Optical waveguide device

一种光波导、波长的技术,应用在光束引导装置、光波导光导、光导等方向,能够解决降低分辨率、不能消除缺陷、增加花费等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

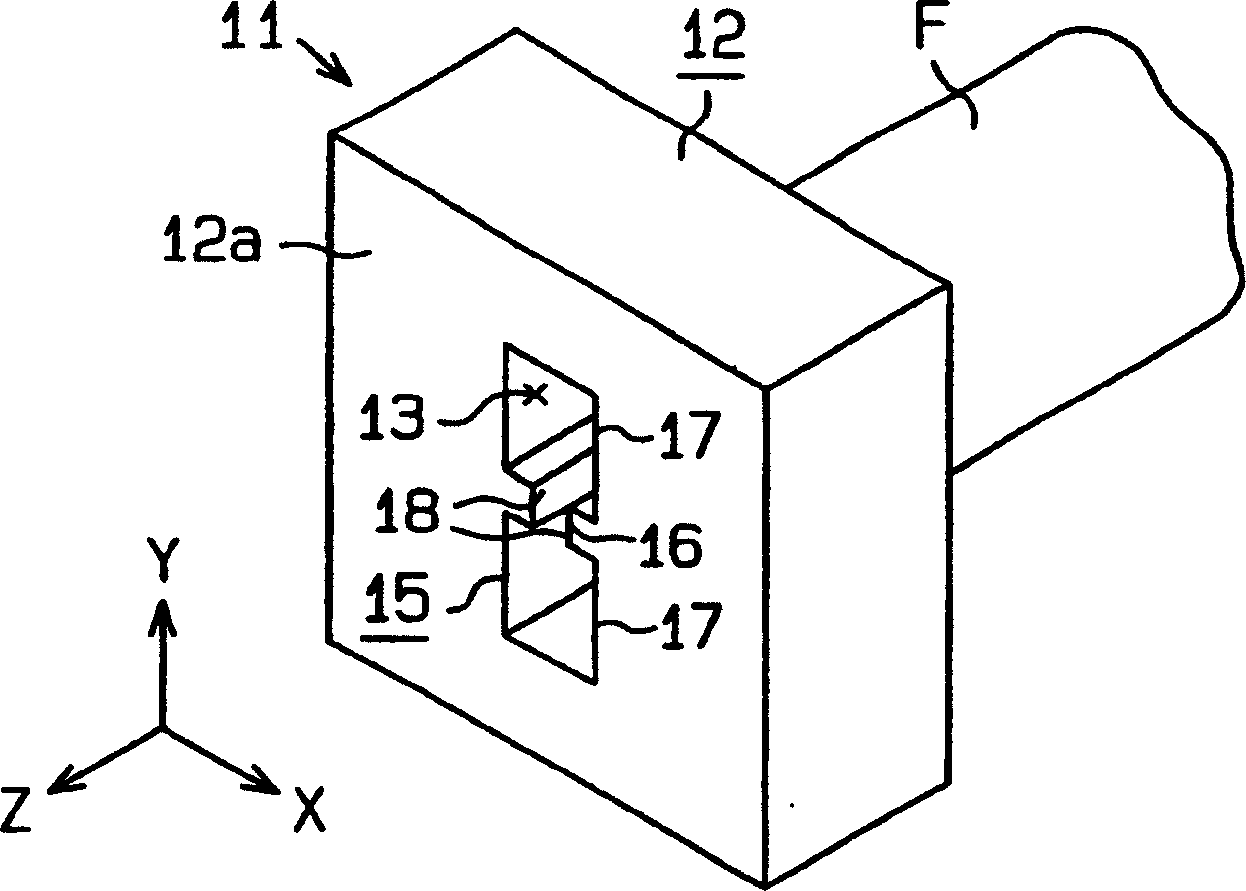

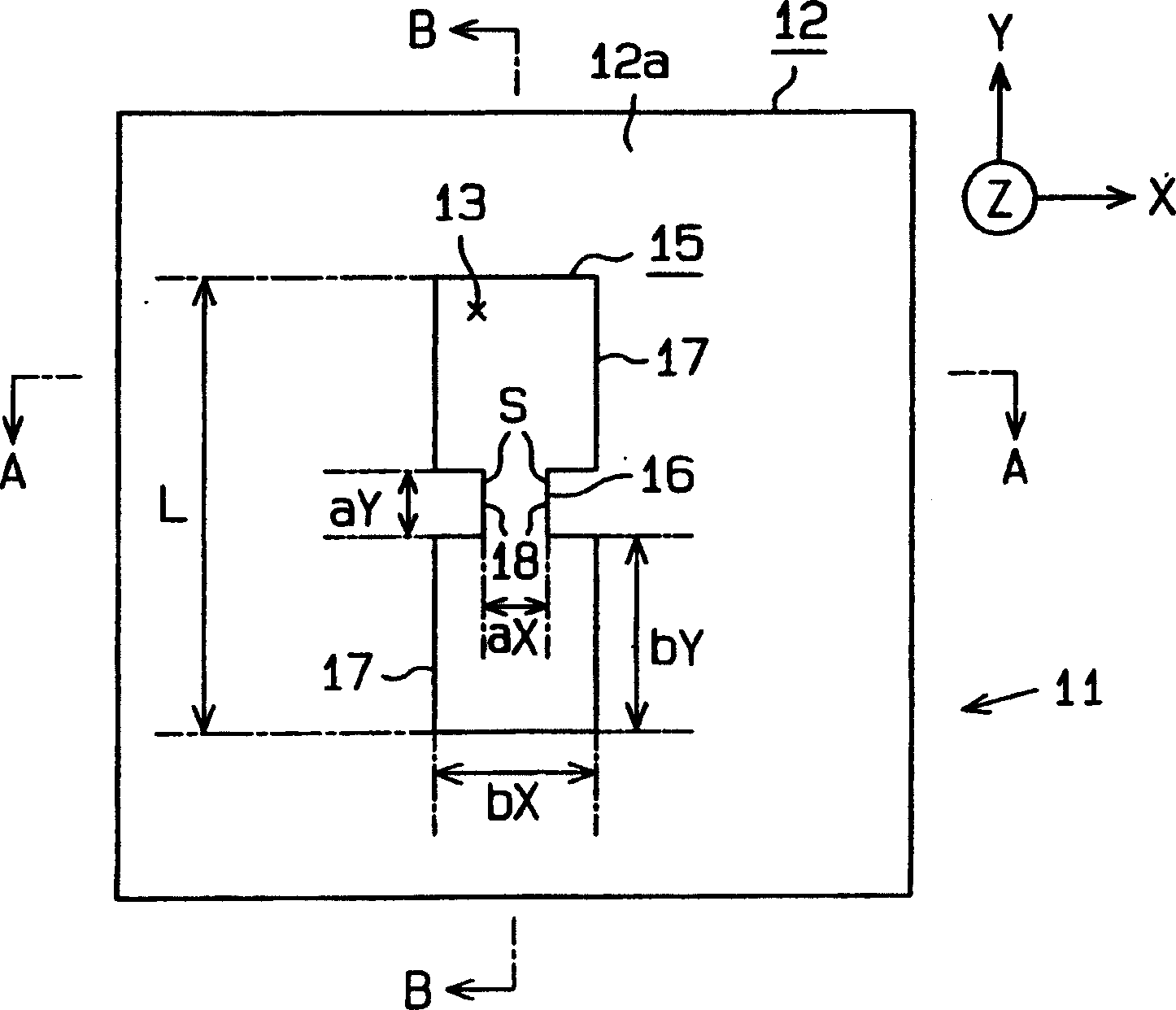

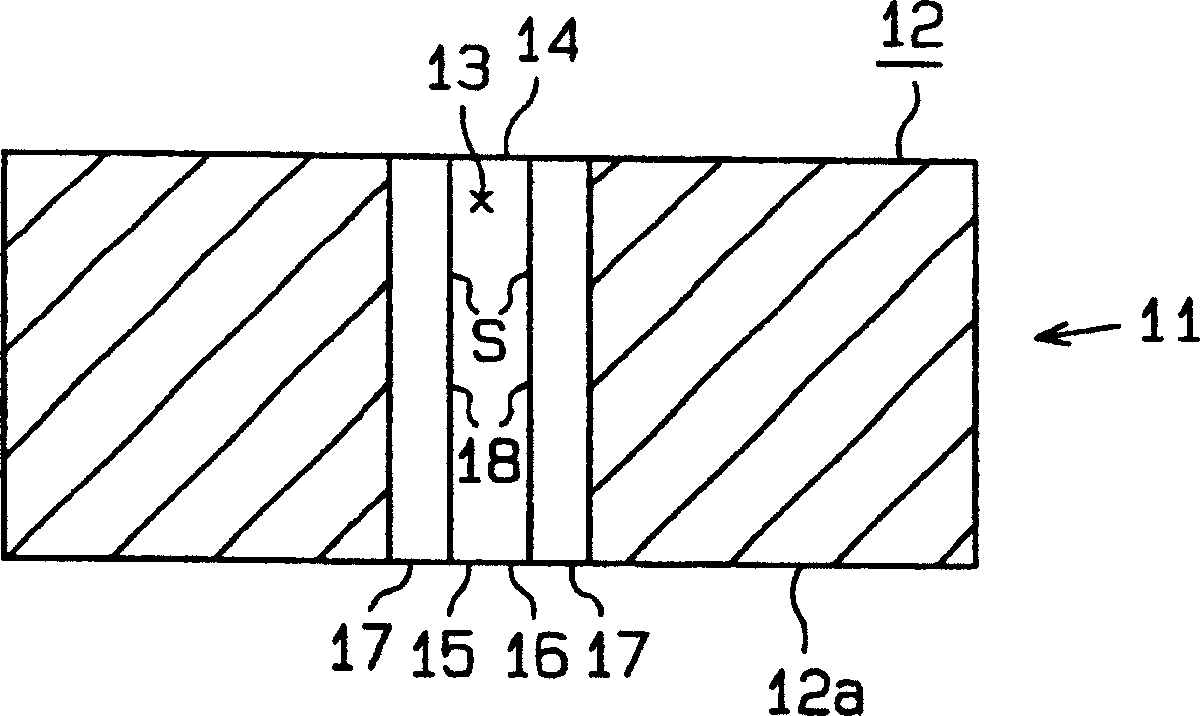

[0058] will now refer to Figure 1 to Figure 8 , describes the optical waveguide device 11 according to the first embodiment, which is an optical probe.

[0059] Such as figure 1 As shown, the optical waveguide device (optical probe) 11 of this embodiment includes: a main body 12, which is a rectangular metal plate. The body 12 is made of a dielectric having a negative real part of the relative complex permittivity. That is, body 12 is made of a negative dielectric (plasmon activation medium). In this embodiment, the wavelength of transmitted light is 488nm (nanometer), and the body 12 is made of silver (Ag), wherein the real part of the relative complex permittivity is -7.38. The relative complex permittivity of the dielectric is represented by the ratio of the permittivity of the dielectric to the permittivity in vacuum.

[0060] Such asfigure 1 , 3(a), and 3(b), an optical waveguide 13 for transmitting light is formed on the main body 12 through the thickness direction....

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com