Patents

Literature

37results about "Work driver" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

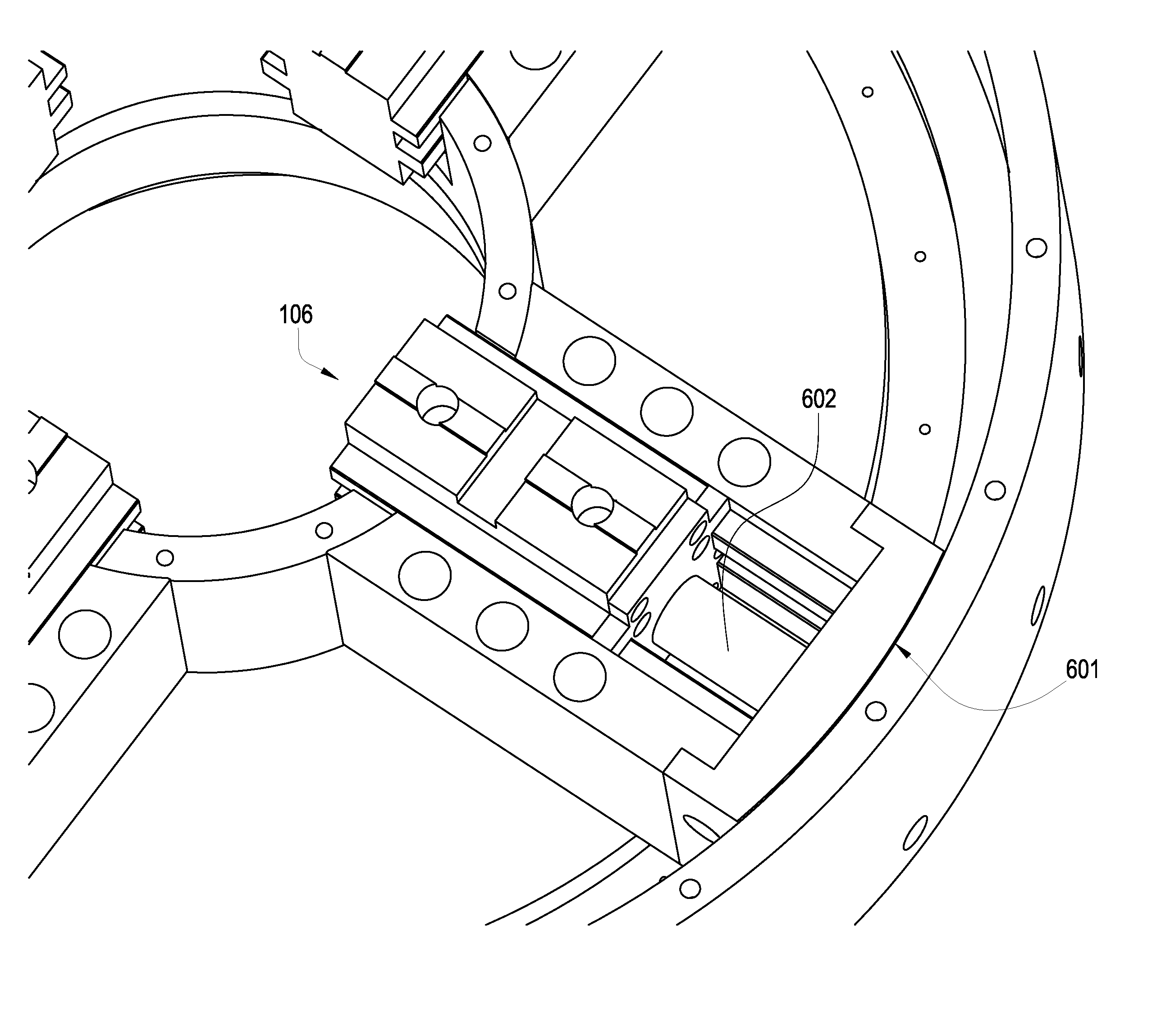

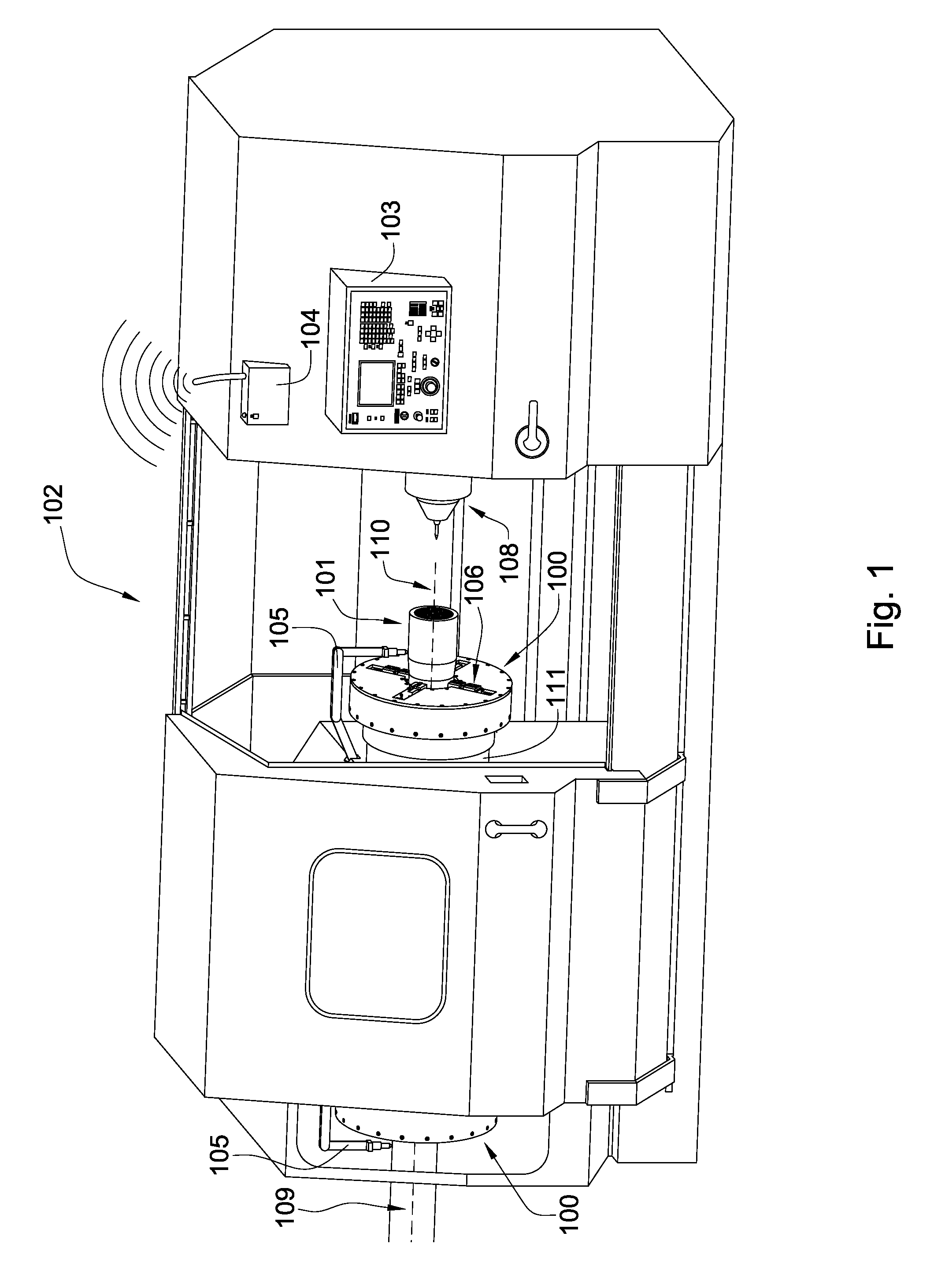

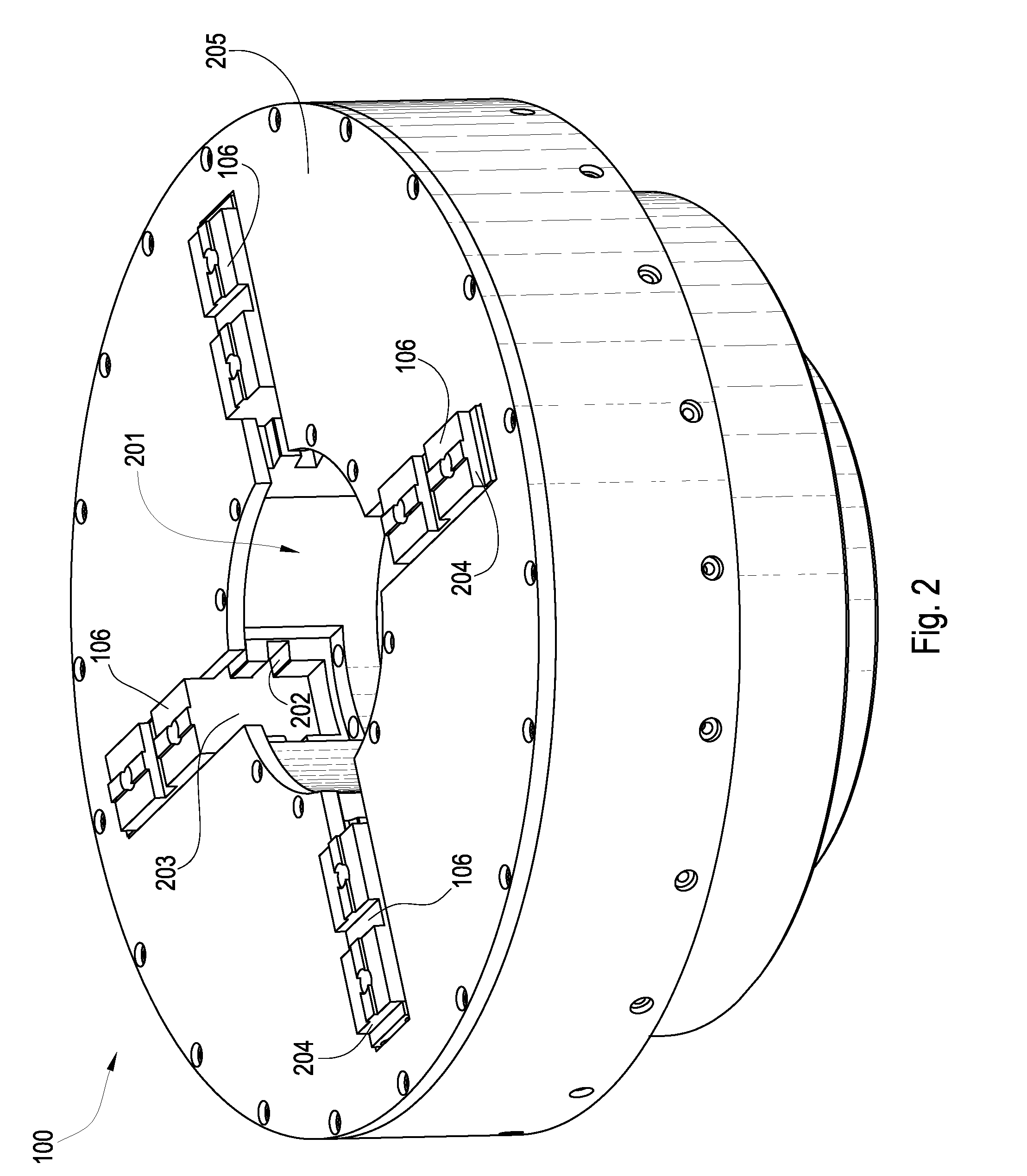

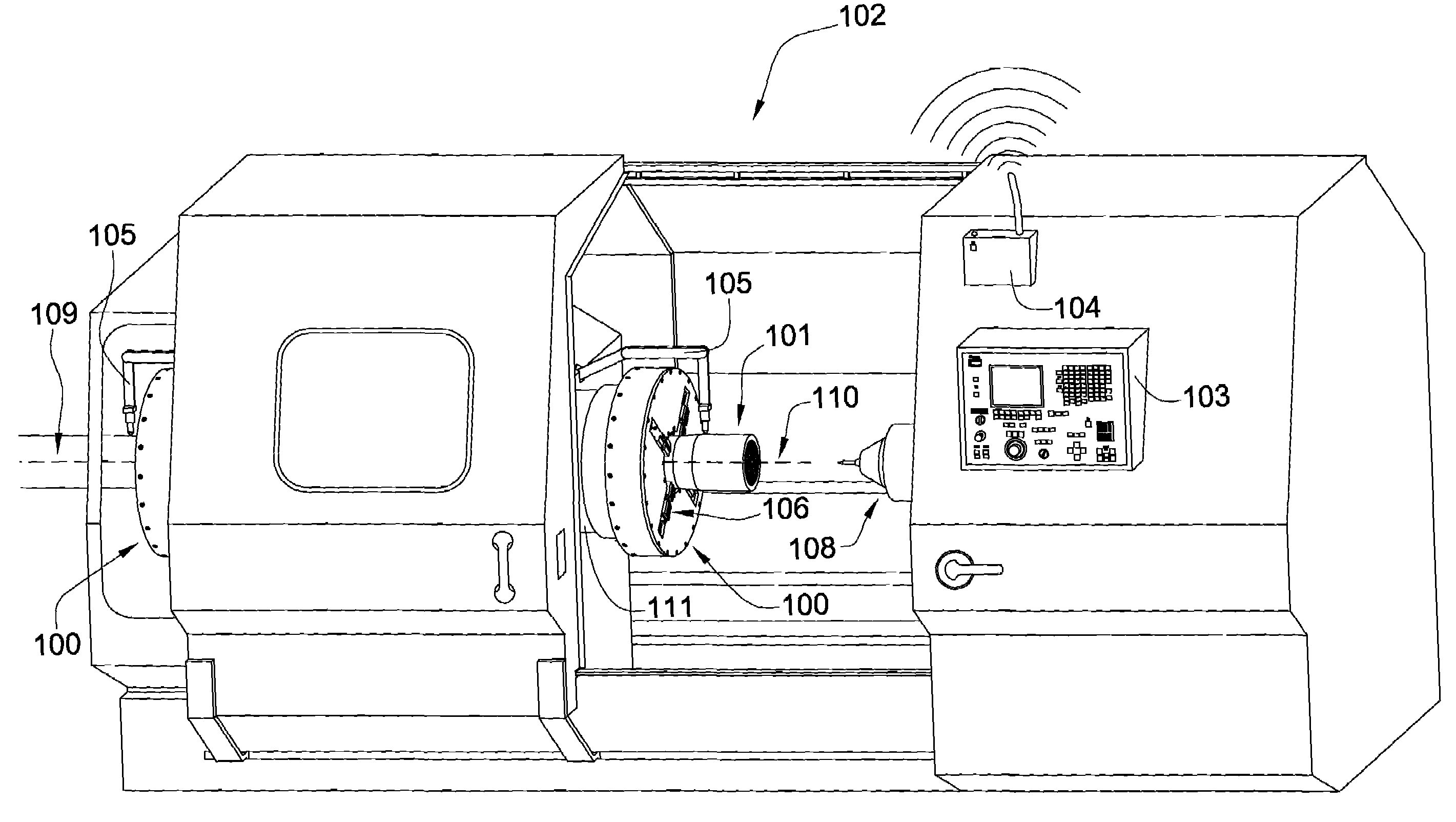

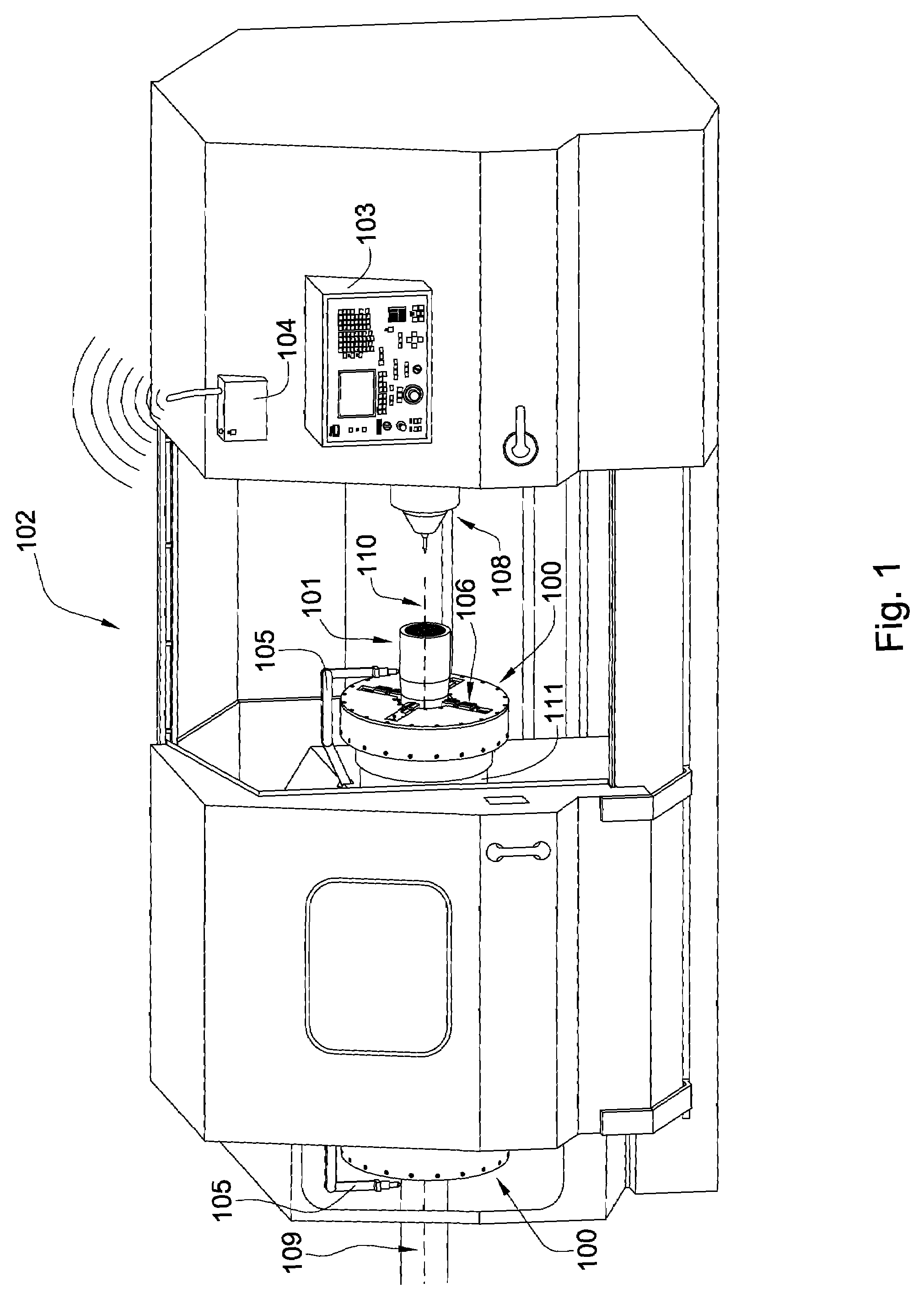

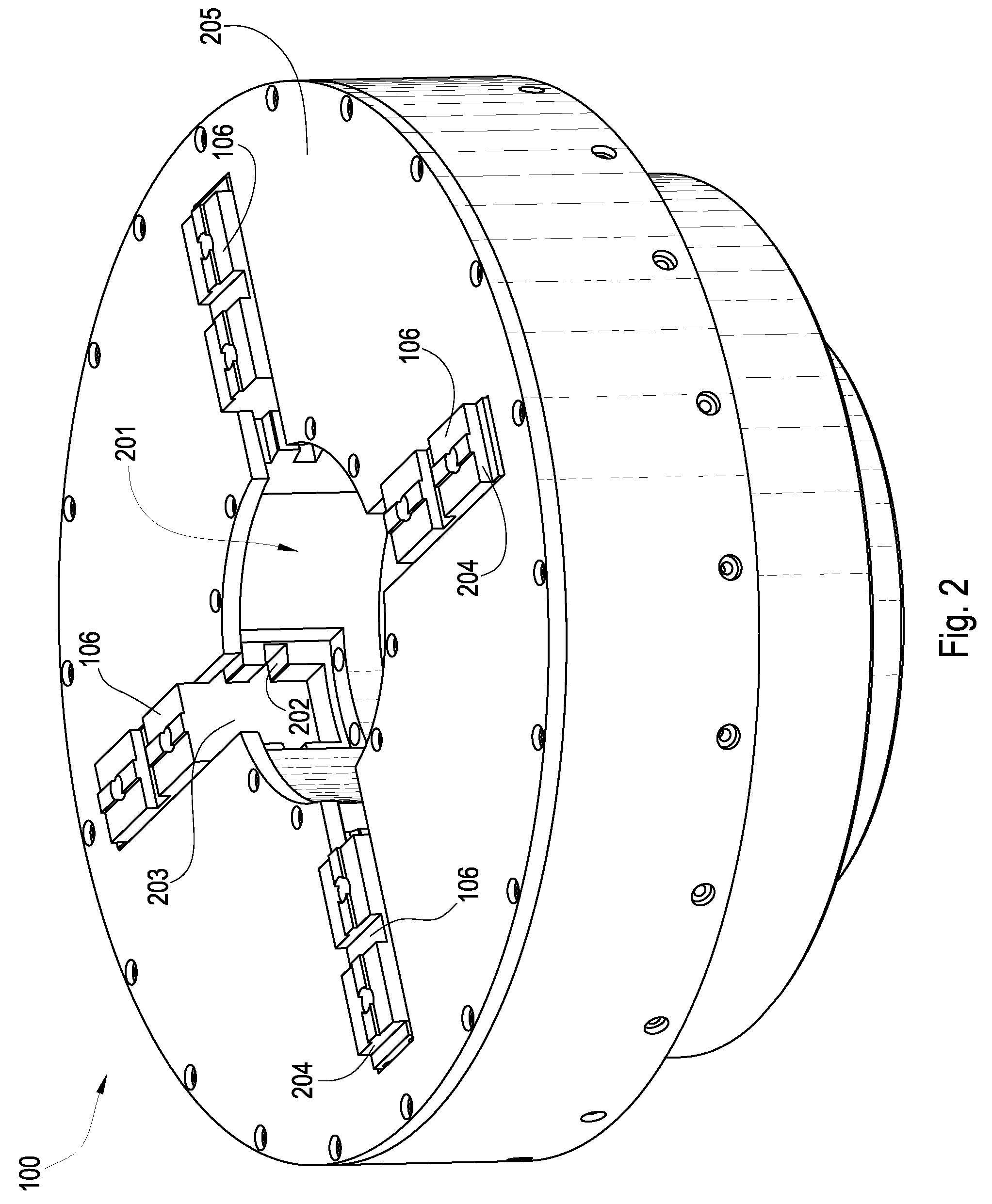

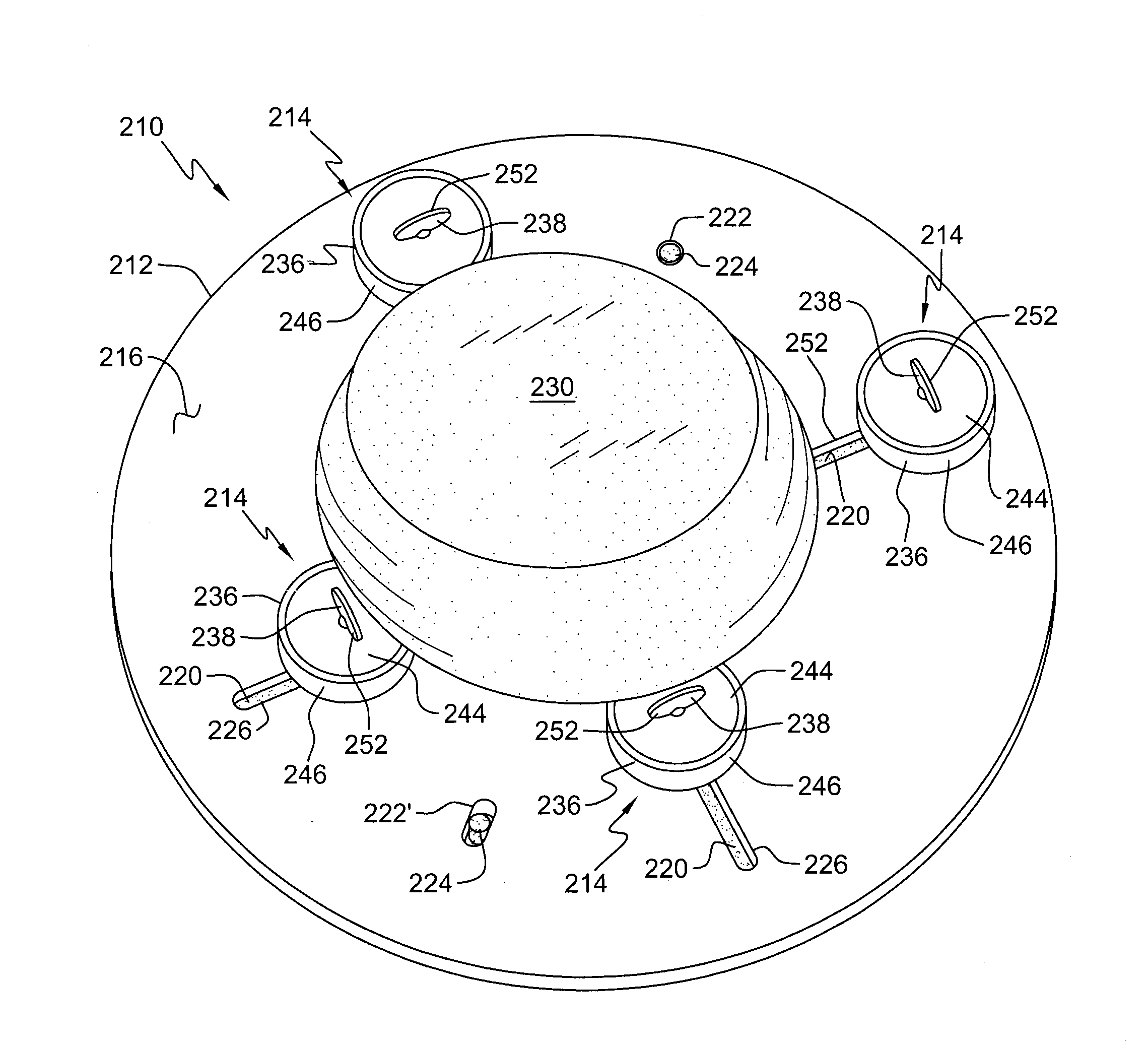

Hydraulic Chuck with Independently Moveable Jaws

A method of dialing a workpiece having an axis into a chuck includes providing a chuck assembly having a plurality of independent hydraulically controlled jaws distributed about a central axis, each jaw having first and second hydraulic chambers. The method further includes the steps of inserting a portion of the workpiece into the chuck assembly, pumping hydraulic fluid uniformly into each of the first chambers until the jaws are substantially touching the perimeter of the workpiece, and adjusting one or more of the jaws to align the axis of the workpiece with the central axis of the chuck assembly by pumping hydraulic fluid into at least one of the chambers of at least one of the jaws. The method also includes the step of pumping hydraulic fluid uniformly into each of the first chambers until the jaws are clamped around the perimeter of the workpiece at a predetermined pressure.

Owner:NOVATEK IP

Hydraulic chuck with independently moveable jaws

A method of dialing a workpiece having an axis into a chuck includes providing a chuck assembly having a plurality of independent hydraulically controlled jaws distributed about a central axis, each jaw having first and second hydraulic chambers. The method further includes the steps of inserting a portion of the workpiece into the chuck assembly, pumping hydraulic fluid uniformly into each of the first chambers until the jaws are substantially touching the perimeter of the workpiece, and adjusting one or more of the jaws to align the axis of the workpiece with the central axis of the chuck assembly by pumping hydraulic fluid into at least one of the chambers of at least one of the jaws. The method also includes the step of pumping hydraulic fluid uniformly into each of the first chambers until the jaws are clamped around the perimeter of the workpiece at a predetermined pressure.

