Wound product and its winding method

A product and winding technology, which is applied in the direction of winding strips, transportation and packaging, and thin material processing, etc., can solve problems such as winding displacement, core damage, and reduction of commercial value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The specific device of the present invention will be introduced below according to the accompanying drawings.

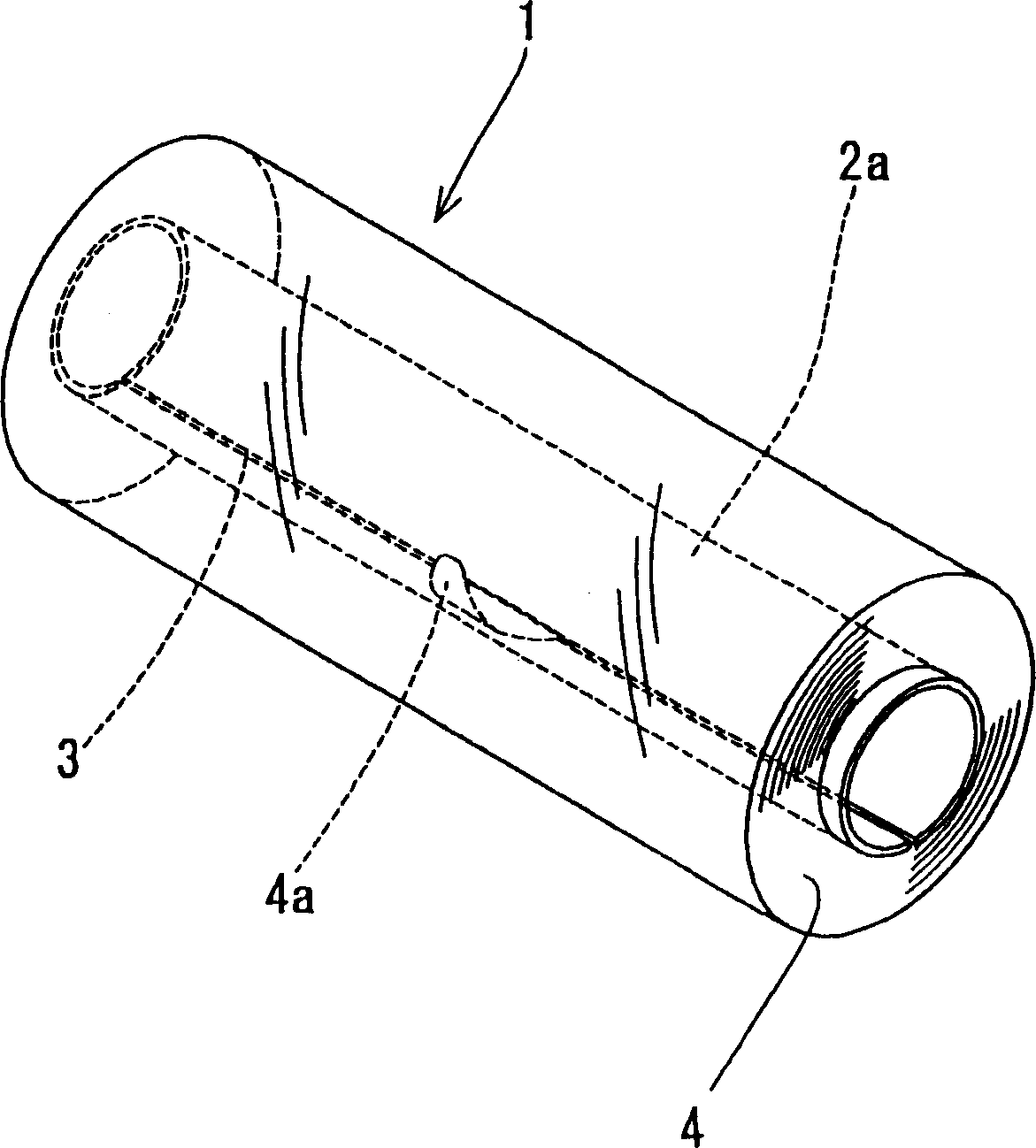

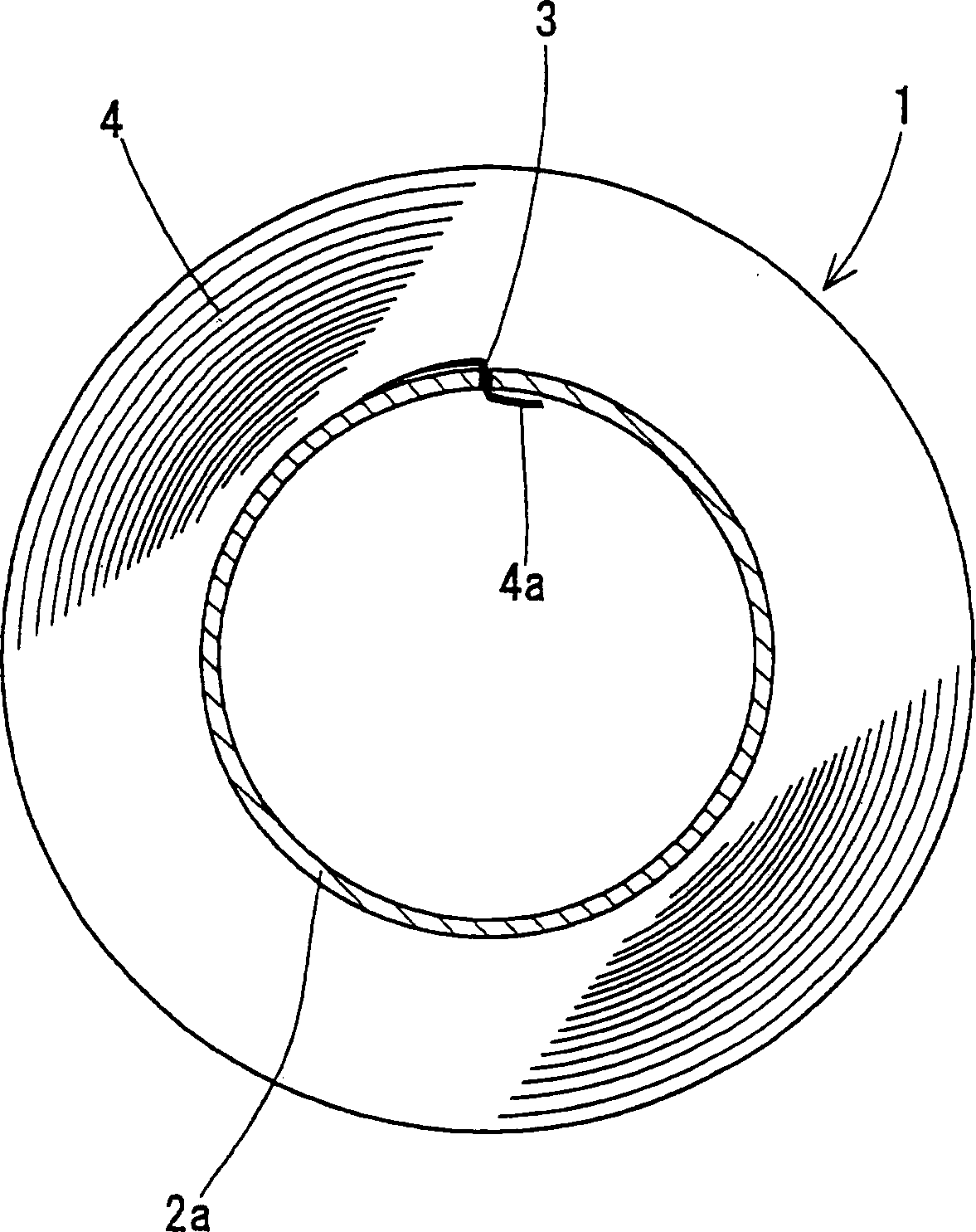

[0056] figure 1 and figure 2 To embody the rolled product 1 of the present invention. as image 3 and Figure 4As shown, the rolled product 1 is a long strip of plastic sheet or film 4 wound on a core by bending a flat cardboard 2 of cardboard, rolling, and forming a gap 3 between the side edges, whereby its end 4a is inserted through the gap 3 inside the bent cardboard 2 .

