Driver for tyre homogeneity testing instrument

A driving device, uniformity technology, applied in the direction of automobile tire testing, measuring device, work drive, etc., can solve the problem of increasing time and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

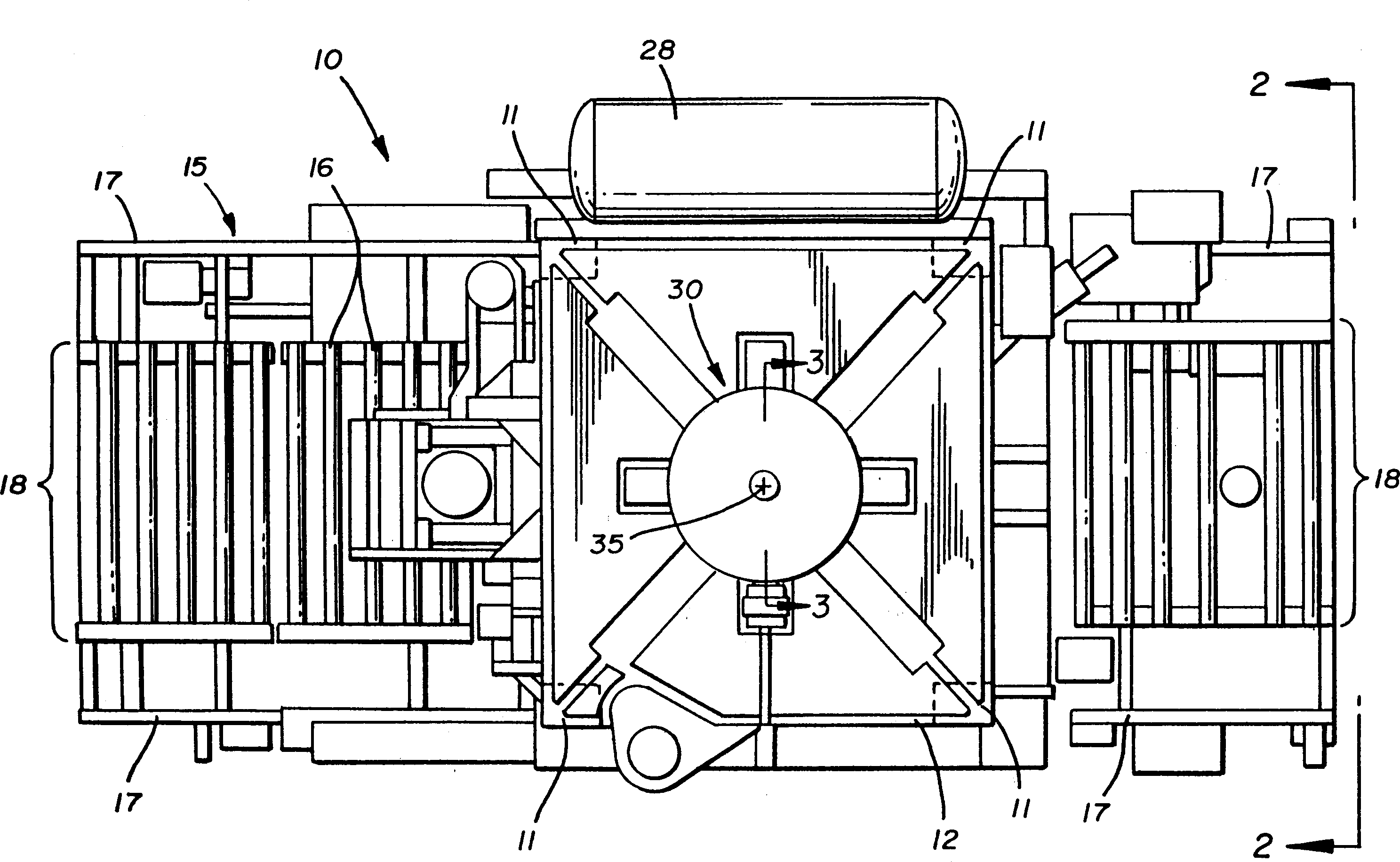

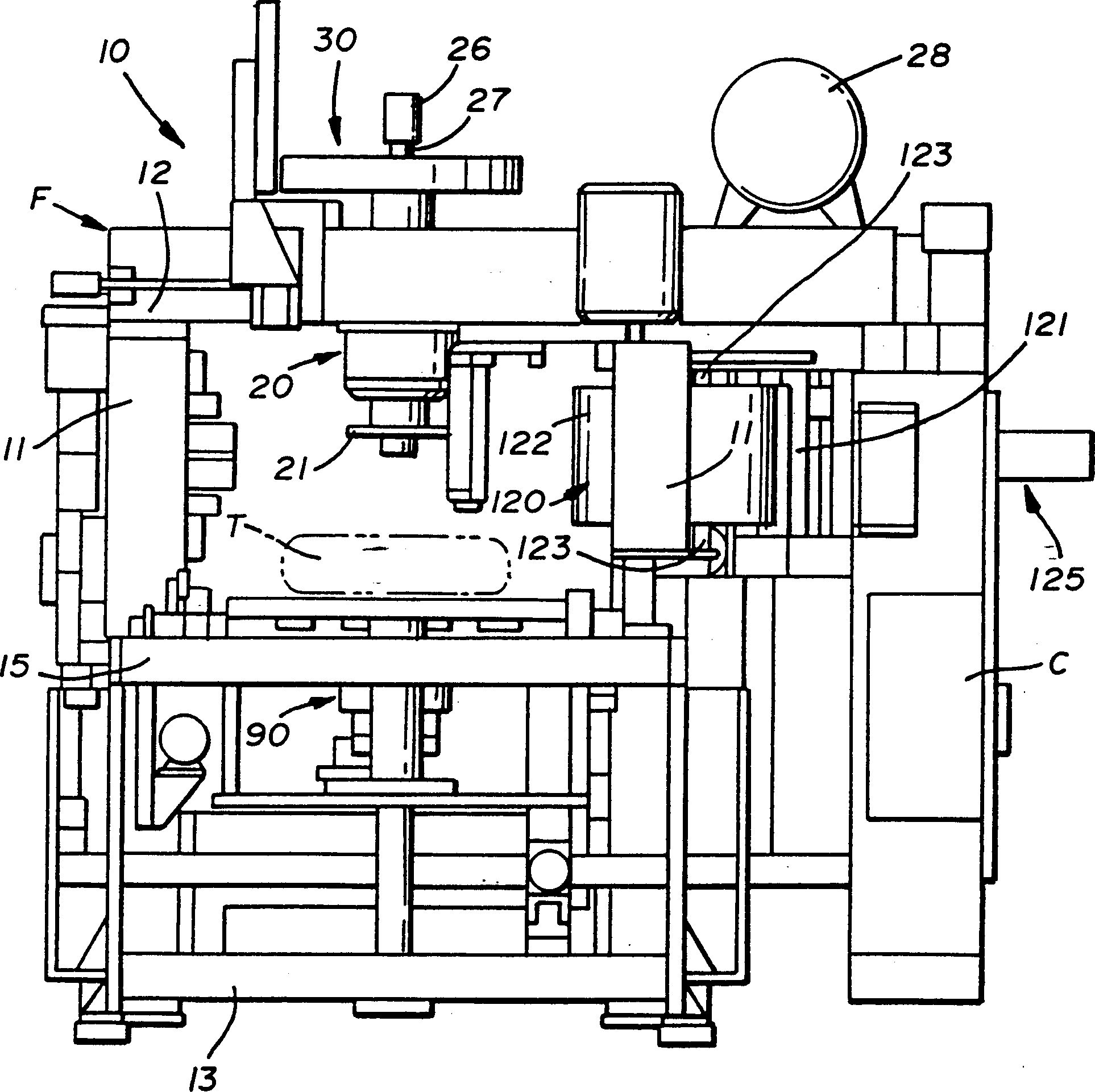

[0016] from figure 1 As can be seen, the tire uniformity testing machine 10 generally includes vertical side frame members 11 , generally horizontal top frame members 12 , and generally horizontal bottom frame members 13 , which form the frame F of the testing machine 10 . The frame members 11, 12, 13 form a generally box-like structure in which the tire T is placed and tested.