Owner:NOVATEK IP

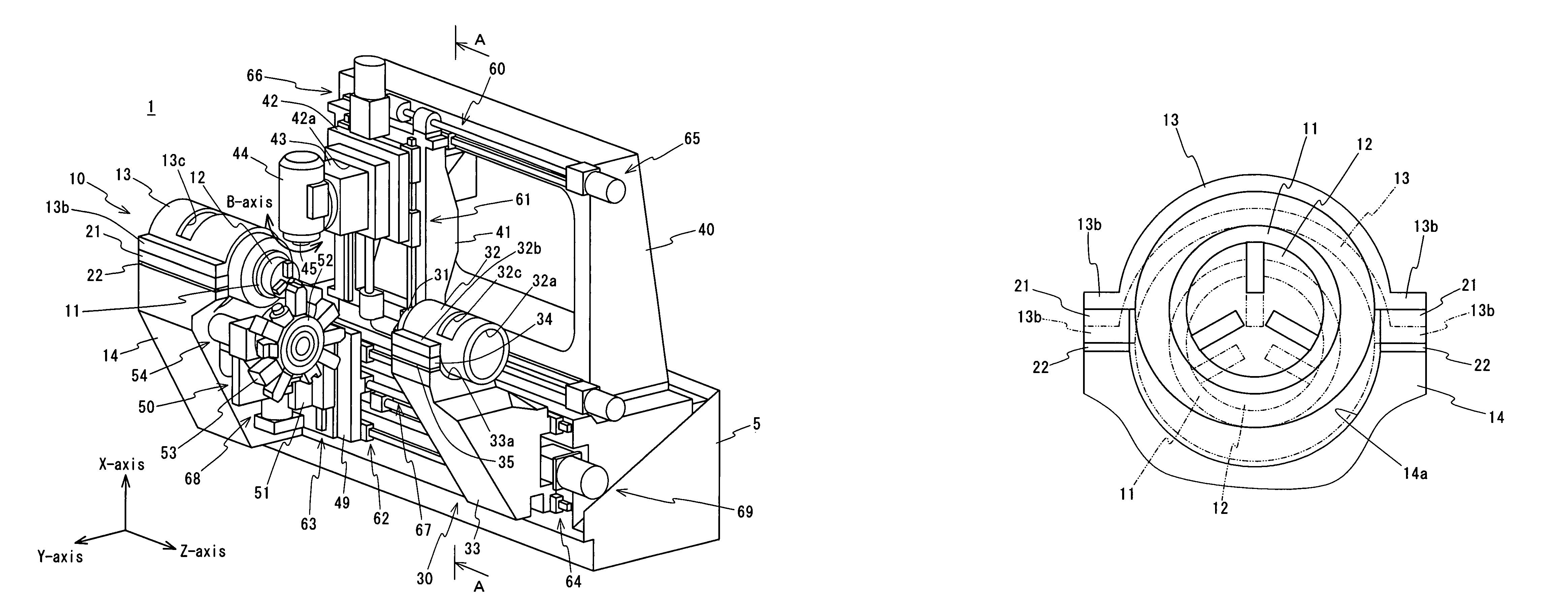

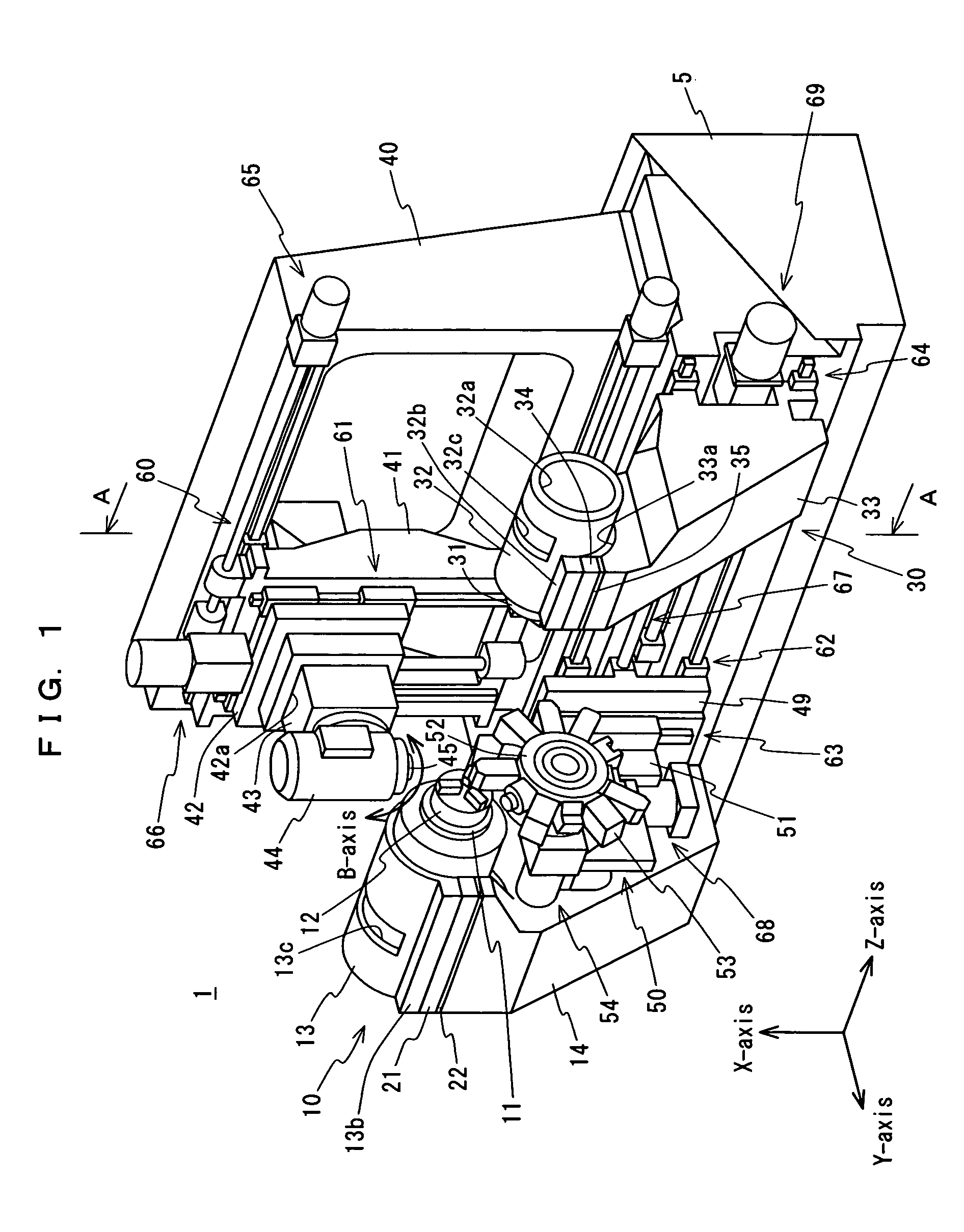

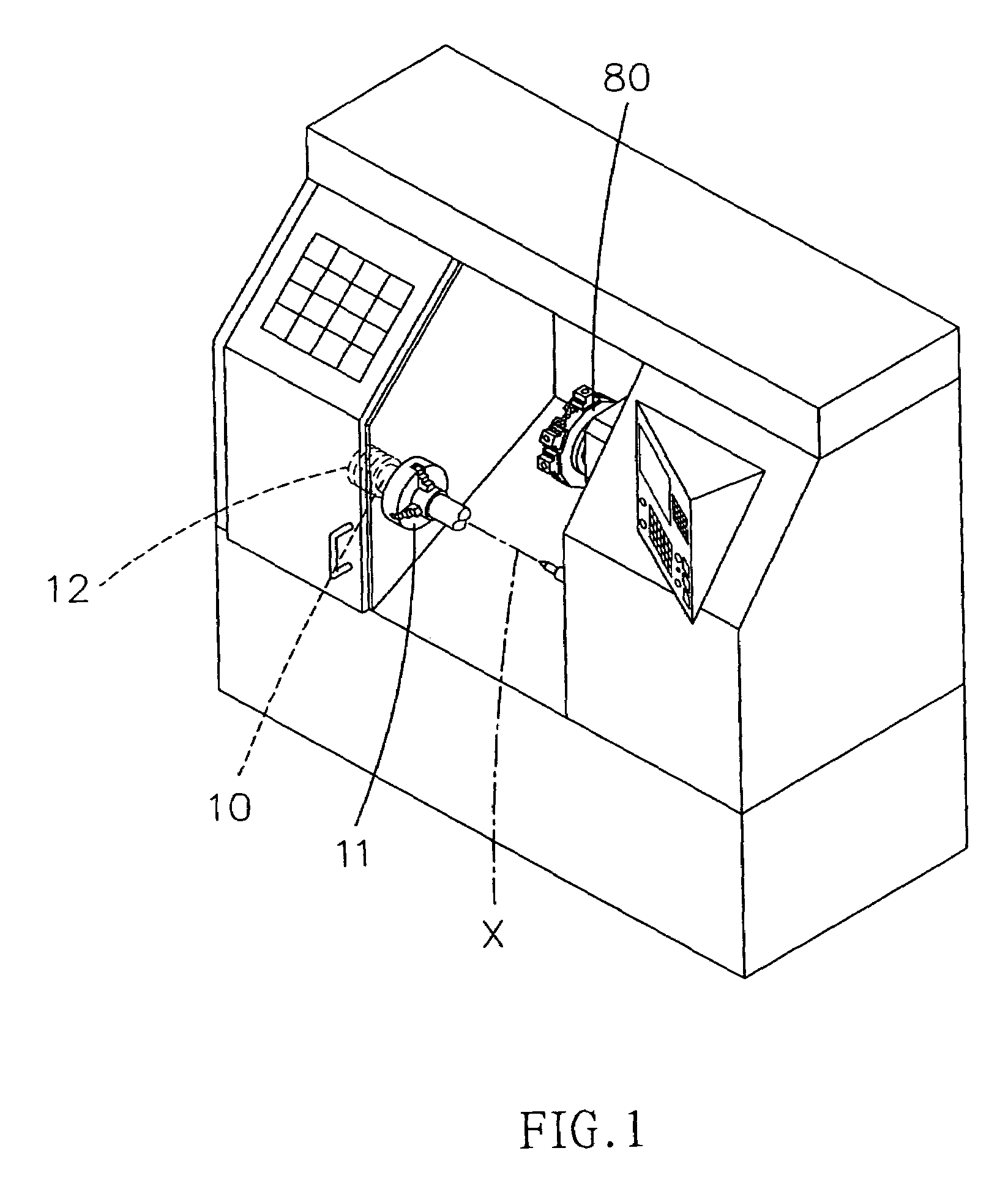

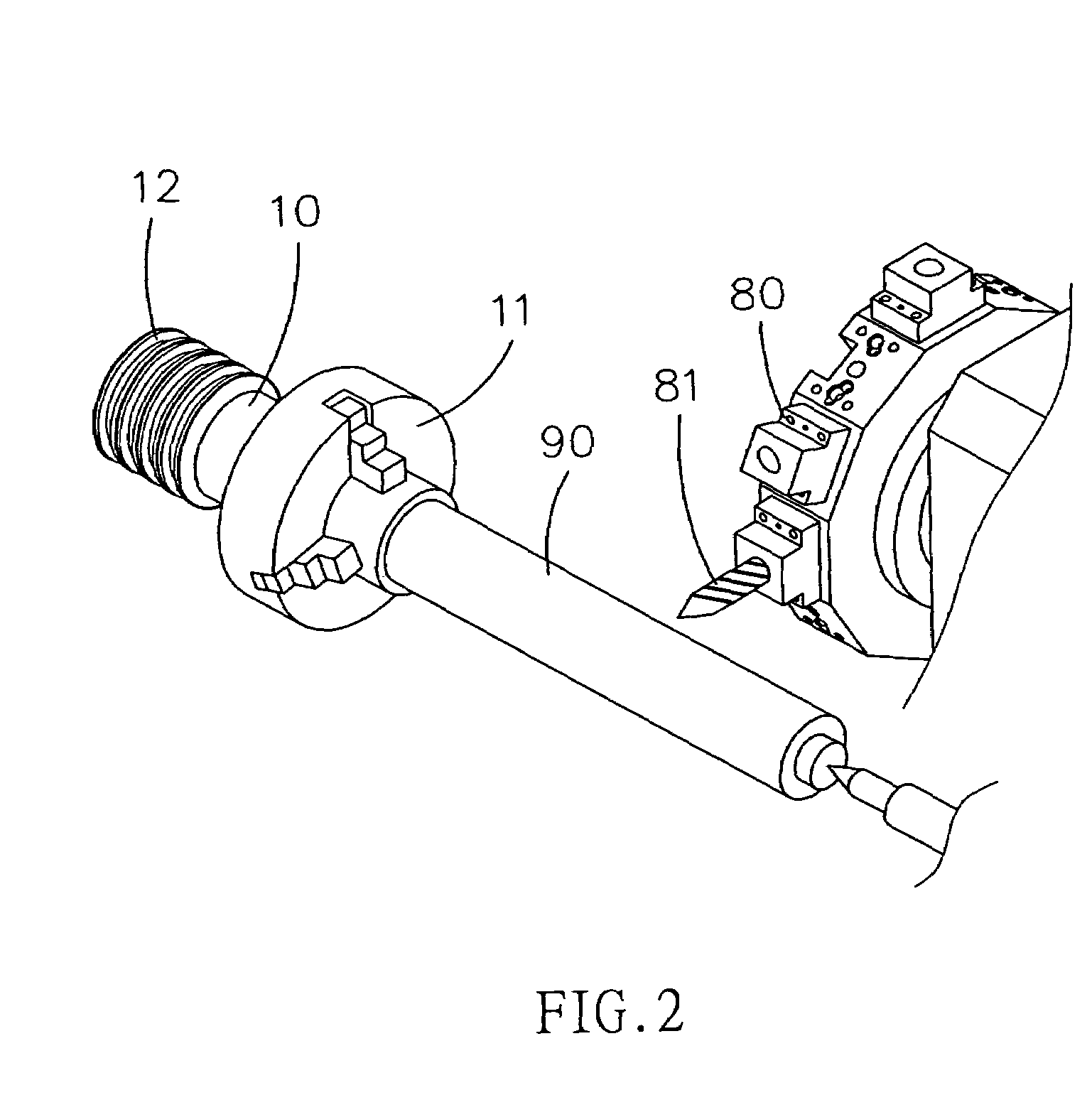

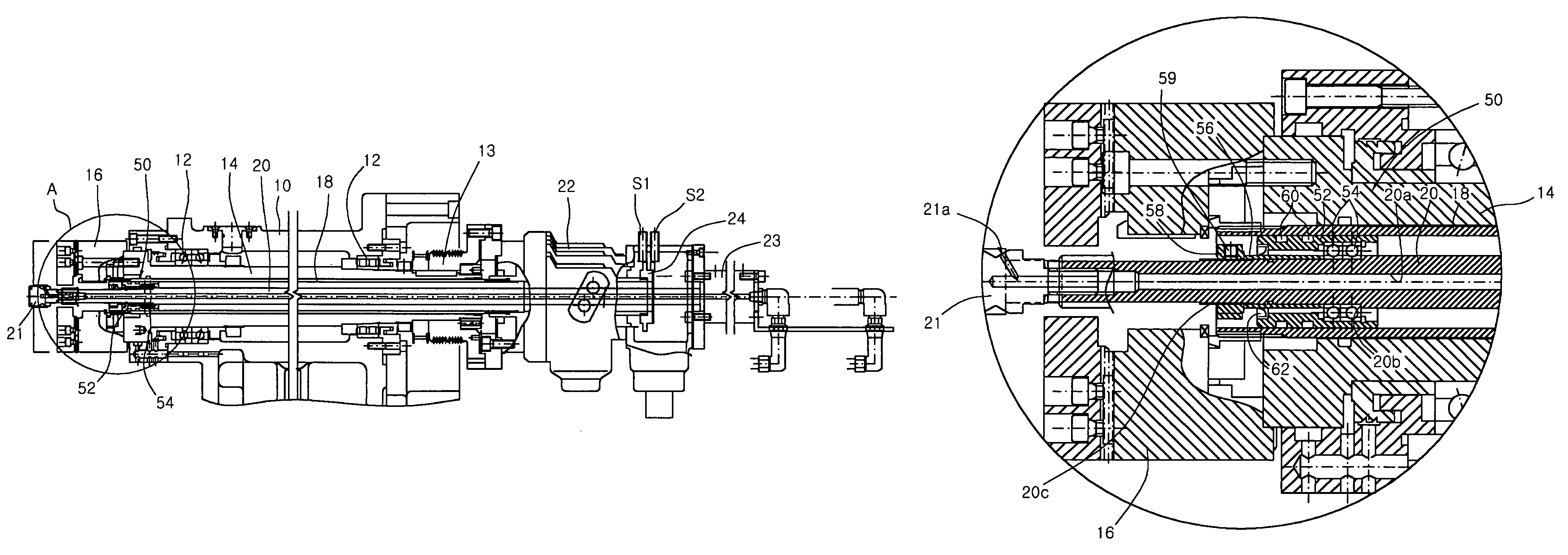

Lathe

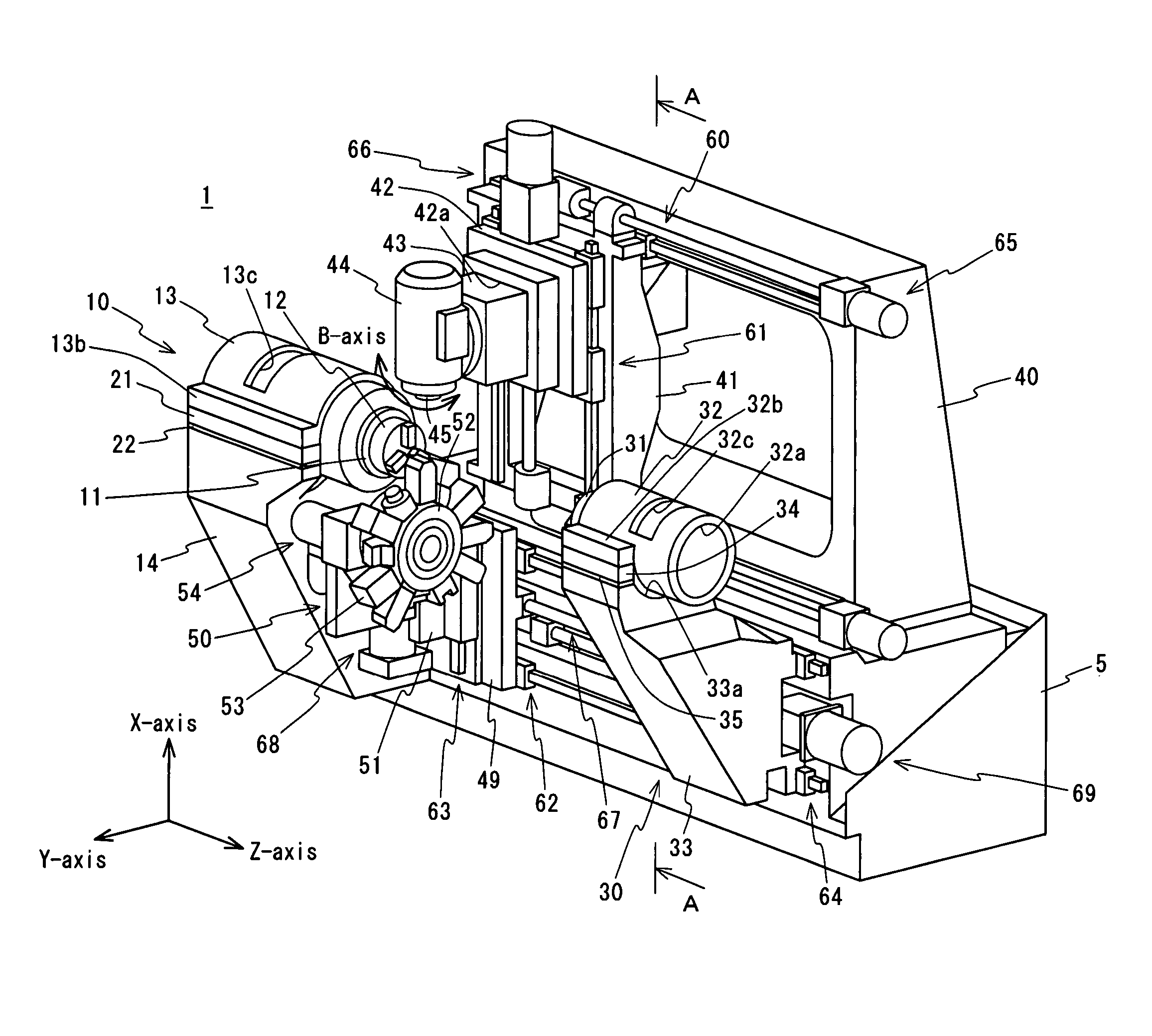

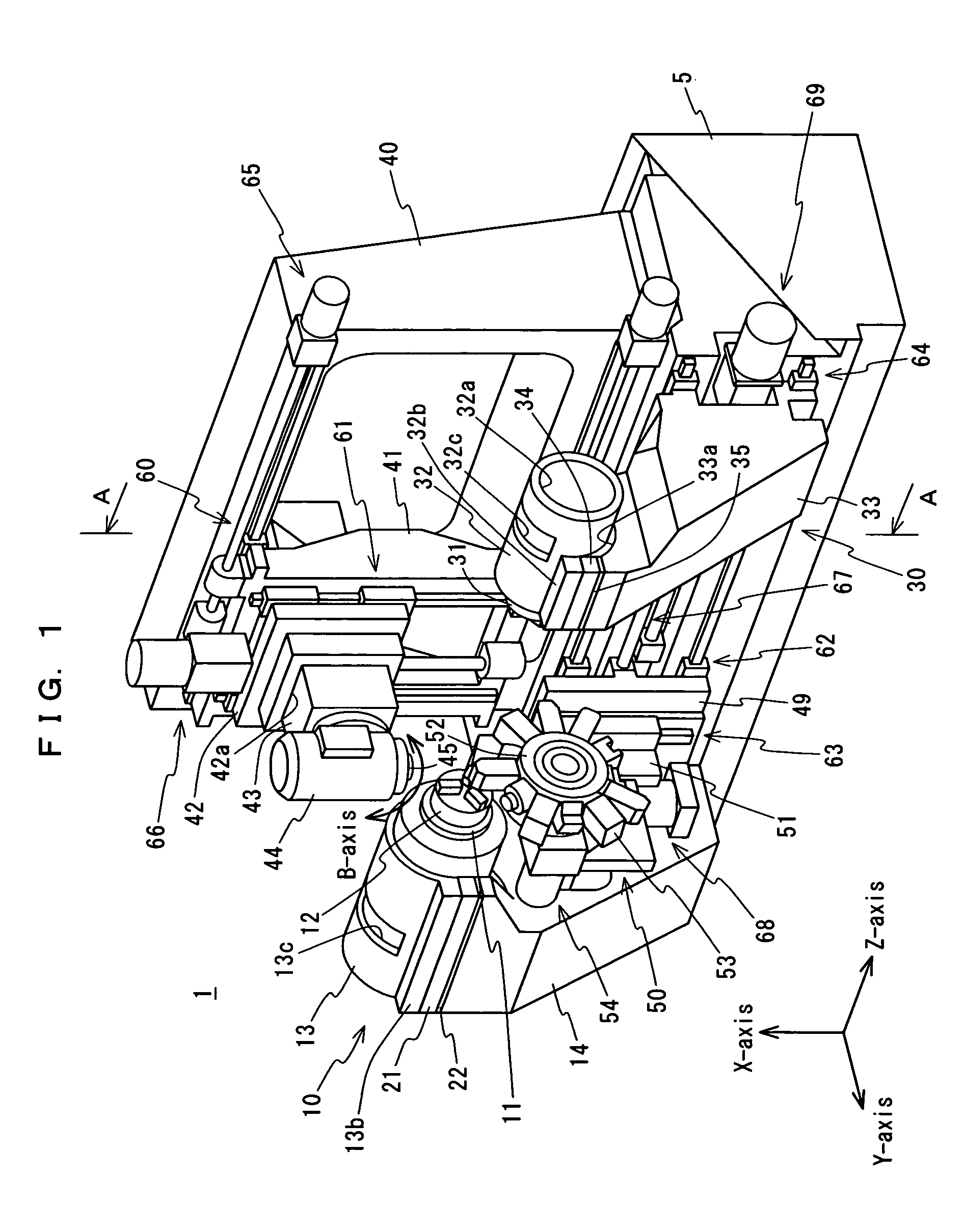

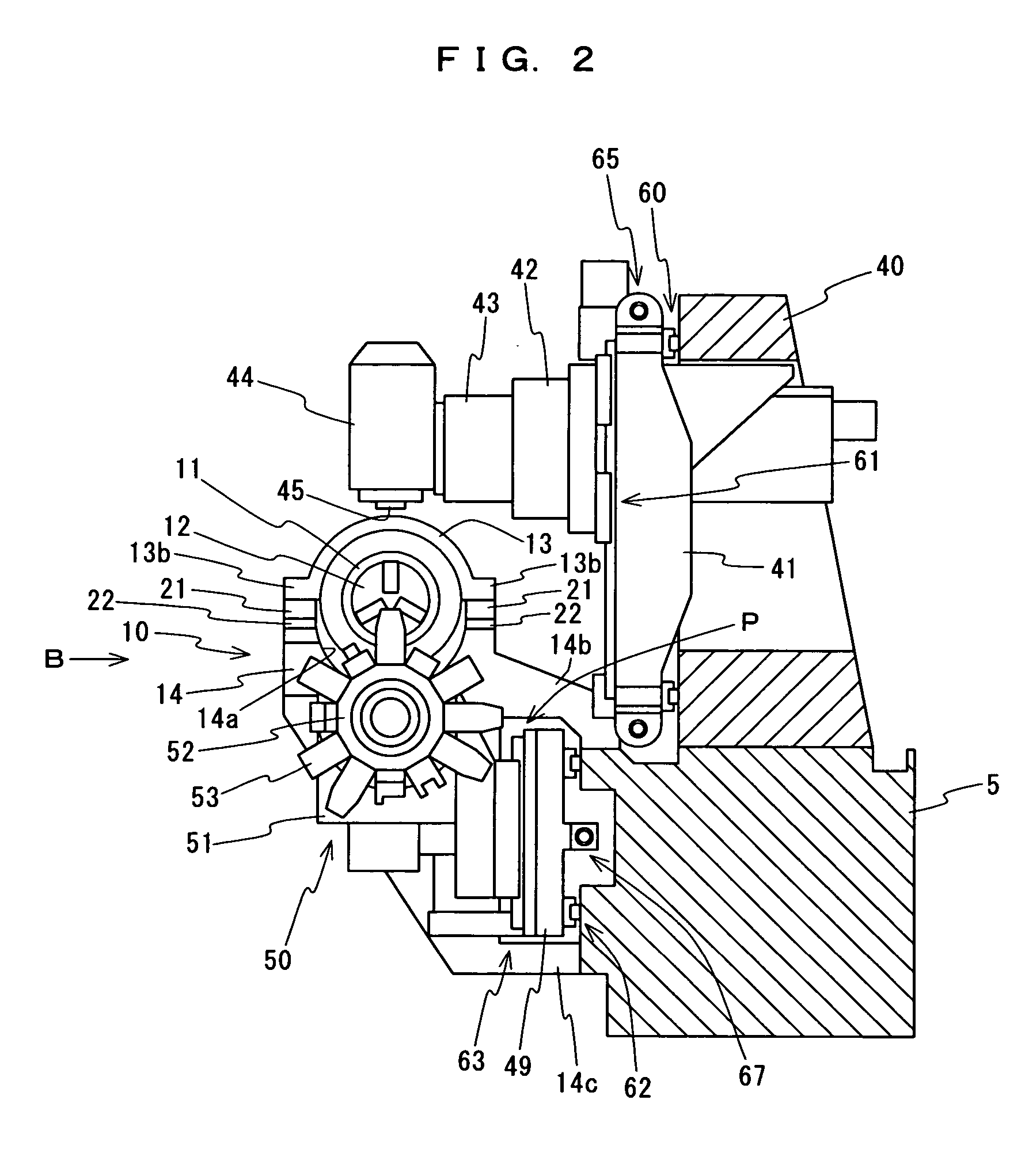

InactiveUS7039992B2Improve accuracyHigh precision machiningAutomatic/semiautomatic turning machinesAuxillary equipmentEngineeringMechanical engineering

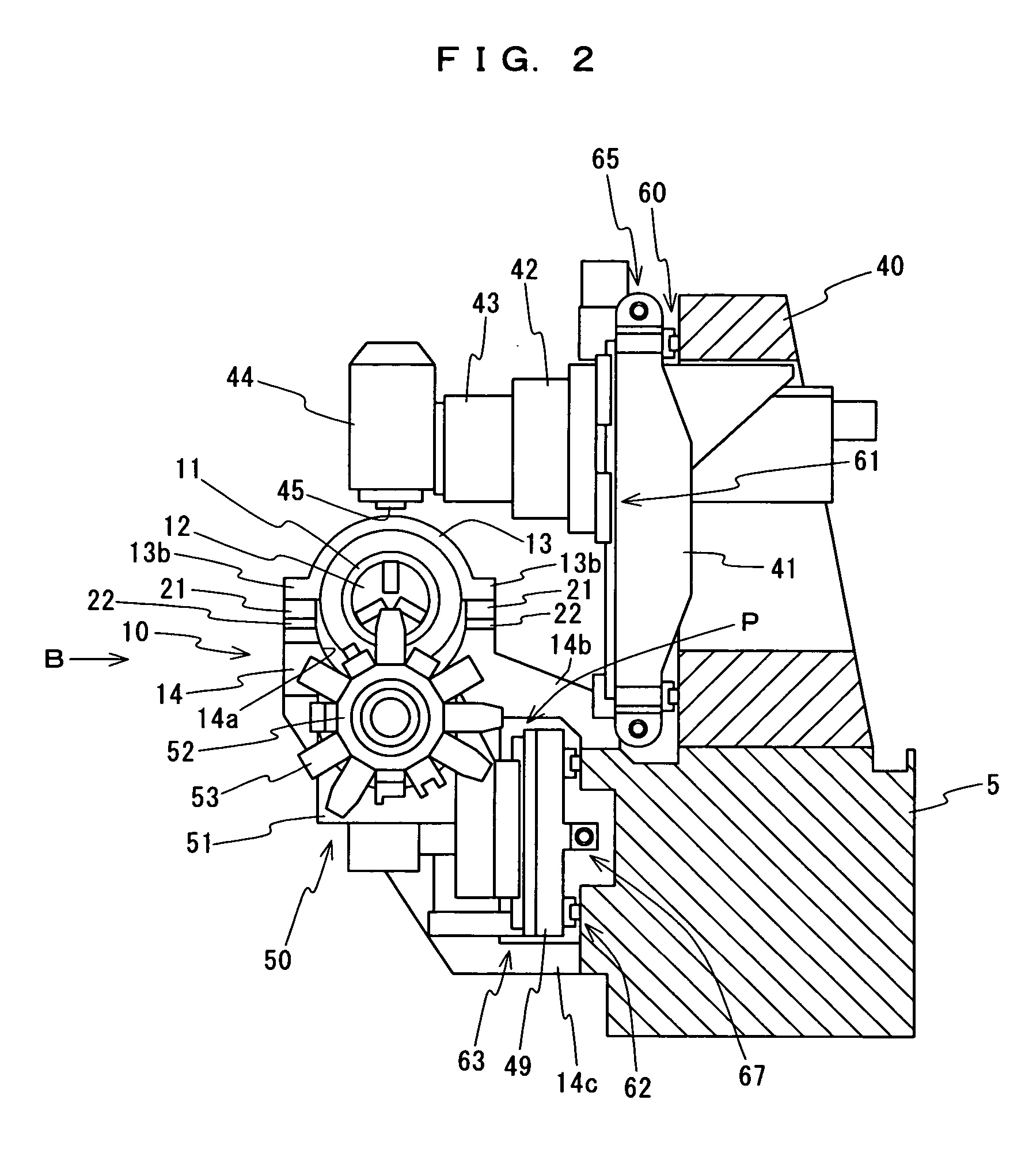

A lathe 1 comprises a bed 5, a headstock 10 having a housing 13 and a support base 14, a main spindle 11, a first tool rest 44, and a second tool rest 50. The support base 14 is formed so as to have a concave portion 14a on the upper portion thereof and so that the upper portion protrudes toward the second tool rest 50. The tool rest body 51 of the second tool rest 50 is configured so as to be movable into and out of a space formed downward from the upper portion of the support base 14. The housing 13 has a holding hole 13a for rotatably holding the main spindle 11, and installation portions 13b. The installation portions 13b are supported on the support base 14 in a state wherein a predetermined clearance is provided between the housing 13 and the concave portion 14a.

Owner:DMG MORI CO LTD

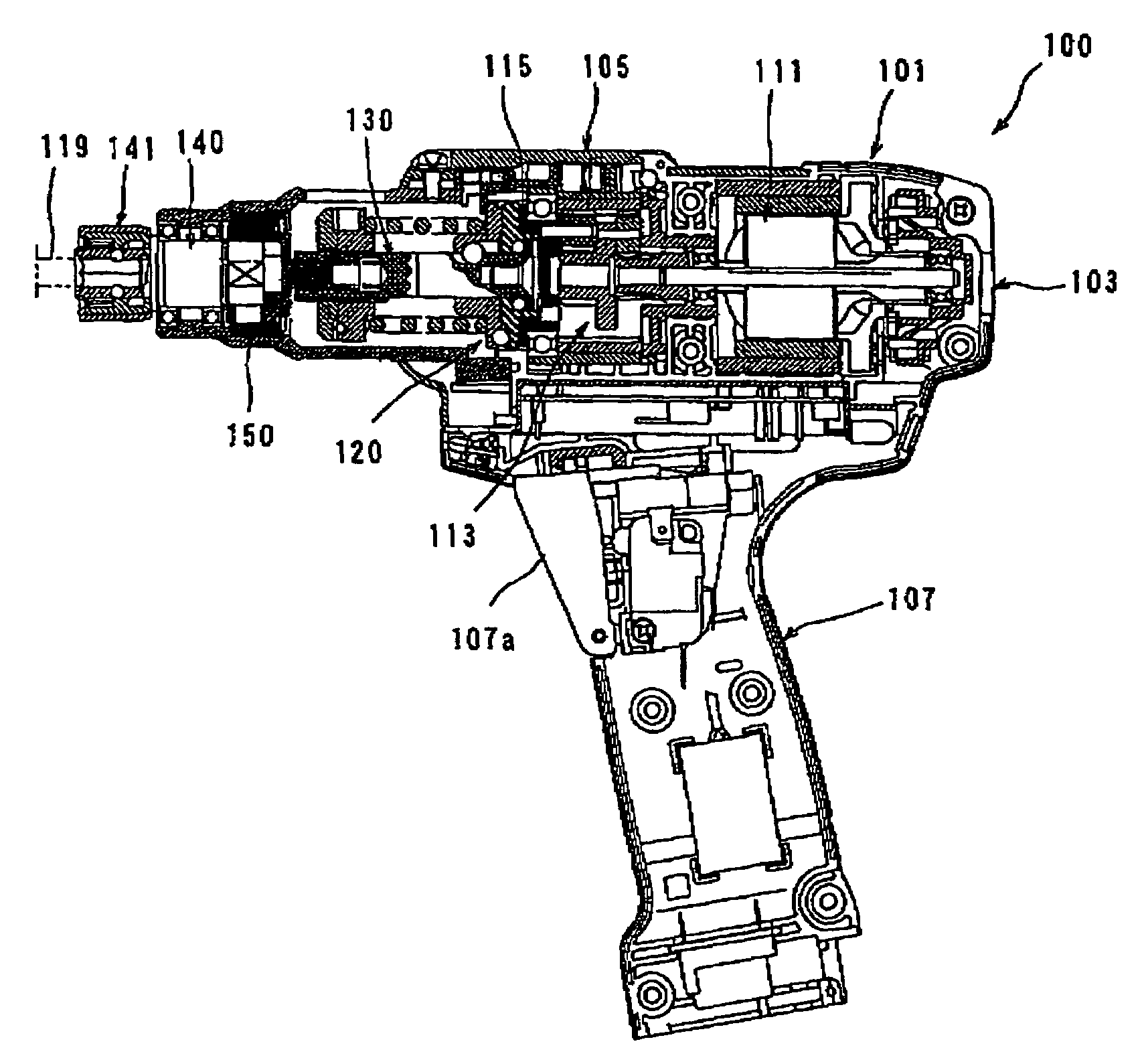

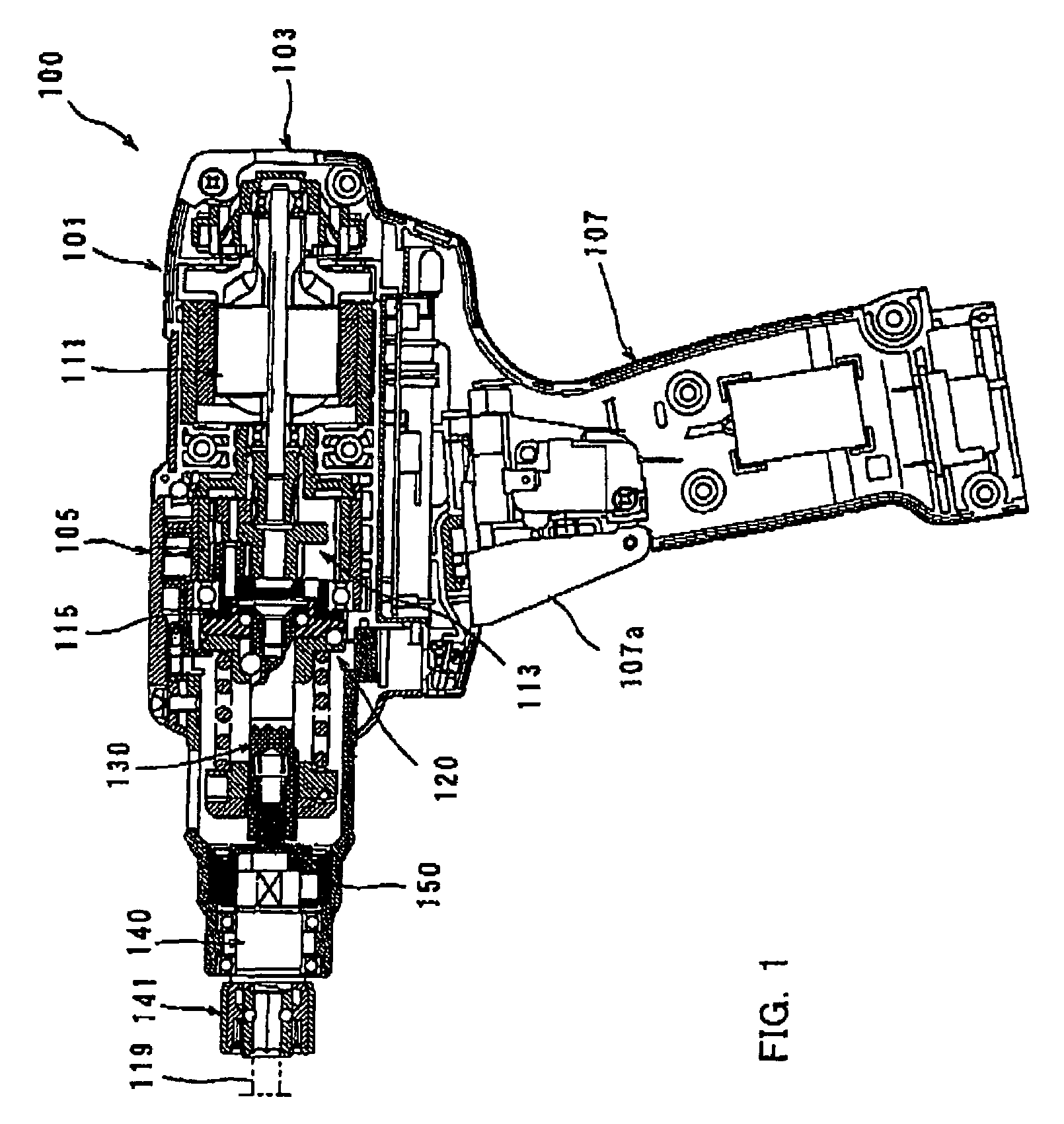

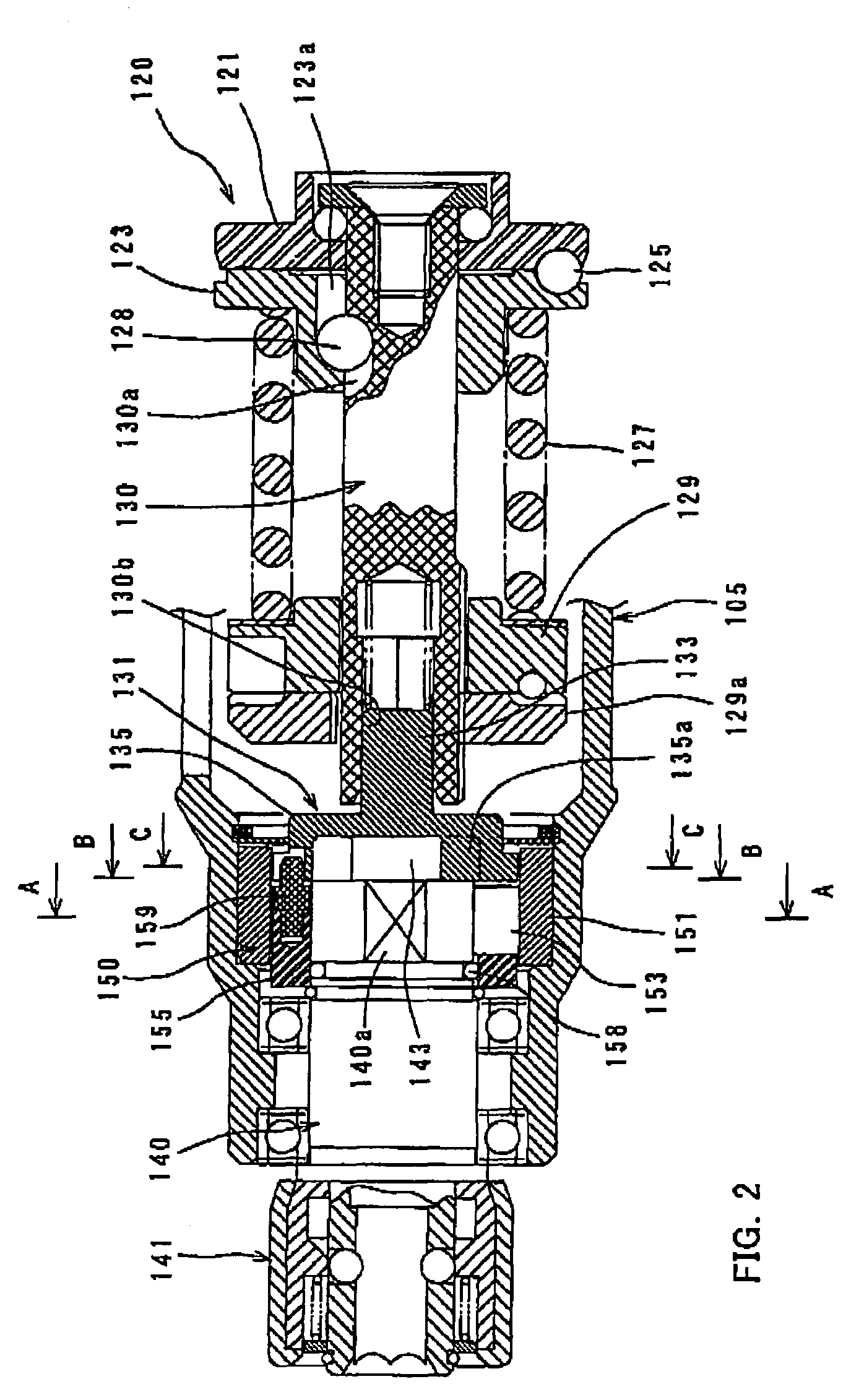

Power tool having torque limiter

Owner:MAKITA CORP

Holder including a hydraulic piston for the detachable assembly of cutting tools

A holder for the detachable assembly of cutting tools includes a clamping mechanism, which has a piston axially movable by applying oil pressure on either of two opposite sides thereof. A projection of the piston includes a cone surface with a moderate cone angle arranged to co-operate with a wedge body which is self-locking in relation to the cone surface to keep the cutting tool clamped, even when oil pressure is relieved. In order to guarantee such self-locking, transverse grooves are provided in the cone surface enabling friction-reducing oil to be evacuated from the interface between the cone surface and an inner, partially cone-shaped surface on the wedge body.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

