Plasma displaying panel and mfg. method thereof

A plasma and display panel technology, which is applied in the direction of alternating current plasma display panel, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problems of reducing output and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Hereinafter, the present invention will be described in detail with reference to examples and drawings.

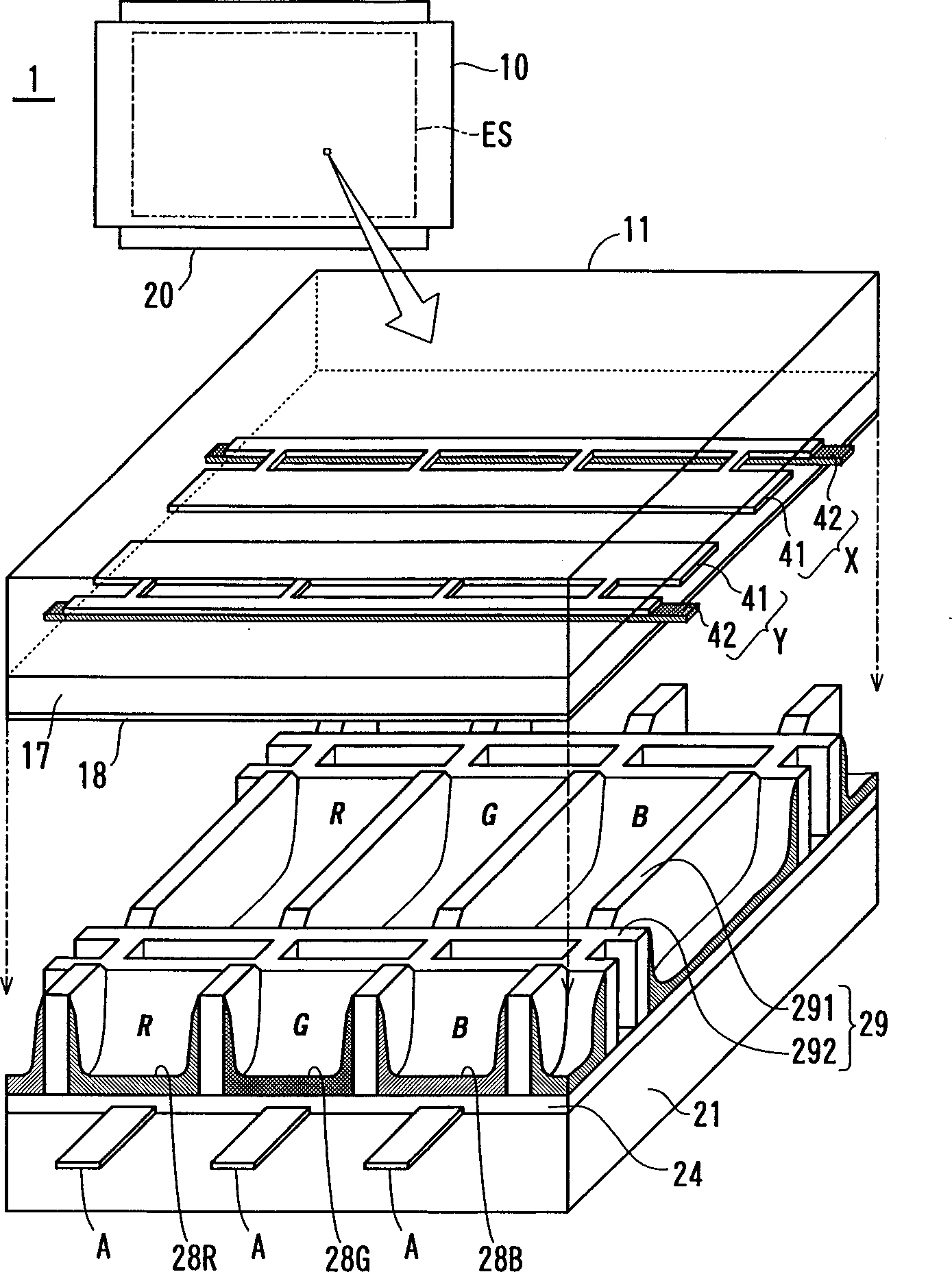

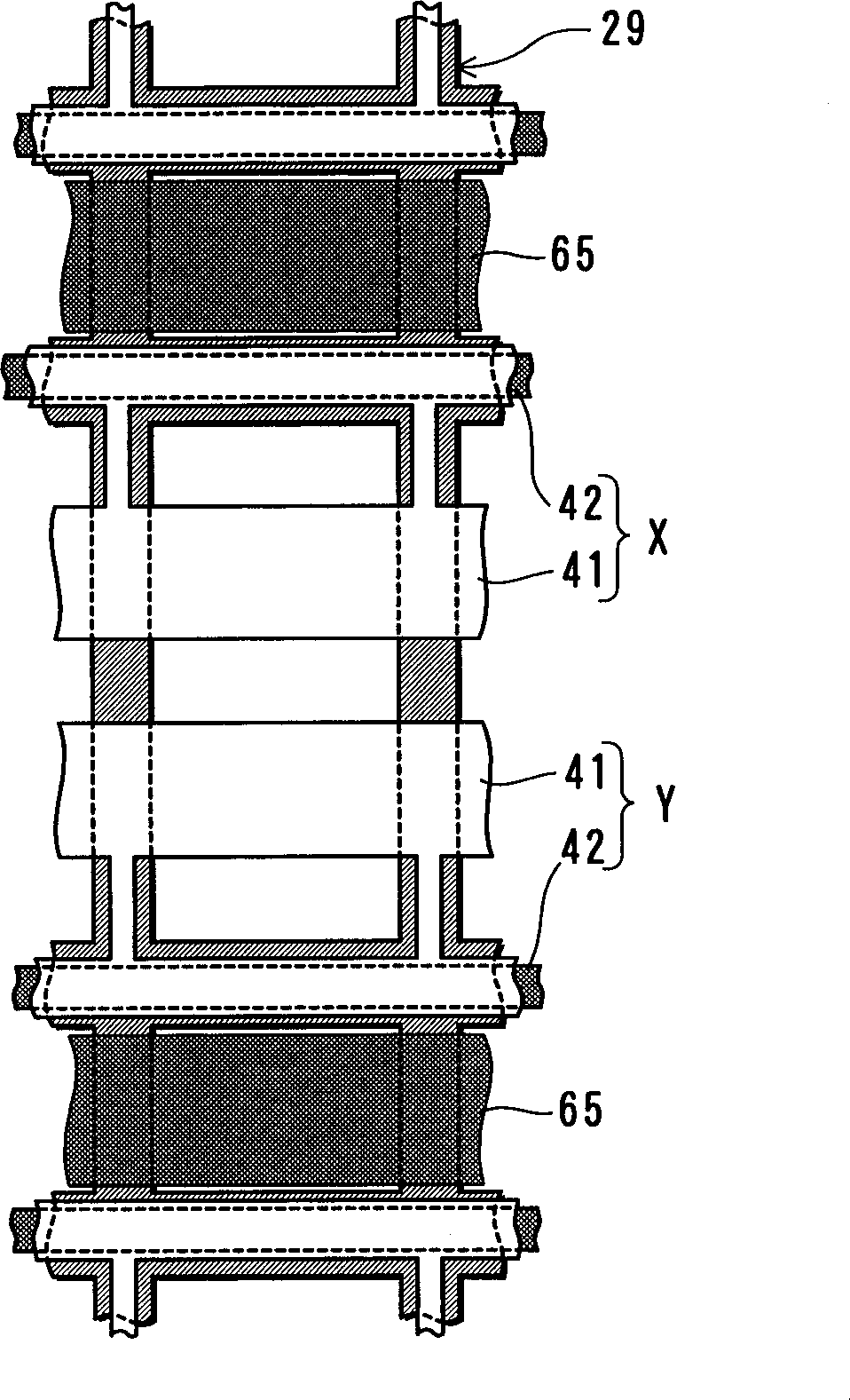

