Process for mfg. self-cleaning antifog glass

A technology of anti-fog glass and a manufacturing method, which is applied in the field of glass surface film coating preparation, can solve the problems of lowering the qualified rate of products, lowering the transparency of glass, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

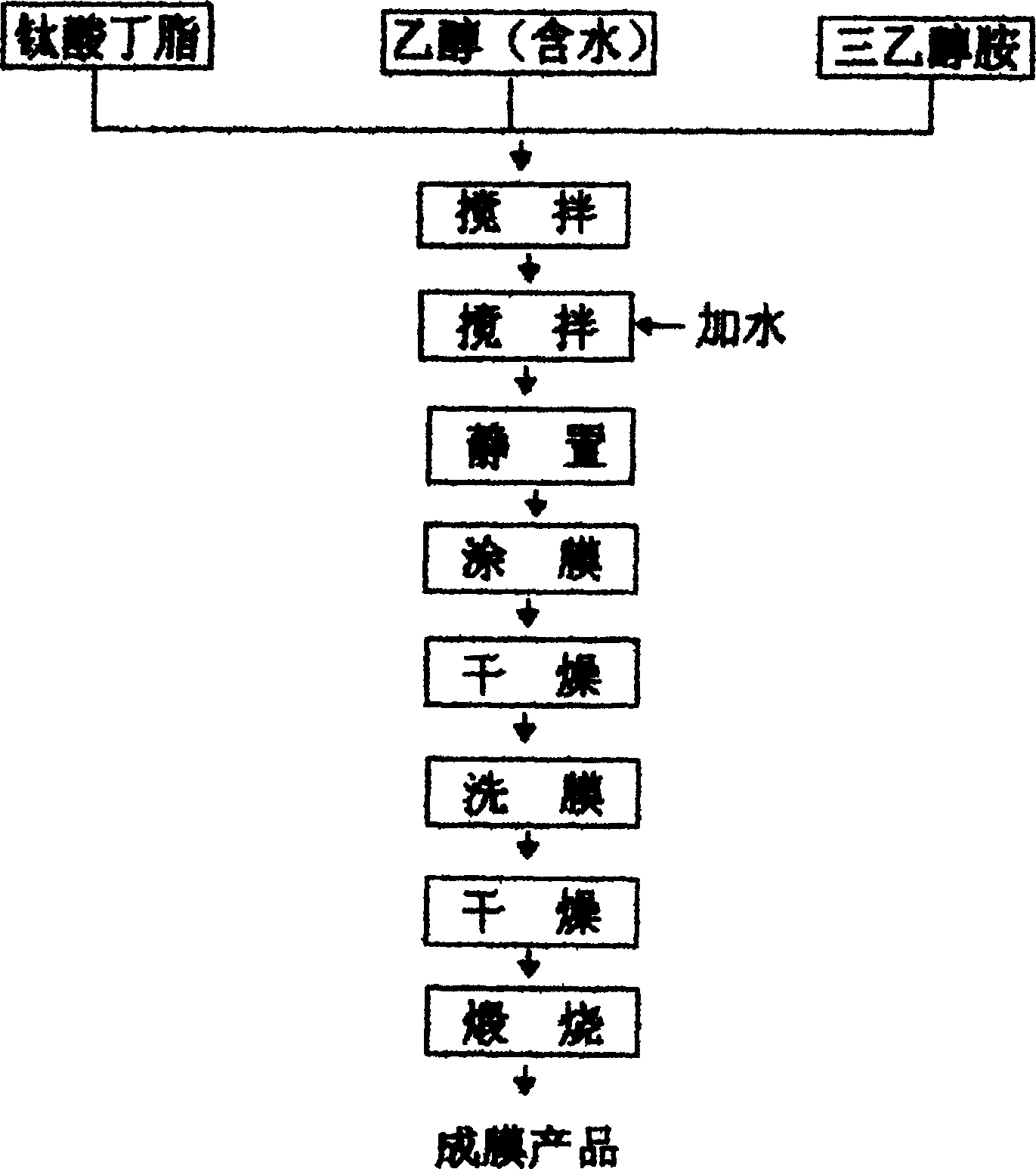

[0011] As shown in the figure, the method for making this self-cleaning anti-fog glass, the titanium sol it adopts is composed of butyl titanate, ethanol, triethanolamine and deionized water, and the formula is butyl titanate: ethanol: triethanolamine : Deionized water = 20:75:5:1-3 ratio preparation.

[0012] When specifically preparing titanium sol, the above three chemical raw materials should be put together and stirred for 1 to 2 hours, then add deionized water according to the preparation amount, and continue to stir for 0.5 to 1 hour to allow them to fully mix. Uniform state, and let the sol stand for 8 to 24 hours, so far the preparation of suitable titanium sol is completed.

[0013] The pretreatment of the coated glass is to use chemical and physical methods to pickle and soak the glass to be coated, then clean it with ethanol and deionized water and dry it;

[0014] The coating film drying refers to immersing the above-mentioned glass into the prepared titanium sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com