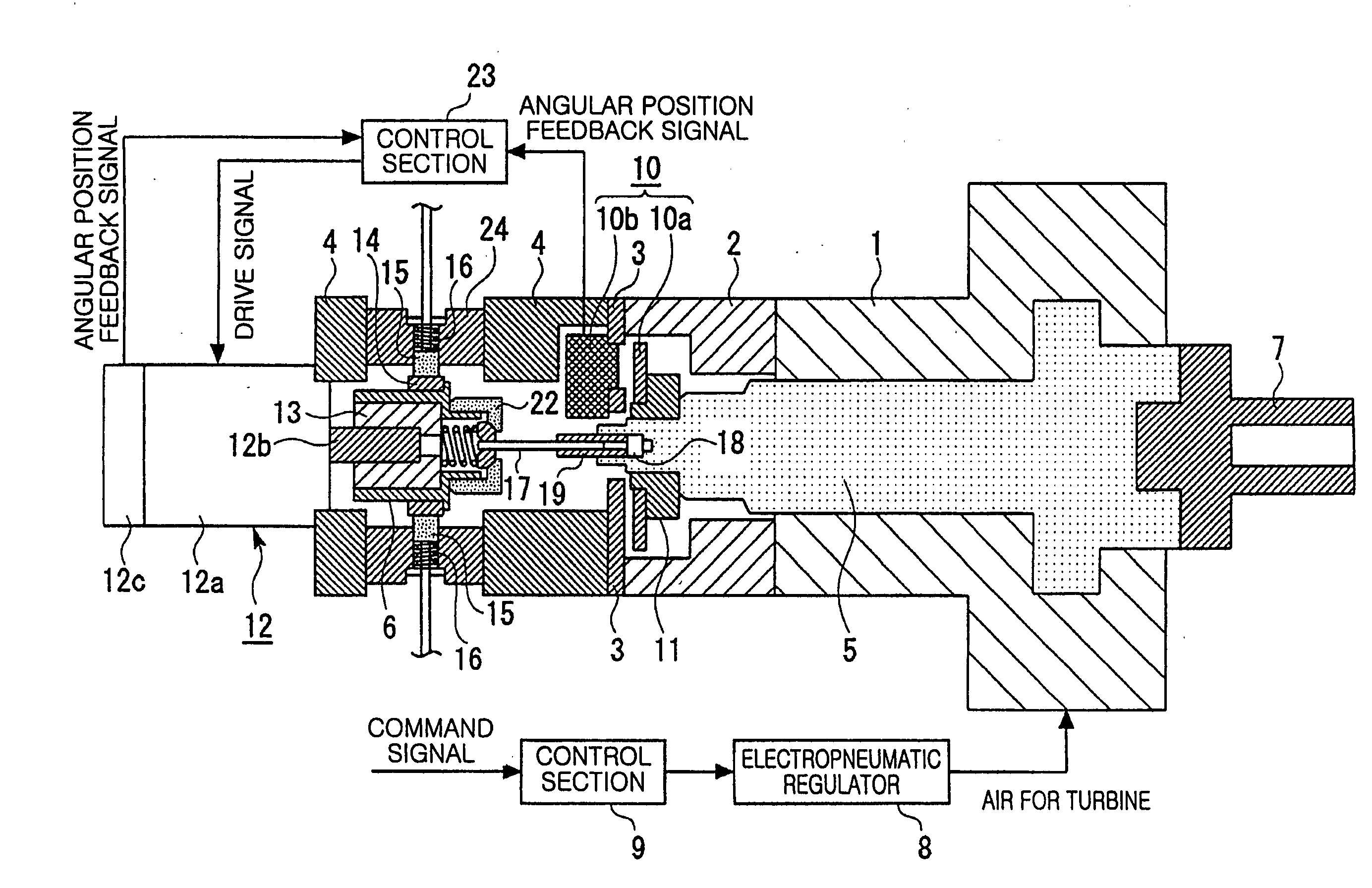

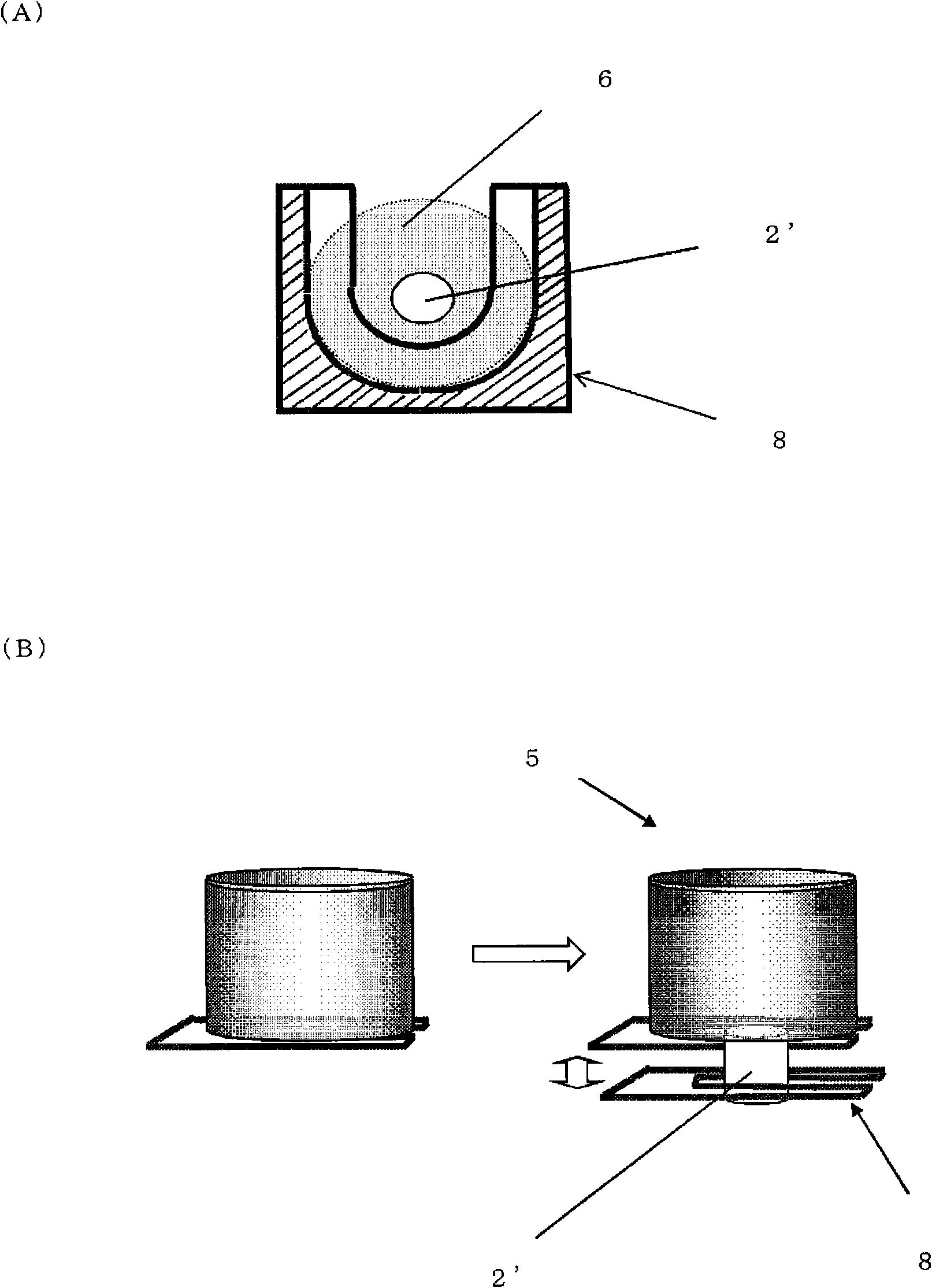

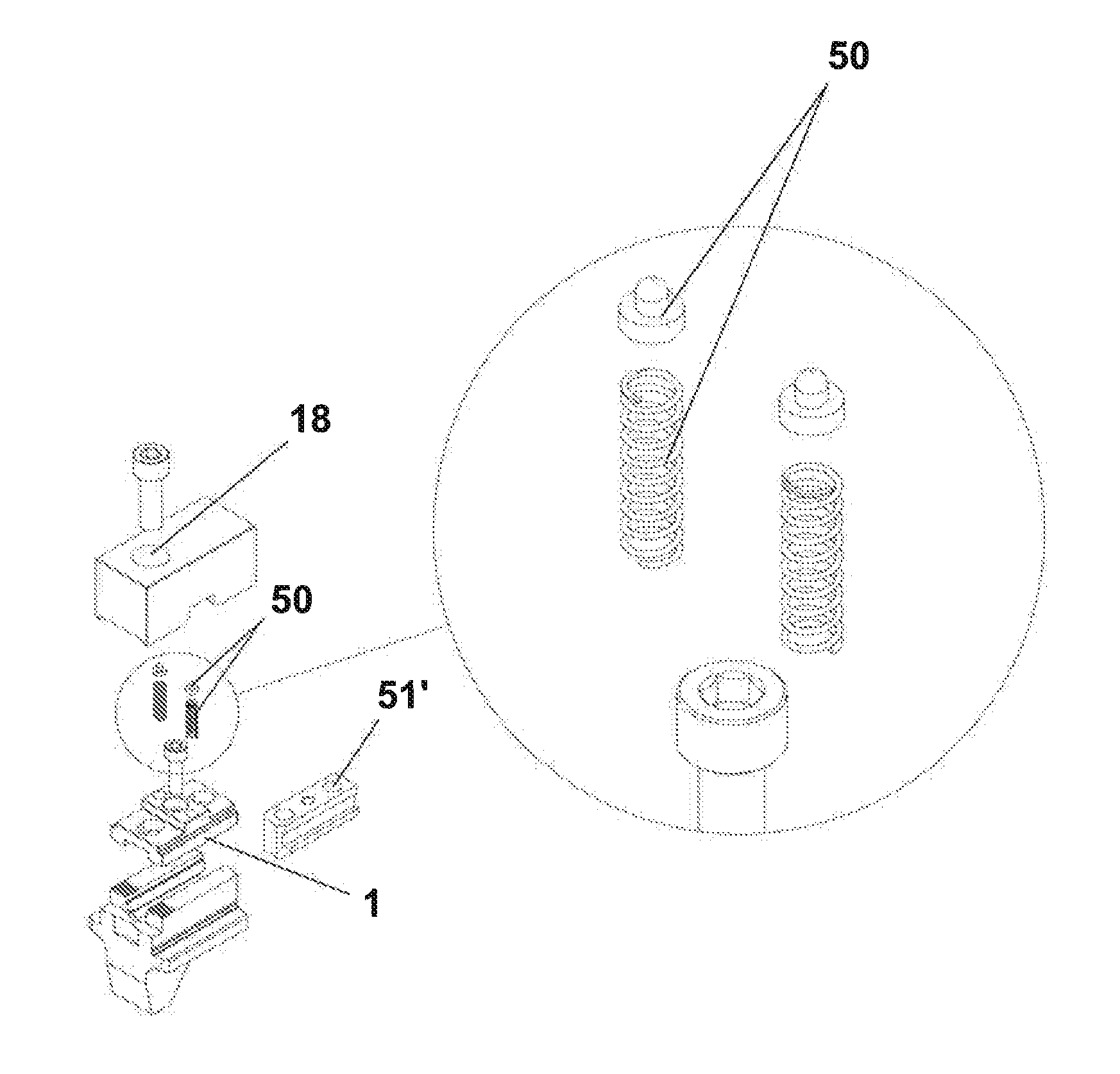

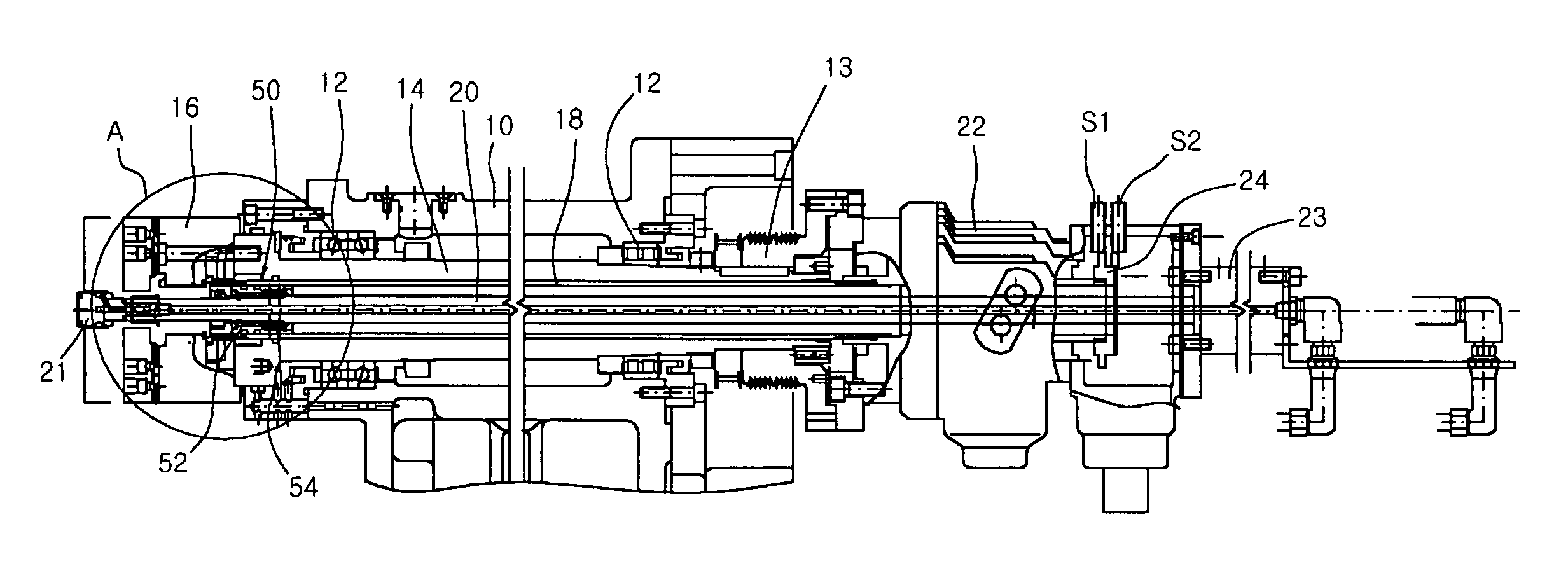

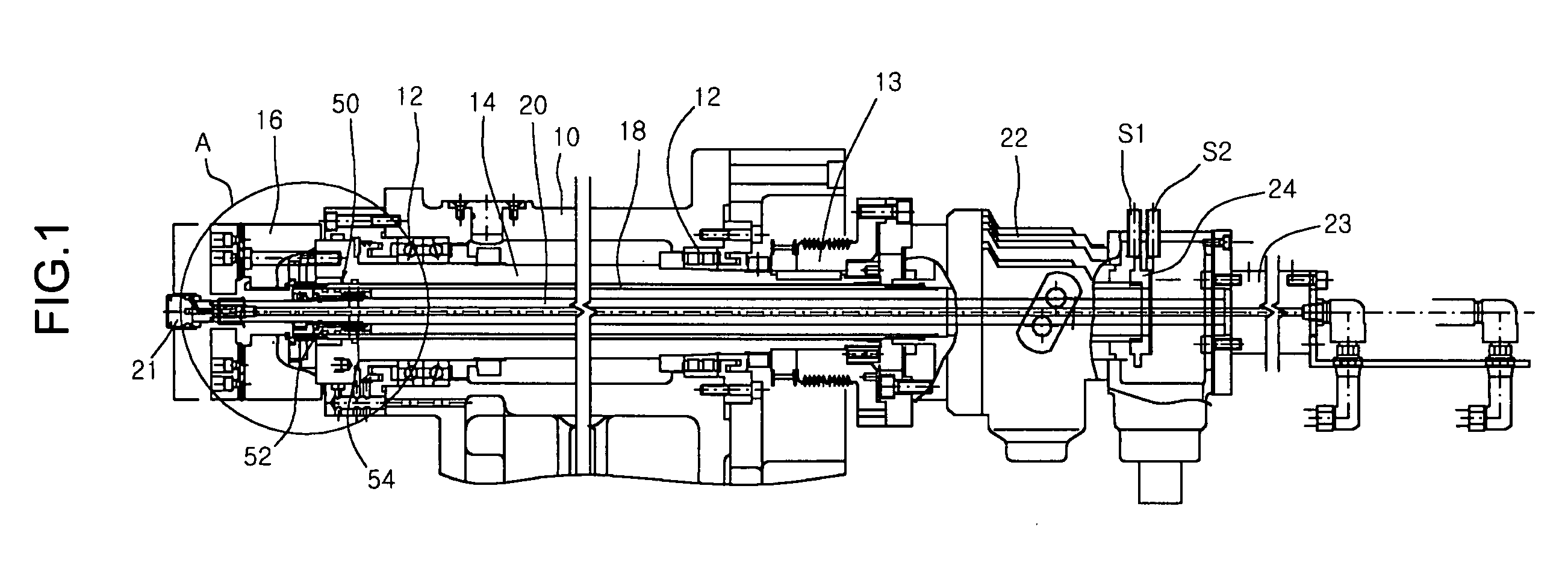

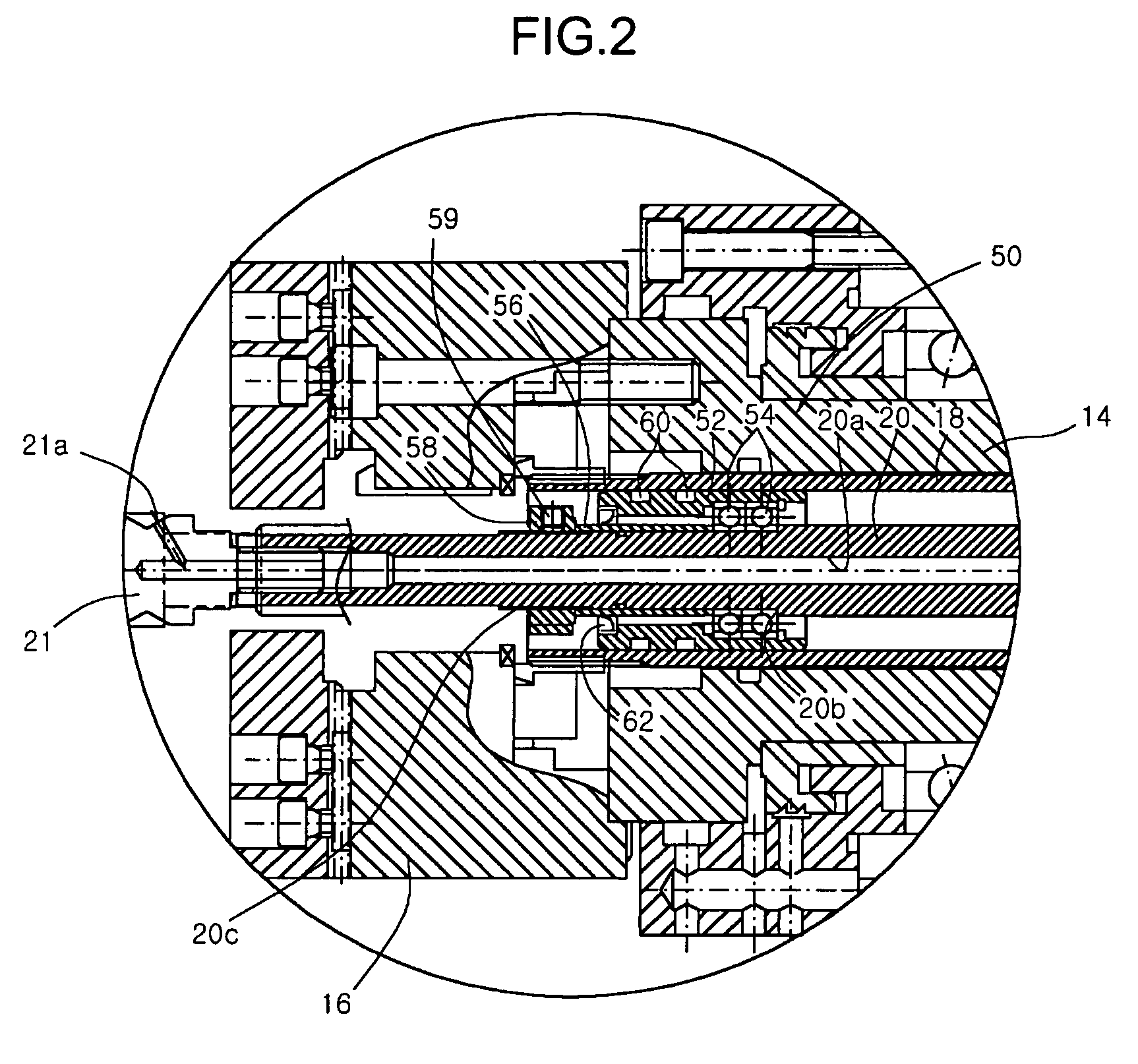

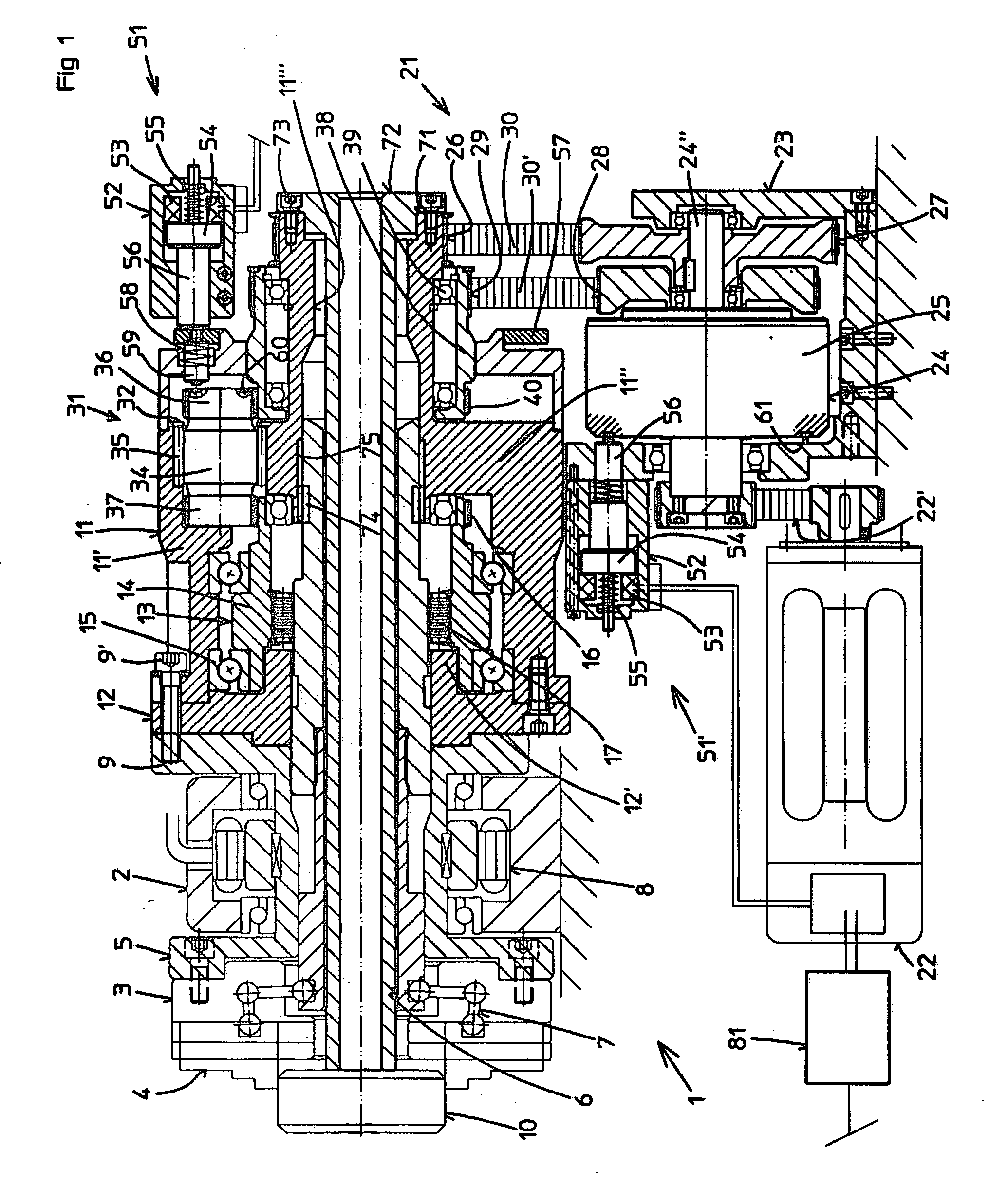

Actuator for workpiece holding device

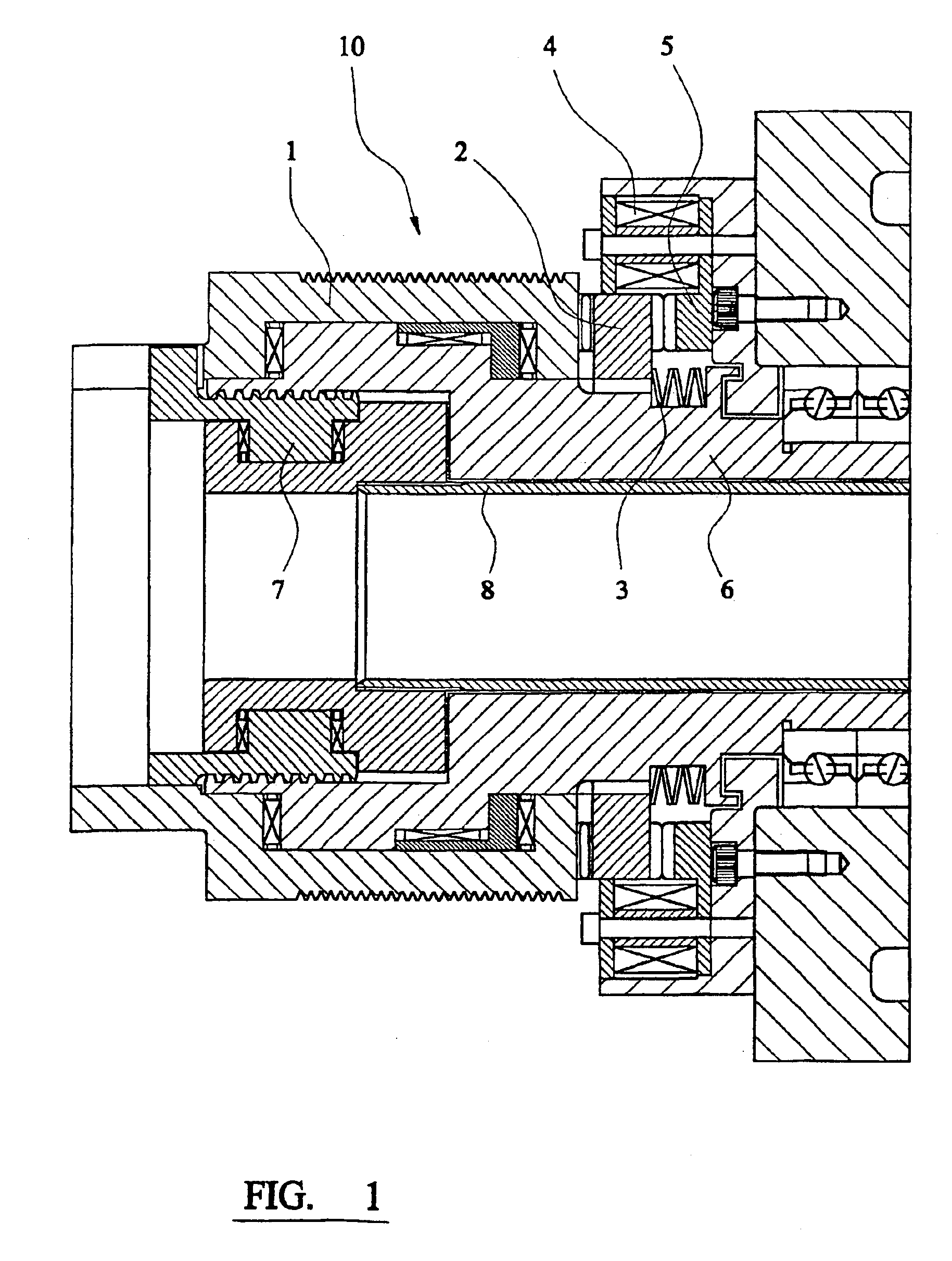

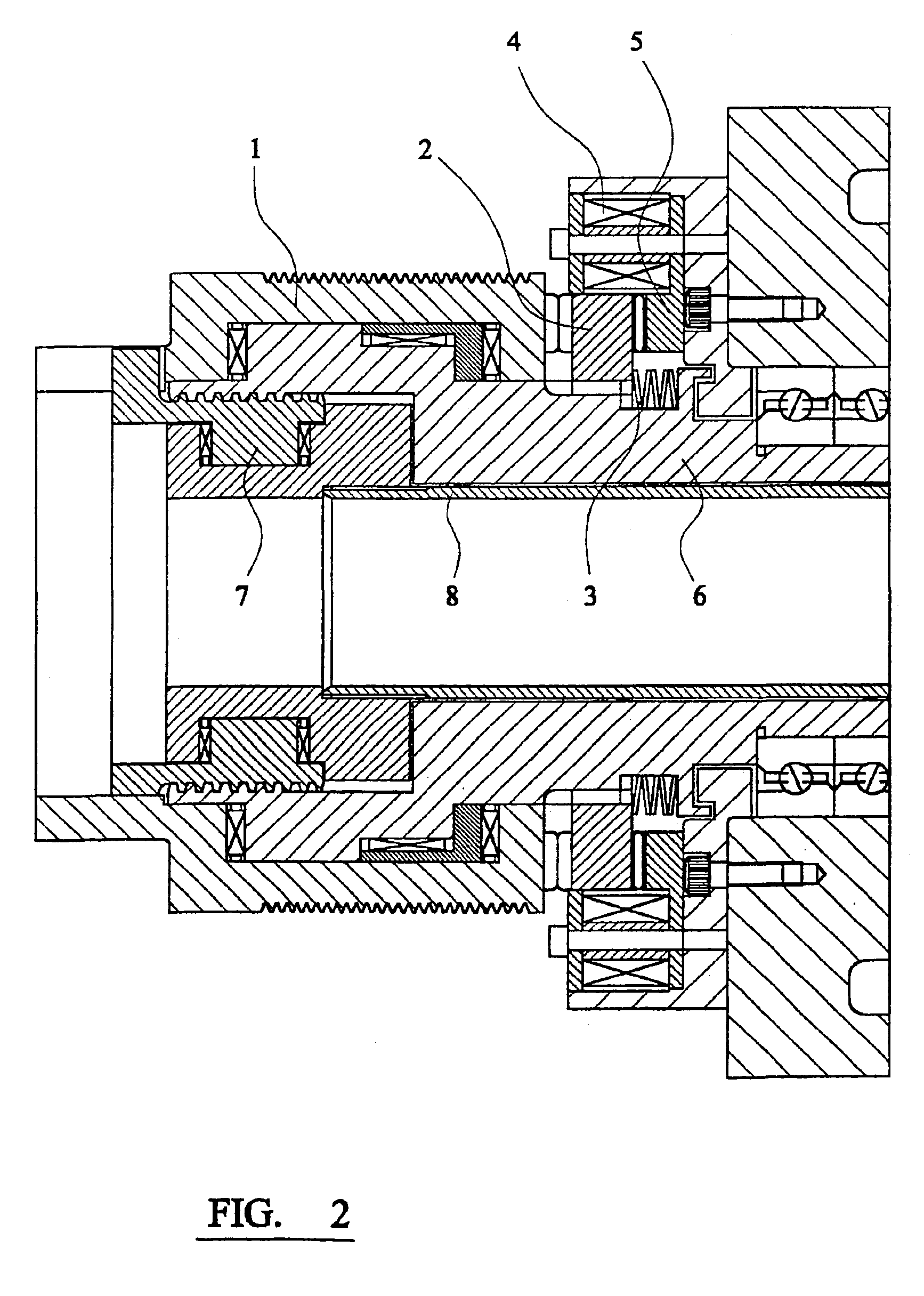

InactiveUS6918327B2Save overall cycle timeRule out the possibilityLathesSleeve/socket jointsActuatorMachine tool

A power chucking system 10 comprises a chuck mounted on a headstock, the chuck with its jaws being caused to rotate by rotation or the machine spindle 6. The spindle 6 may be engaged with the pulley 1 in order to rotate a work piece retained within the chuck jaws. A clutch 2 may be used to disengage the spindle 6 from the pulley 1 and to lock the spindle 6 to the head stock. In this configuration, rotation of the pulley 1 will cause an actuator jack 7 to screw or unscrew, into or out of spindle 6, in order to open or close the chuck jaws to grip release the workpiece.

Owner:PRATT BURNERD INT

Lathe

InactiveUS20050022350A1Improve accuracyAvoid displacementAutomatic/semiautomatic turning machinesAuxillary equipmentMechanical engineering

A lathe 1 comprises a bed 5, a headstock 10 having a housing 13 and a support base 14, a main spindle 11, a first tool rest 44, and a second tool rest 50. The support base 14 is formed so as to have a concave portion 14a on the upper portion thereof and so that the upper portion protrudes toward the second tool rest 50. The tool rest body 51 of the second tool rest 50 is configured so as to be movable into and out of a space formed downward from the upper portion of the support base 14. The housing 13 has a holding hole 13a for rotatably holding the main spindle 11, and installation portions 13b. The installation portions 13b are supported on the support base 14 in a state wherein a predetermined clearance is provided between the housing 13 and the concave portion 14a.

