Method of manufacturing an optical storage medium and optical storage medium

A storage medium and optical technology, applied in the field of manufacturing optical storage media and optical storage media, can solve the problems of inability to provide storage capacity, trouble, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

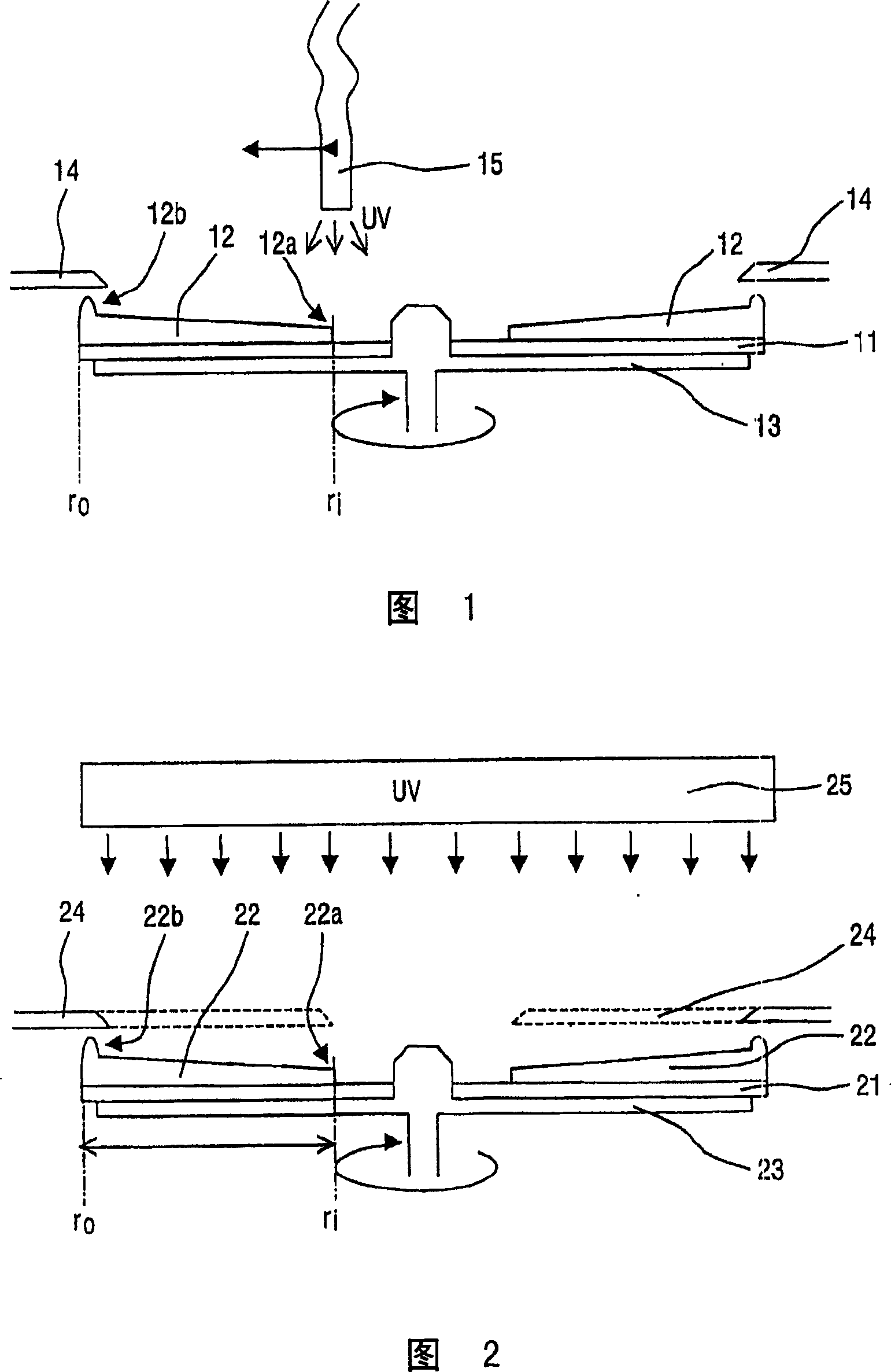

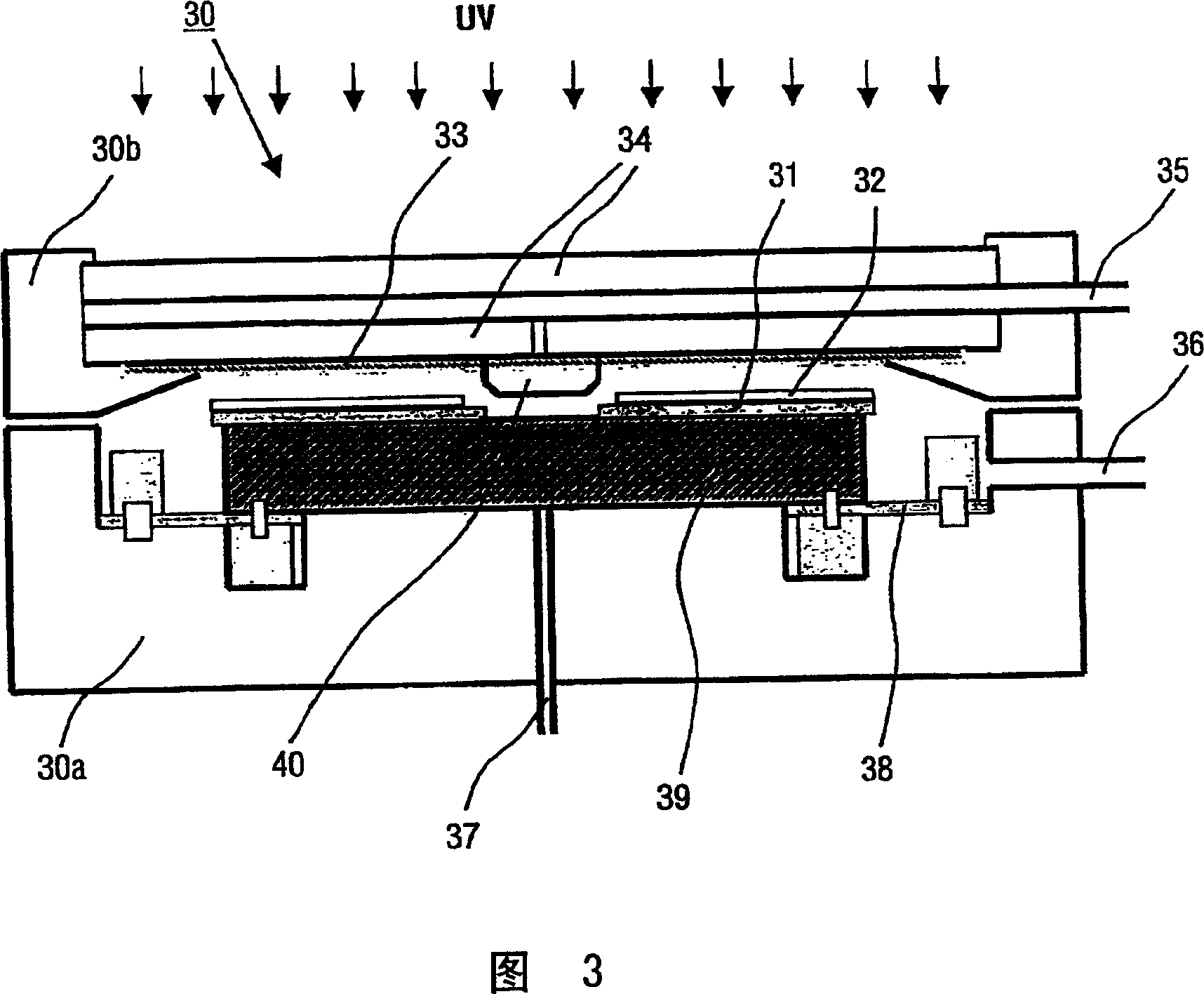

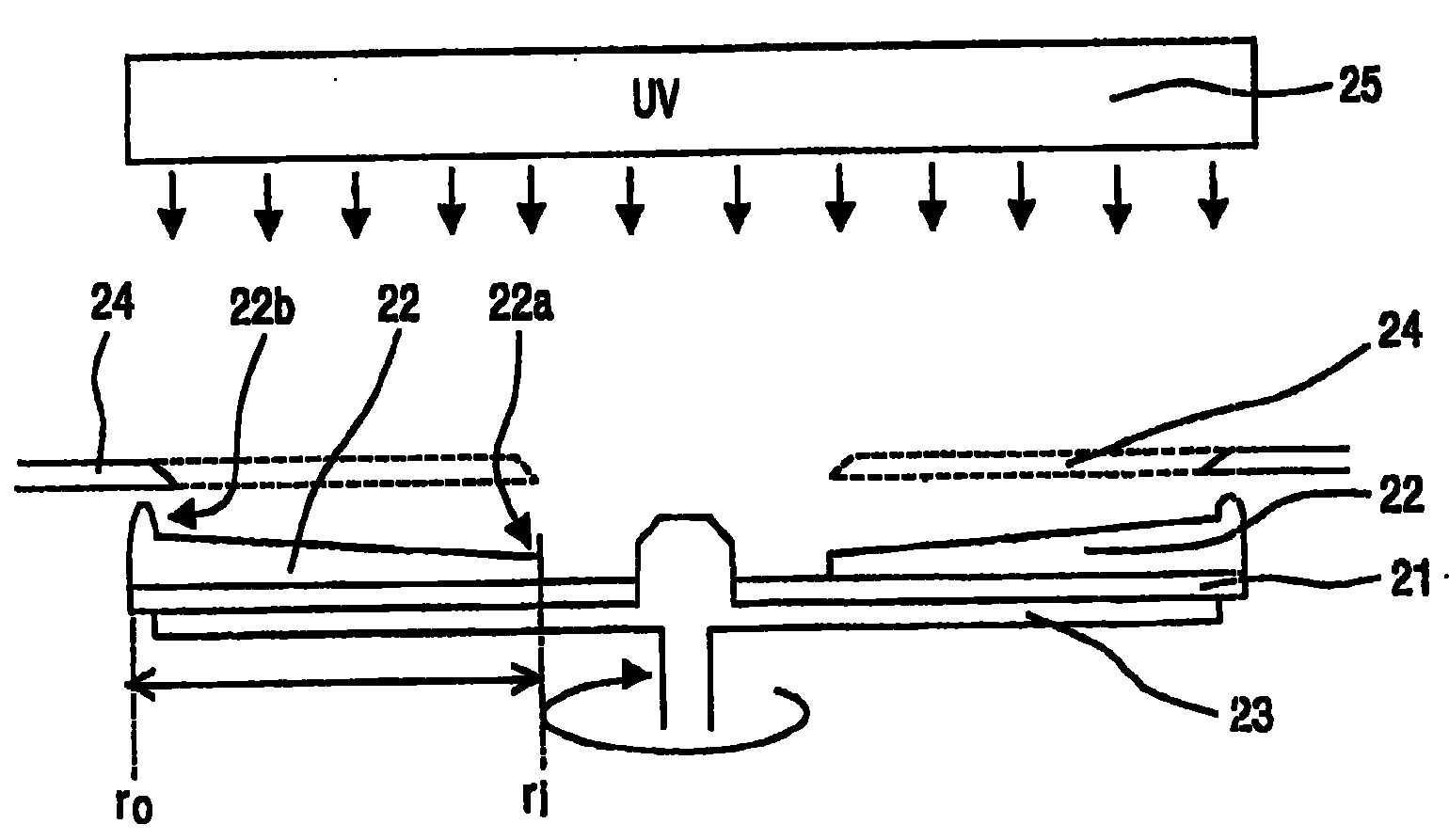

[0033] In FIG. 1 is shown a mechanism for implementing an embodiment of a method of manufacturing an optical storage medium. The medium comprises a substrate 11 having a plurality of layers, such as a recording stack (not shown). The transparent spacer layer 12 is provided by applying a liquid to the rotating substrate 11 and further rotating the substrate 11 so that the liquid has an inner diameter r i = 20mm and outer diameter r 0 =60mm between substantially evenly spread into layer 12. The liquid layer 12 is a UV curable varnish of type SD 694 manufactured by DIC with a viscosity of 350 mPas. During solidification, the rotation frequency of the substrate 11 was 11 Hz. The substrate 11 is supported by a chuck 13 . The liquid layer 12 is solidified by radiation exposure. The solidification of the liquid layer 12 is defined as t=t i time from r i started at. in r 0 Freezing of the liquid layer at takes place at defined as t = t 0 and t 0 = t i +δ and the moment of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com