Improvement for backlight module support

A backlight module and support technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of board sagging and high assembly costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

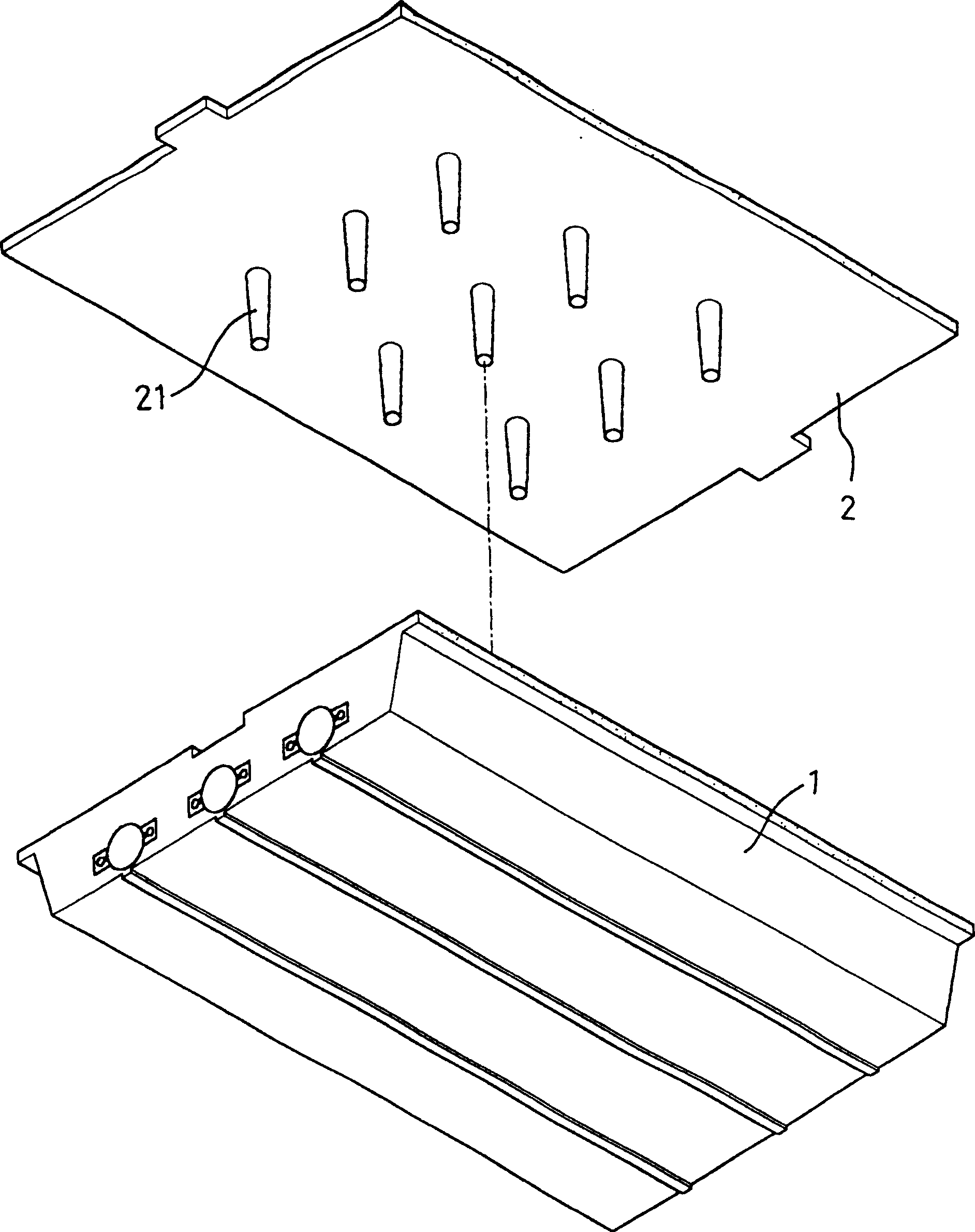

[0019] Please refer to the accompanying drawings again, the present invention is as follows after being assembled Figure 4 As shown, since the diffuser plate 2 itself is supported and abutted by the support member 21, it can be always flat and free from deformation.

[0020] Therefore, through the implementation of the present invention, the diffusion plate 2 can be well supported to prevent deformation without any process, which can be regarded as a major breakthrough of the backlight module.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com