Owner:DMG MORI SEIKI CO LTD

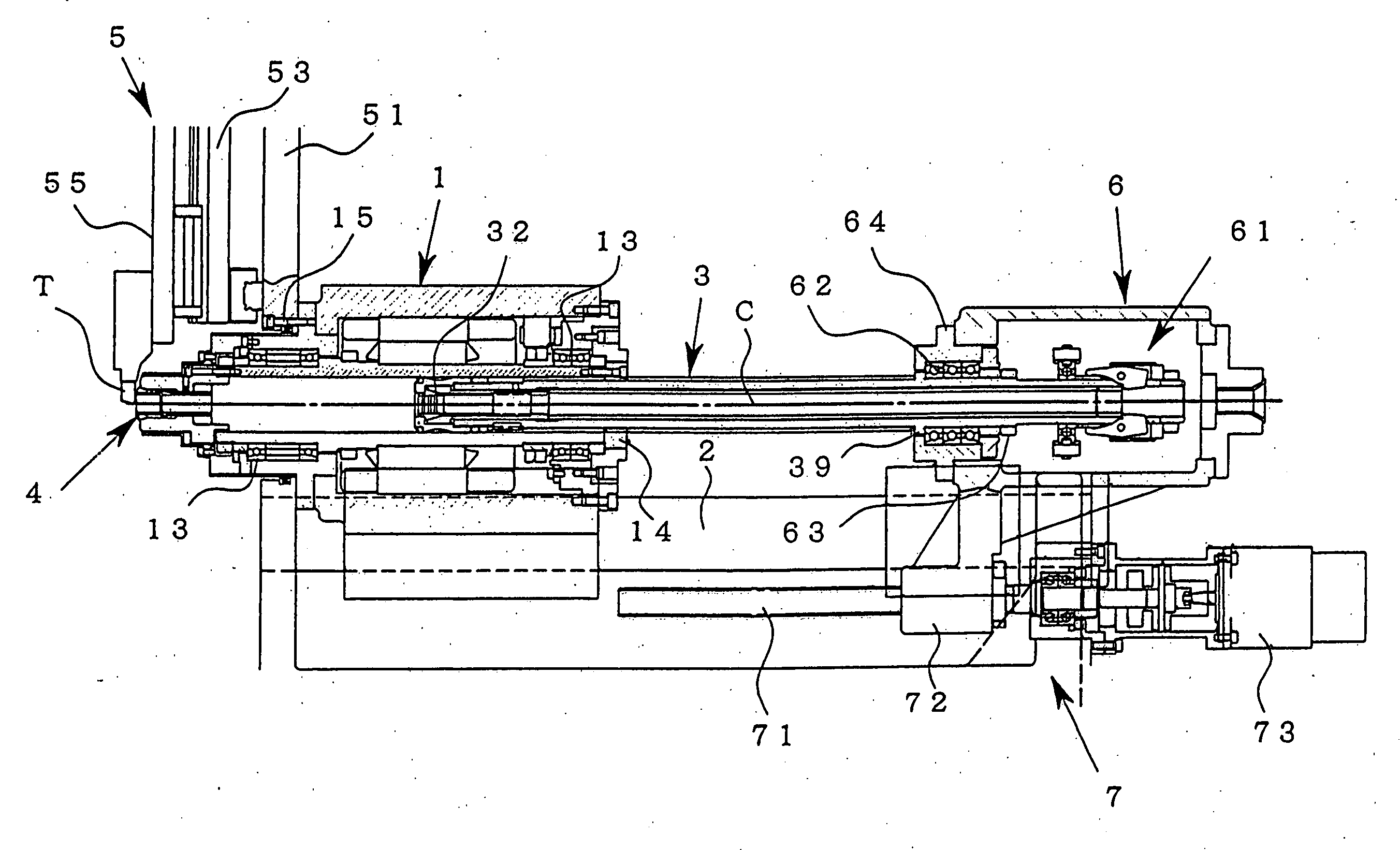

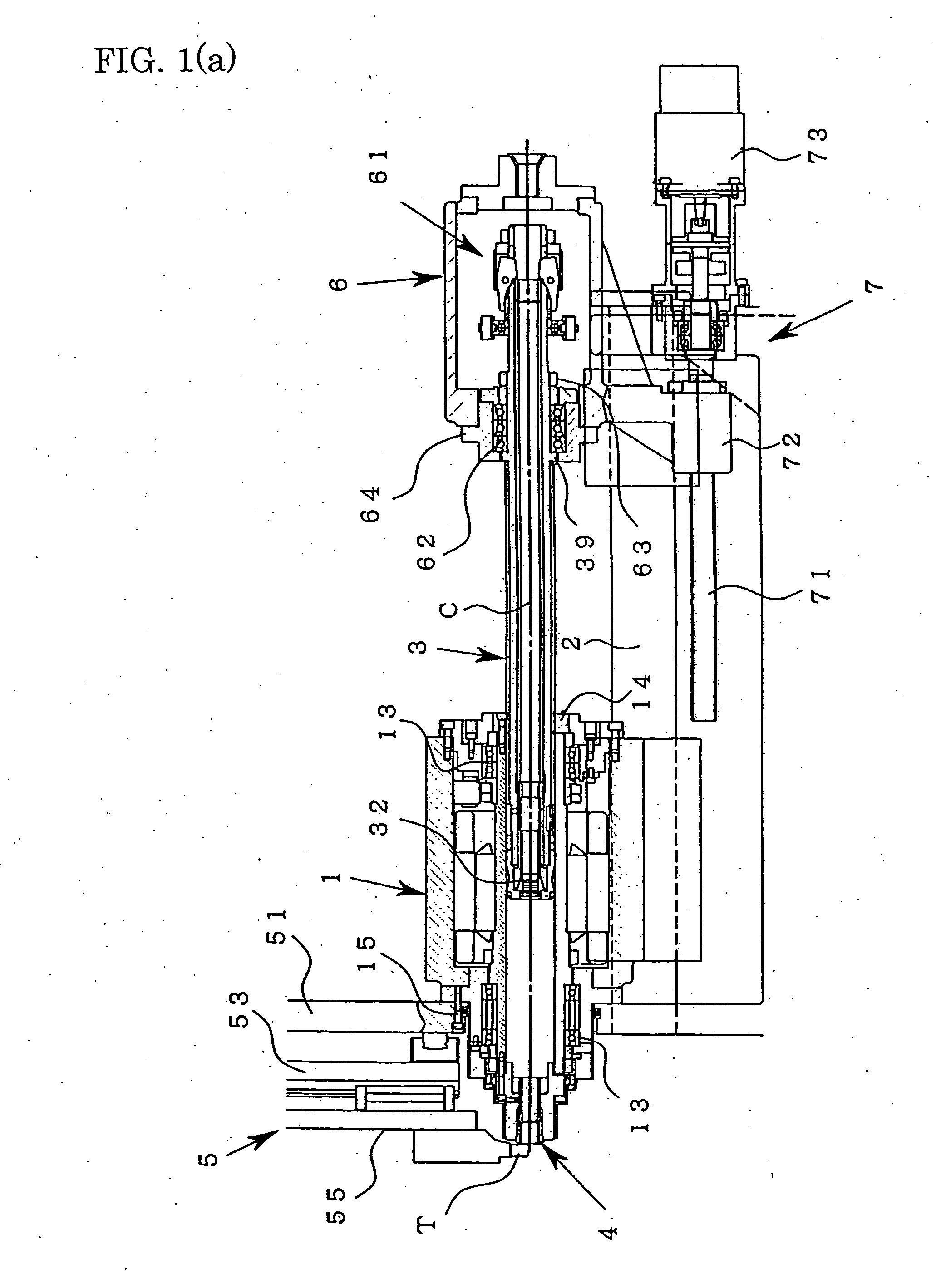

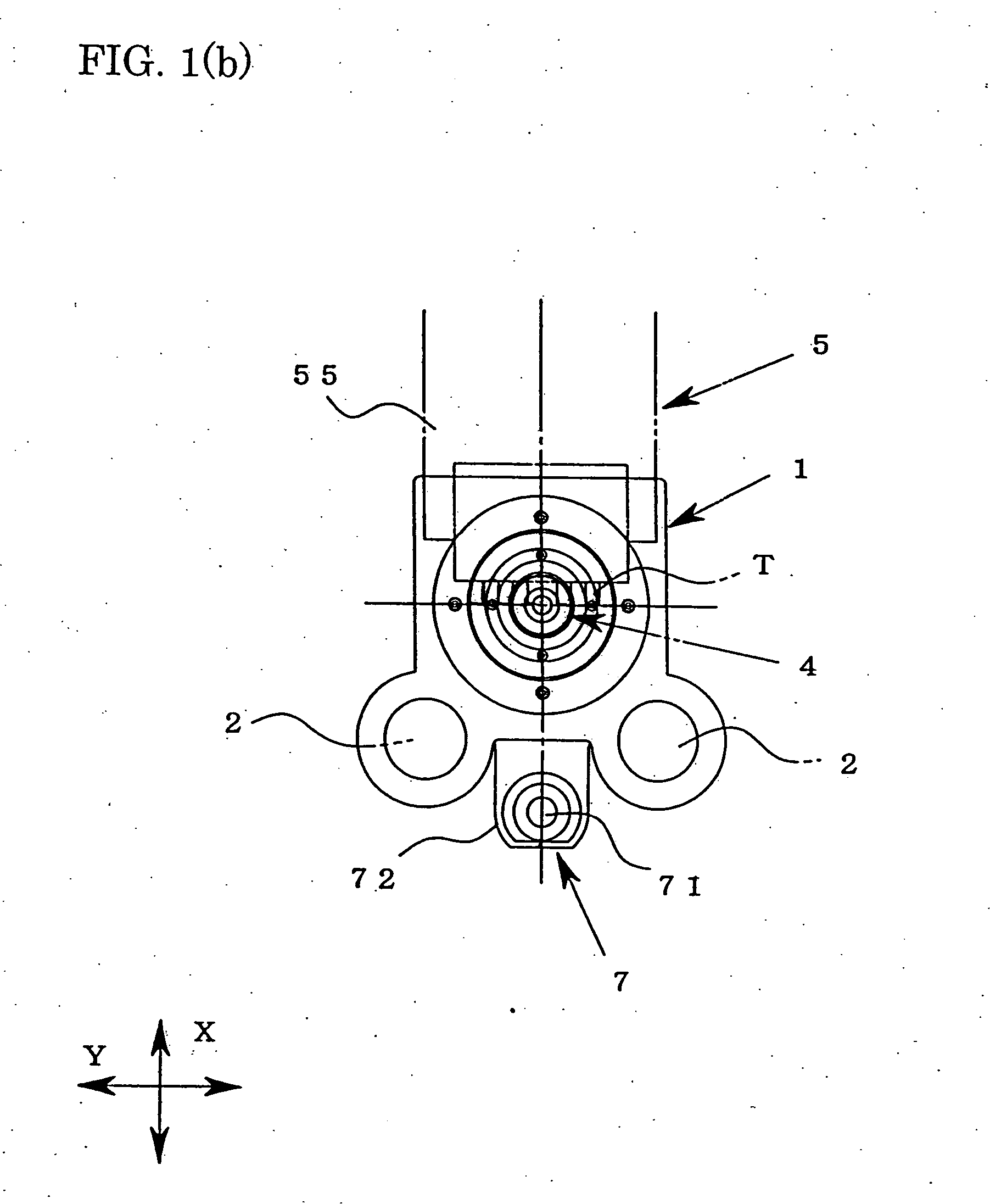

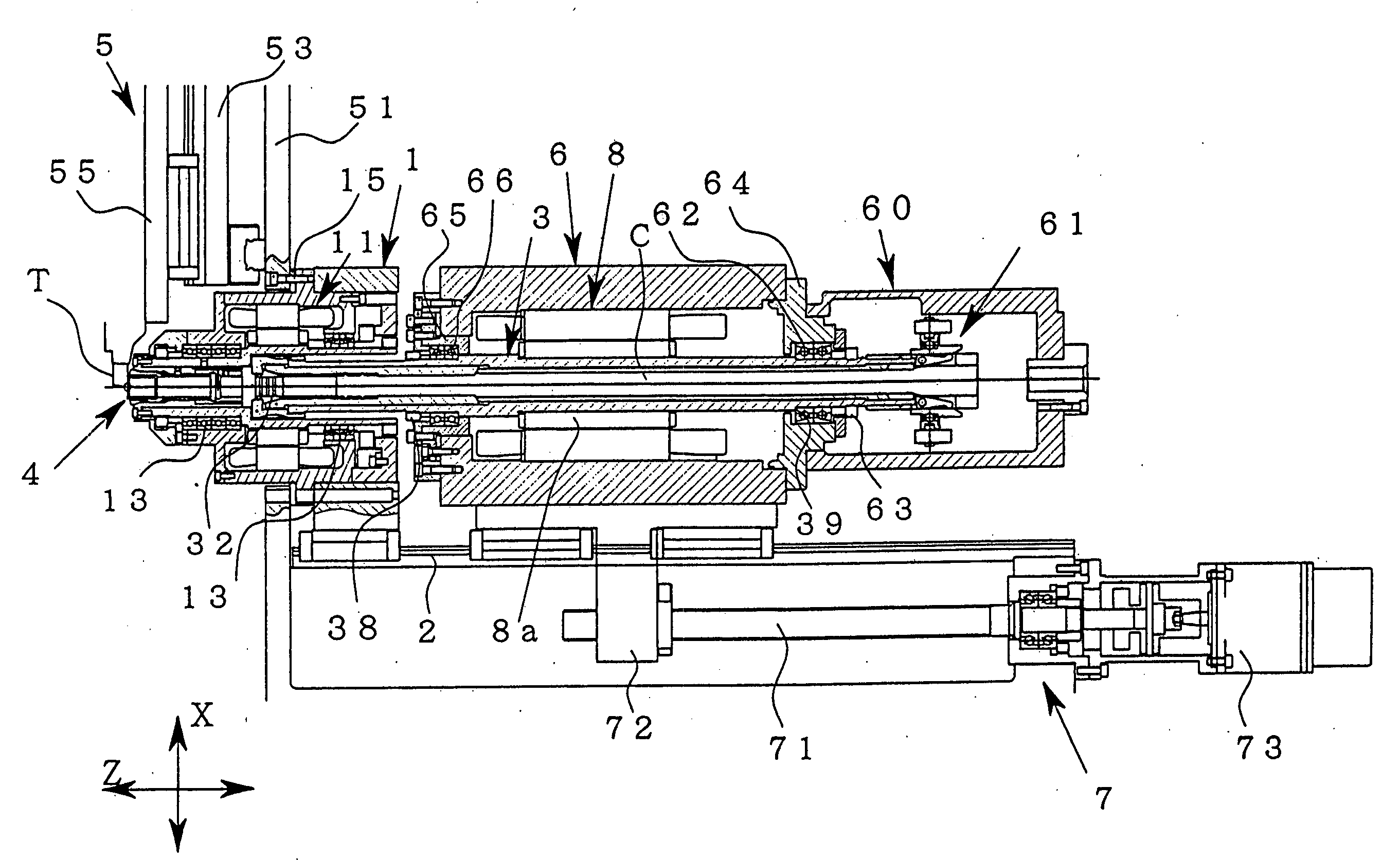

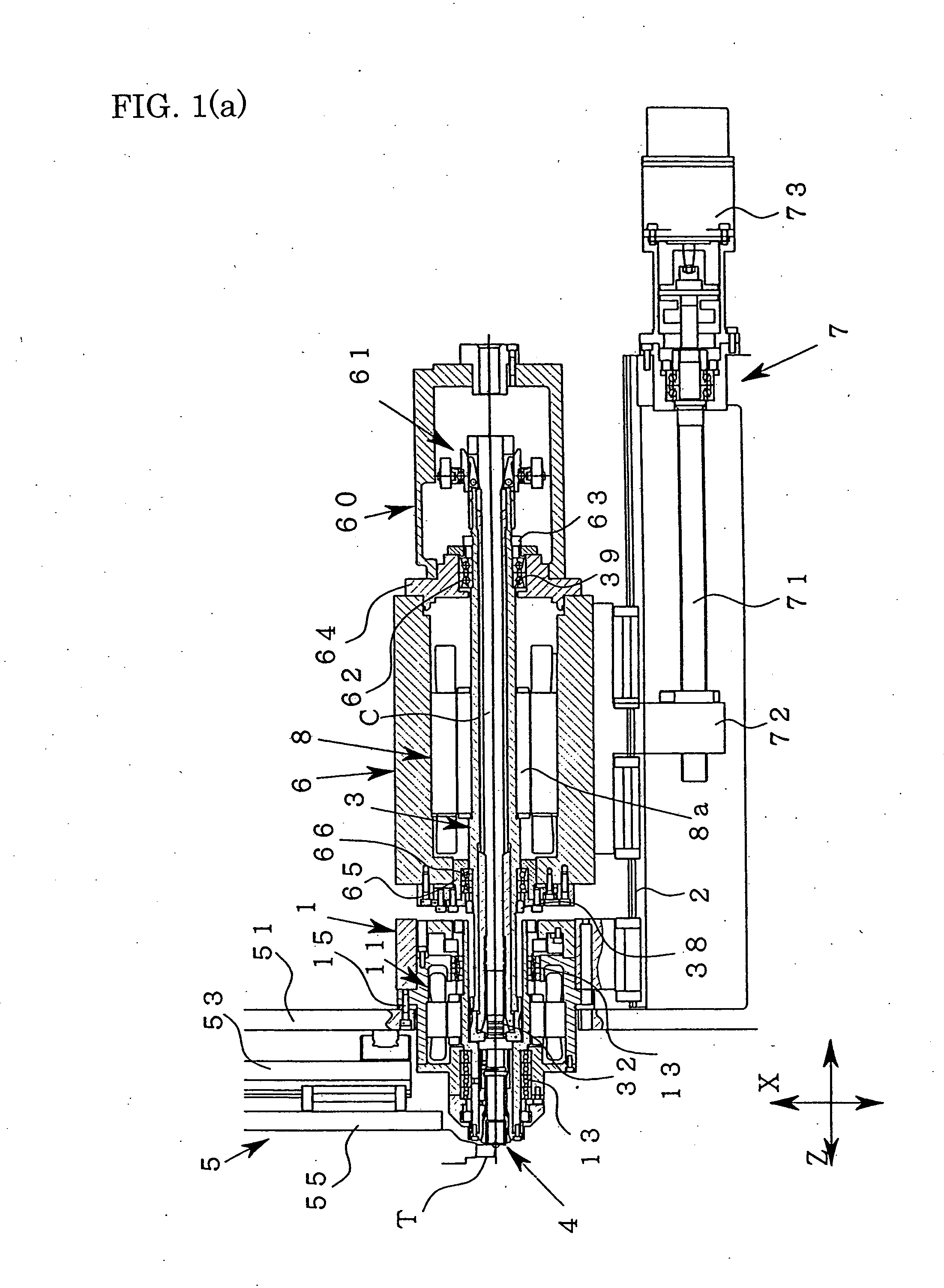

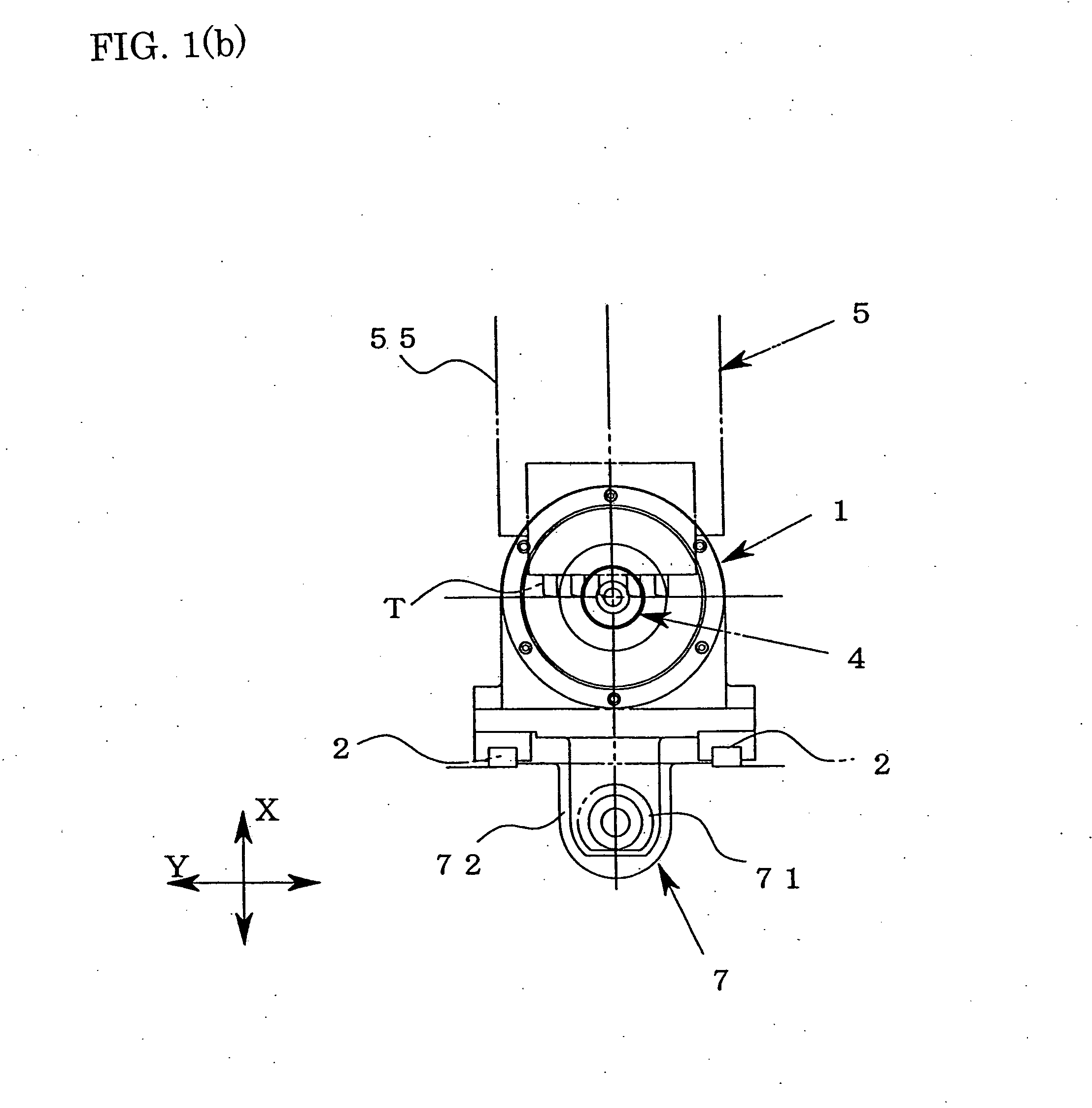

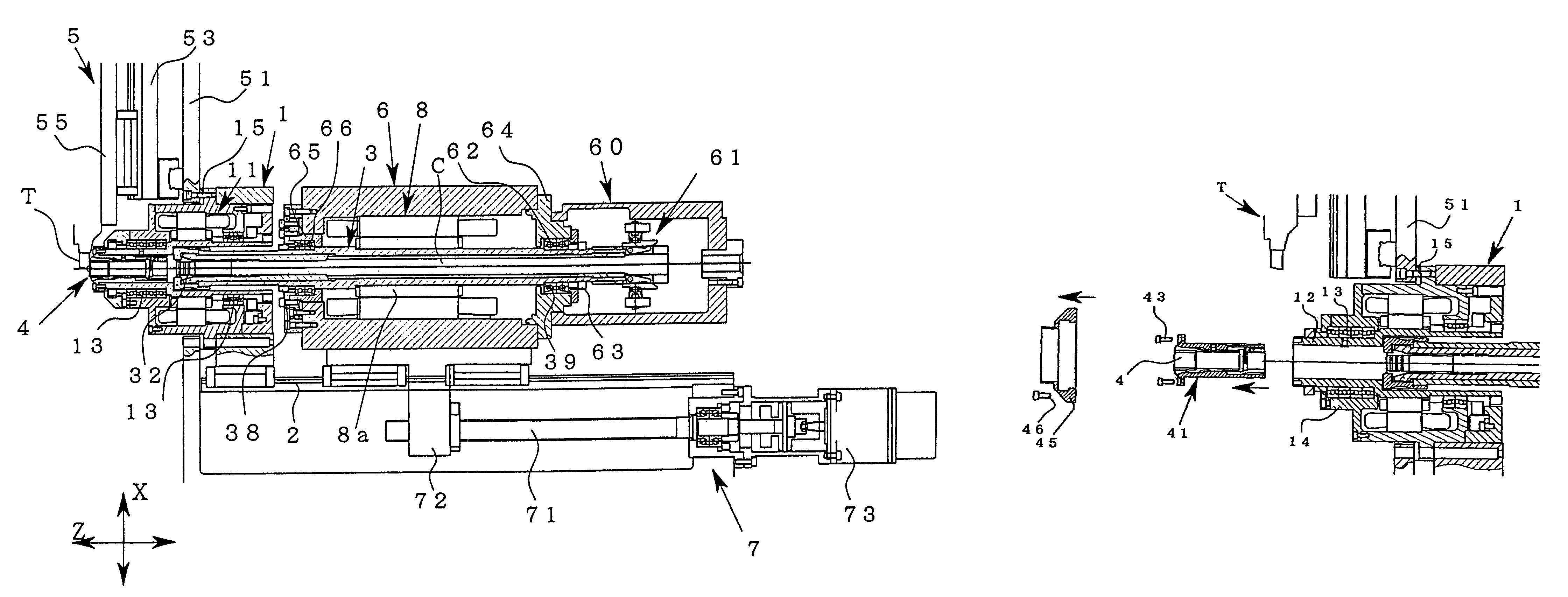

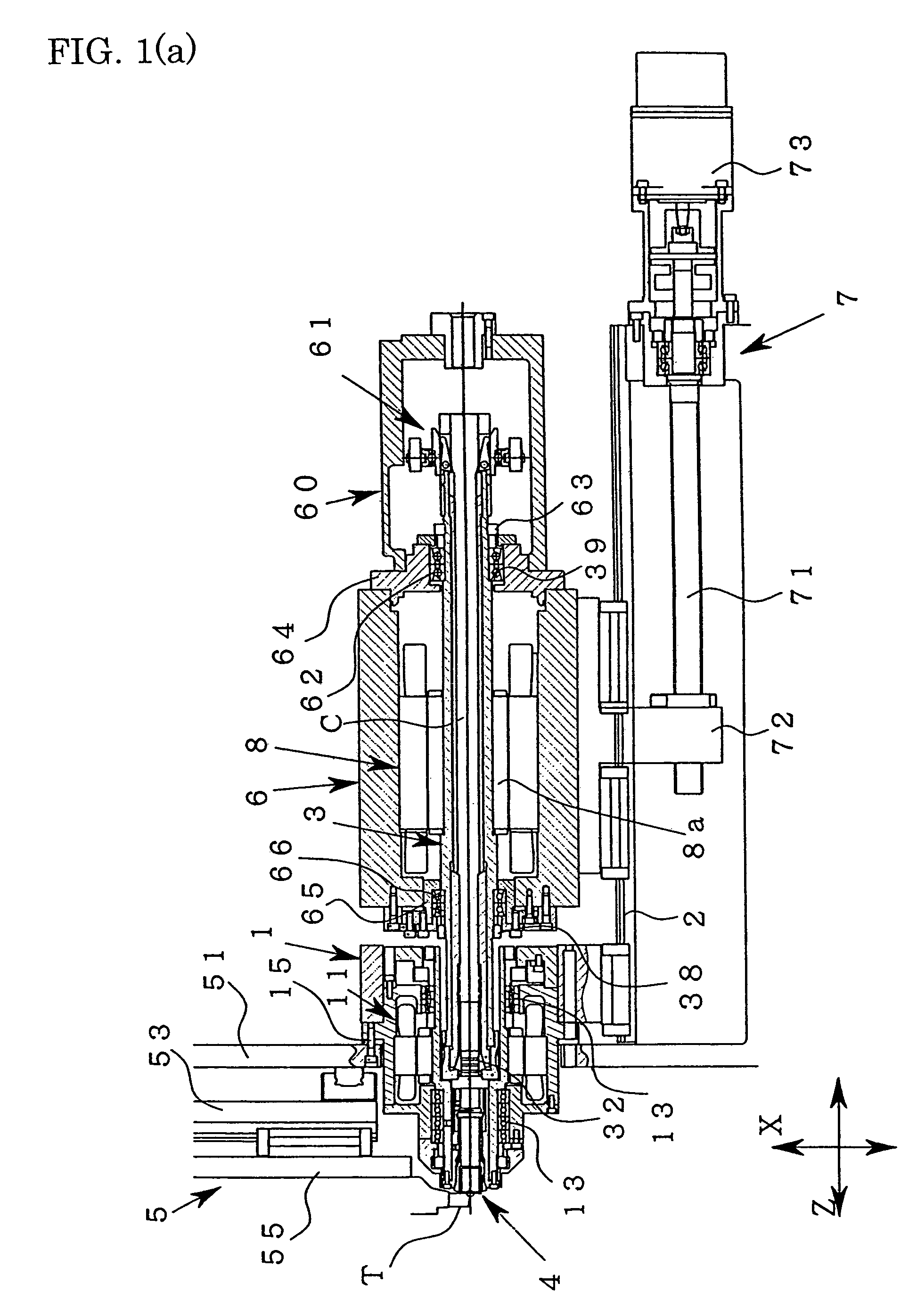

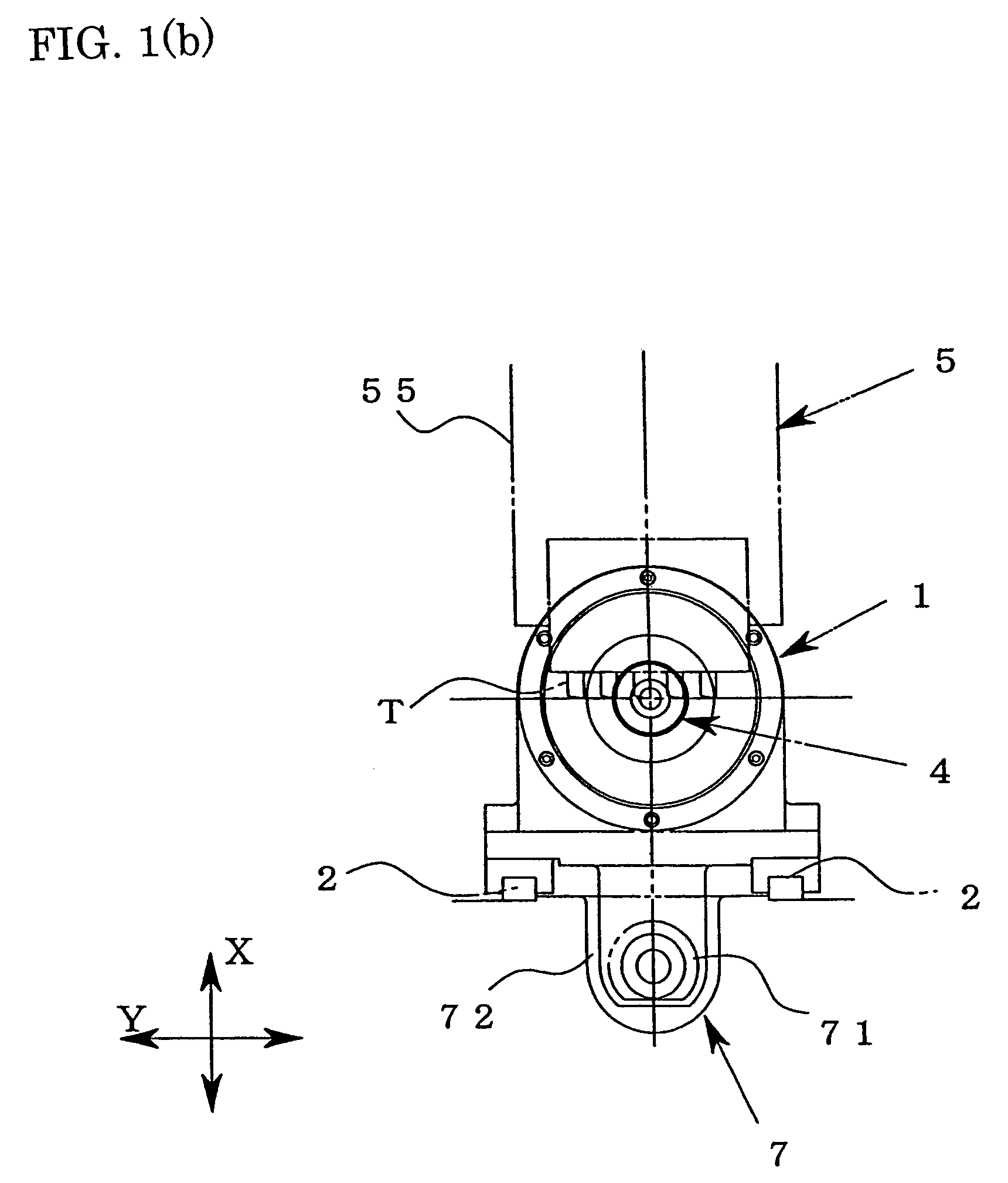

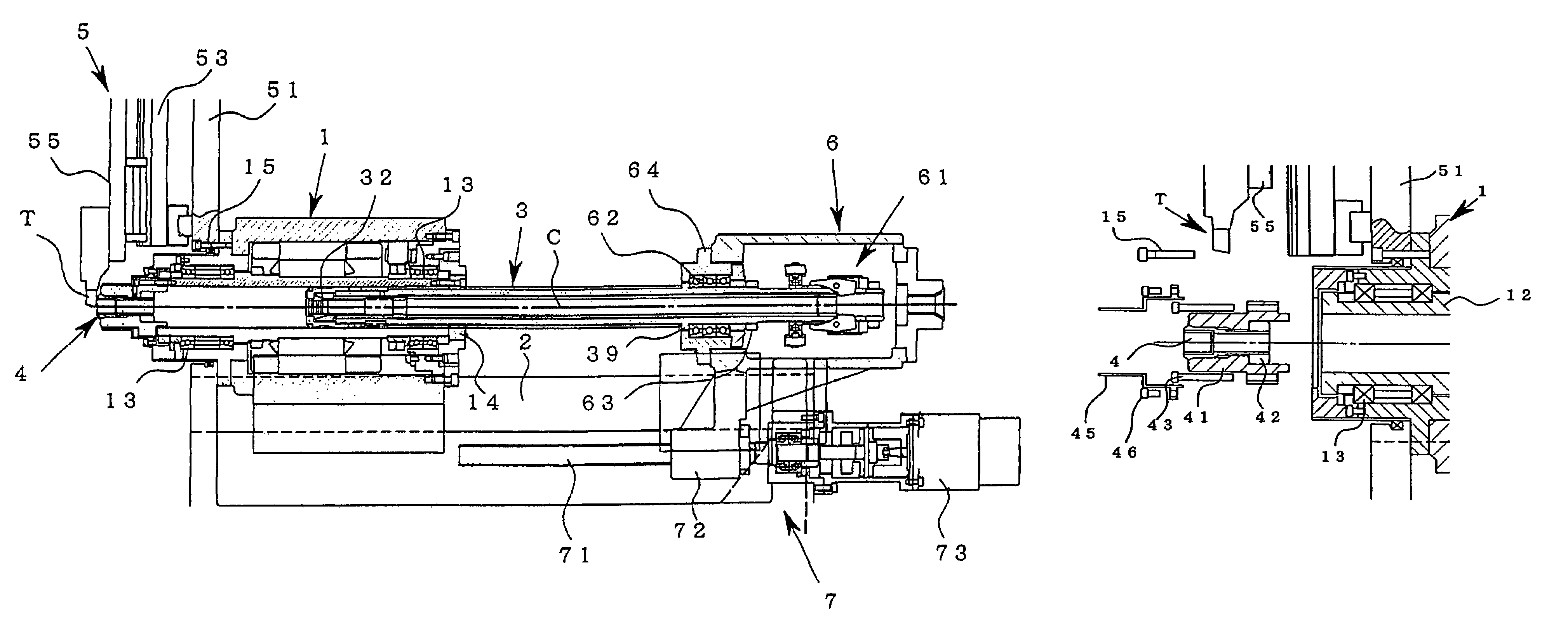

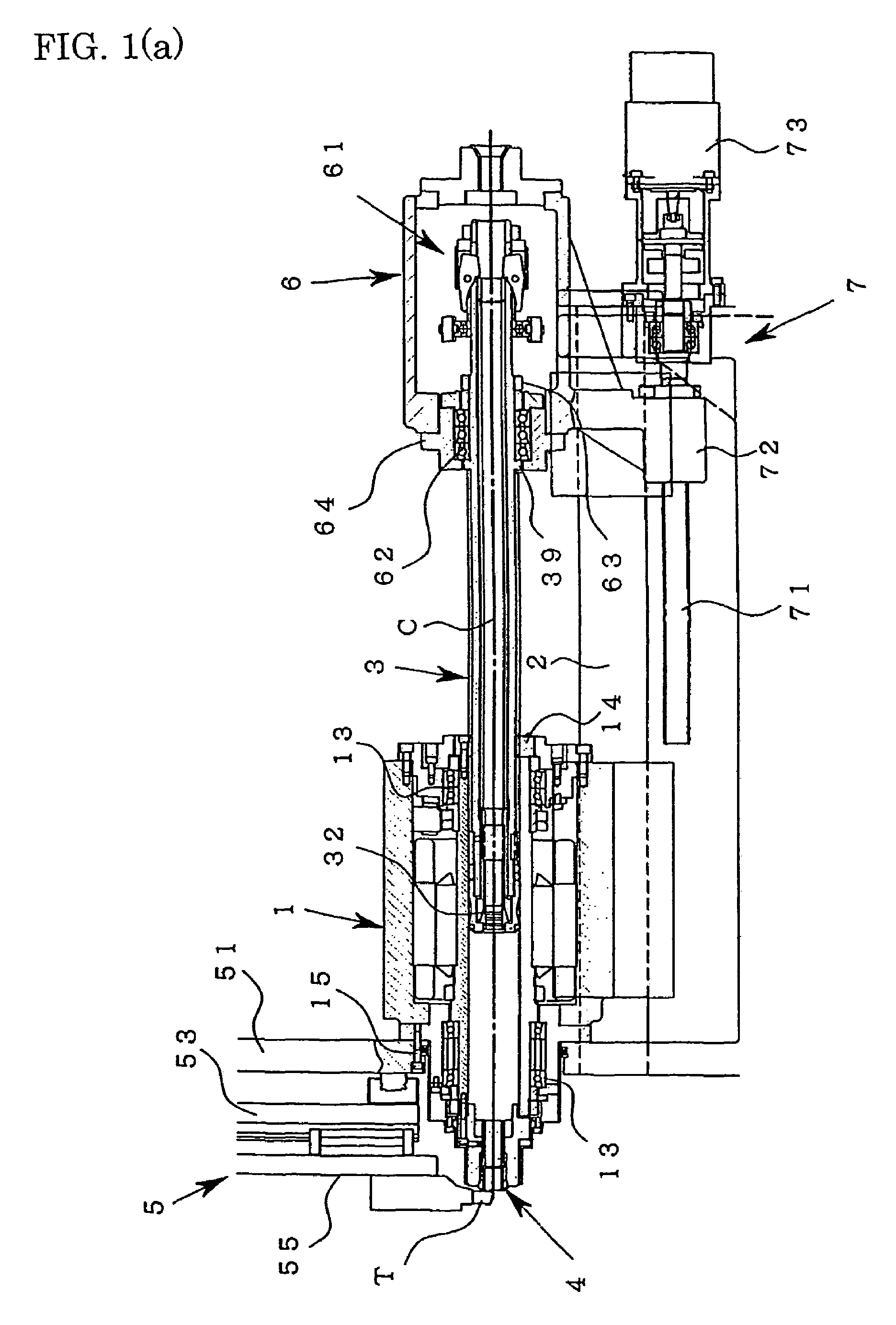

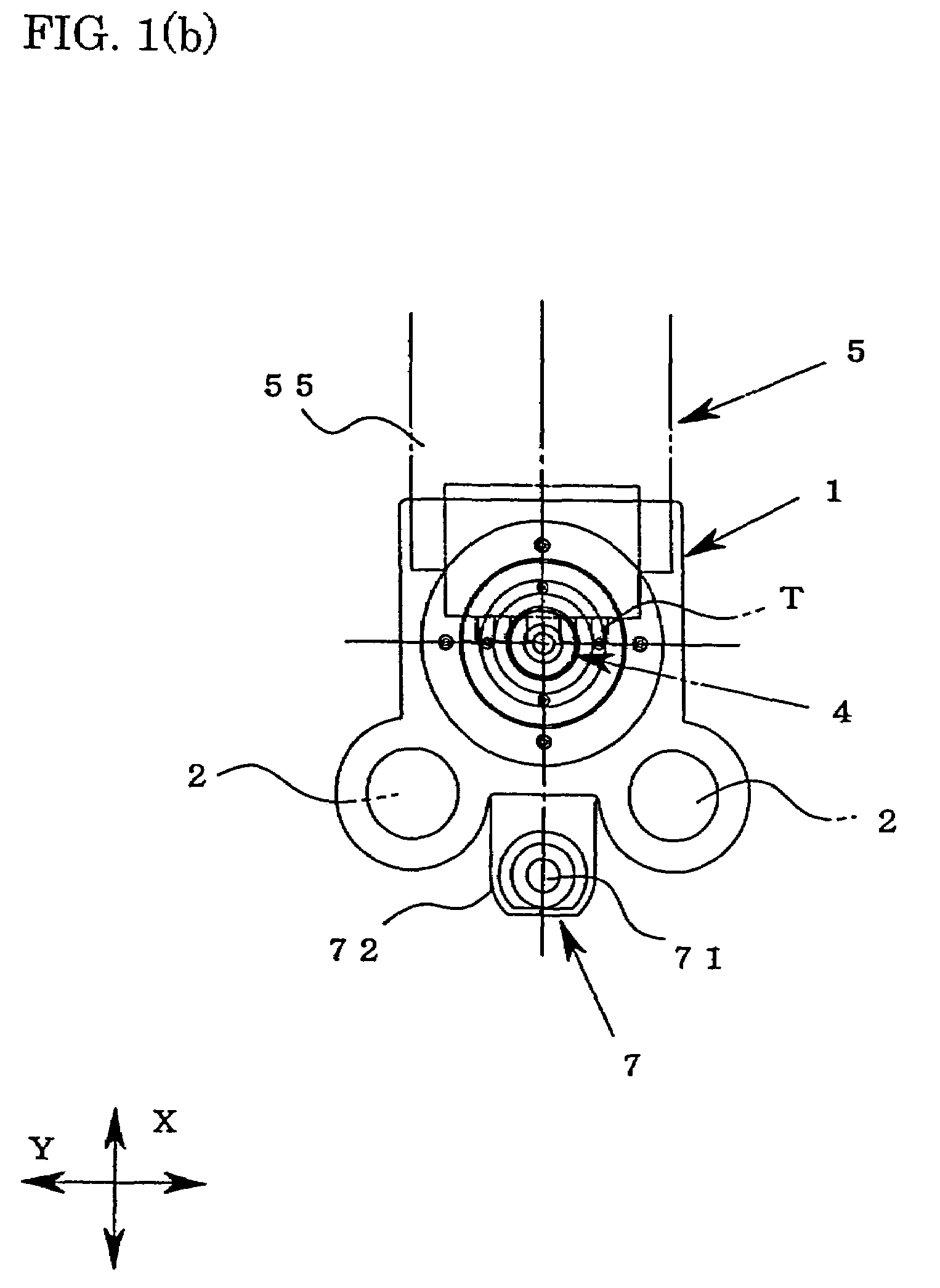

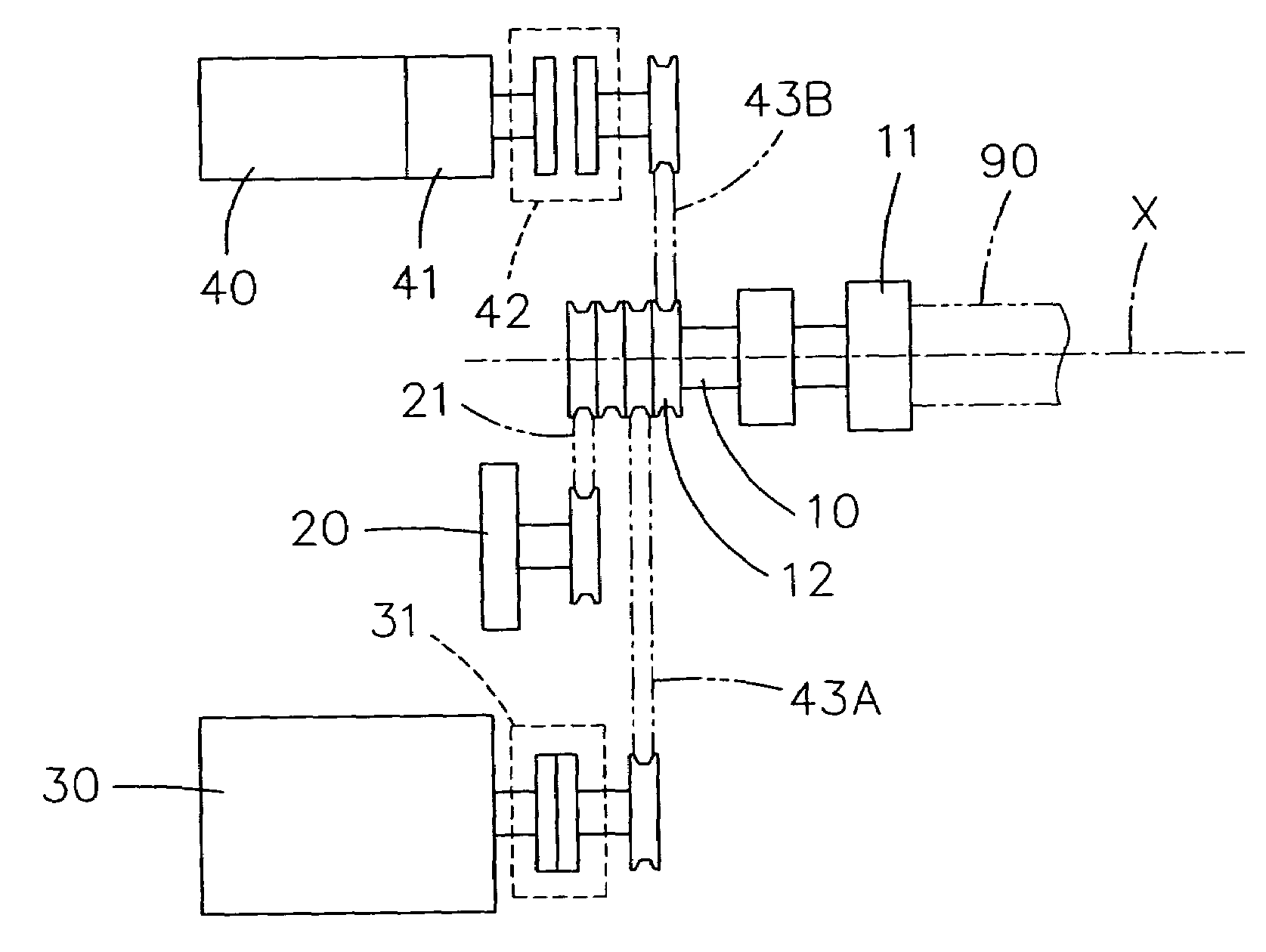

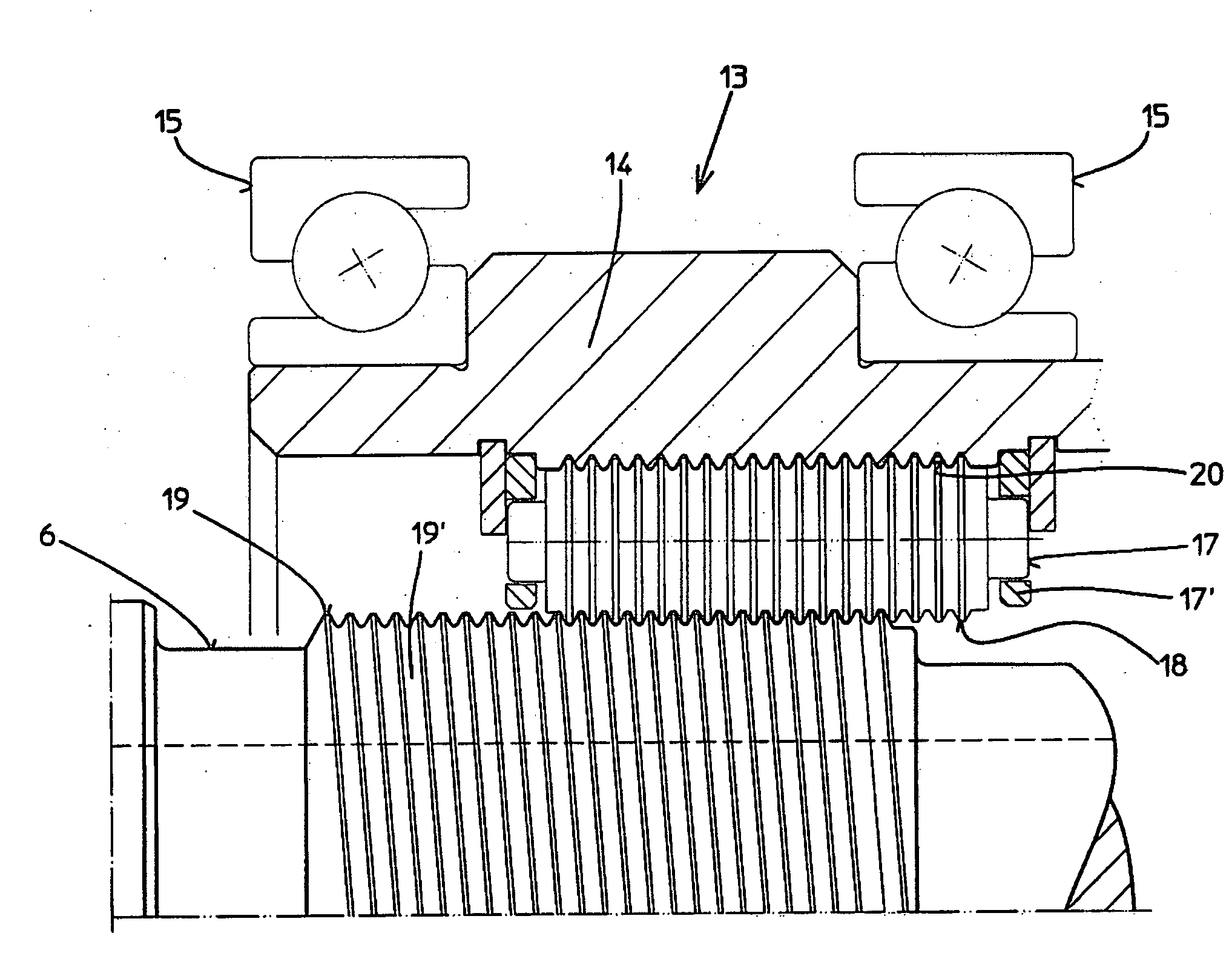

Automatic Lathe

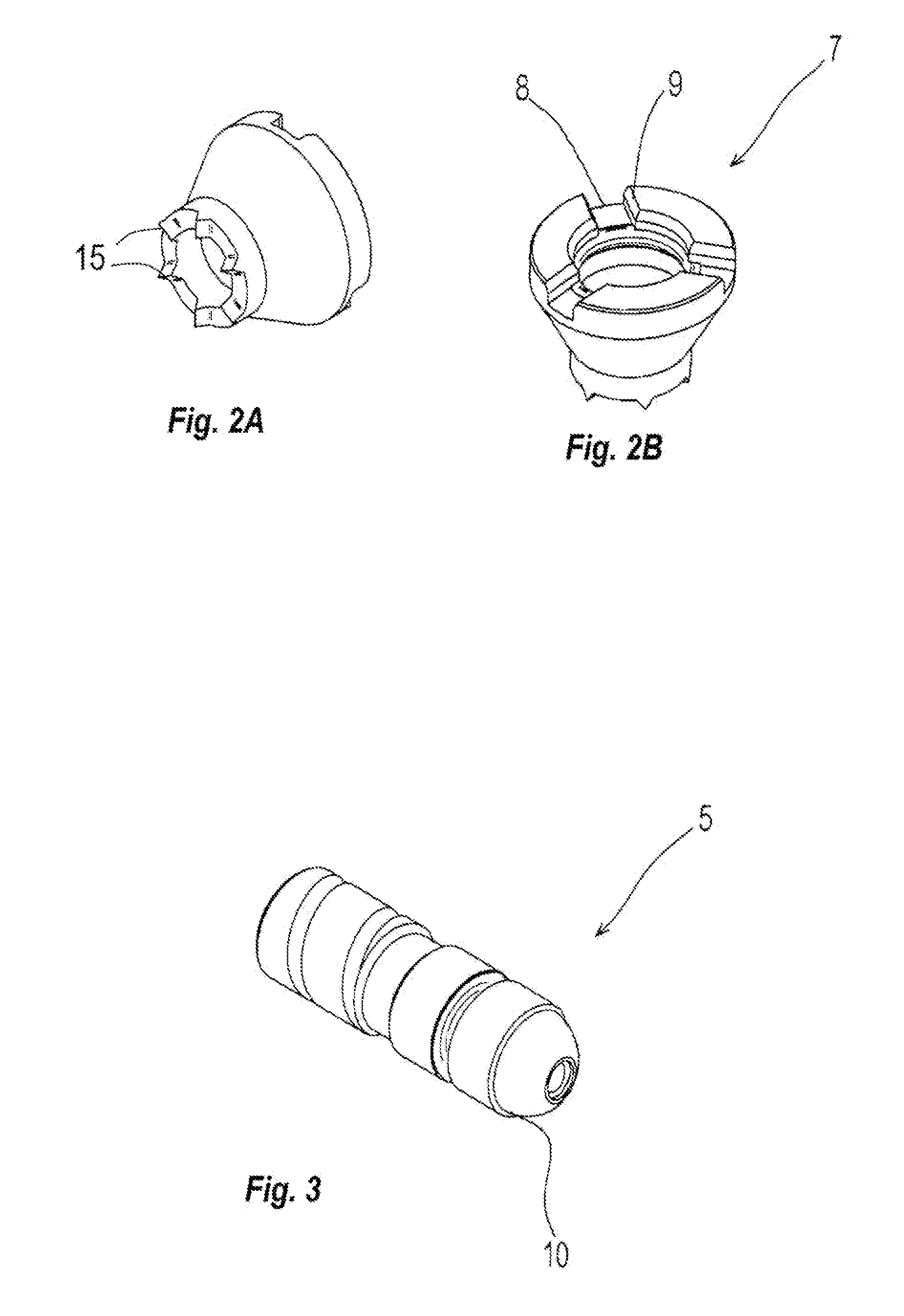

InactiveUS20070227317A1Easily fitted/removedReduce equipment costsAutomatic/semiautomatic turning machinesAutomatic conveying/guiding stockMaterials processingMachining

An automatic lathe is provided which is capable of rapidly and easily switching between machining of a material with a guide bush and machining of the material without the guide bush. The automatic lathe has a guide bush support table (1) disposed closer to a tip side of a spindle (3) than a head stock (6); support table fixing means (15) for fixing the guide bush support table (1); a guide member (12) rotatably installed on the guide bush support table (1) so as not to move forward and backward; a guide bush (4) detachably fitted to the tip of the guide member (12); driving means (11) for rotating the guide bush (4); rotation transmission means (14a) and (31) for transmitting the rotation of the guide member (12) to the spindle (3); spindle moving means (7) for moving the spindle (3) forward and backward within the guide member (12); and spindle fixing means (17), (36) and (38) for positioning and fixing the spindle (3) at a specified position on the guide bush support table (1) when the guide bush (4) is removed from the guide member (12).

Owner:CITIZEN WATCH CO LTD

Automatic Lathe

InactiveUS20070224007A1Easily fitted/removedReduce equipment costsLathesThread cutting toolsDrive motorMaterials processing

An automatic lathe is provided which is capable of rapidly and easily switching between machining of a material with a guide bush and machining of the material without the guide bush. The automatic lathe has a head stock (6) and a guide bush support table (1). The head stock (6) is provided with a spindle drive motor (8). The guide bush support table (1) is provided with a guide bush rotating motor (11). There are provided: support table fixing means (15) for positioning and fixing the guide bush support table (1); a guide member (12) rotatably installed on the guide bush support table (1) and regulated so as not to move forward and backward and having a through-hole formed for a spindle (3) to be inserted therein; a guide bush (4) detachably fitted to the tip of the guide member (12); and spindle fixing means (37) for positioning and fixing the spindle (3) on the guide bush support table (1) at a specified position when the guide bush (4) is removed from the guide member (12).

