Golf club head with face composed of forged material

A golf club head, golf ball technology, applied in golf balls, golf clubs, rackets, etc., can solve problems such as failure to provide, high rebound coefficient, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

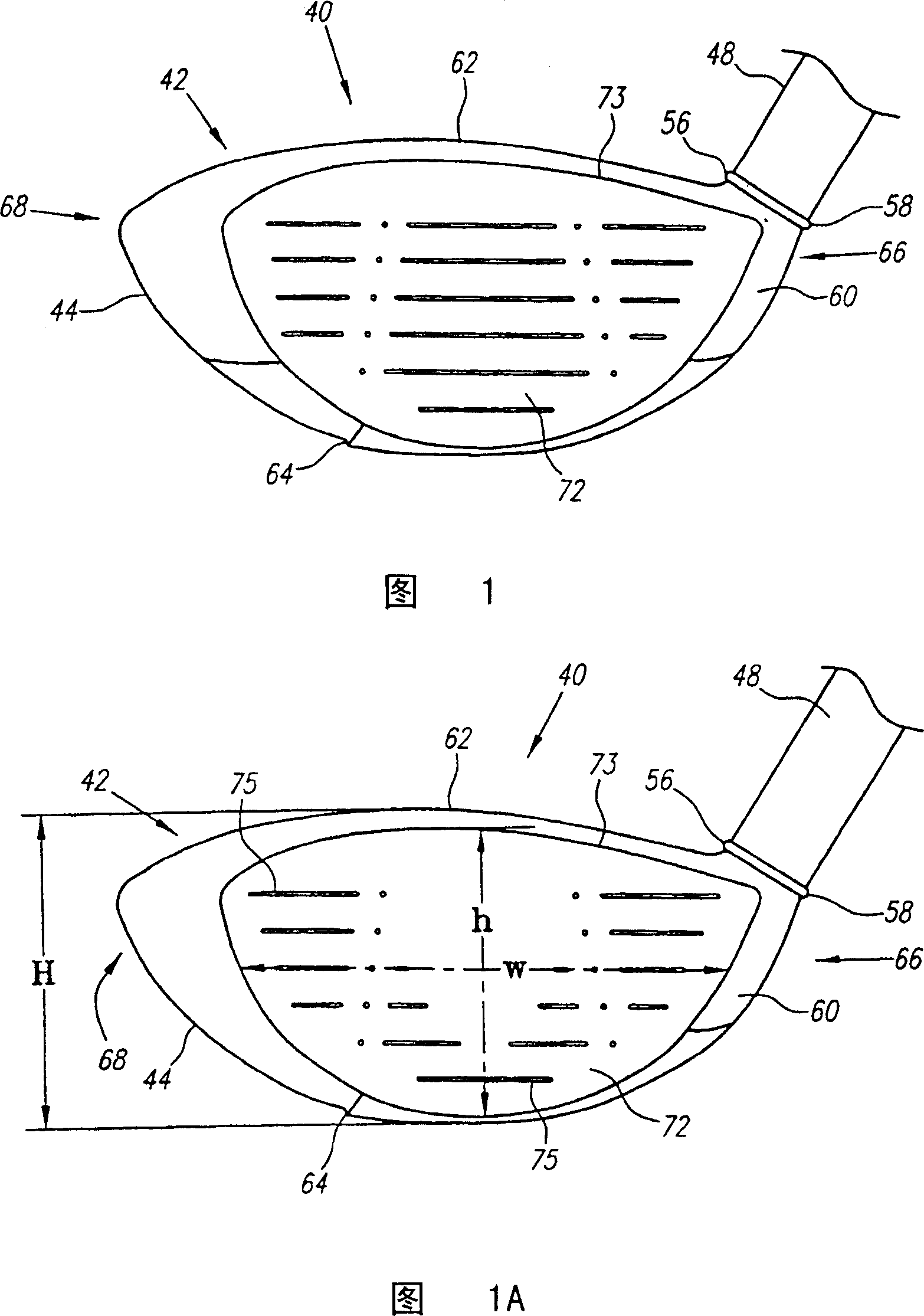

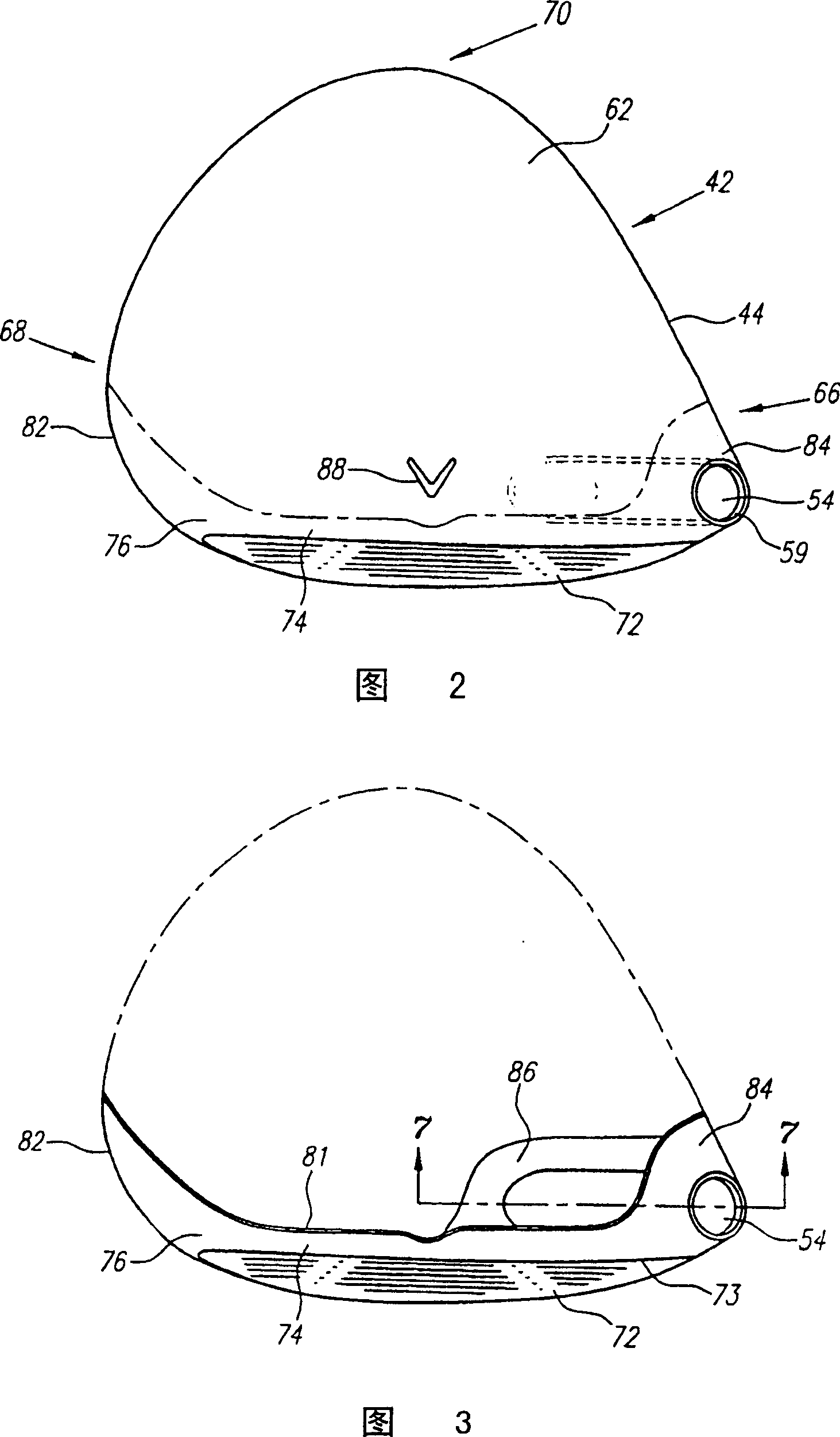

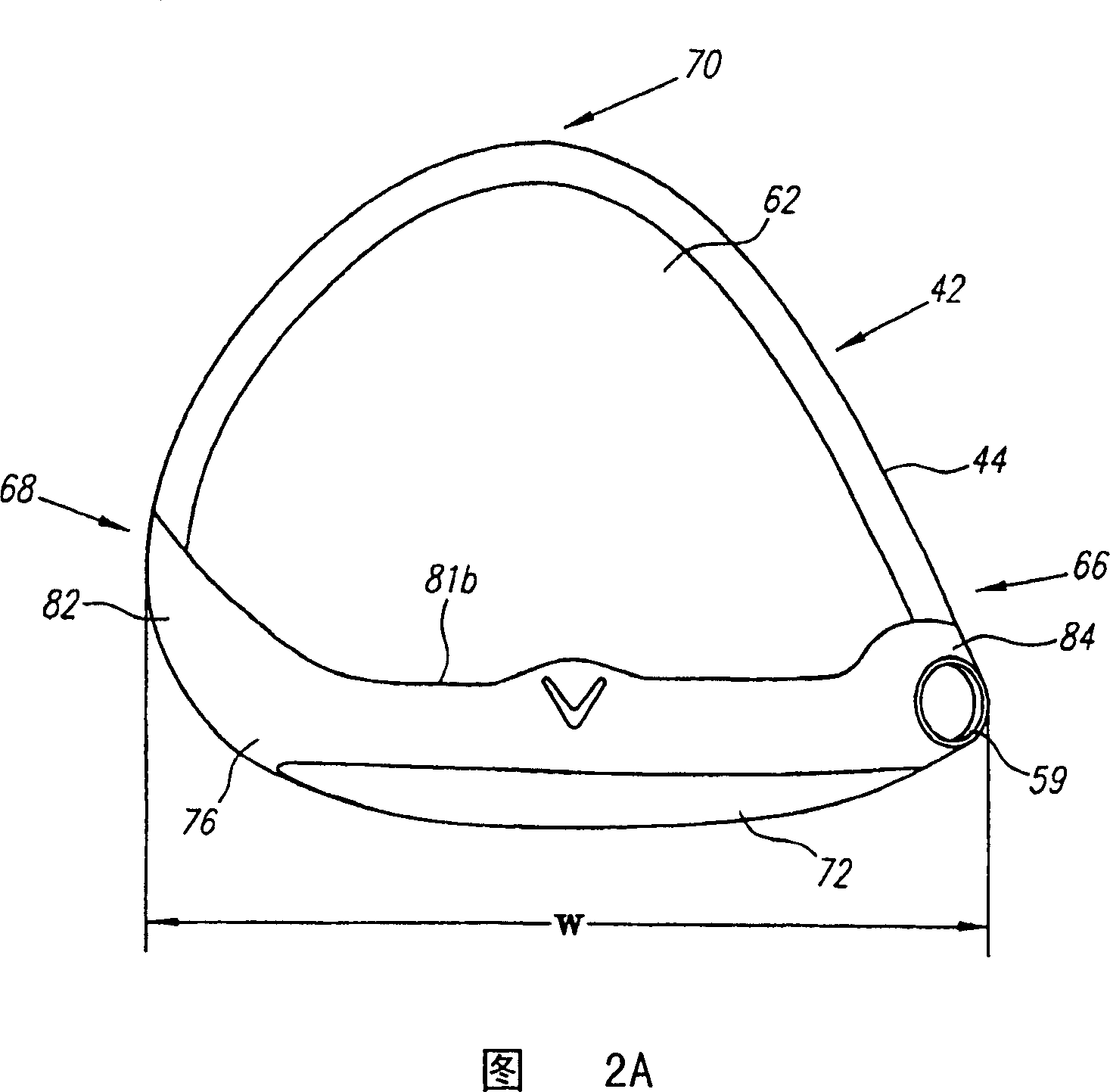

[0043] The present invention relates to a golf club head with a blade that is thin and has a high rebound coefficient, so that a golf ball hit by the golf club head of the present invention can fly farther. The coefficient of rebound ("COR") is calculated by the following formula:

[0044] e=(v2-v1) / (U1-U2)

[0045] Among them, U1 is the speed of the club head before the collision; U2 is the speed of the golf ball before the collision, which is 0; v1 is the speed of the club head immediately after the golf ball is separated from the surface of the club head; v2 is the surface of the golf ball and the club head The speed of the golf ball immediately after separation; e is the rebound coefficient between the golf ball and the club surface.

[0046] For systems without additional energy, the value of e is limited to 0 to 1.0. For materials such as soft soil or putty, the coefficient of resilience e is close to 0, while for fully elastic materials whose deformation does not cause ener...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com