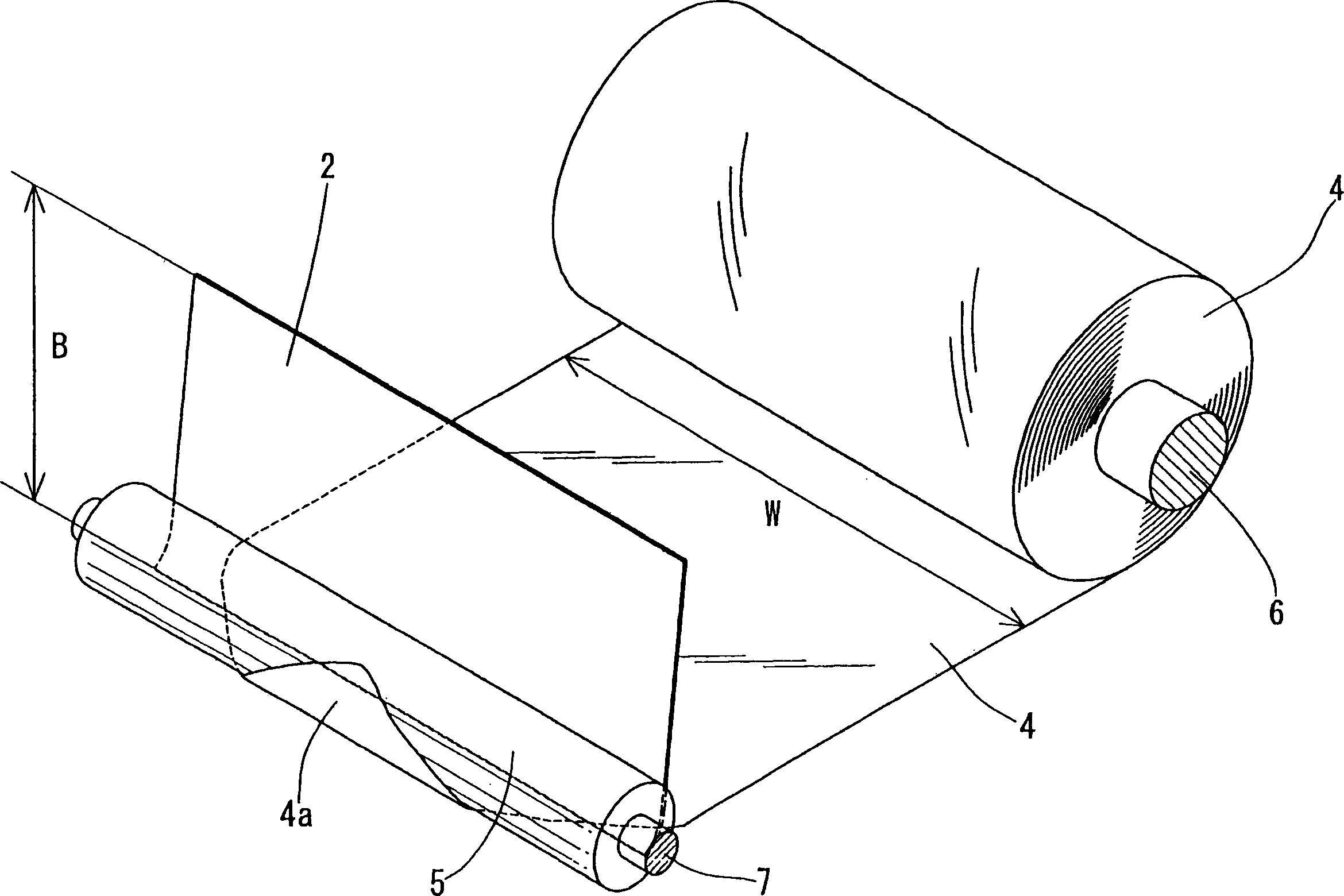

[0057] as image 3 and Figure 4 As shown, at the beginning of winding into the rolled product 1, the tapered end 4a of the rolled sheet or film 4 placed on the winder drum 6 is placed on the outer peripheral surface of the winder drum 5. Thereafter, a flat sheet of cardboard having a length B, with a gap 3 between the side edges when wound around the roll 5, is provided, inside the sheet or film 4, with slightly bent ends so as to be in contact with the sides of the roll 5. exte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com