Owner:CITIZEN WATCH CO LTD

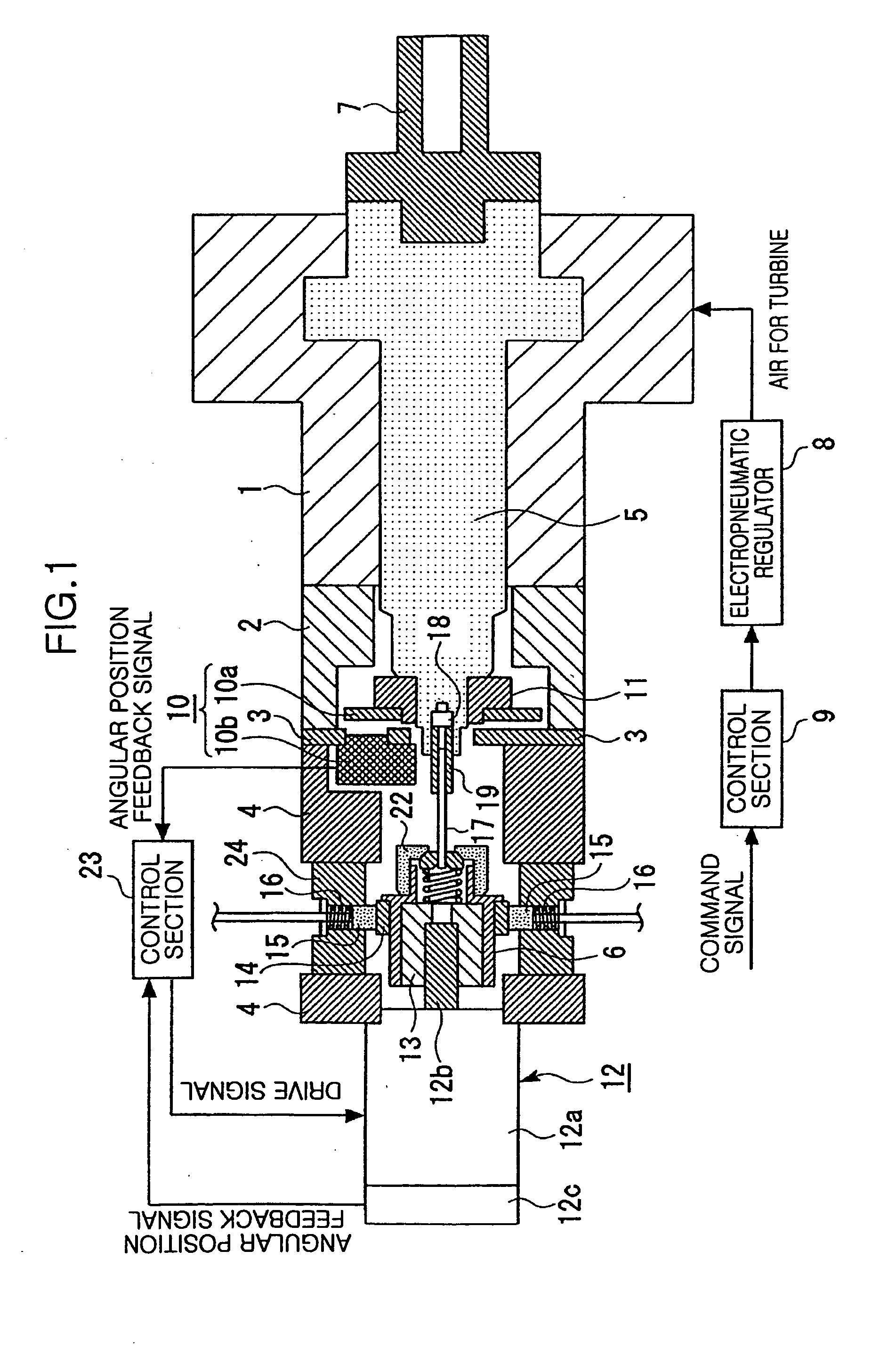

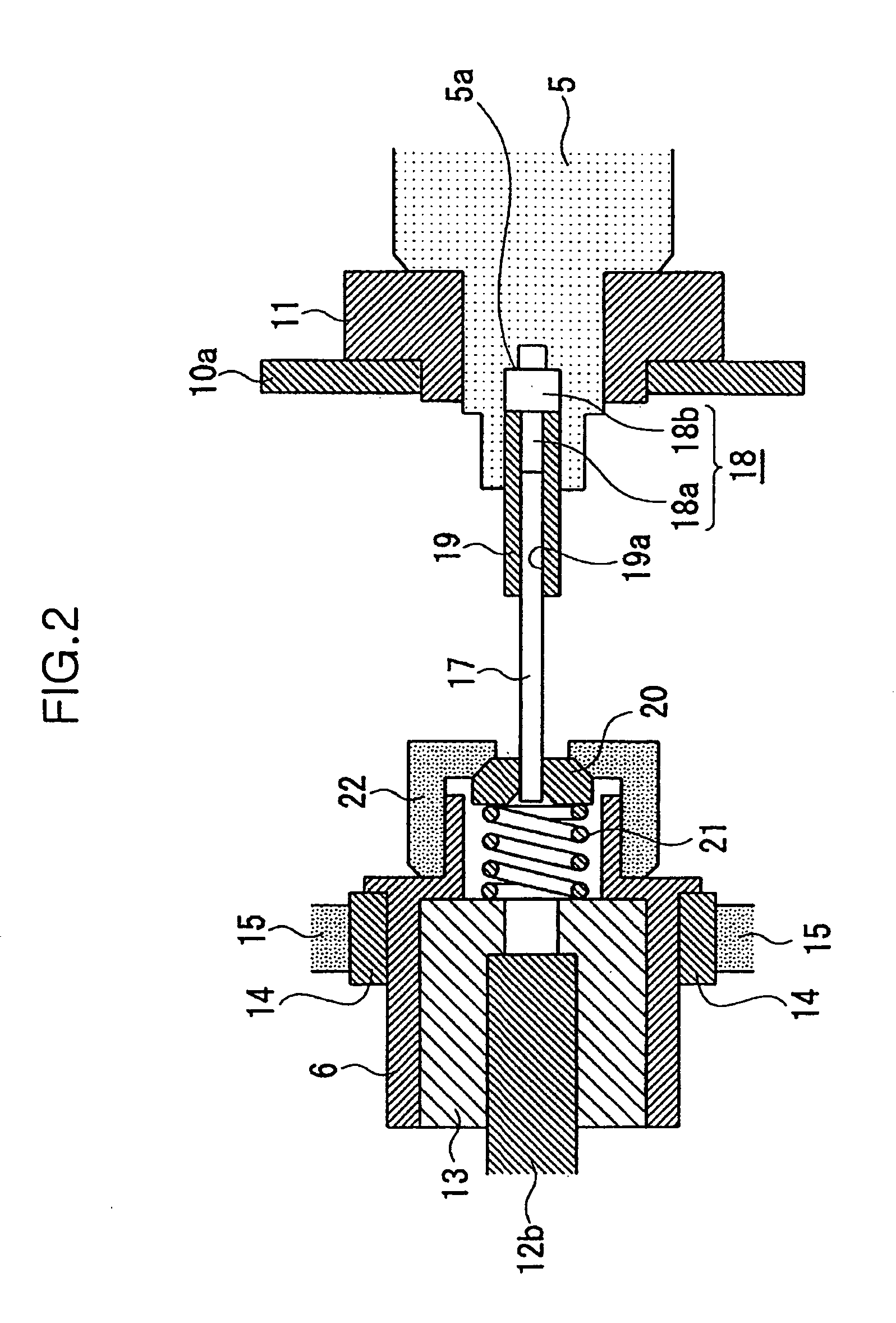

Spindle Apparatus

ActiveUS20090133546A1Improve accuracyReduce vibrationLathesAuxillary equipmentCoil springElectrical connection

A spindle apparatus includes a rotatable first spindle (5, 32) to which a tool can be attached. The first spindle is supported in a base with high precision using an air hydrostatic bearing. The spindle apparatus further includes a second spindle (6, 33) capable of rotation about an axis substantially aligned with the axis of the first spindle, first connection means for electrically connecting a base side and the second spindle, and second connection means for electrically connecting the first spindle and the second spindle. Electrical connection between the base side and the first spindle is carried out via the first and second connection means. The first connection means is, for example, a brush (15, 36). The second connection means has a degree of mechanical freedom and is, for example, a flexible electrical wire (17, 39) or a helical spring (51).

