Vehicle fuel pressure Linkage braking apparatus

A braking device and oil pressure technology, applied in the field of vehicle braking device, can solve problems such as time-consuming, and achieve the effect of enhancing safety and improving life support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

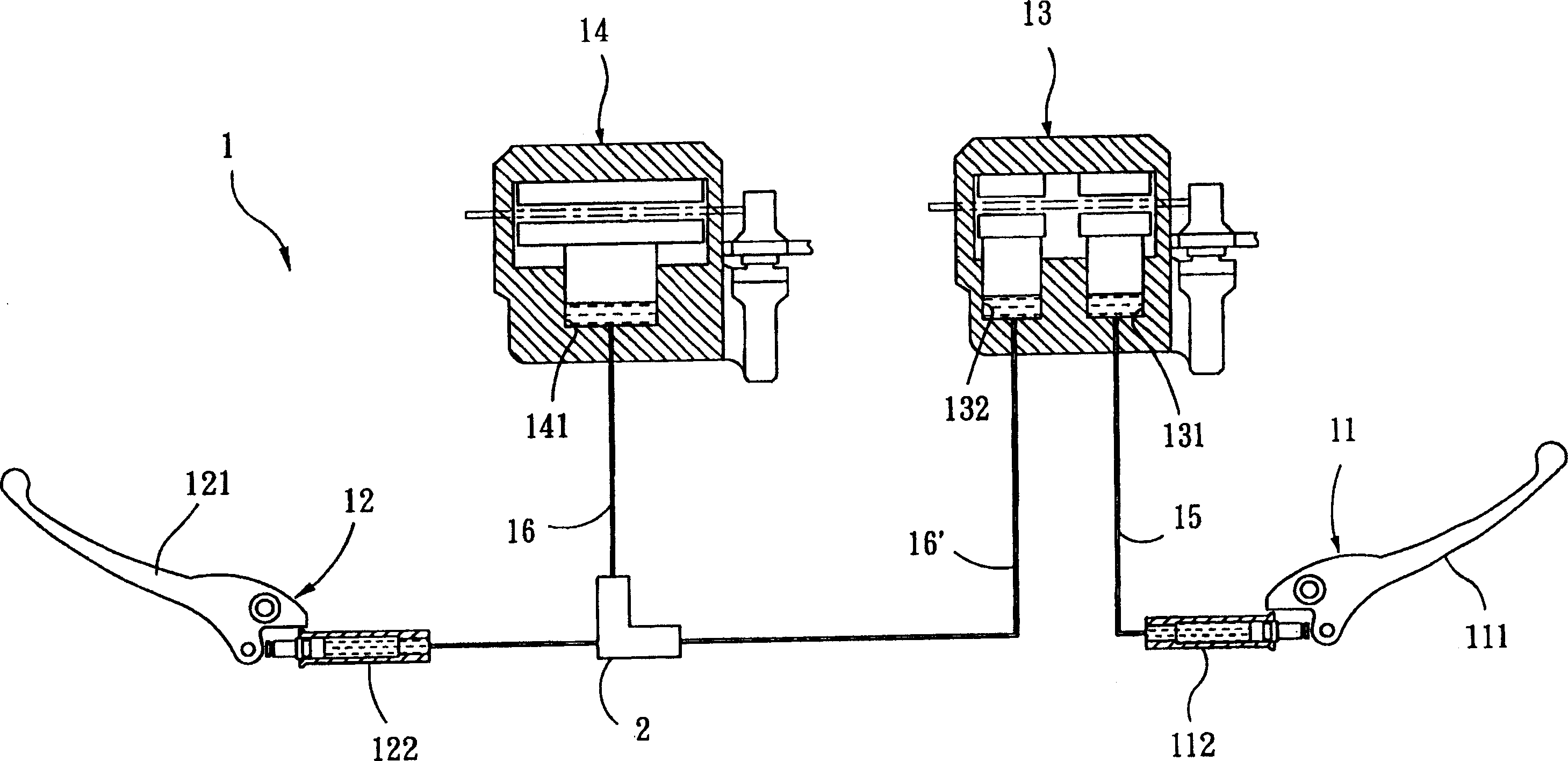

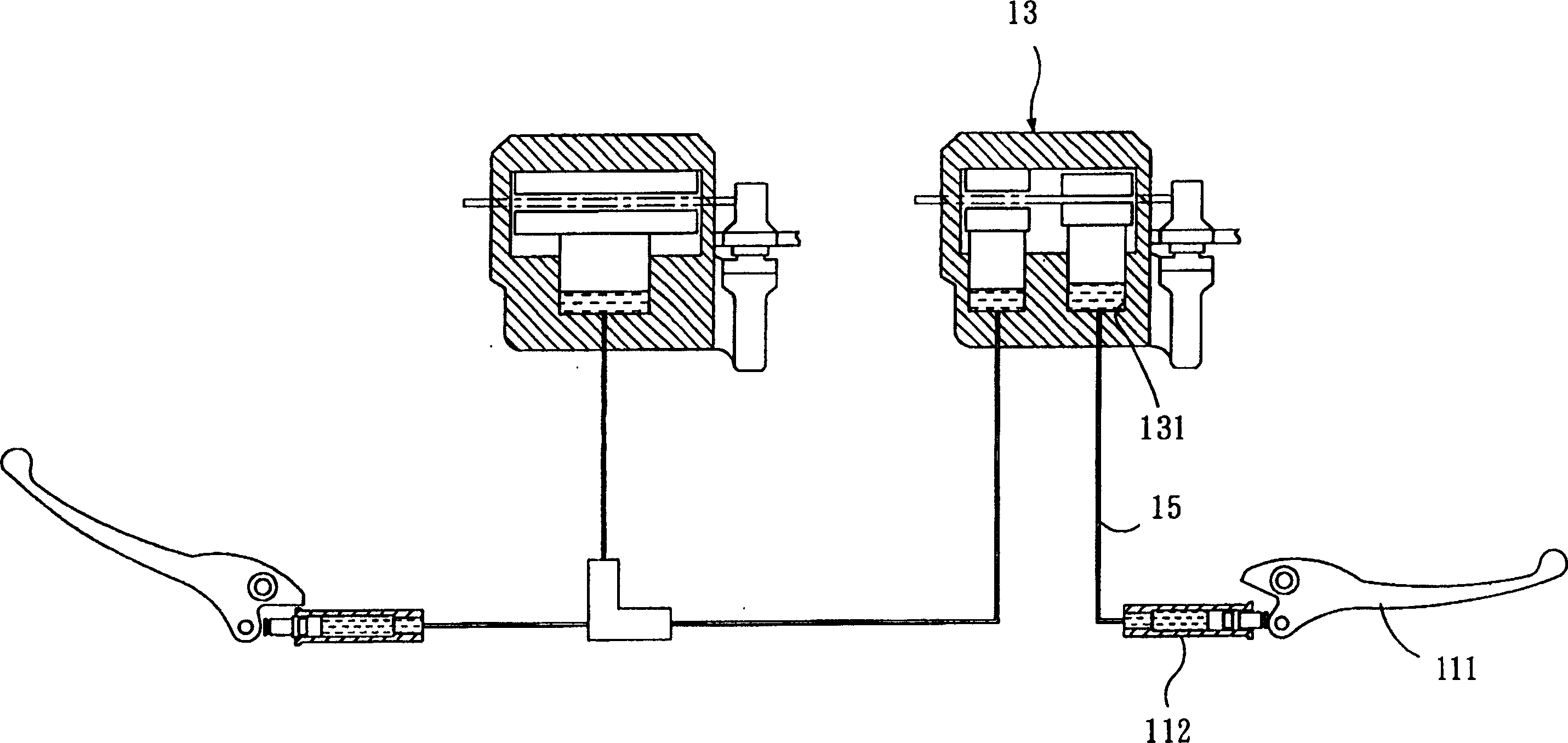

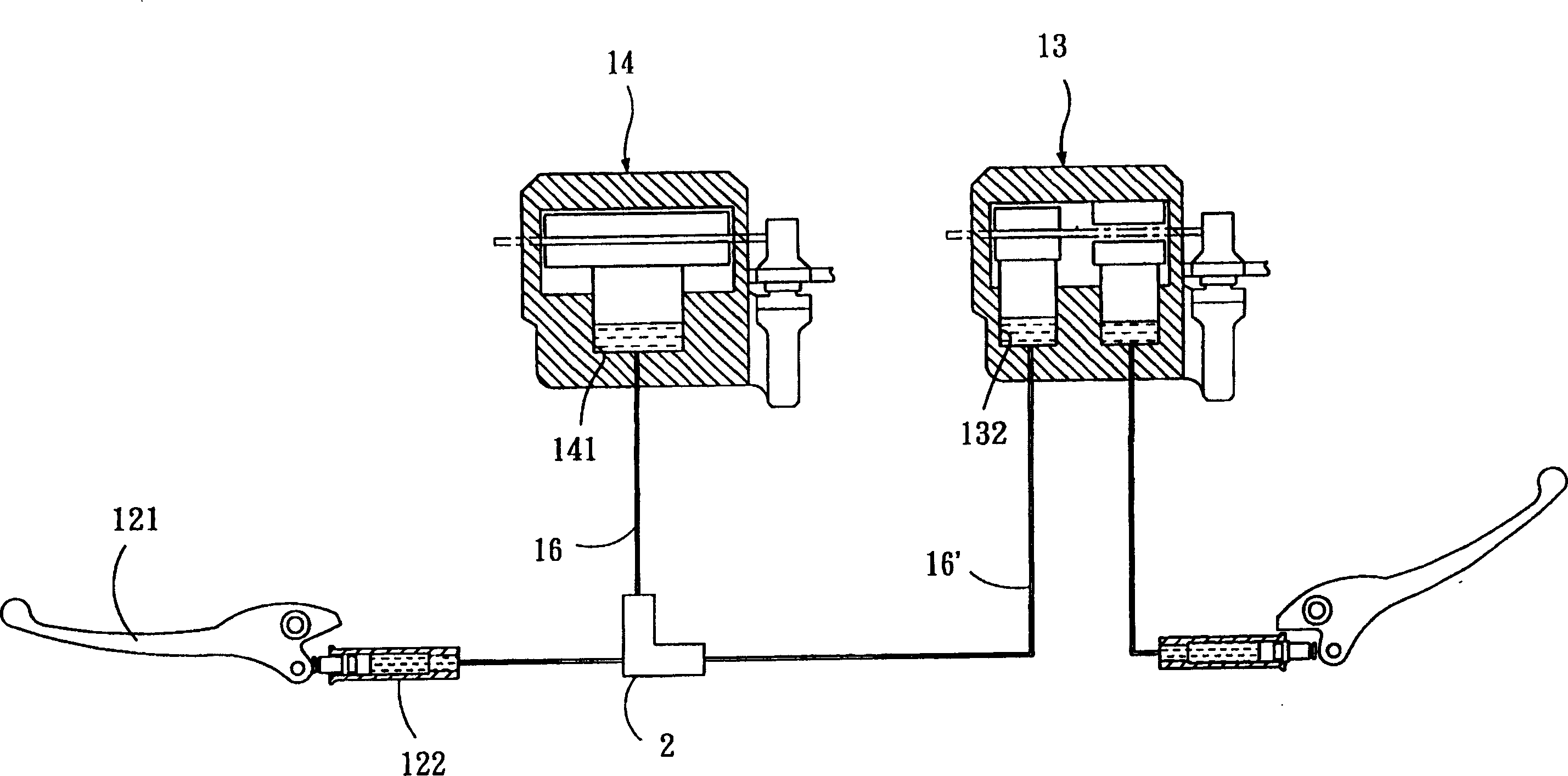

[0057] refer to Figure 4 , the preferred embodiment of the vehicle hydraulic interlocking braking device 3 of the present invention is suitable for a front and rear wheel (for ease of description, not drawn in the figure) of a motorcycle. The vehicle hydraulic linkage braking device 3 includes a first control unit 31, a second control unit 32, a hydraulic cylinder 33, a first hydraulic pipeline 34, a second hydraulic pipeline 35, a The front wheel is connected with a front brake unit 36 to stop the front wheel, and a rear brake unit 37 is connected with the rear wheel to stop the rear wheel.

[0058] The first control unit 31 has a right handle 311 and a cylinder 312 adjacent to each other. The second control unit 32 has a left handle 321 and a cylinder 322 adjacent to each other.

[0059] The hydraulic cylinder 33 has a body 331, a first through groove 333 defined by the first inner wall surface 332 of the body 331, and a second through groove defined by the second inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com