[0017] figure 1 As clearly shown, the tires T may be fed into and withdrawn from the frame F of the testing machine 10 by means of a conveyor 15 which may comprise a plurality of rollers 16 rotatably supported on parallel side beams In the middle of 17, a roller table is formed. The side beams 17, 17 of the conveyor 15 and the side frame members 11, 11 of the testing machine 10 are generally spaced apart to accommodate tires of various diameters. Once the tire T enters the frame F of the testing machine 10, the tire T is Clipped and ready to test.

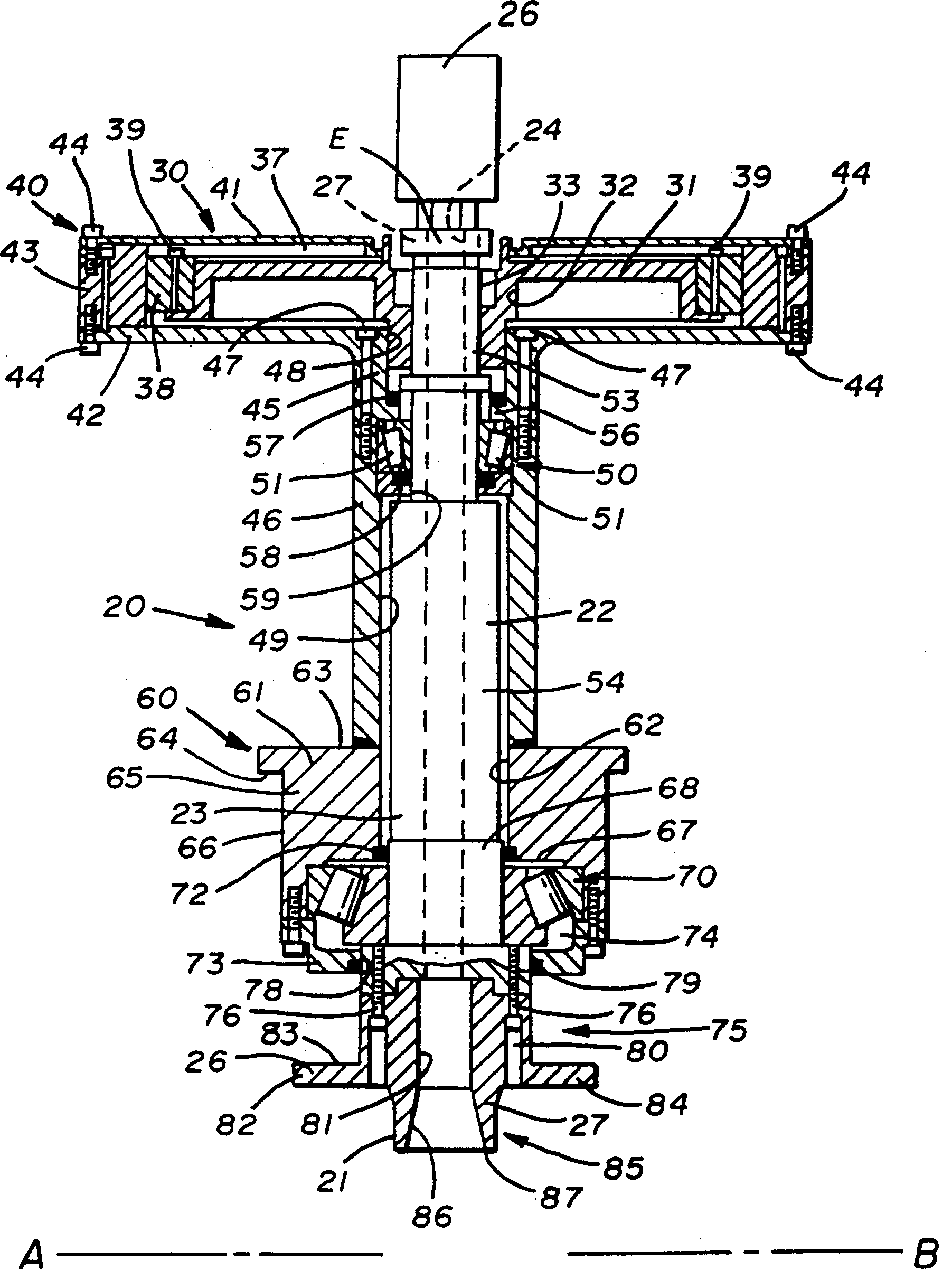

[0018] To briefly illustrate this again, the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com