Owner:SODICK CO LTD

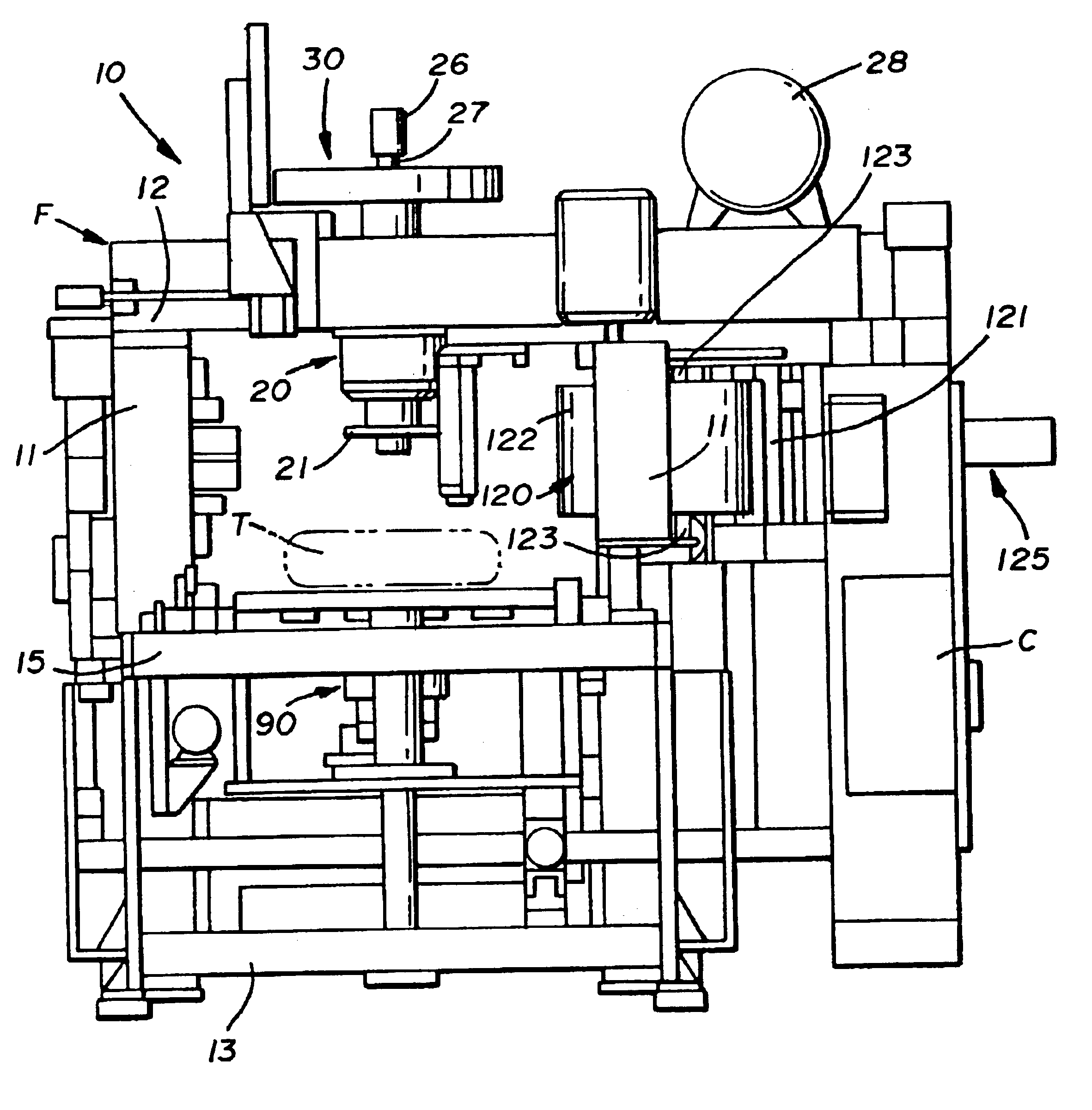

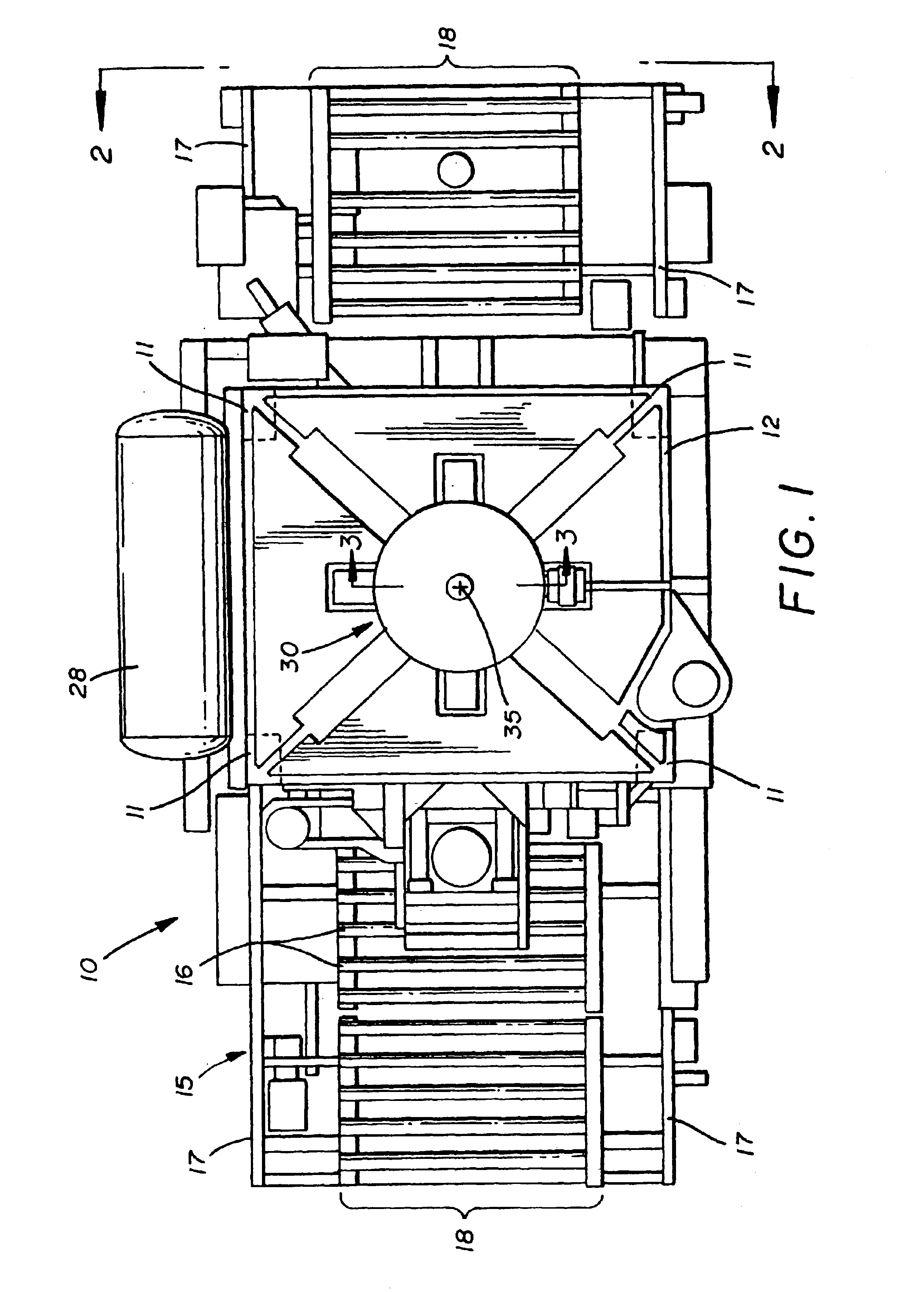

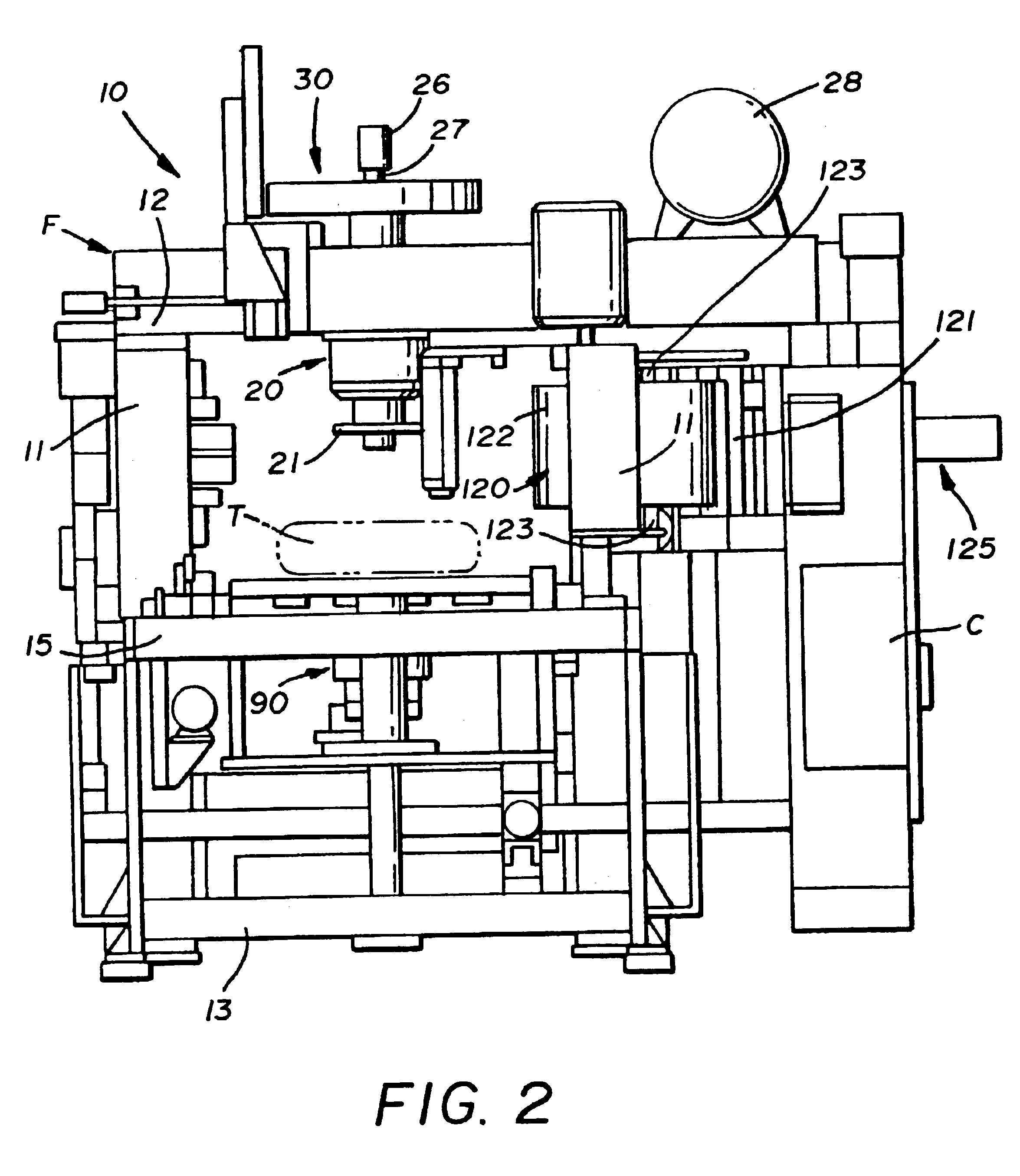

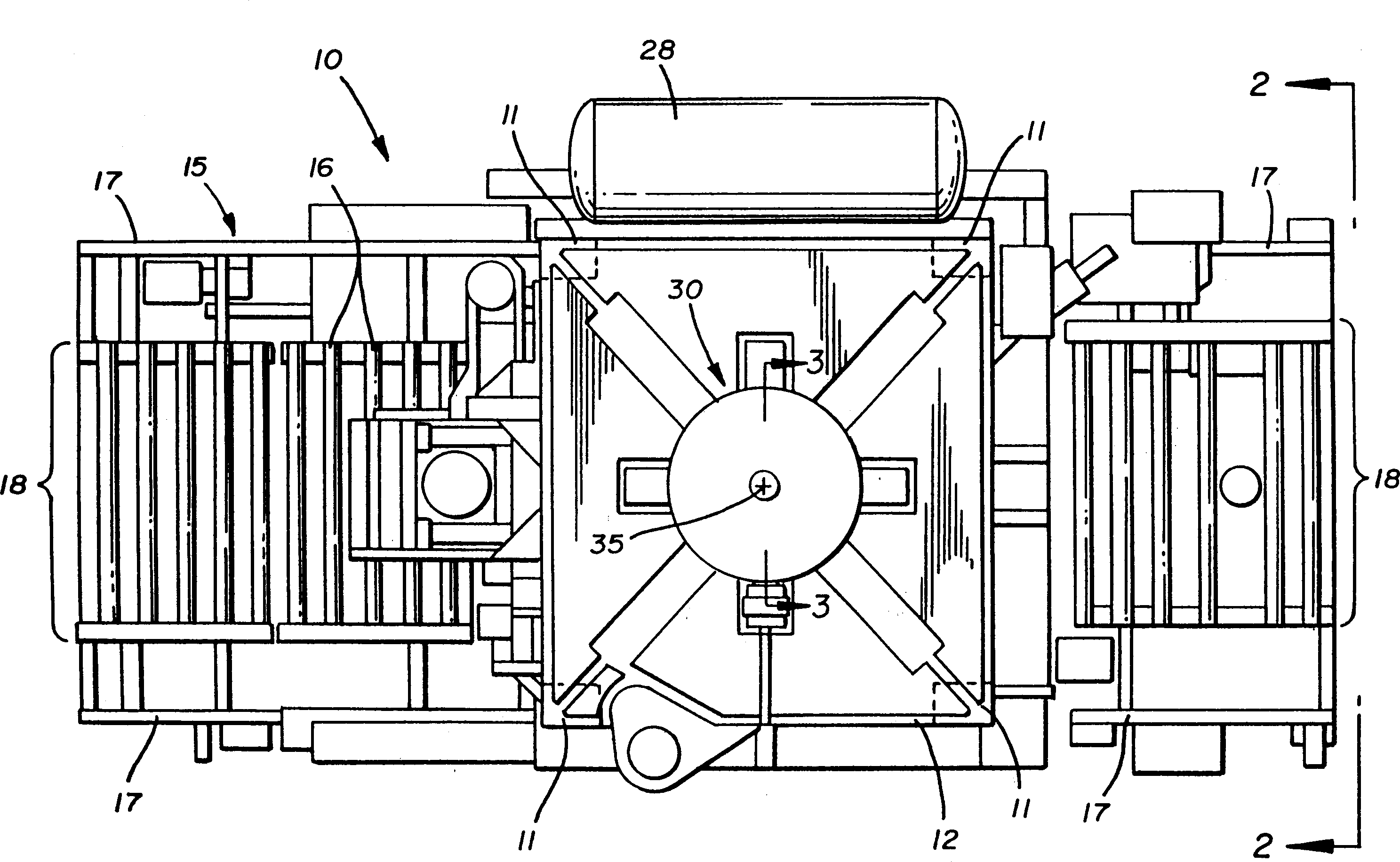

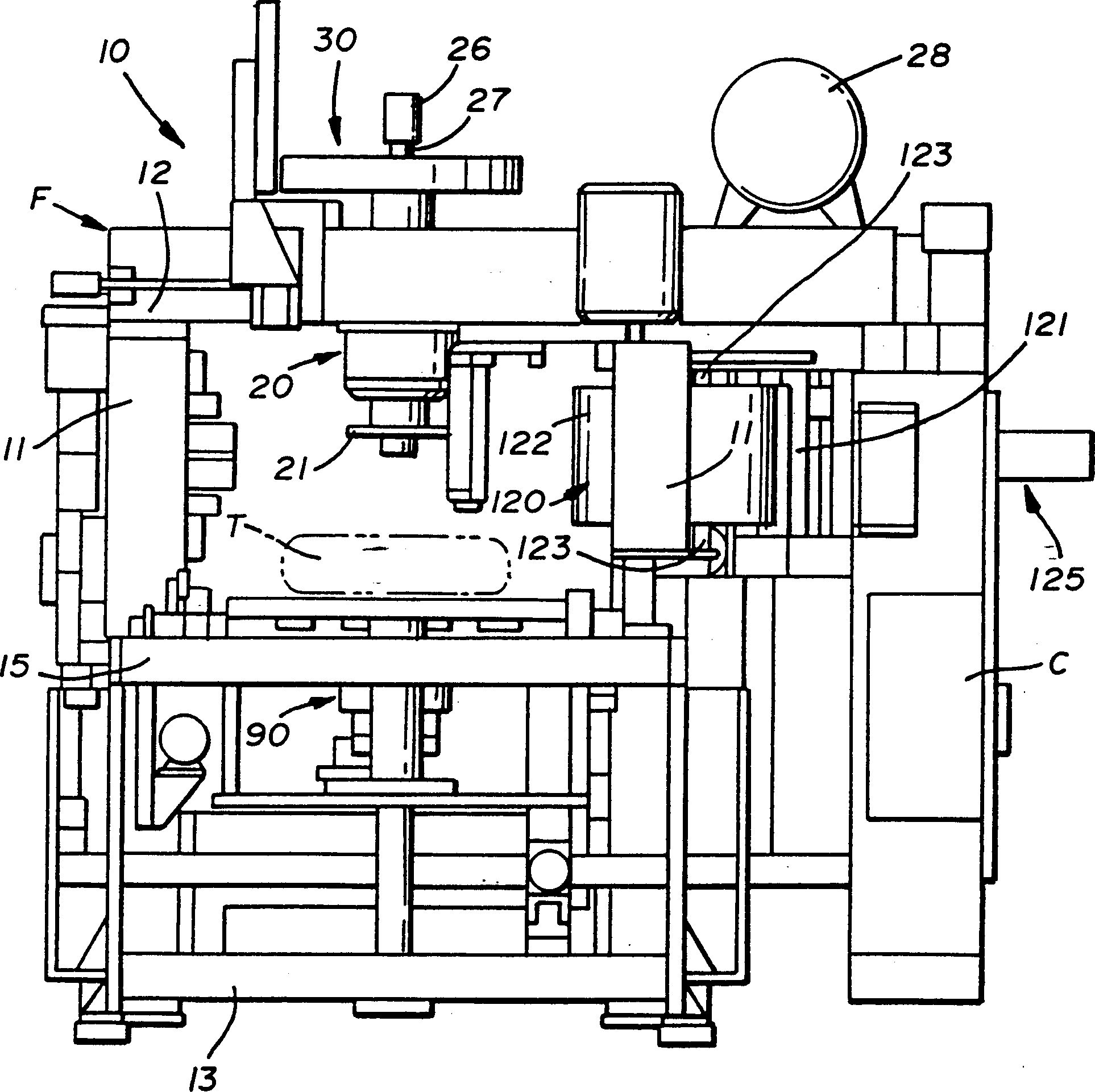

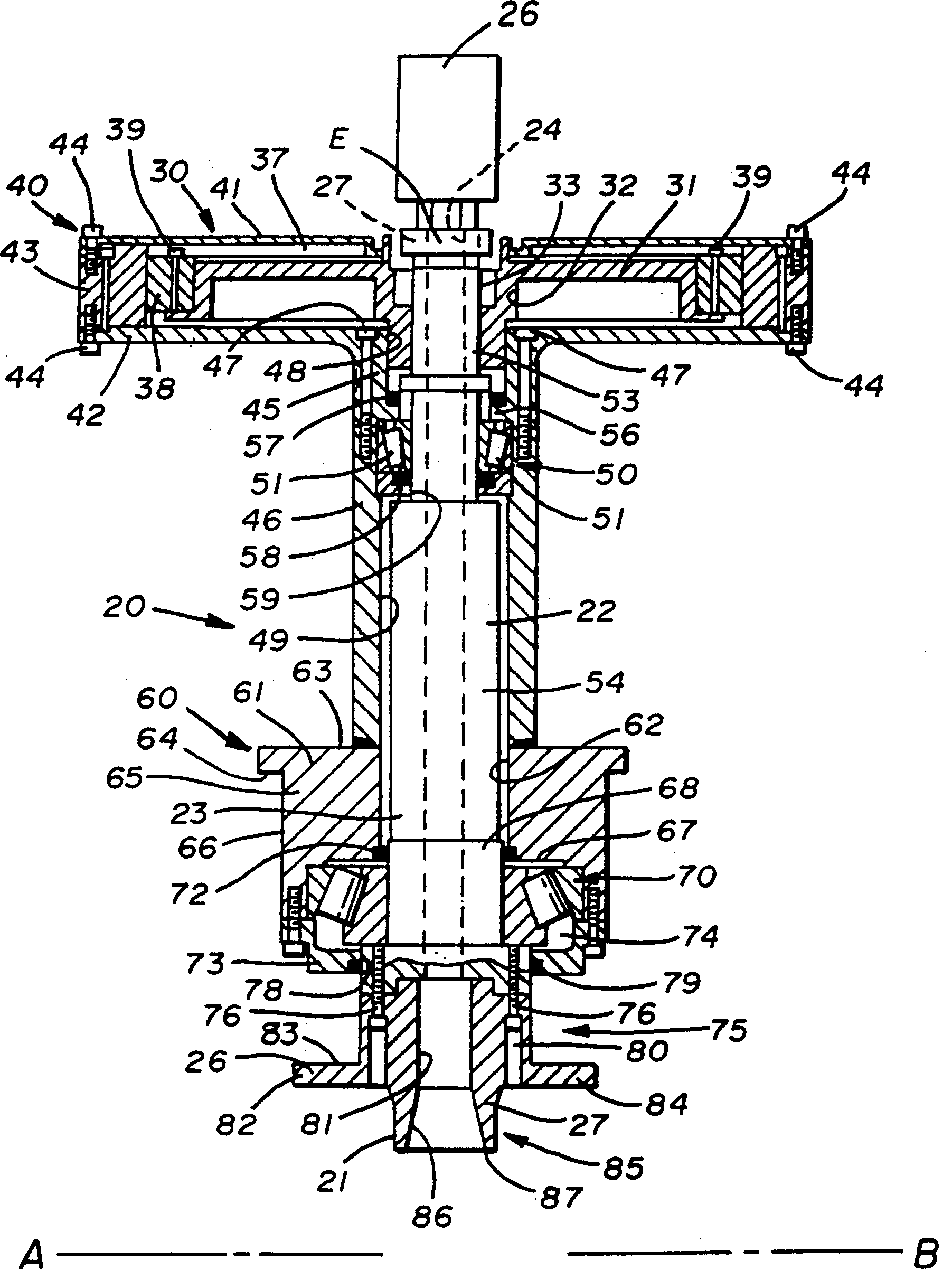

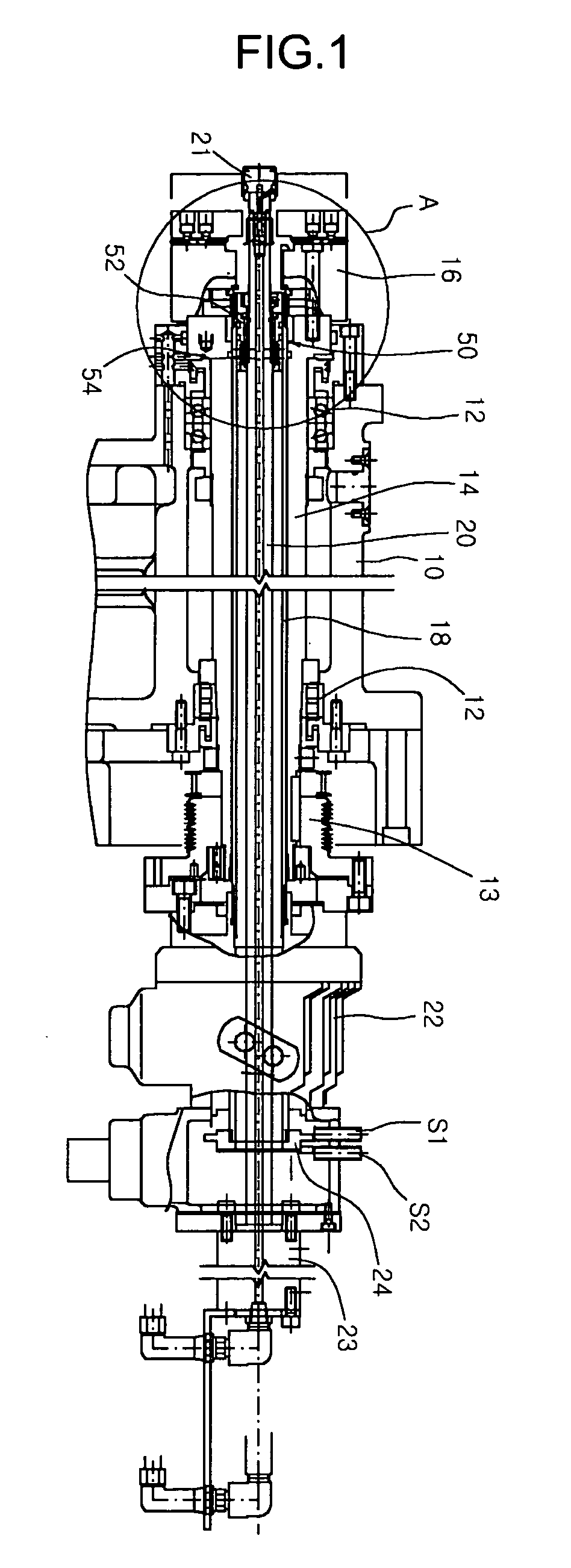

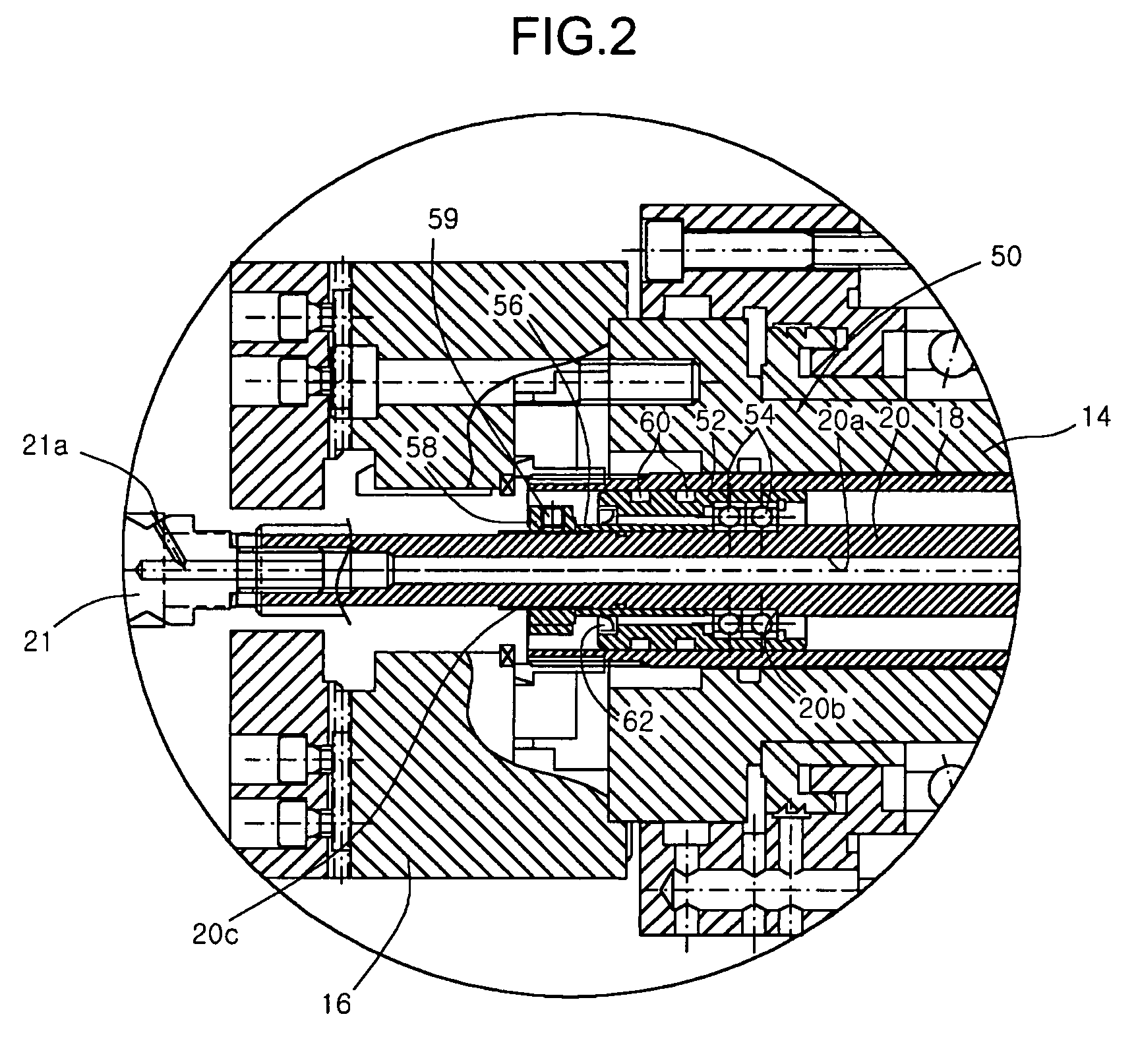

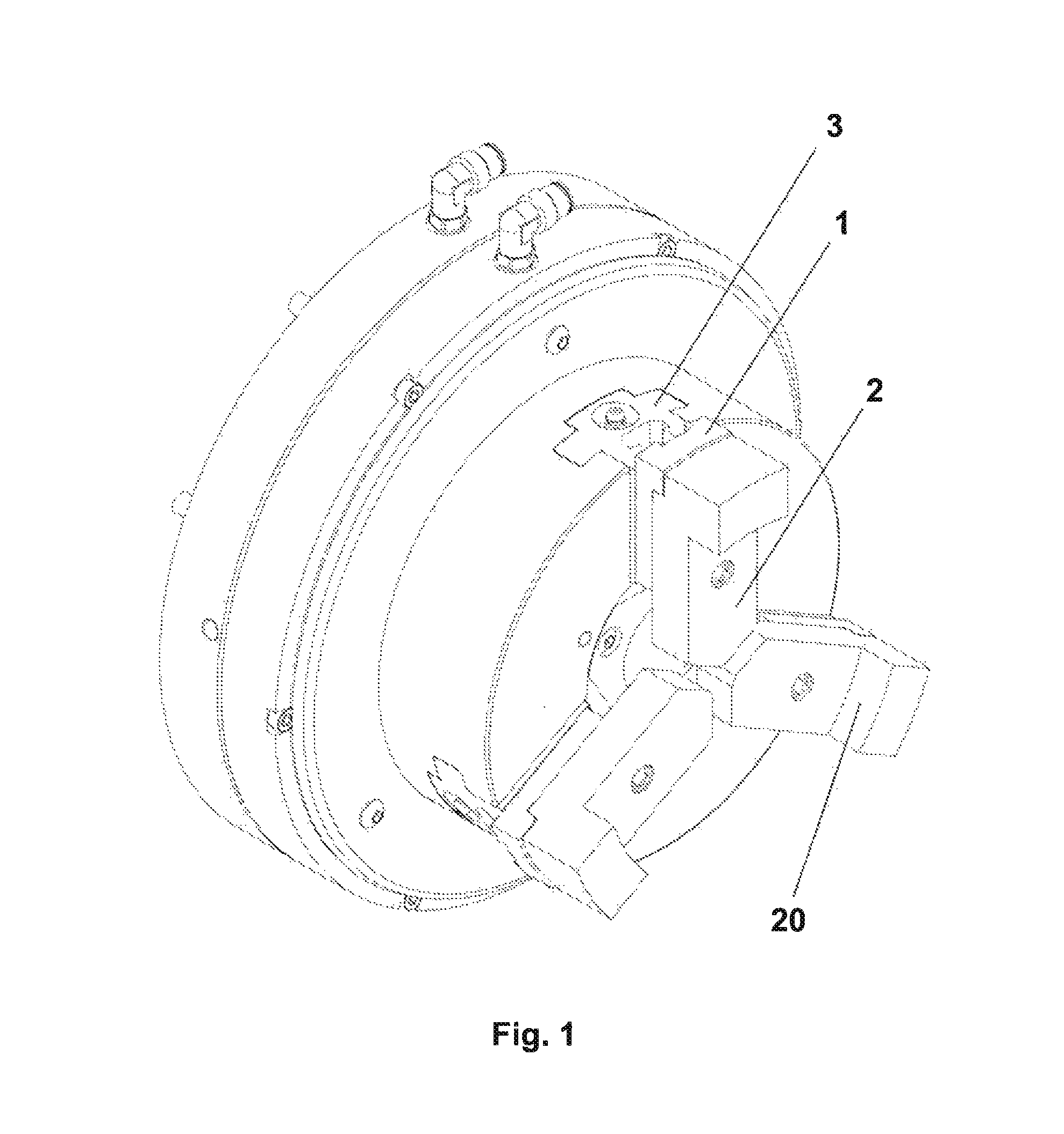

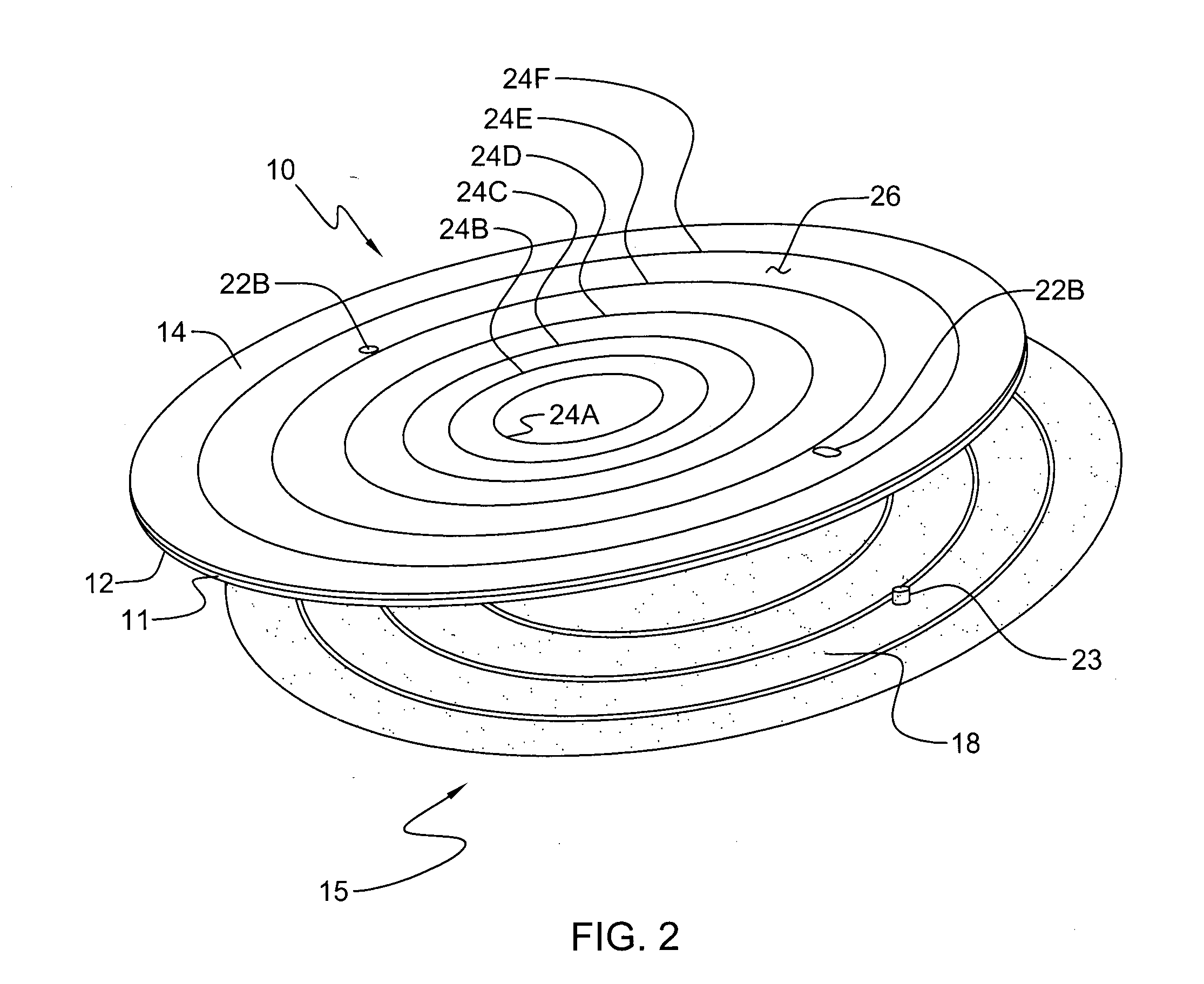

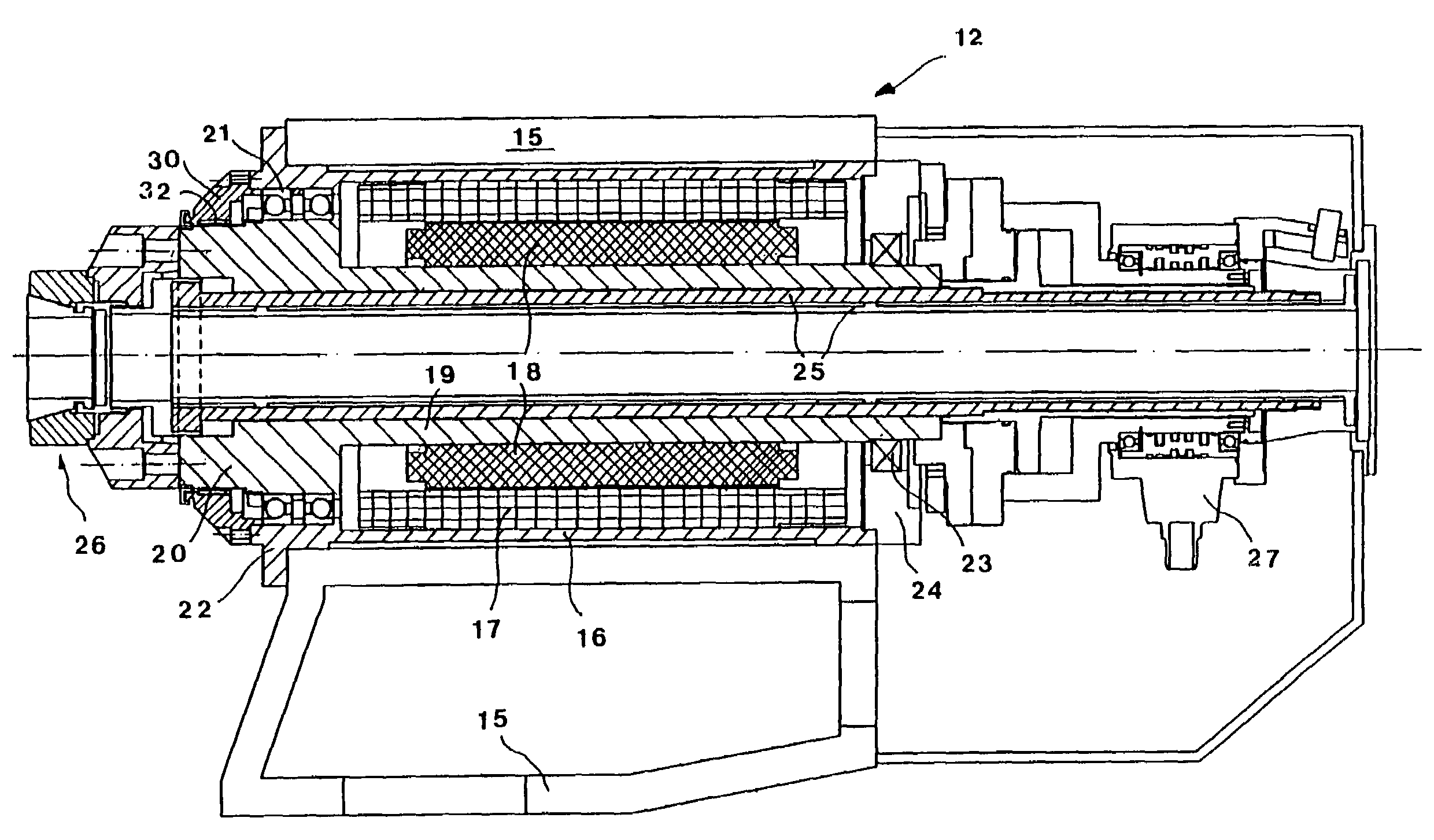

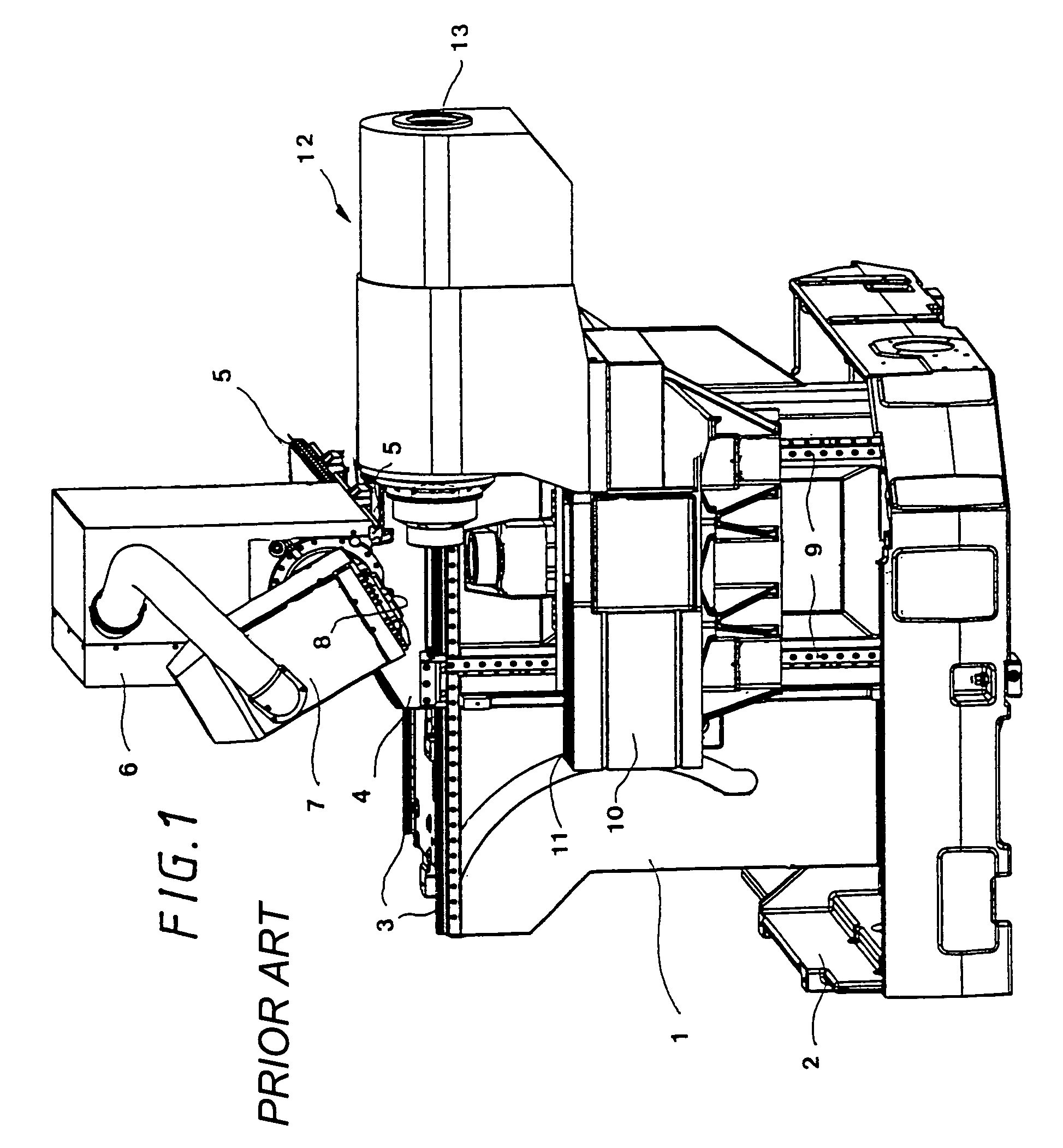

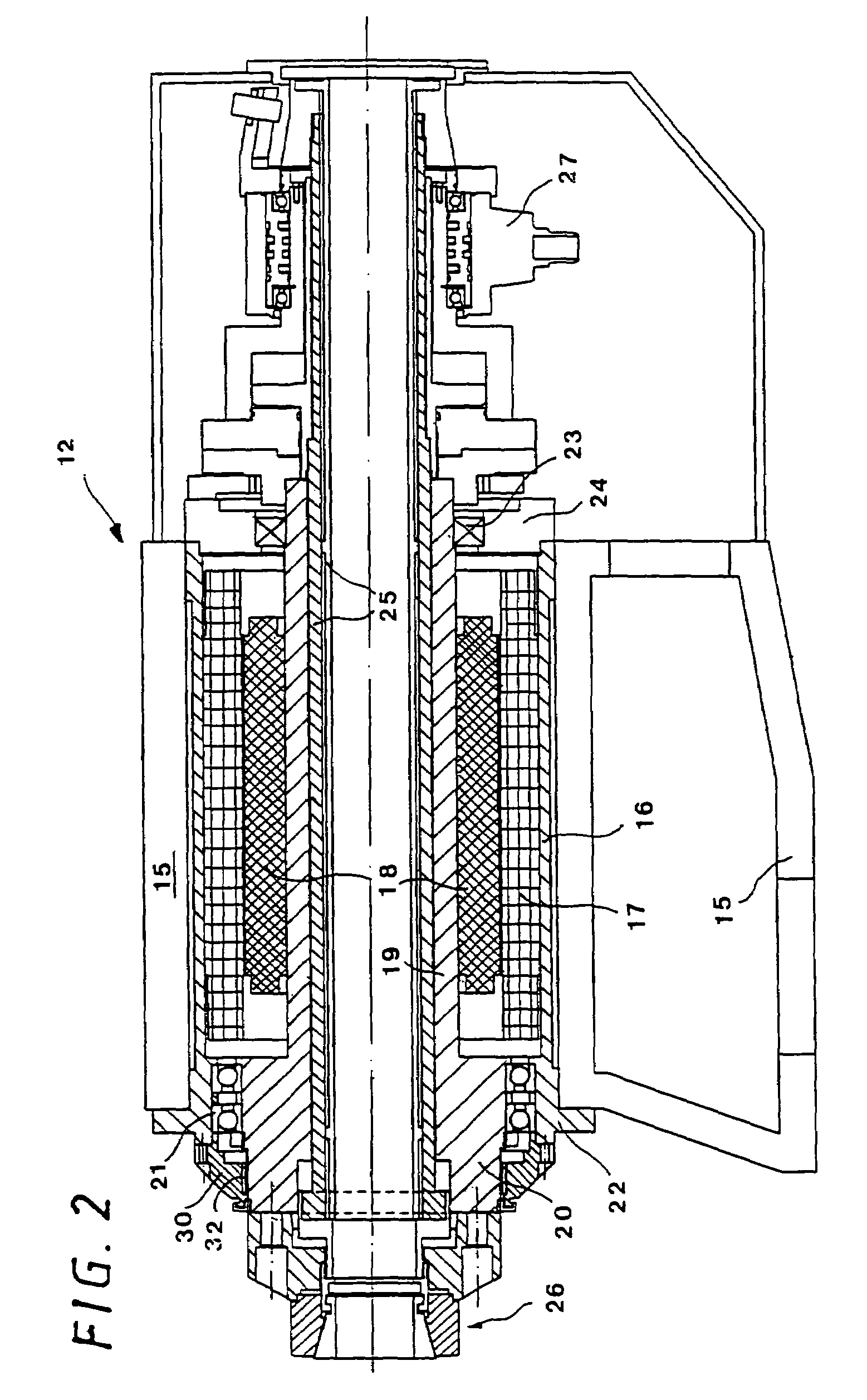

Tire uniformity machine drive assembly

A tire uniformity machine having a framework for receiving a tire to be tested, a rotatable chuck located within the framework and having a spindle driven by a motor directly coupled to the spindle to selectively cause rotation thereof, whereby the tire is chucked within the chuck assembly and caused to rotate by the motor. The motor is disposed in axial alignment with the spindle.

Owner:AKRON SPECIAL MACHINERY

Driver for tyre homogeneity testing instrument

A tire uniformity testing machine having a frame for receiving a tire to be tested, a rotatable chuck located in the frame, and a spindle directly driven by a motor connected to the spindle so that the tire is clamped It is held in the chuck assembly and rotated by the motor. The motor is arranged axially aligned with the mandrel.

Owner:AKRON SPECIAL MACHINERY

Automatic lathe

InactiveUS7464628B2Improve mechanical rigidityHigh precision machiningLathesThread cutting toolsEngineeringDrive motor

An automatic lathe is provided which is capable of rapidly and easily switching between machining of a material with a guide bush and machining of the material without the guide bush. The automatic lathe has a head stock (6) and a guide bush support table (1). The head stock (6) is provided with a spindle drive motor (8). The guide bush support table (1) is provided with a guide bush rotating motor (11). There are provided: support table fixing means (15) for positioning and fixing the guide bush support table (1); a guide member (12) rotatably installed on the guide bush support table (1) and regulated so as not to move forward and backward and having a through-hole formed for a spindle (3) to be inserted therein; a guide bush (4) detachably fitted to the tip of the guide member (12); and spindle fixing means (37) for positioning and fixing the spindle (3) on the guide bush support table (1) at a specified position when the guide bush (4) is removed from the guide member (12).

Owner:CITIZEN WATCH CO LTD

Automatic lathe

InactiveUS7555973B2Improve mechanical rigidityHigh precision machiningAutomatic/semiautomatic turning machinesAutomatic conveying/guiding stockEngineeringMechanical engineering

An automatic lathe is capable of rapidly and easily switching between machining of a material with a guide bush and machining of the material without the guide bush. The automatic lathe has a guide bush support table, a support table fixing device for fixing the guide bush support table, a guide member rotatably installed on the guide bush support table so as not to move forward and backward, a guide bush detachably fitted to the tip of the guide member, a driving device for rotating the guide bush, a rotation transmission device for transmitting the rotation of the guide member to the spindle, and a spindle moving device for moving the spindle forward and backward within the guide member. A spindle fixing device positions and fixes the spindle at a specified position on the guide bush support table when the guide bush is removed from the guide member.

Owner:CITIZEN WATCH CO LTD

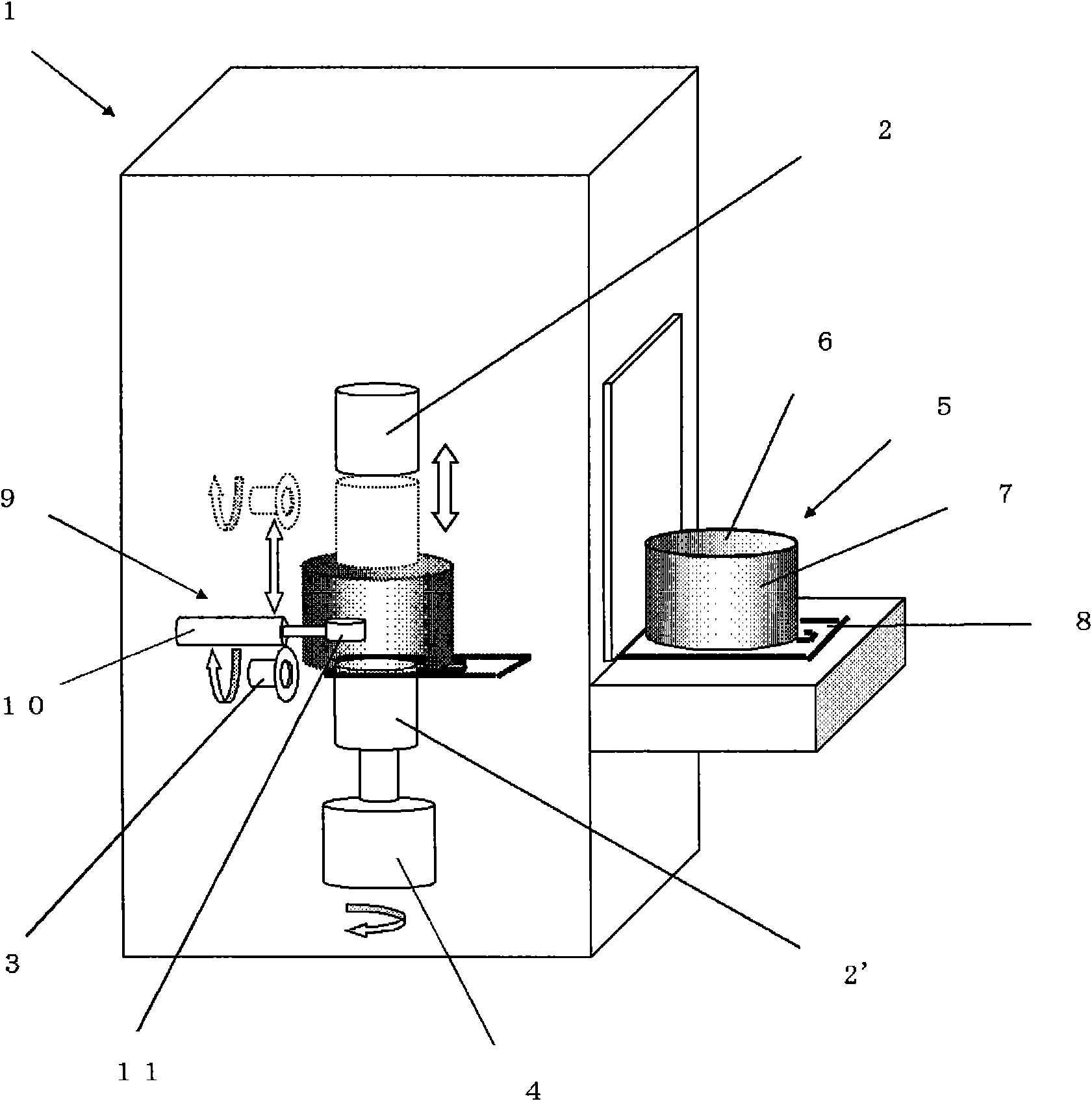

Cylindrical grinding apparatus and method for grinding

ActiveCN101945732AImprove grinding efficiencyReduce processing timeLathesRevolution surface grinding machinesIngotCylindrical grinding

Owner:SHIN-ETSU HANDOTAI CO LTD

C-axis driving device of a computer numerical controlled lathing and milling machine

InactiveUS7155788B1Simple structureIncrease speedLathesPrecision positioning equipmentNumerical controlManufacturing cost reduction

A C-axis driving device of a computer numerical controlled (CNC) lathing and milling machine includes a spindle, an encoder, a spindle motor, and a servo motor. The spindle has a clamping device and a transmission portion. This encoder connects with the transmission portion via an auxiliary timing belt. The spindle motor and the servo motor connect with the transmission portion via at least one driving timing belt. Only at most one of the spindle motor and the servo motor is to drive this transmission portion at any time during operation. So, it has a simple structure to achieve the clutching change function. It can save more space. And, it can significantly reduce the manufacturing cost.

Owner:LEADJECK AUTOMATION

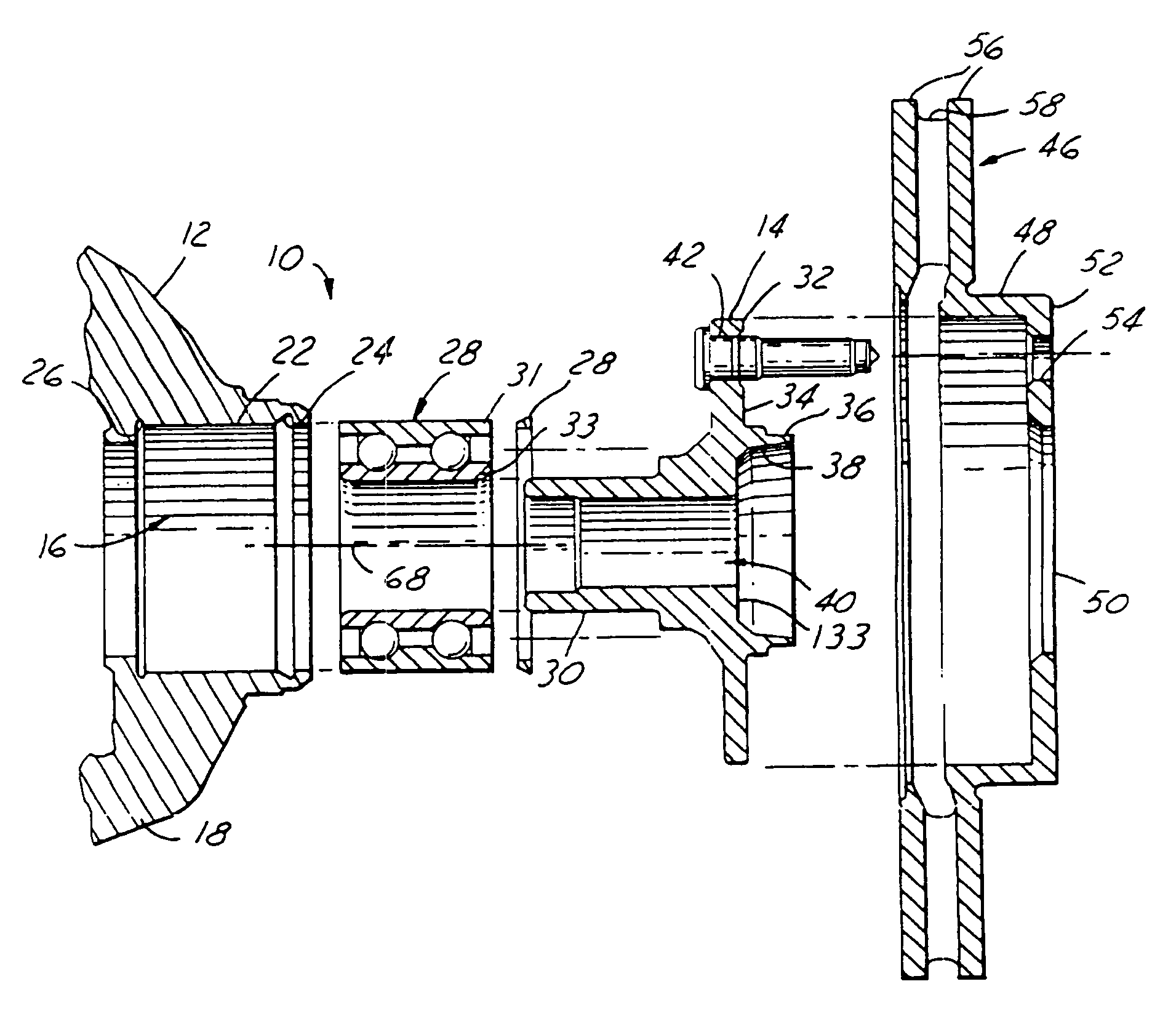

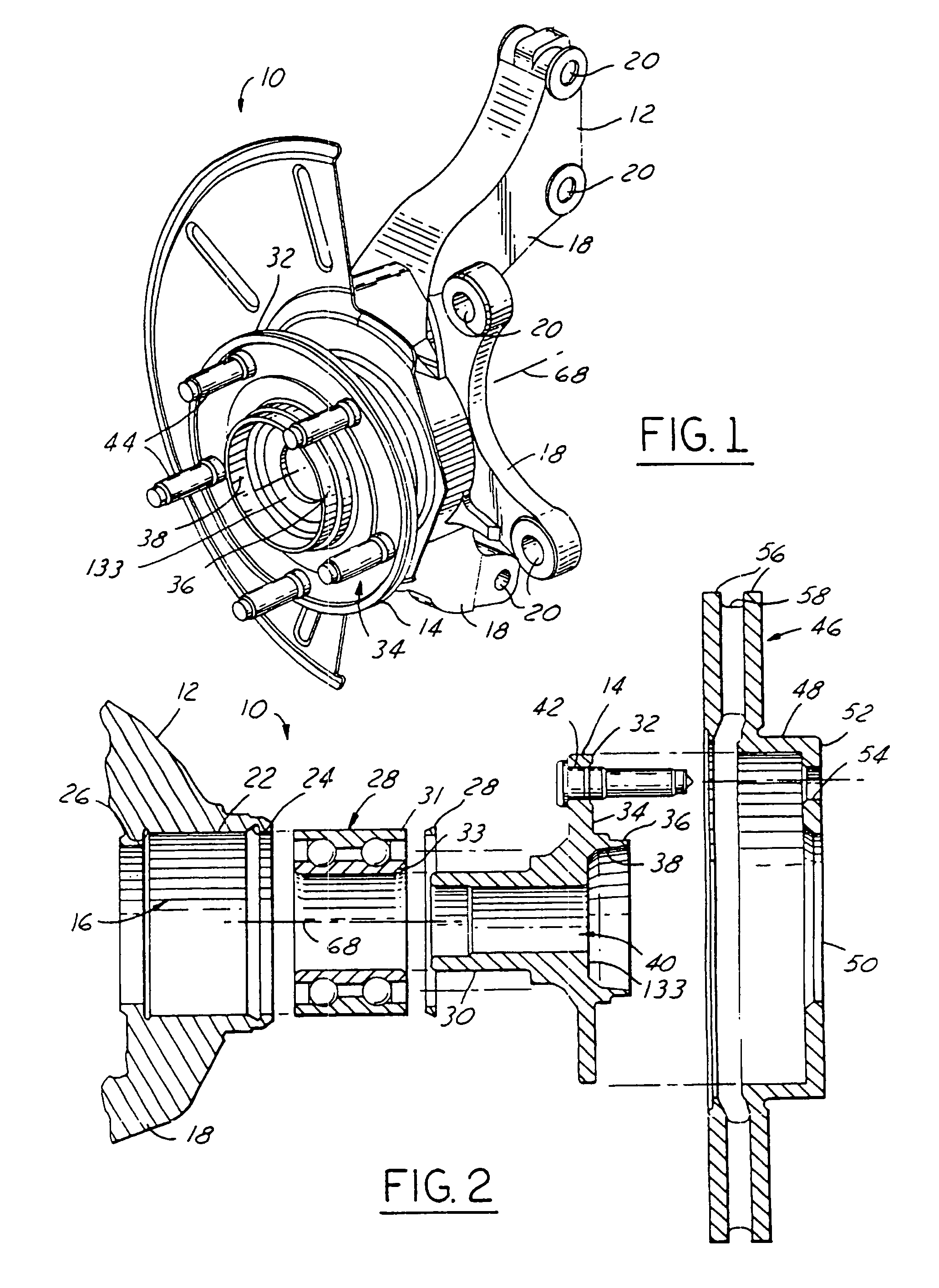

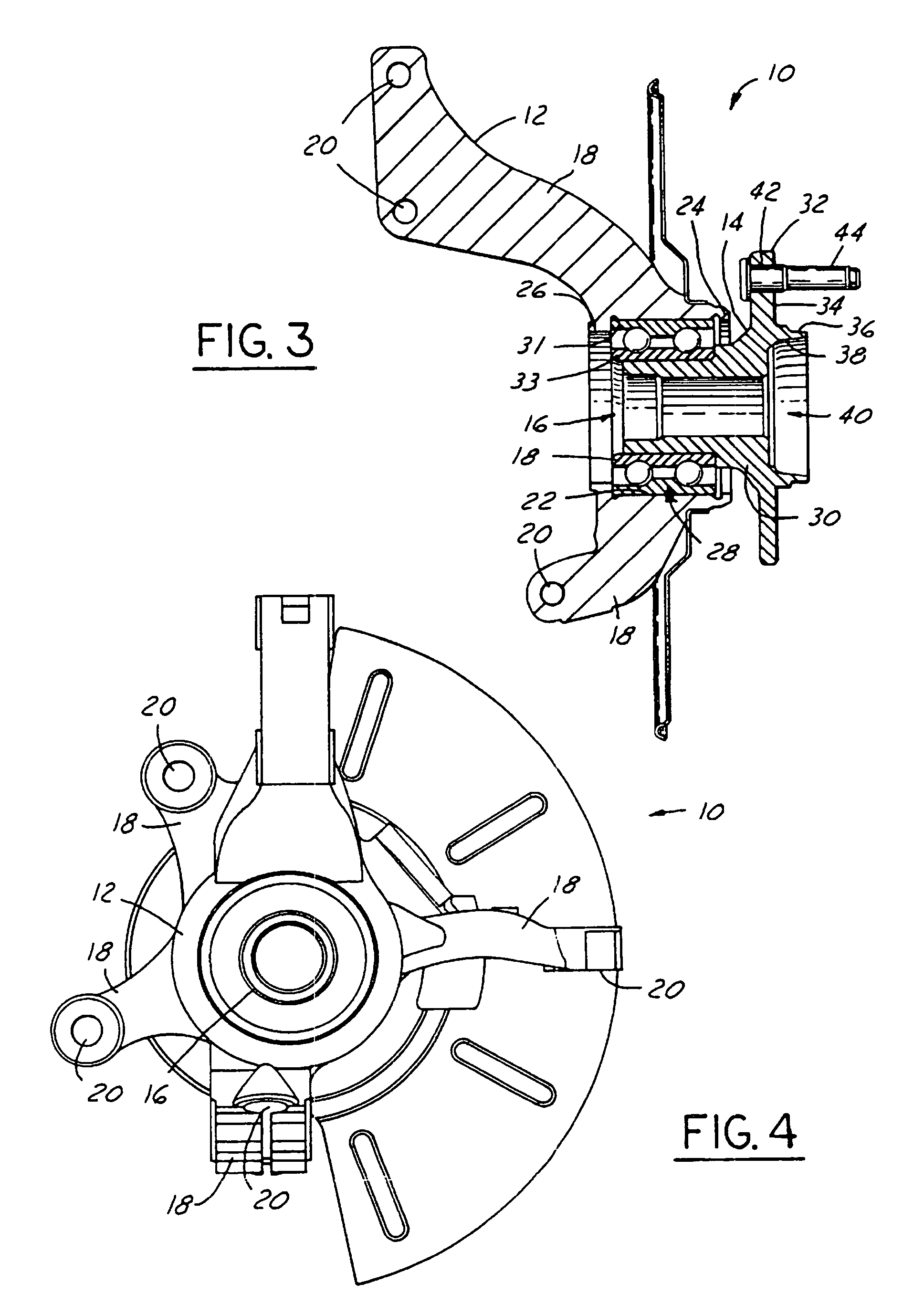

Knuckle hub assembly and method for making same

InactiveUSRE42914E1Reduced wheel hub lateral run-outMinimal run-outSleeve/socket jointsHubsEngineeringFlange

A knuckle hub assembly (10) and a method for manufacturing same whereby brake run out is produced includes a knuckle (12), a bearing (28) press fit into the knuckle (12), and a wheel hub (14) coupled to the bearing (28) and rotateable with respect to the knuckle (12). The wheel hub (14) has a flange surface (34) having a relief channel (60) formed therein. A plurality of wheel studs (44) are press fit into bolt opening (42) formed in the relief channel (60). This arrangement provides a flat flange surface (34) for mating with a rotor (42) to minimize brake run out. The knuckle hub assembly (10) is mounted into a floating tool for finish turning of the flange surface (34) to provide minimal run out and maximum flatness.

