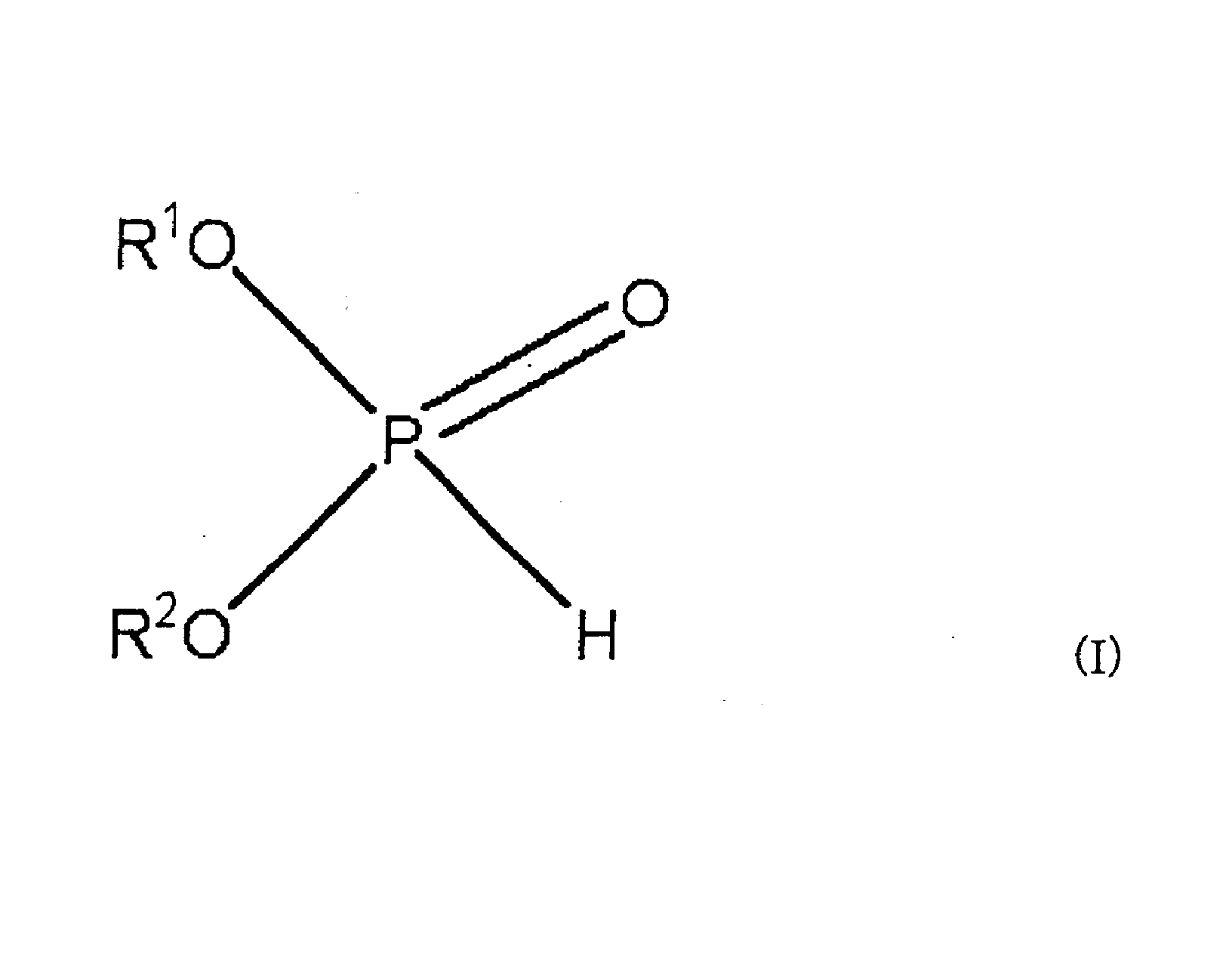

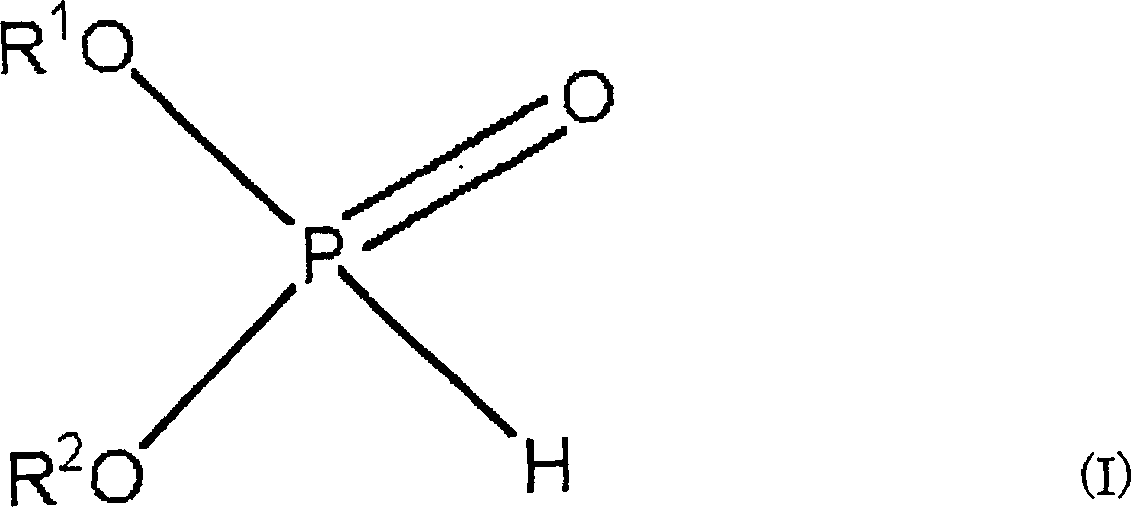

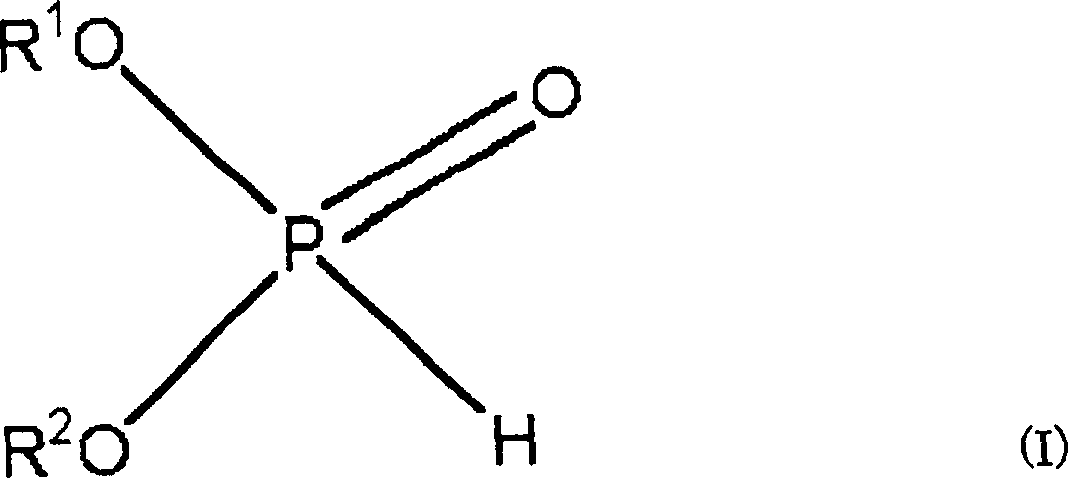

Image

Examples

Embodiment 1

[0090] To a reactor equipped with a stirrer, torque meter, nitrogen conduit, thermometer and reflux condenser was added 1064 g (7.7 moles) of p-hydroxybenzoic acid, 307 g (1.65 moles) of 4,4′-dihydroxybiphenyl, 260.8 g ( 1.57 mol) terephthalic acid, 13.2 g (0.08 mol) isophthalic acid and 1235 g (12.1 mol) acetic anhydride. The reactor atmosphere was thoroughly purged with nitrogen, then the mixture was heated to 150°C under nitrogen flow over a period of 15 minutes and maintained at this temperature under reflux for 3 hours.

[0091] Thereafter, the mixture was heated to 320° C. over 2 hours and 50 minutes while distilling by-product acetic acid and unreacted acetic anhydride. When an increase in torque was confirmed at a certain point, the reaction was considered complete, and the contents of the reactor were taken out. The resulting solid component was cooled to room temperature, ground with a fine grinder, and then heated from room temperature to 250°C for 1 hour under nitr...

Embodiment 2

[0094] Except using the phosphite compound shown in formula (III), repeat the procedure identical with embodiment 1, evaluate the property (existence of black impurity, melt viscosity stability) of this resin, evaluation result is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com