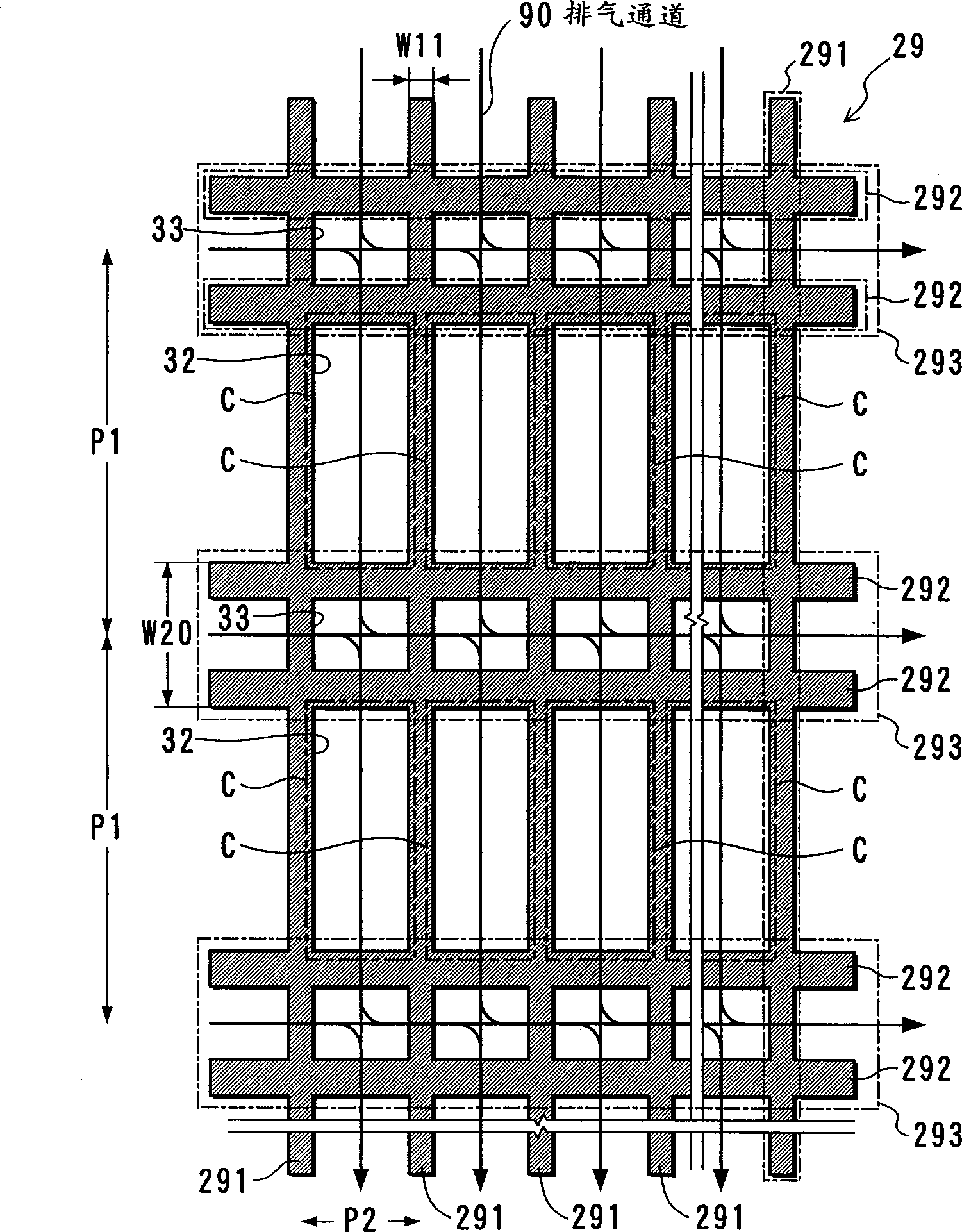

[0020] figure 1 is a schematic diagram of the cell structure of the PDP of the present invention. figure 2 is a plan view showing the arrangement relationship between electrodes and barriers. figure 1 Showing the internal structure, a pair of substrate structures spaced apart from each other are shown.

[0021] The PDP 1 includes a pair of substrate structures (a structure including a substrate on which cell components are arranged) 10, 20, and a display surface ES includes m*n cells. In each cell, the display electrodes X and Y form a pair of electrodes for generating display discharge, the display electrodes extend along the horizontal direction (horizontal direction) of the matrix display, and the address electrodes A extend along the longitudinal direction (vertical direction).

[0022] Display electrodes X, Y are arranged on the inner surface of the glass s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com