Owner:ALUDYNE NORTH AMERICA INC

Workpiece ejecting device for a machine tool

Owner:DN SOLUTIONS CO LTD

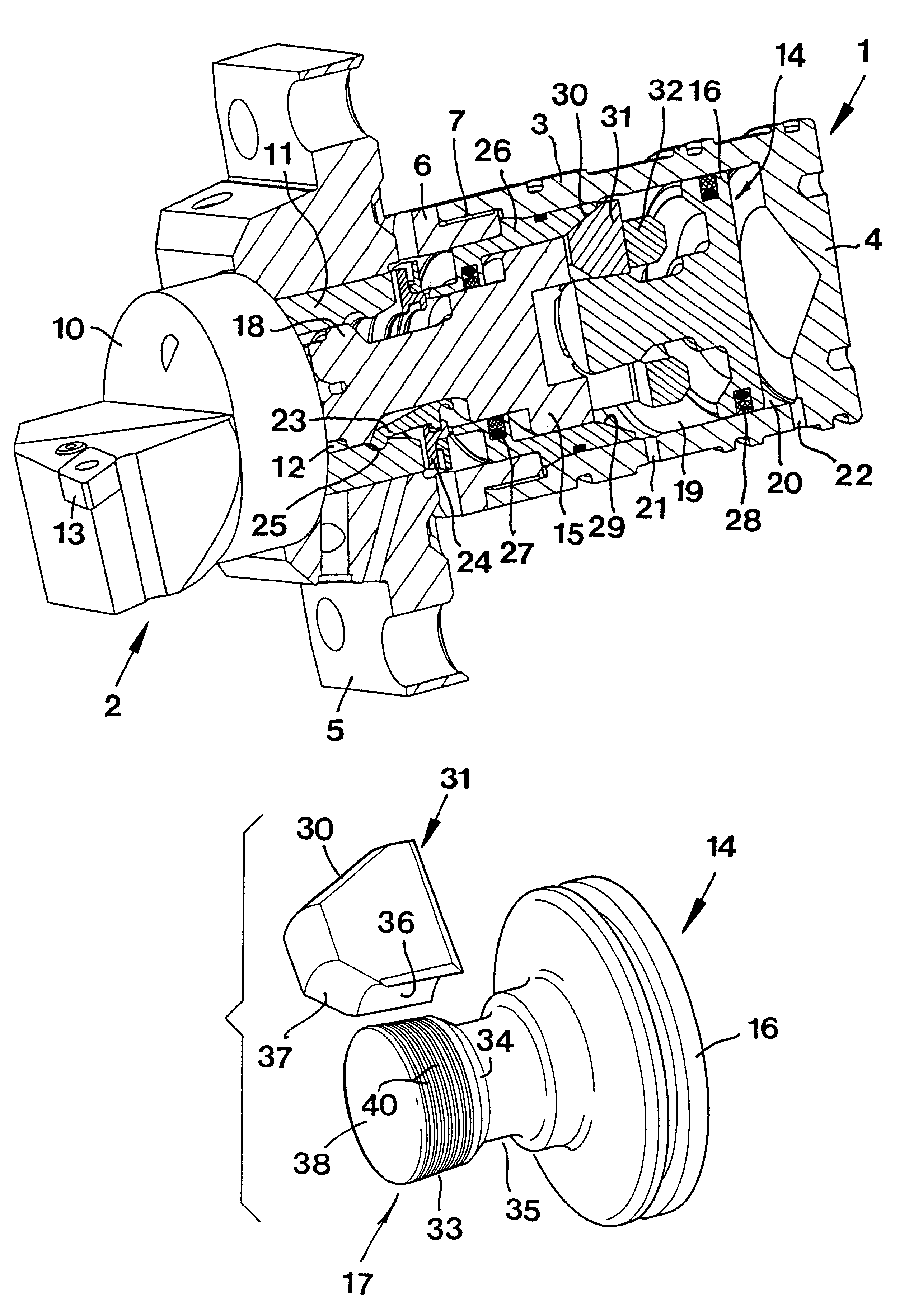

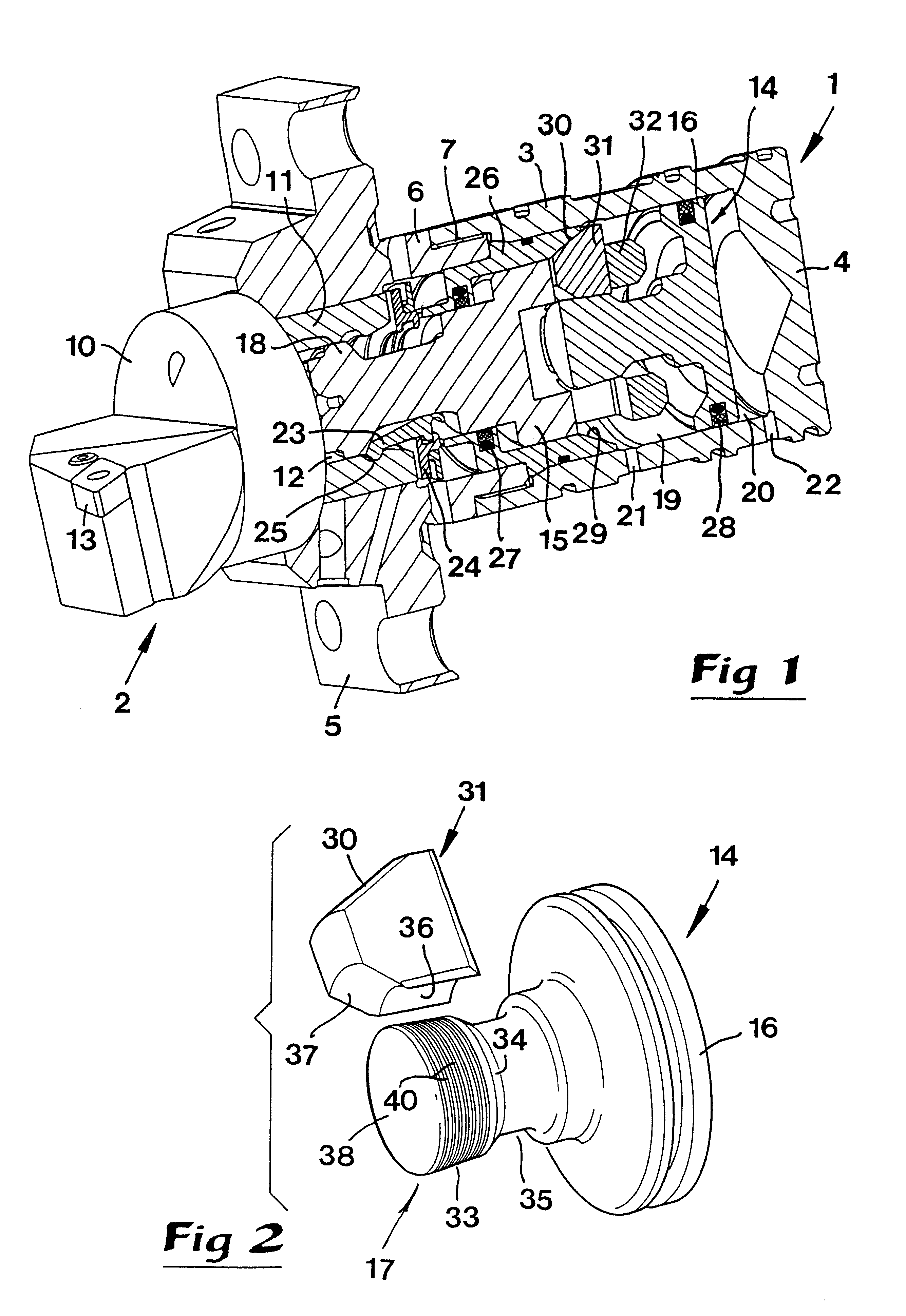

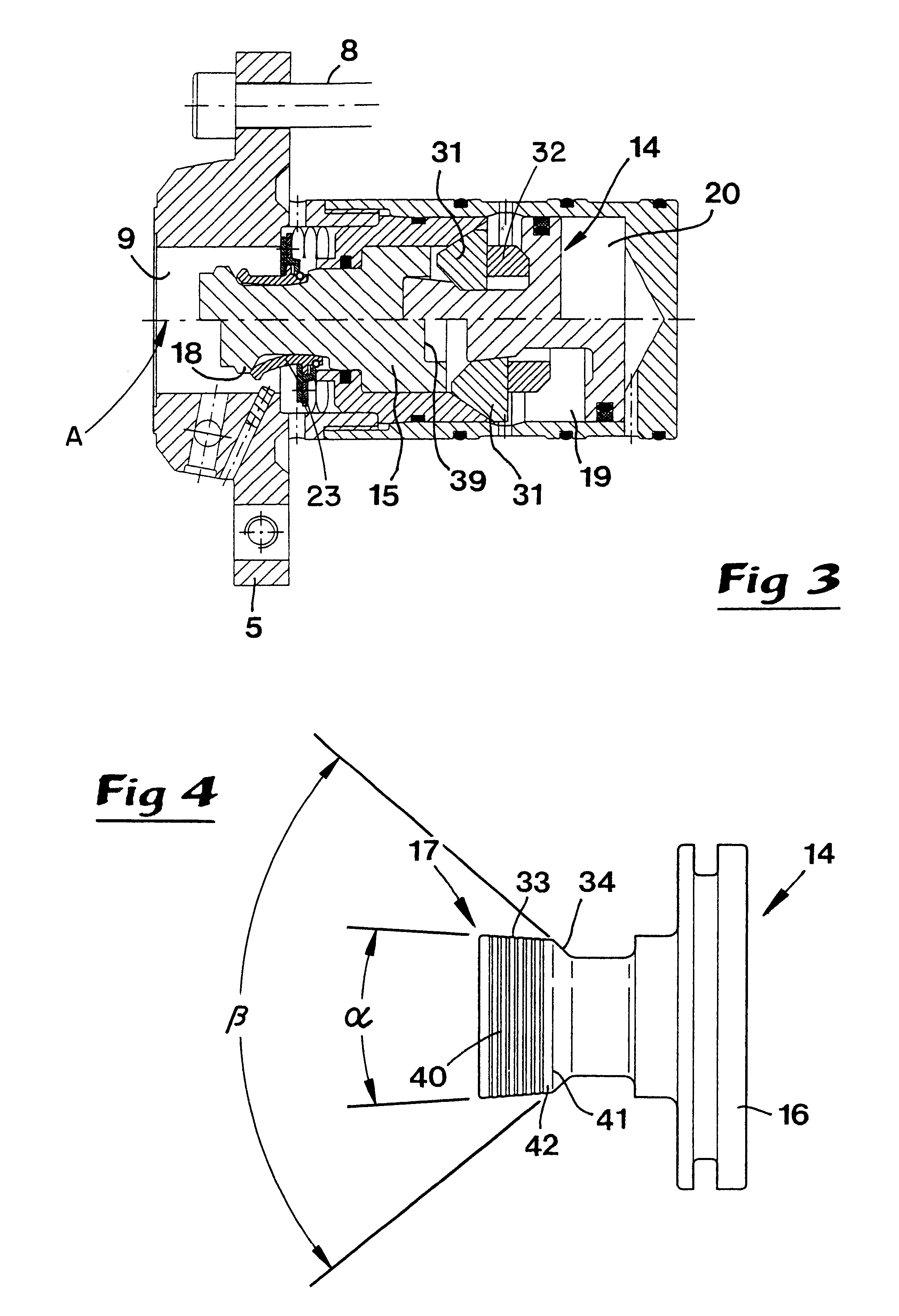

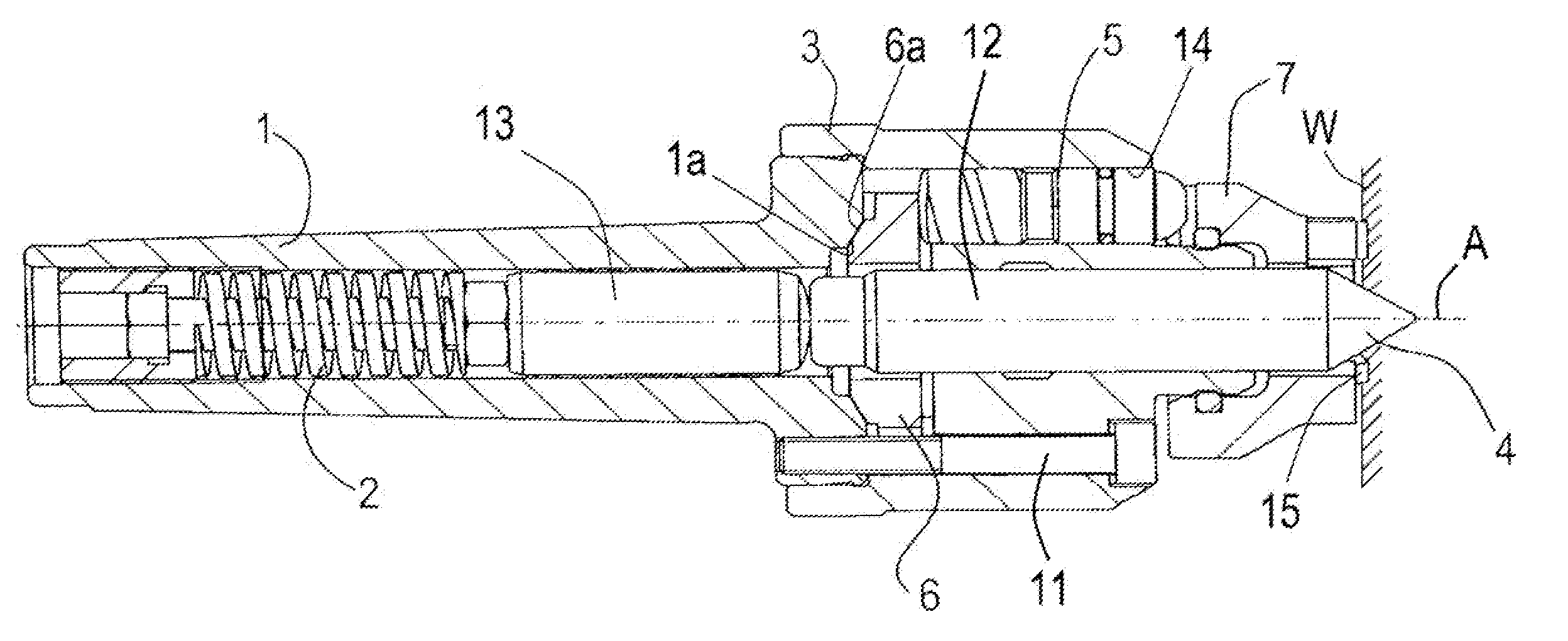

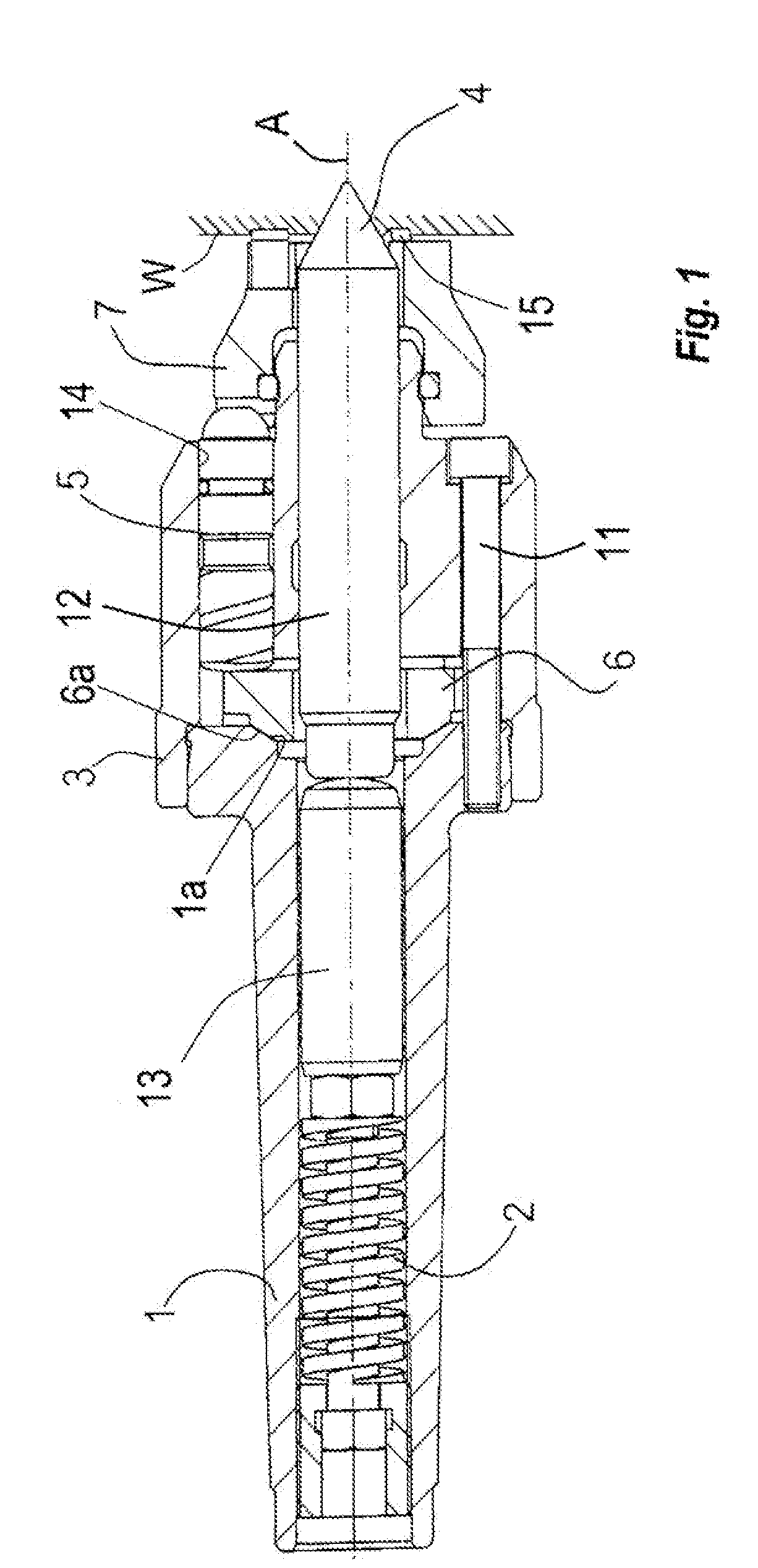

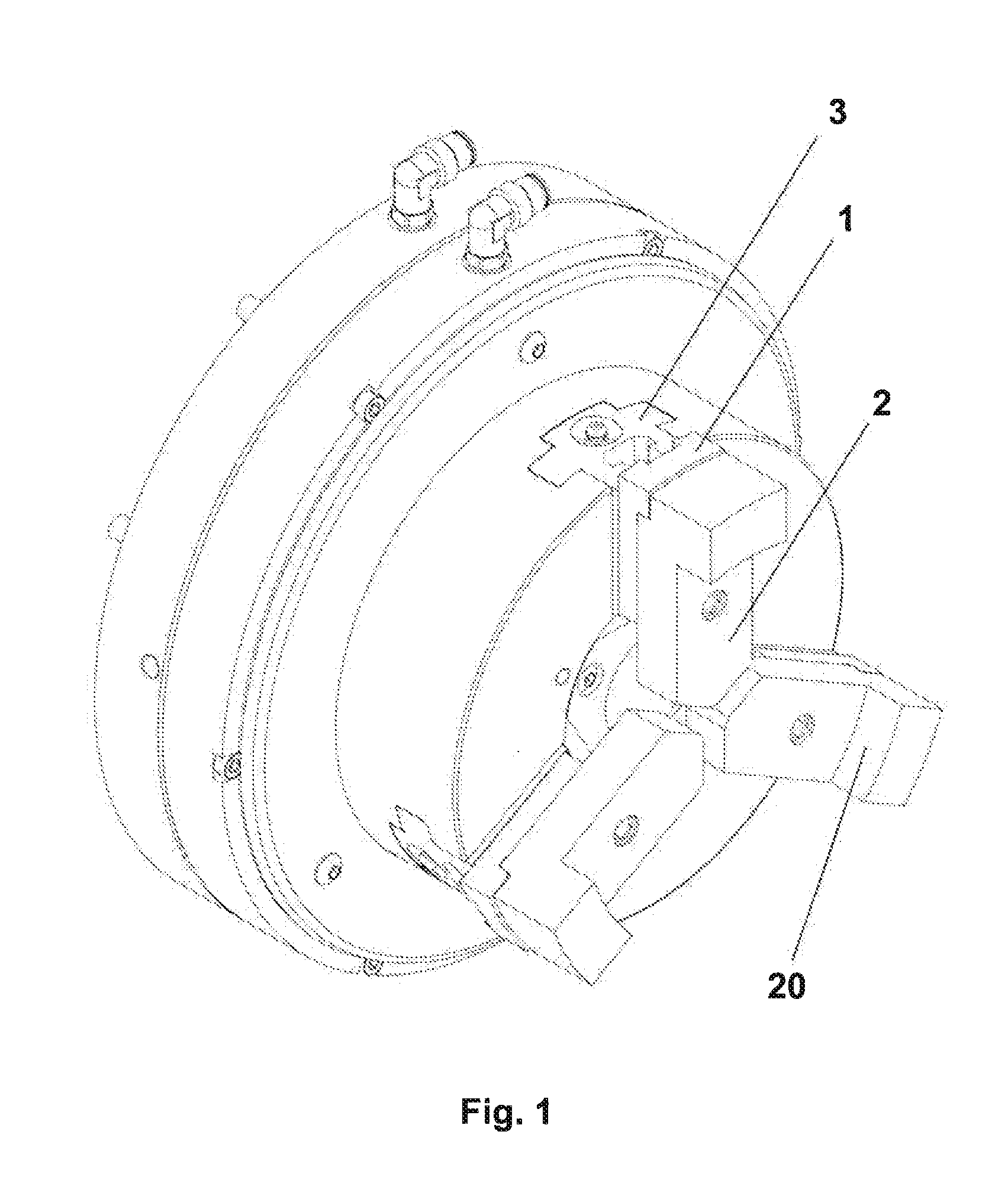

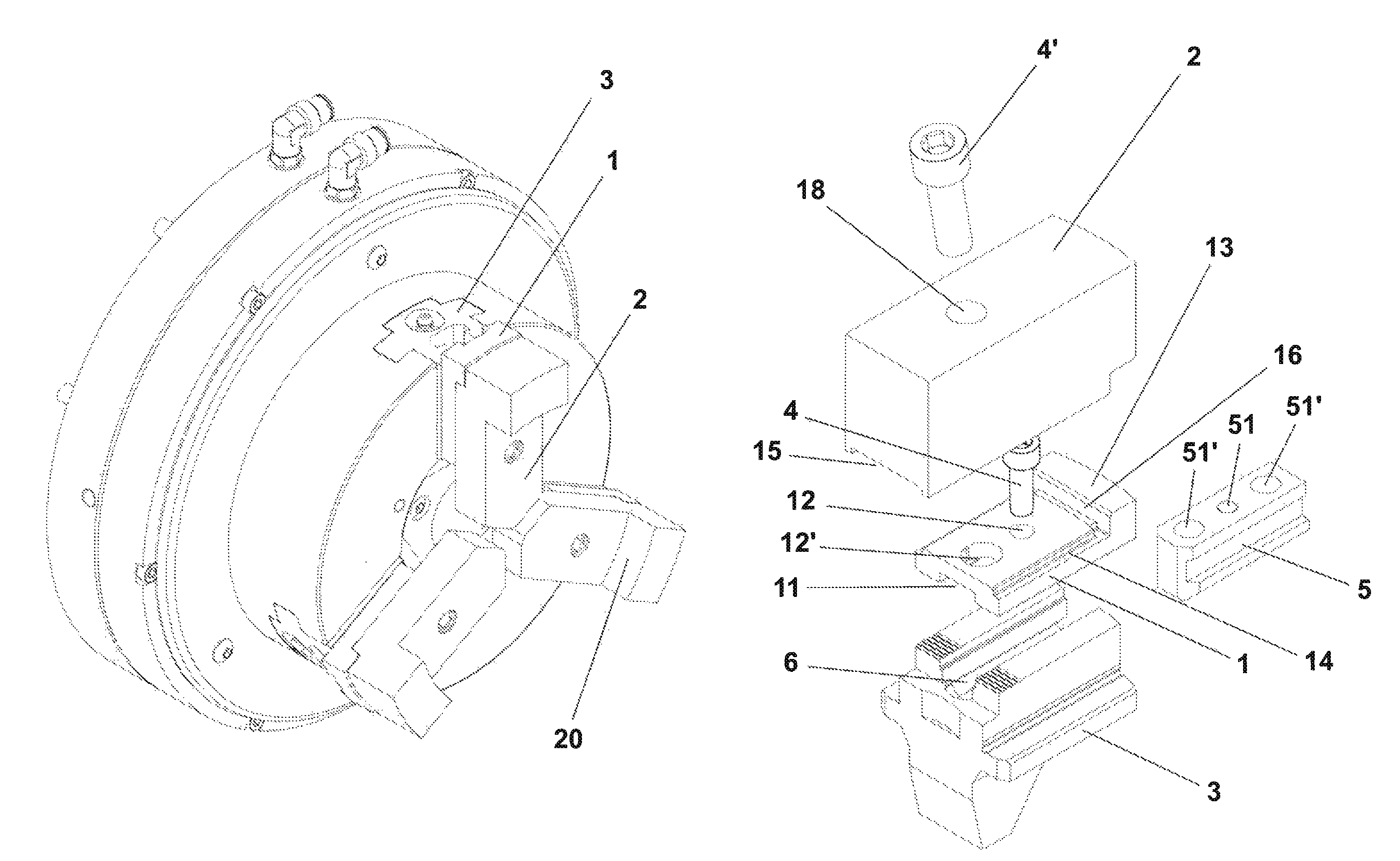

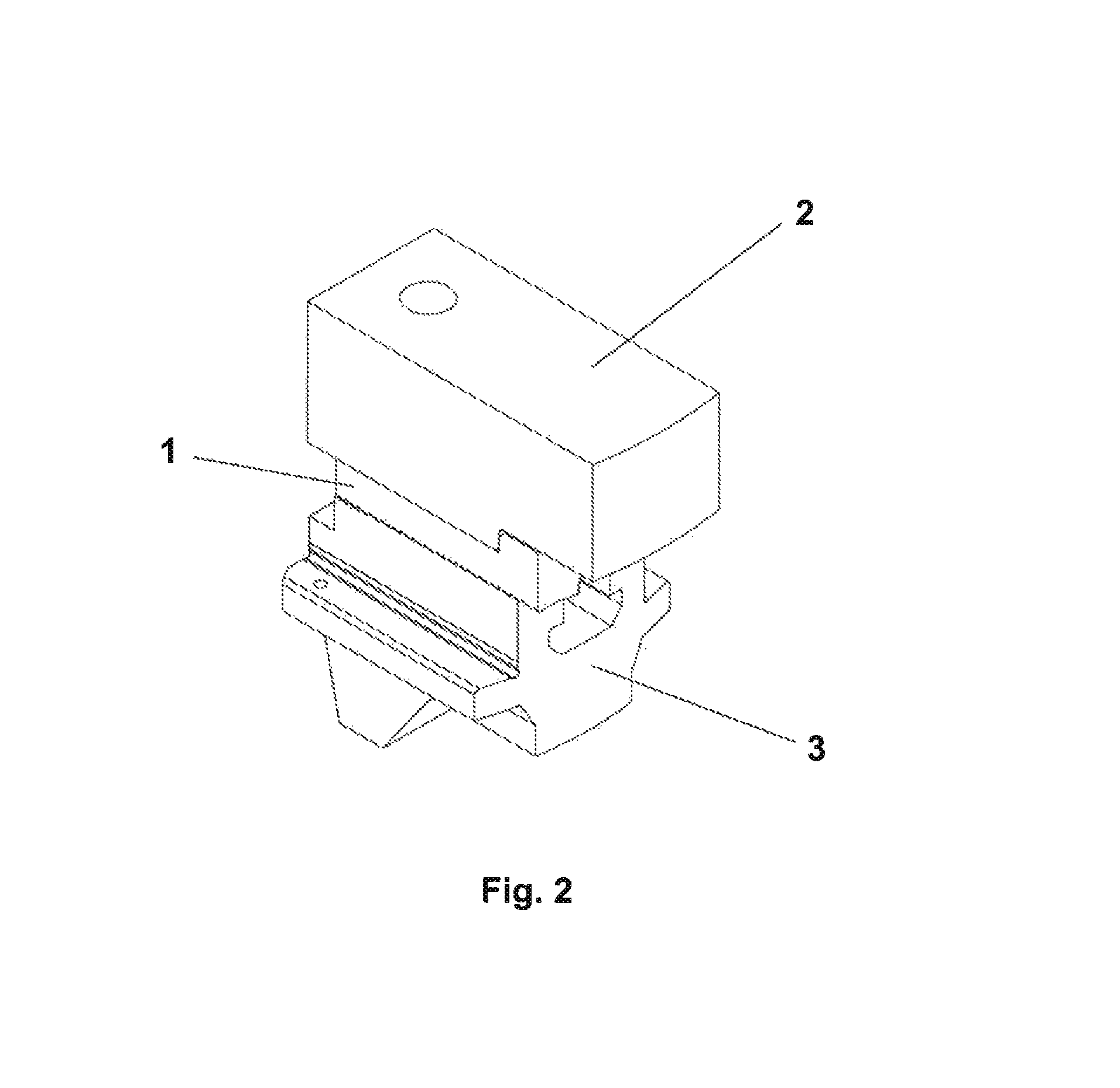

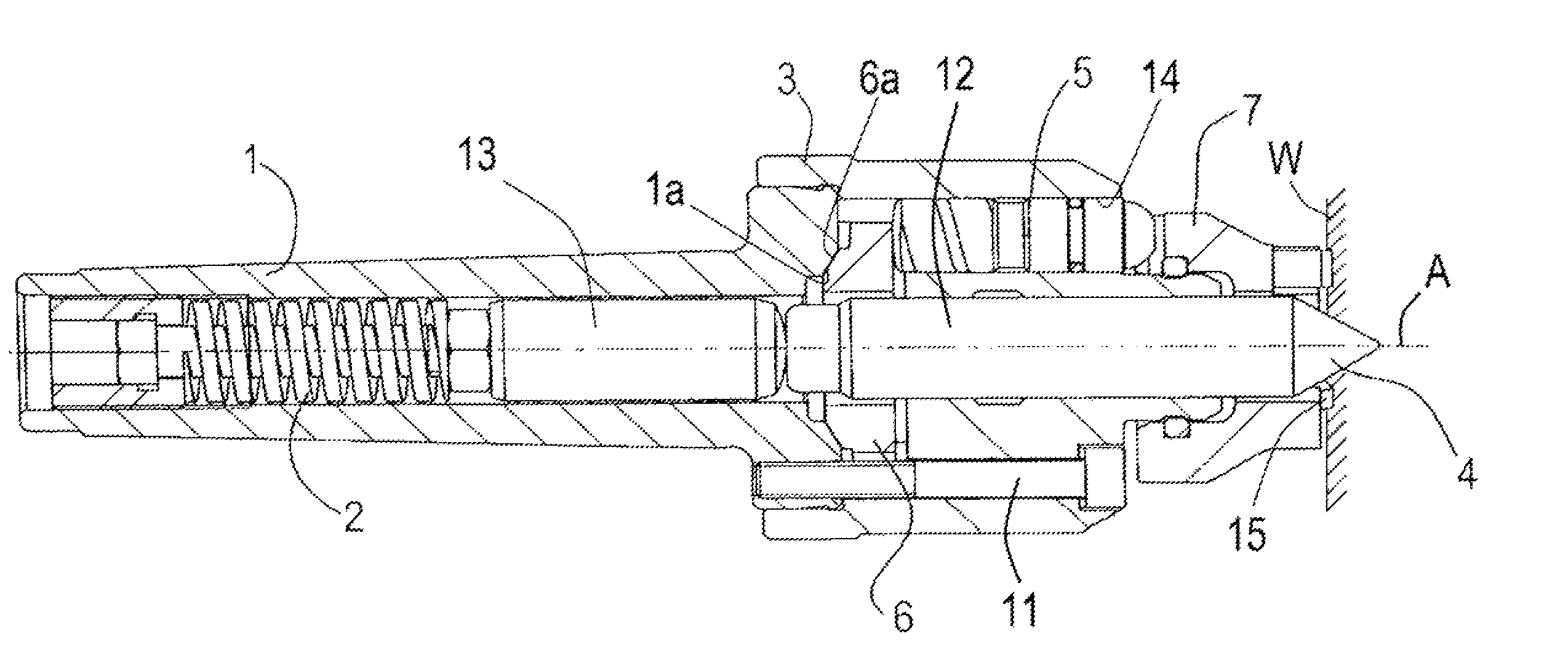

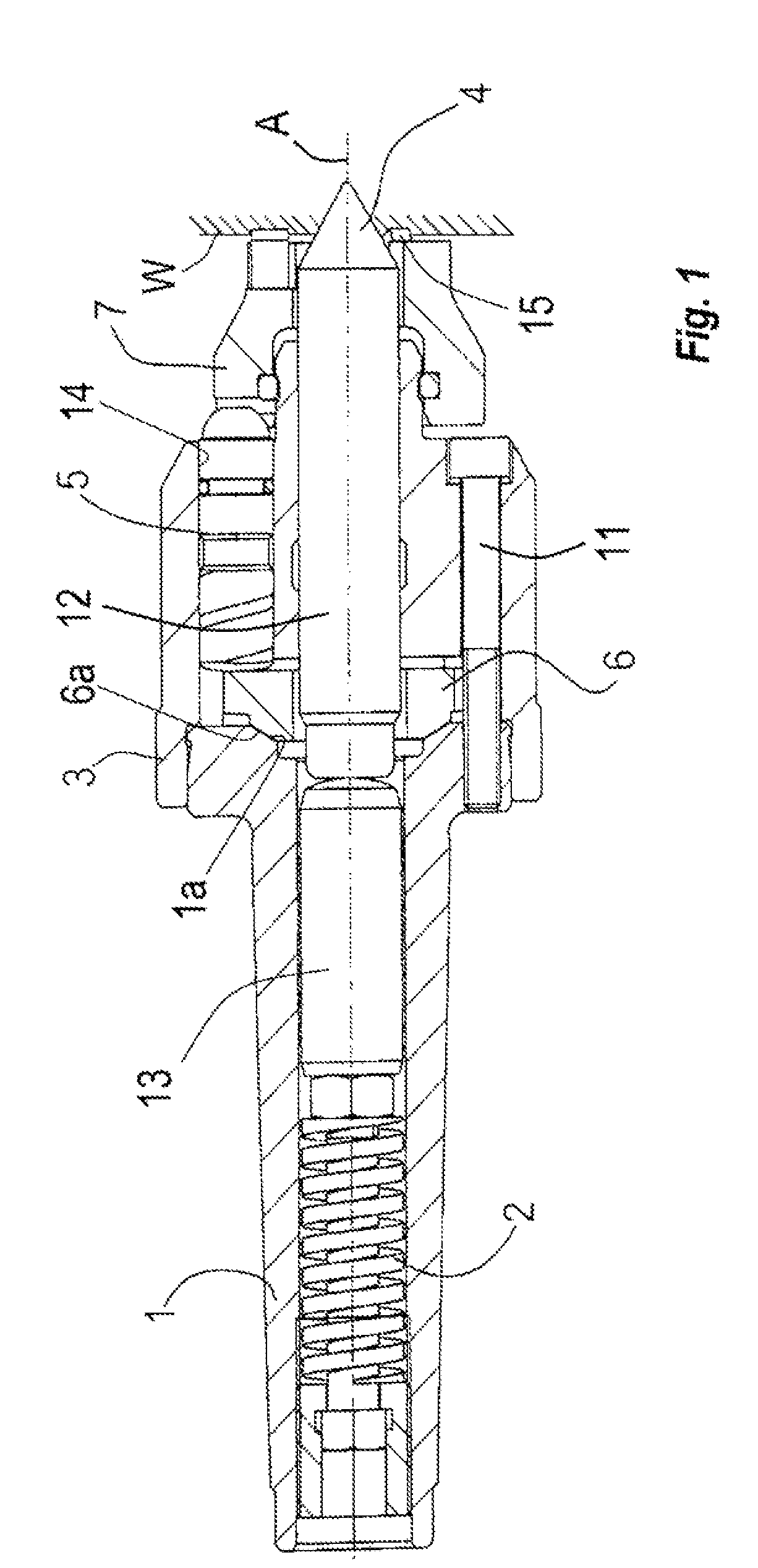

Face driver

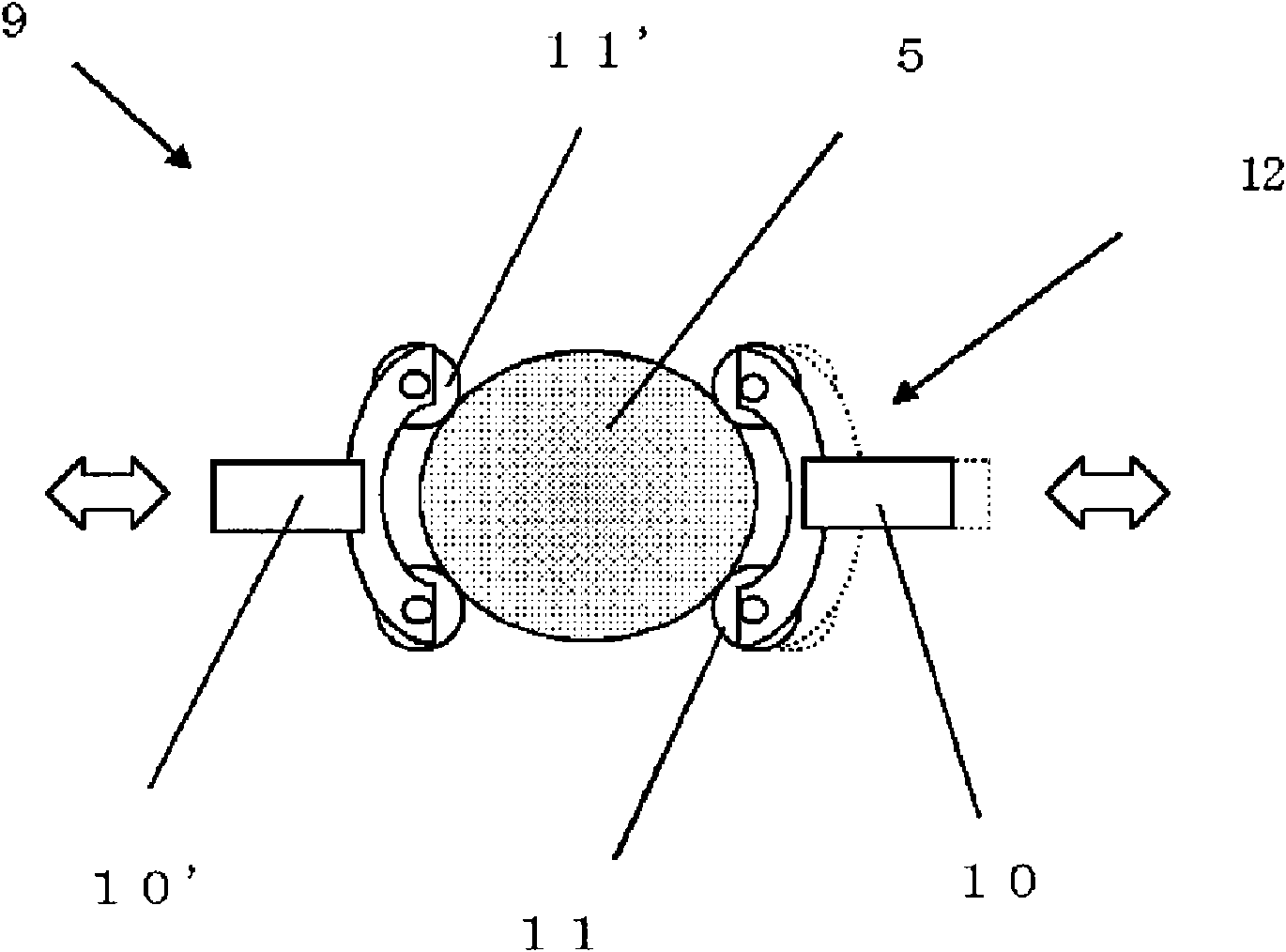

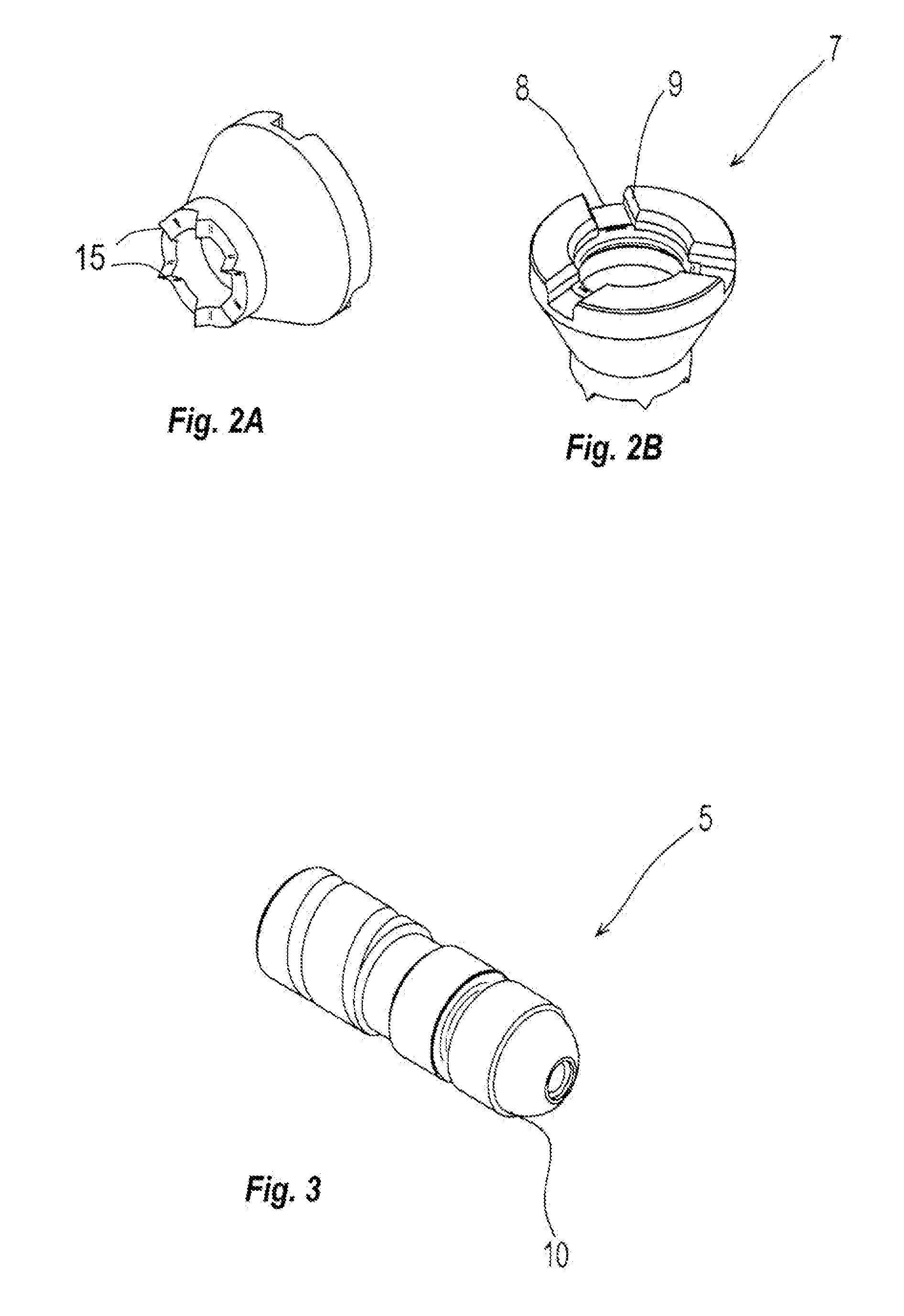

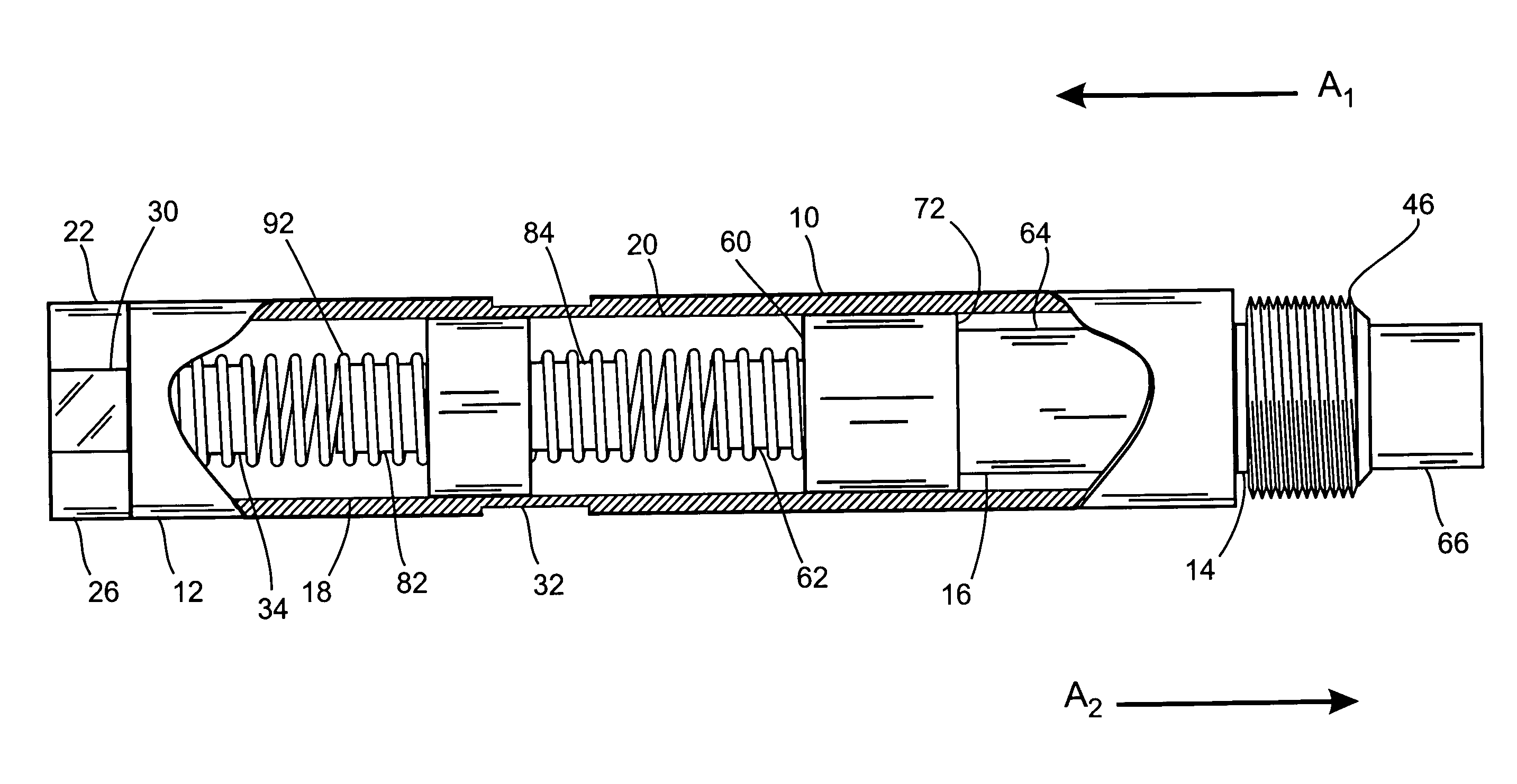

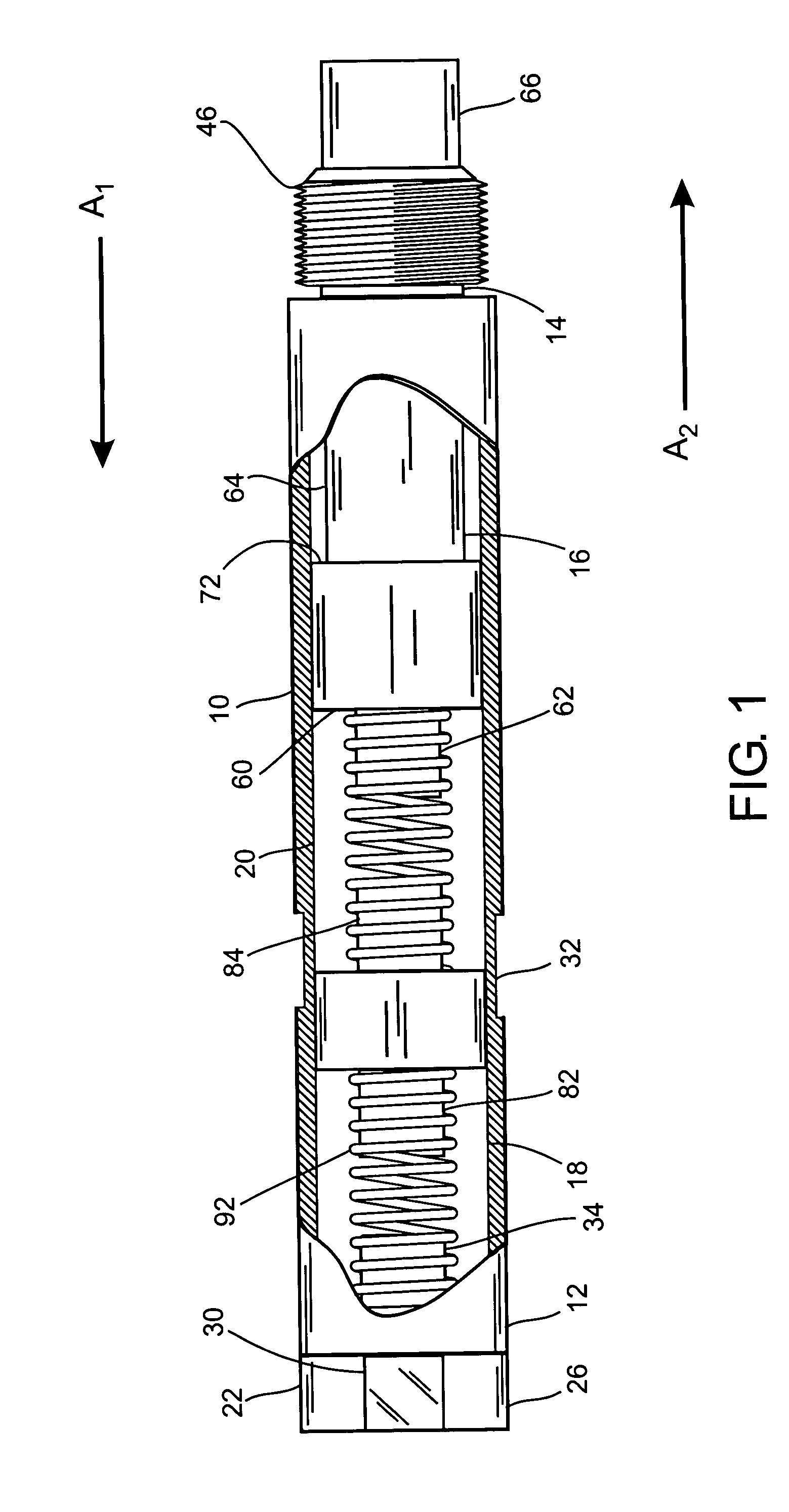

InactiveUS20120097000A1Facilitating play-free cooperationAvoid distortionWork driverAxial displacementEngineering

A face driver has a body rotatable about an axis and a head rotationally fixed on the body and formed with a plurality of guides open axially forwardly toward a workpiece and radially offset from the axis. A centering rod axially shiftable in the body on the axis has a front-end point engageable with the face of the workpiece. A compression spring in the body urging the rod axially forward toward the workpiece, a driver disk has a front face engageable with the workpiece and a back face formed with a plurality of rearwardly open and radially extending grooves aligned with the guides. Respective support pins axially shiftable in the guides have heads engaged in the respective grooves so as to rotationally couple the driver disk rotationally to the body while permitting the driverd disk to tip with axial displacement of the pins.

Owner:ROHM GMBH

Device for the fast exchange of nuts in a lathe plate

Owner:SYSTEC METALURGICA

Workpiece ejecting device for a machine tool

ActiveUS20060060039A1Avoid it happening againEject evenlyLathesSleeve/socket jointsEngineeringMachine tool

Disclosed herein is a workpiece ejecting device for a machine tool, in which the ejecting bar cannot be rotatably driven at the time of high velocity rotation of the spindle to thereby prevent occurrence of vibration, noise and frictional heat owing to the movement of the spindle, so that the machined workpiece can be ejected smoothly. According to the first embodiment of the present invention, there is provided a workpiece ejecting device for a machine tool for ejecting a workpiece clamped to a chuck installed at a spindle by means of a drawing tube connected to a chucking cylinder, the workpiece ejecting device comprising: a front bearing unit installed at an inner peripheral surface of a front end portion of the drawing tube to support the rotation of the drawing tube; and an ejecting cylinder located behind the chucking cylinder and installed directly on an axial line identical with that of the front bearing unit, and having an ejecting rod, wherein the ejecting rod is provided at a center axis thereof with at least one fluid passing opening through which fluid for removing alien materials is supplied, and a front end of the ejecting rod is installed to be supported by the front bearing unit.

Owner:DN SOLUTIONS CO LTD

Device for the fast exchange of nuts in a lathe plate

Owner:SYSTEC METALURGICA

Pottery holding device and method

Owner:BAILEY JAMES G

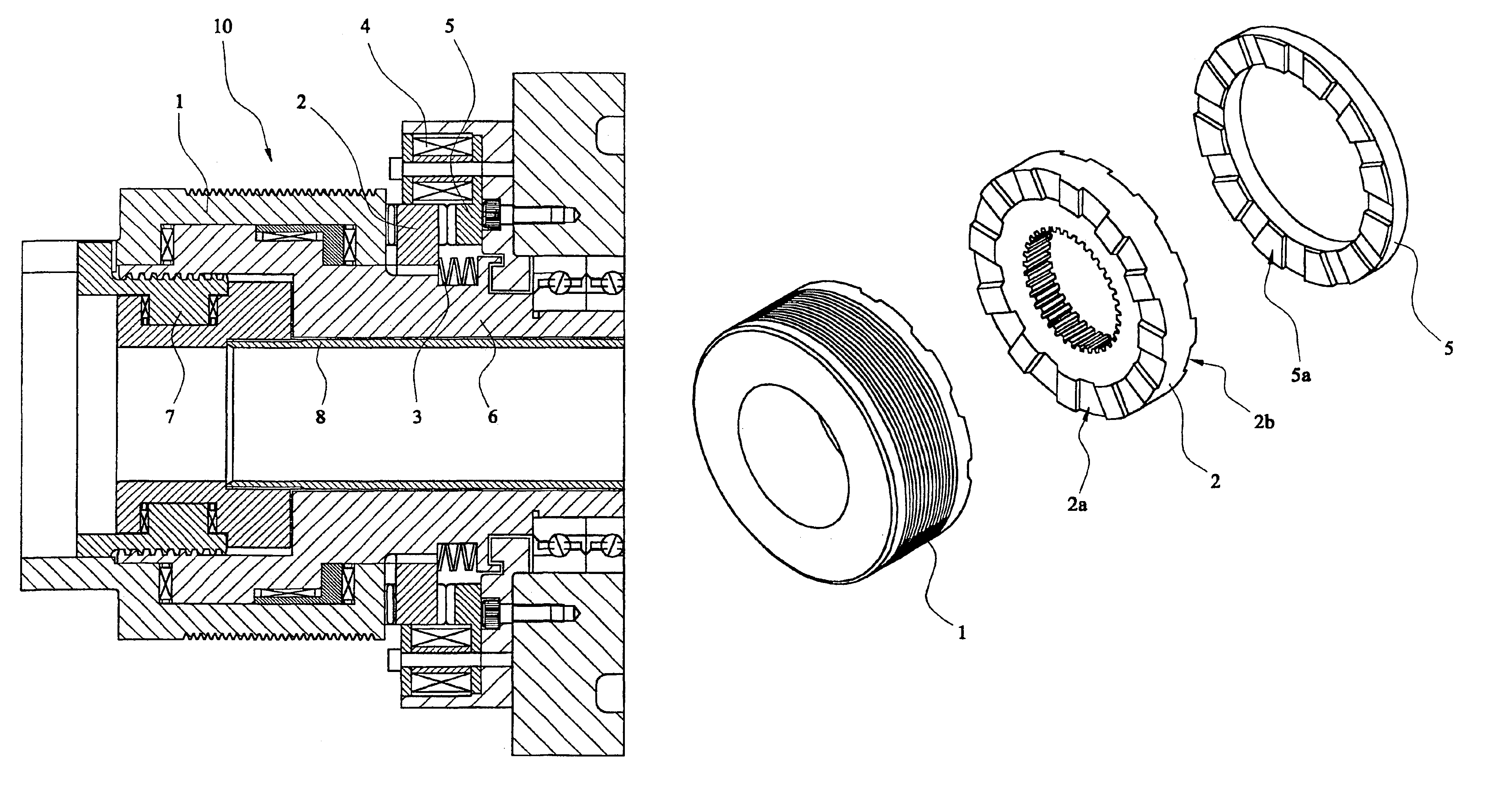

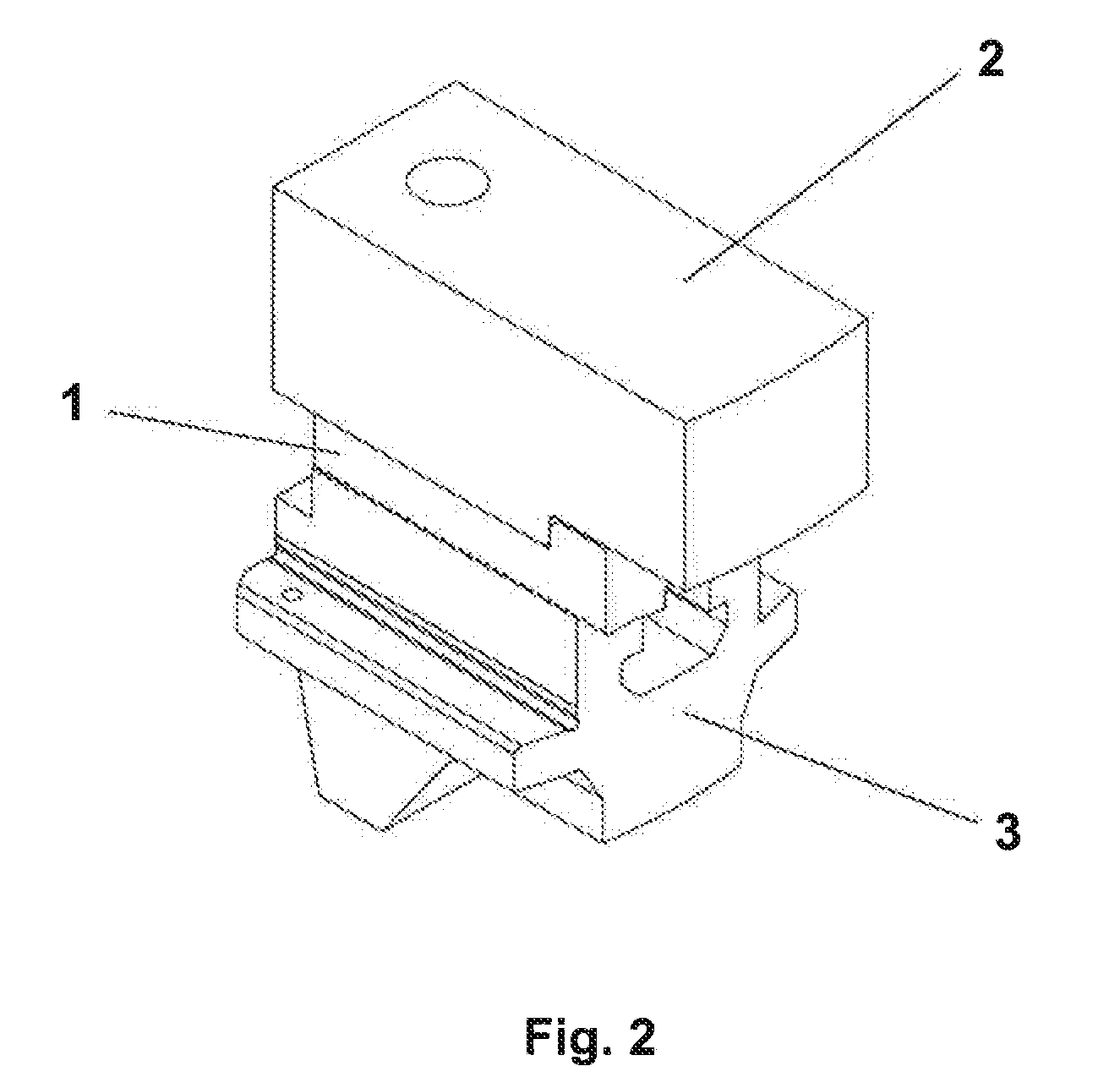

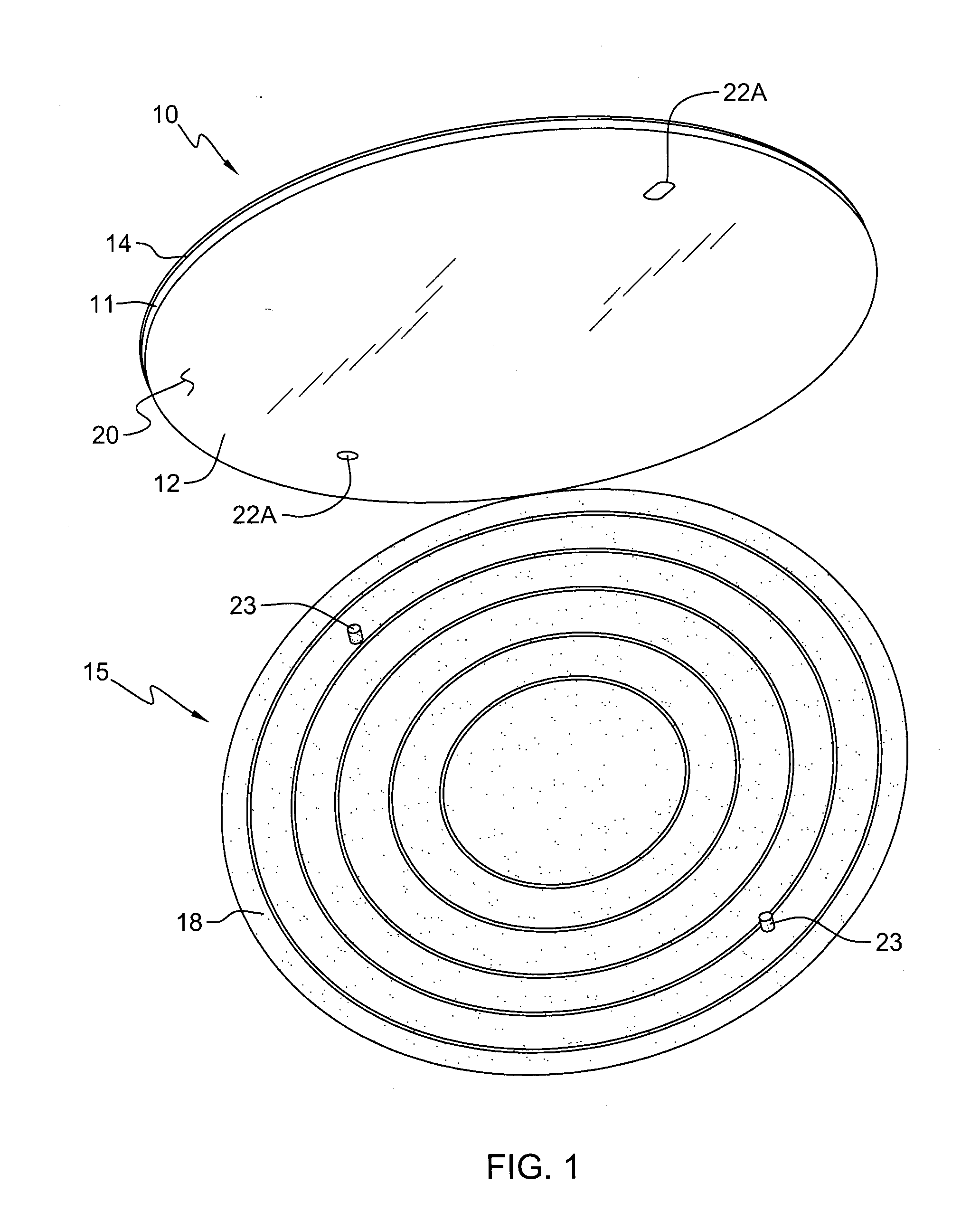

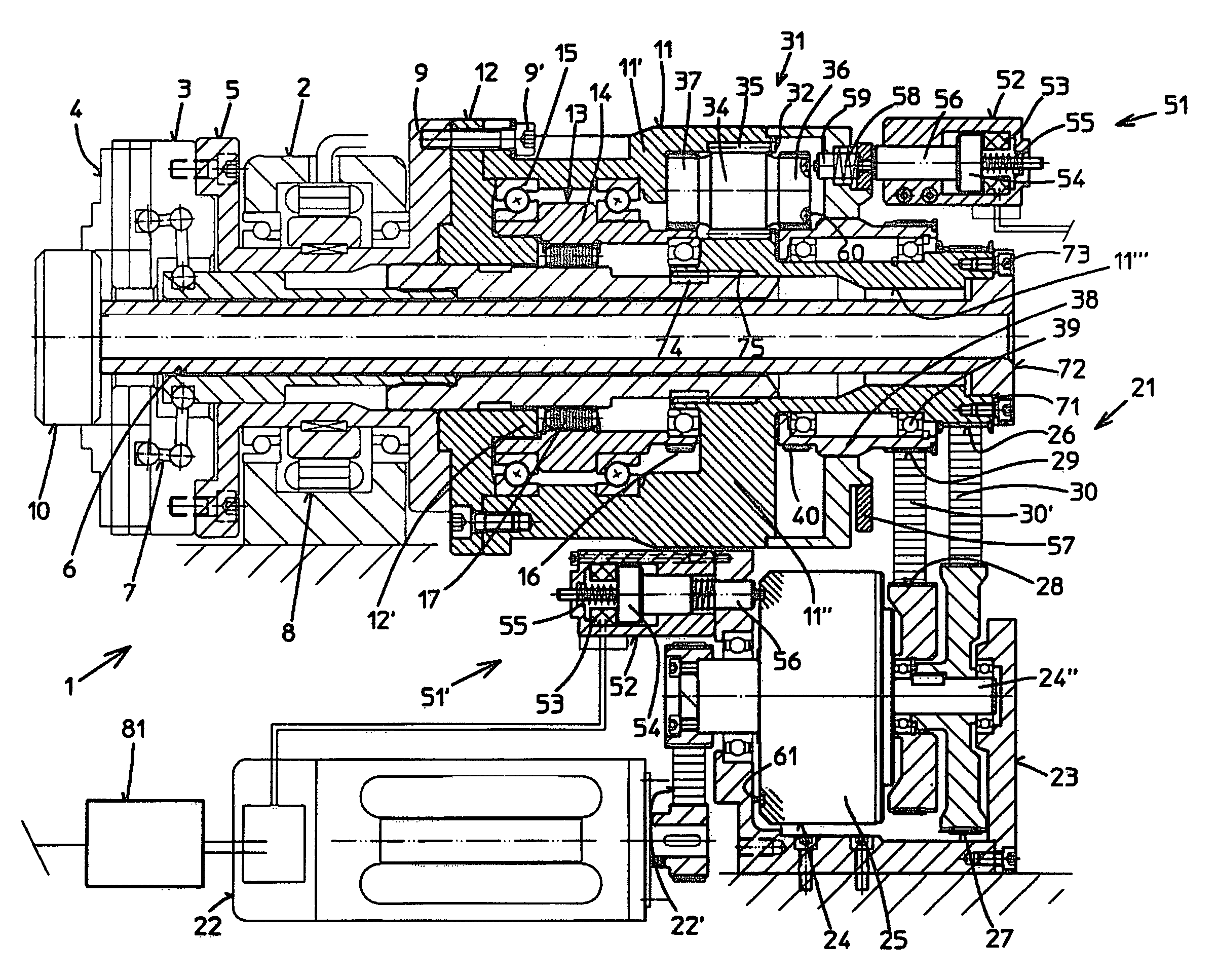

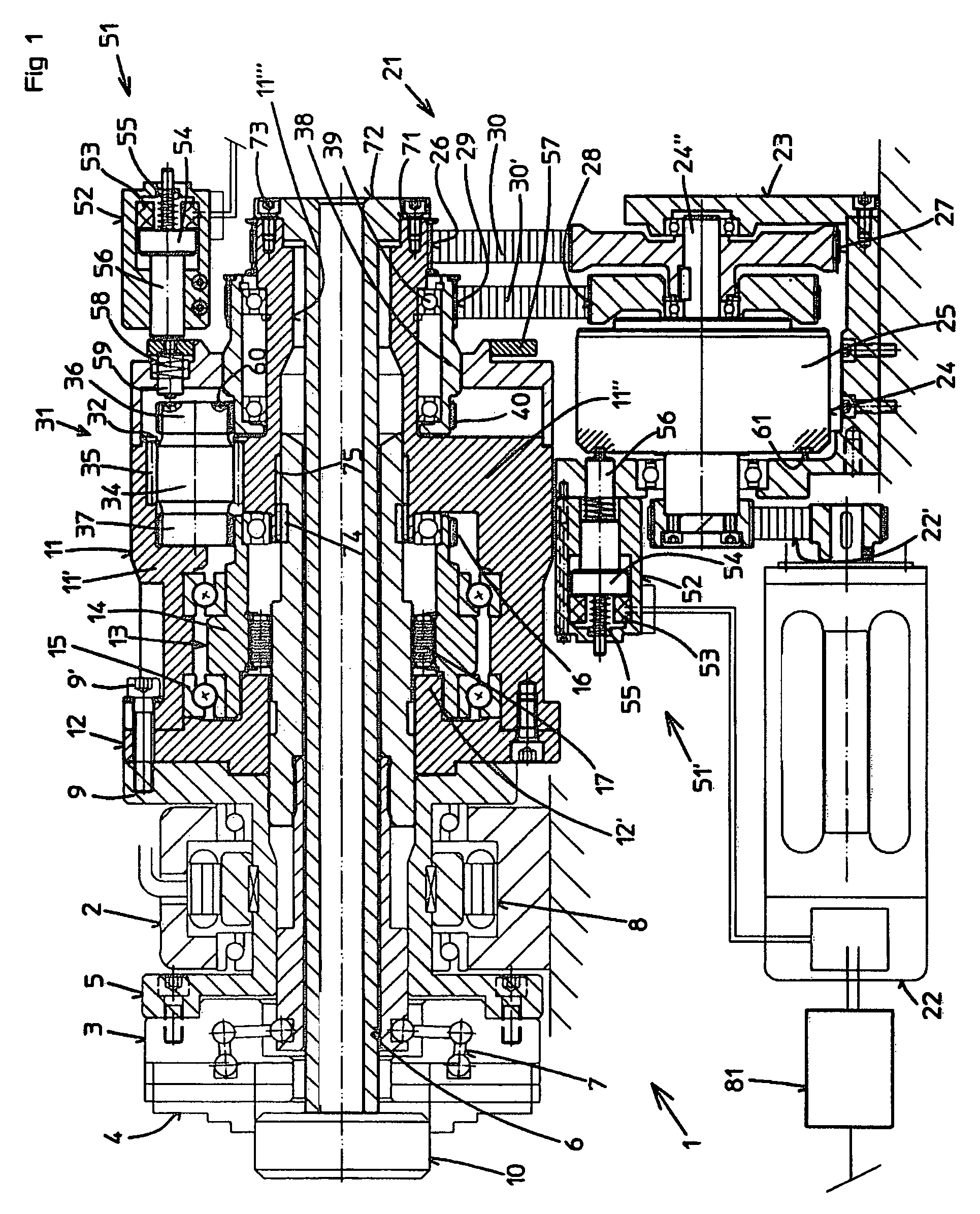

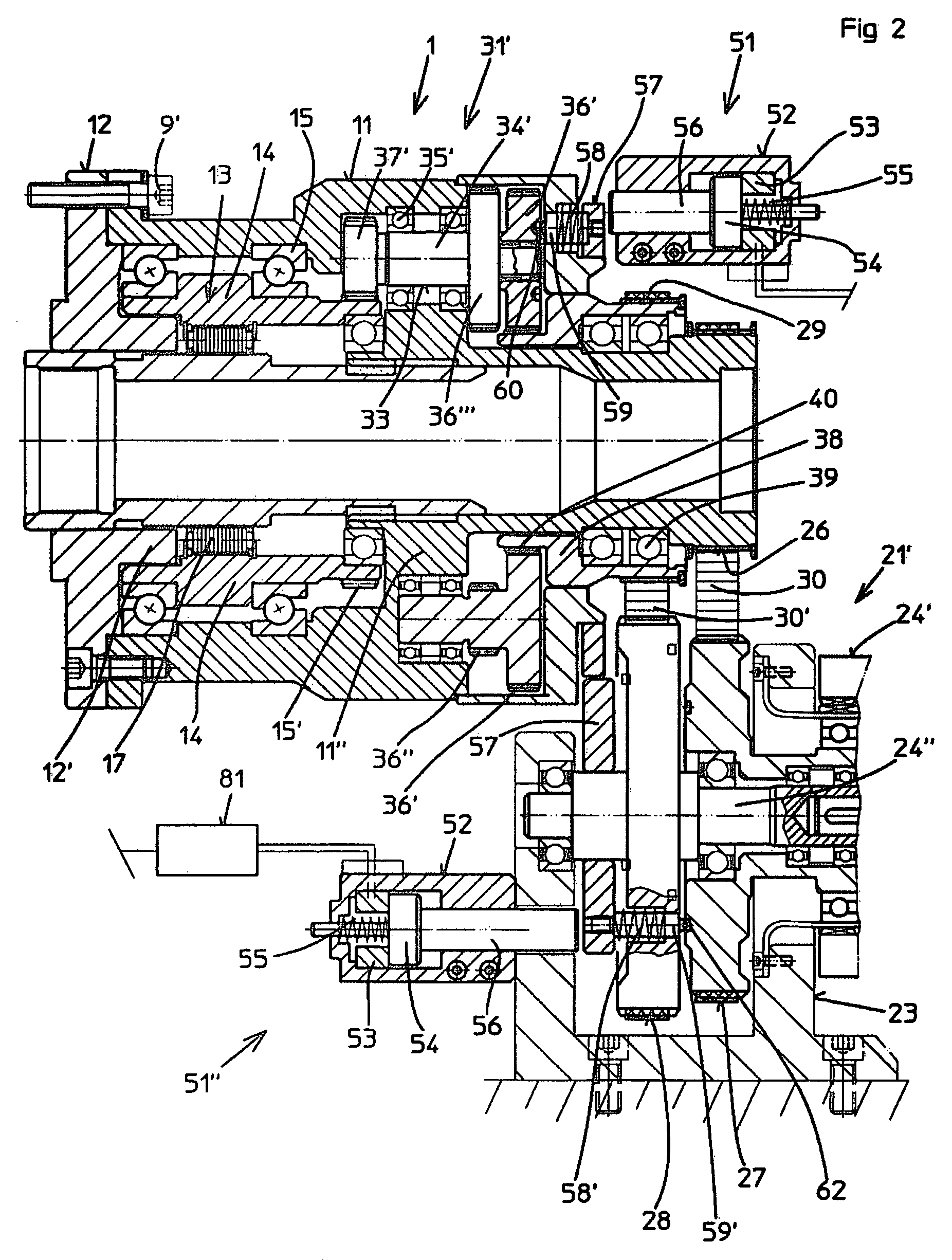

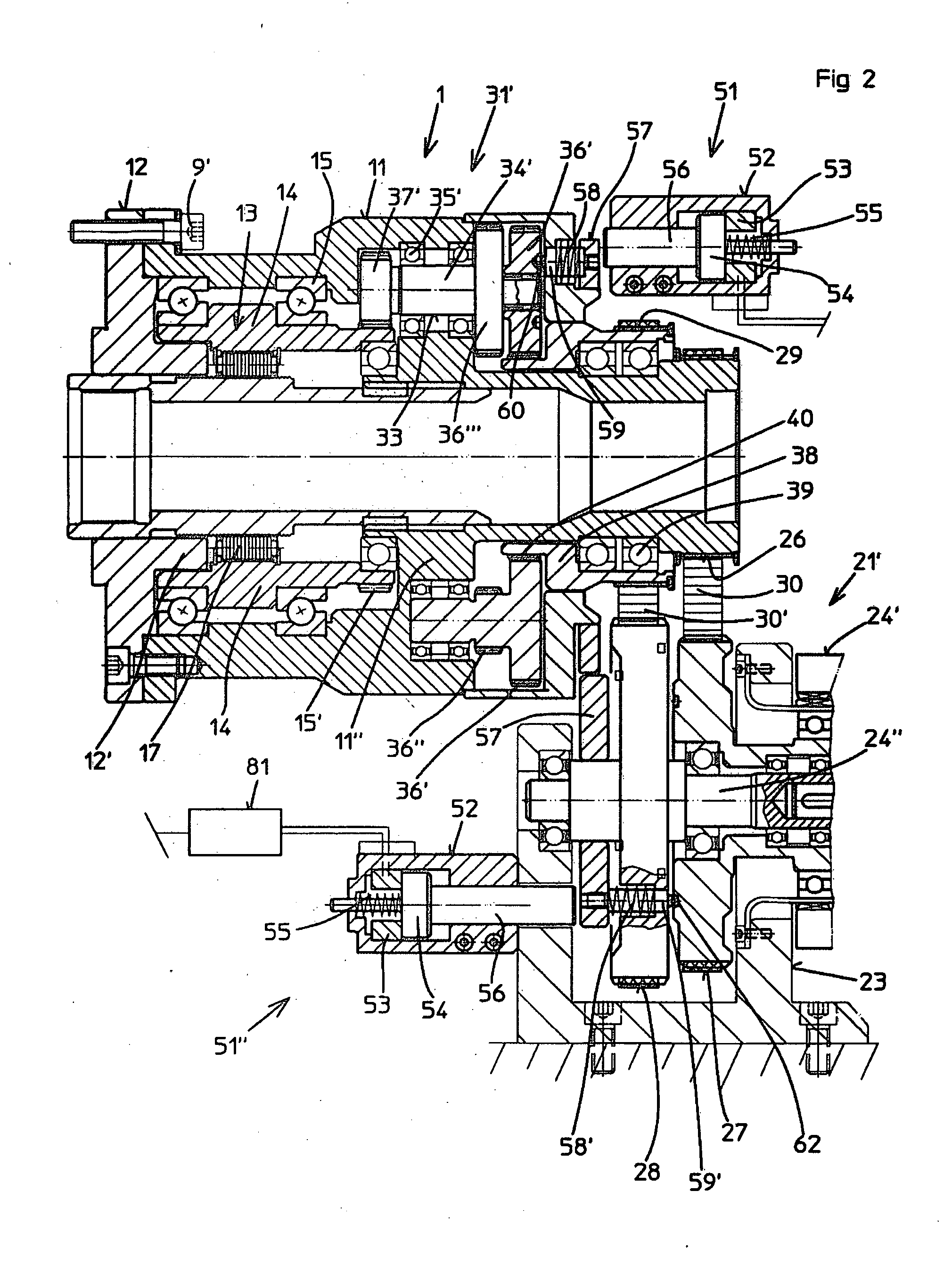

Clamping unit

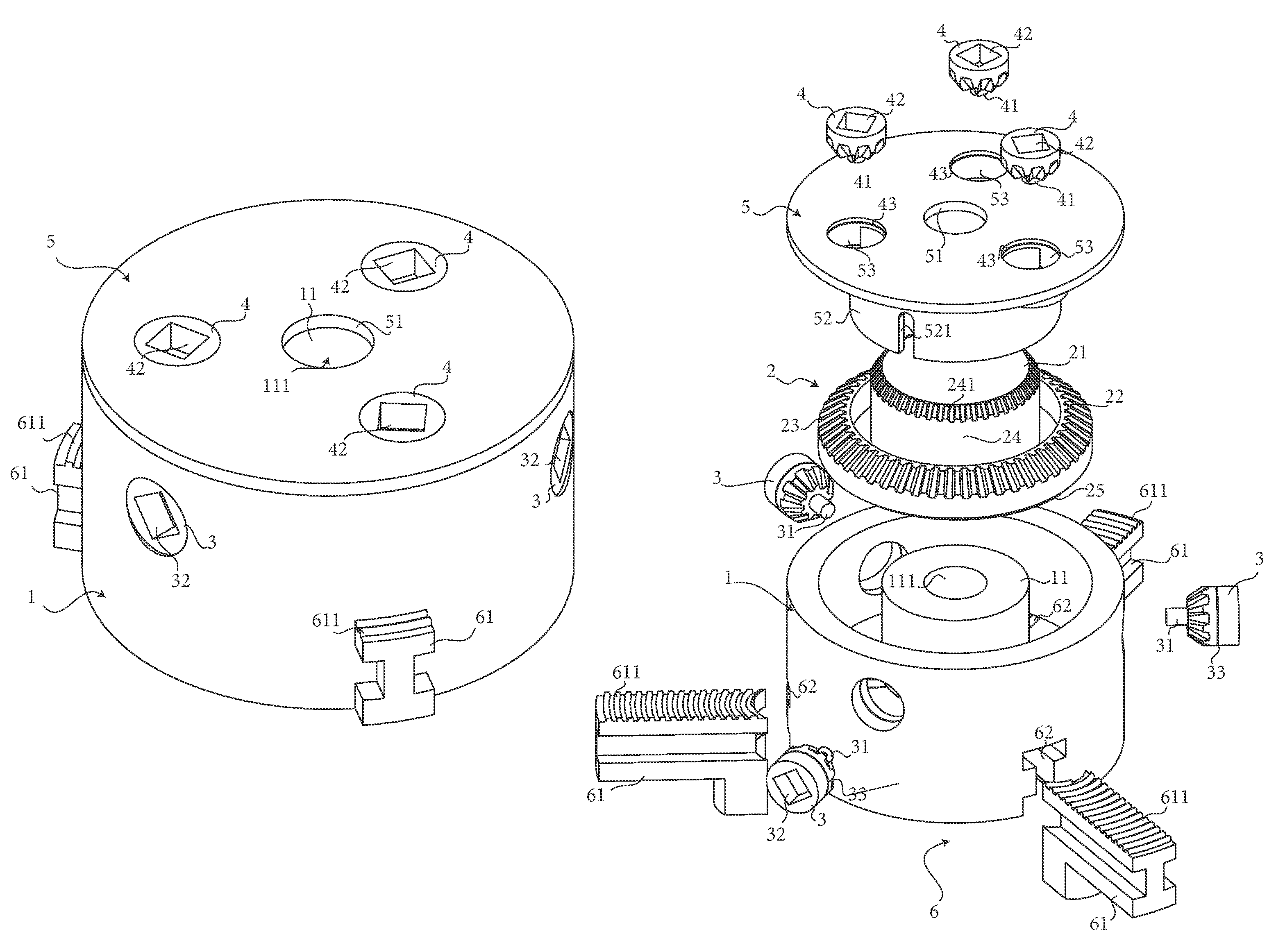

InactiveUS8955852B2Permitting safe and trouble free operationConvenient ArrangementSleeve/socket jointsWork driverElectrical controlEngineering

A clamping unit (1) for machine tools (2) with a housing (11) connected in a rotationally fixed arrangement with a machine spindle, (5) and a screw drive (13) that interacts with a draw rod (6) such that rotational movements are converted into translational movements, the housing (11) being provided with an output element by which rotational movements are transmitted to an actuator (21). The housing (11) has an input element in a rotating mounting, with the actuator (21) acting on the input element, and the input element (29) is in driving connection with a shaft (14) by means of intermediate elements (31), whereby to direct rotational movements of the machine spindle (5) via the clamping unit (1), and for adjustment movements of differently configured clamping devices, to be converted into axial adjustment movements and transmitted directly onto the draw rod (6). No complicated electrical control devices and programs are required for adjusting and adapting a power chuck (3) linked to the draw rod (3) to different operating conditions.

Owner:HIESTAND KARL

Workpiece seat for bar-shaped workpieces

InactiveUS7080433B2Reduce vertical sizeImprove working precisionLathesAutomatic conveying/guiding stockEngineeringMachining

A workpiece seat for the machining of bar-shaped workpieces by milling and turning. The workpiece seat has an elongated housing, a spindle rotatably supported in the housing, and an electric direct drive for the spindle. The drive rotor is fixed on the spindle and the drive stator is fixed in the housing. Clamping means are provided at the working end in the spindle for fixing a bar-shaped workpiece in the spindle. A connection unit is provided at the rear part of the housing for power supply. A fixing means is provided for fixing the spindle in the housing. To achieve high machining accuracy of thick bars and high clamping forces at reduced longitudinal dimensions, as well as relatively simple design, the fixing means is formed as a compact part and is arranged at the working end of the housing.

Owner:DECKEL MAHO PFRONTEN GMBH

Clamping unit

InactiveUS20110068546A1Reduce designLow design complexitySleeve/socket jointsWork driverElectrical controlEngineering

A clamping unit (1) for machine tools (2) with a housing (11) connected in a rotationally fixed arrangement with a machine spindle, (5) and a screw drive (13) that interacts with a draw rod (6) such that rotational movements are converted into translational movements, the housing (11) being provided with an output element by which rotational movements are transmitted to an actuator (21). The housing (11) has an input element in a rotating mounting, with the actuator (21) acting on the input element, and the input element (29) is in driving connection with a shaft (14) by means of intermediate elements (31), whereby to direct rotational movements of the machine spindle (5) via the clamping unit (1), and for adjustment movements of differently configured clamping devices, to be converted into axial adjustment movements and transmitted directly onto the draw rod (6). No complicated electrical control devices and programs are required for adjusting and adapting a power chuck (3) linked to the draw rod (3) to different operating conditions.

Owner:HIESTAND KARL

Face driver

InactiveUS8621965B2Reduce the difficulty of operation and maintenanceSimple designTailstocks/centresWork driverAxial displacementEngineering

Owner:ROHM GMBH

Material stock advancing apparatus and method

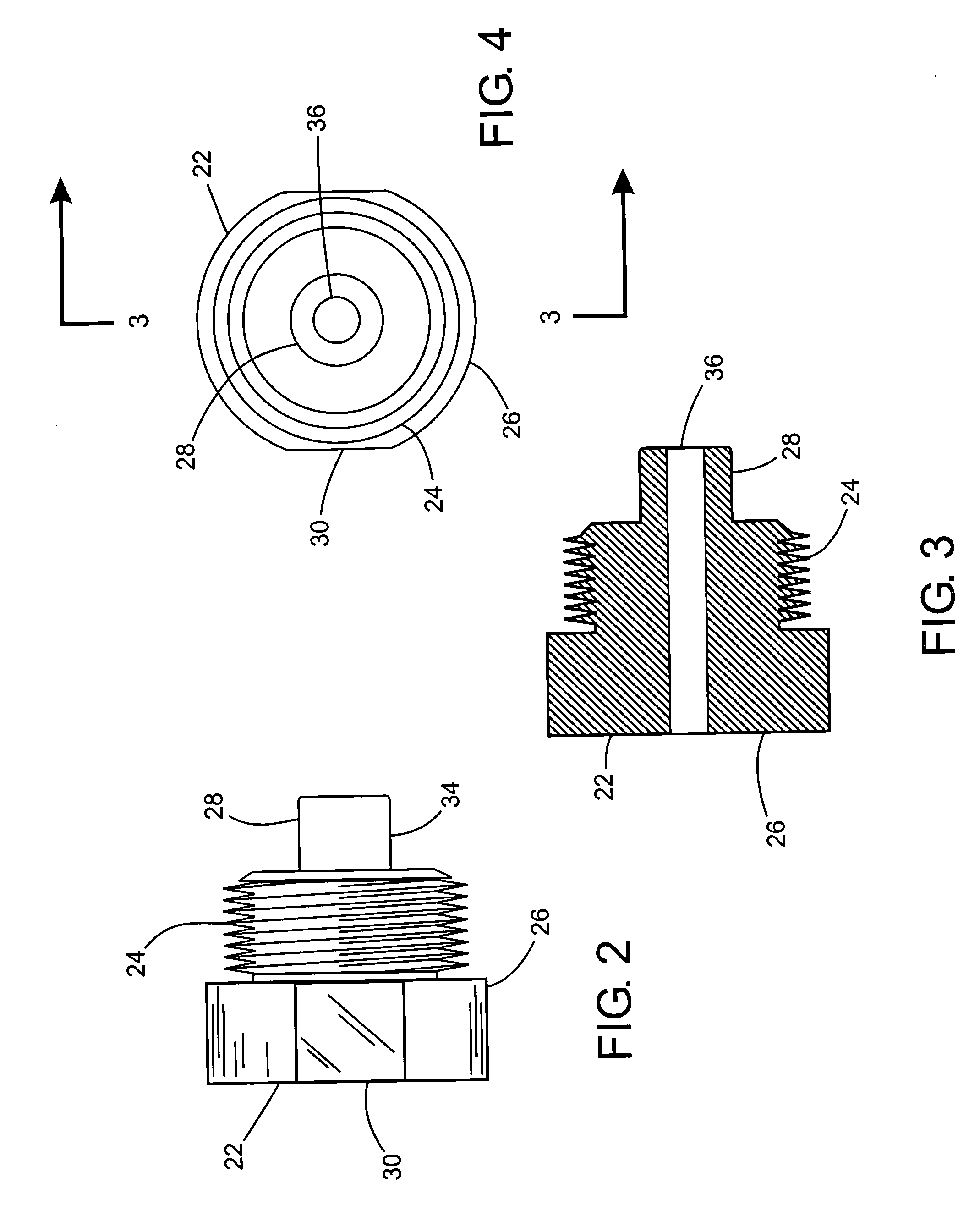

InactiveUS20050092145A1Afford flexibilityAfford versatilityLathesAutomatic conveying/guiding stockEngineeringScrew thread

A material stock advancing apparatus for use with a turning and milling machine having a computerized numeric controller or lacking programmable capabilities. The material stock advancing apparatus generally comprising an elongate body of cylindrical form having first and second ends and an interior chamber for housing therein a plunger assembly operably working therewithin. The second end comprising means for attaching the elongate body to an external holding device such as a collet or chuck adapter seated in a headstock spindle assembly. The first end comprising an end plug having a threaded section situated in between external and internal ends thereof, with the threaded section being threadably attached to the first end to permit the internal end to substantially engage a portion of the plunger assembly and ensure proper axial positioning of the plunger assembly during cyclic operation. The plunger assembly comprising a ram operably acting longitudinally within the interior chamber of the elongate body via biasing means comprising at least one spring operably acting in conjunction with controller means used in opening and closing the external holding device, which collectively controls the advancement of material stock toward and beyond the second end to permit the machining thereof for conversion into a useful product.

Owner:MOTL DANIEL WAYNE

Method and apparatus for machining parts of partial revolution

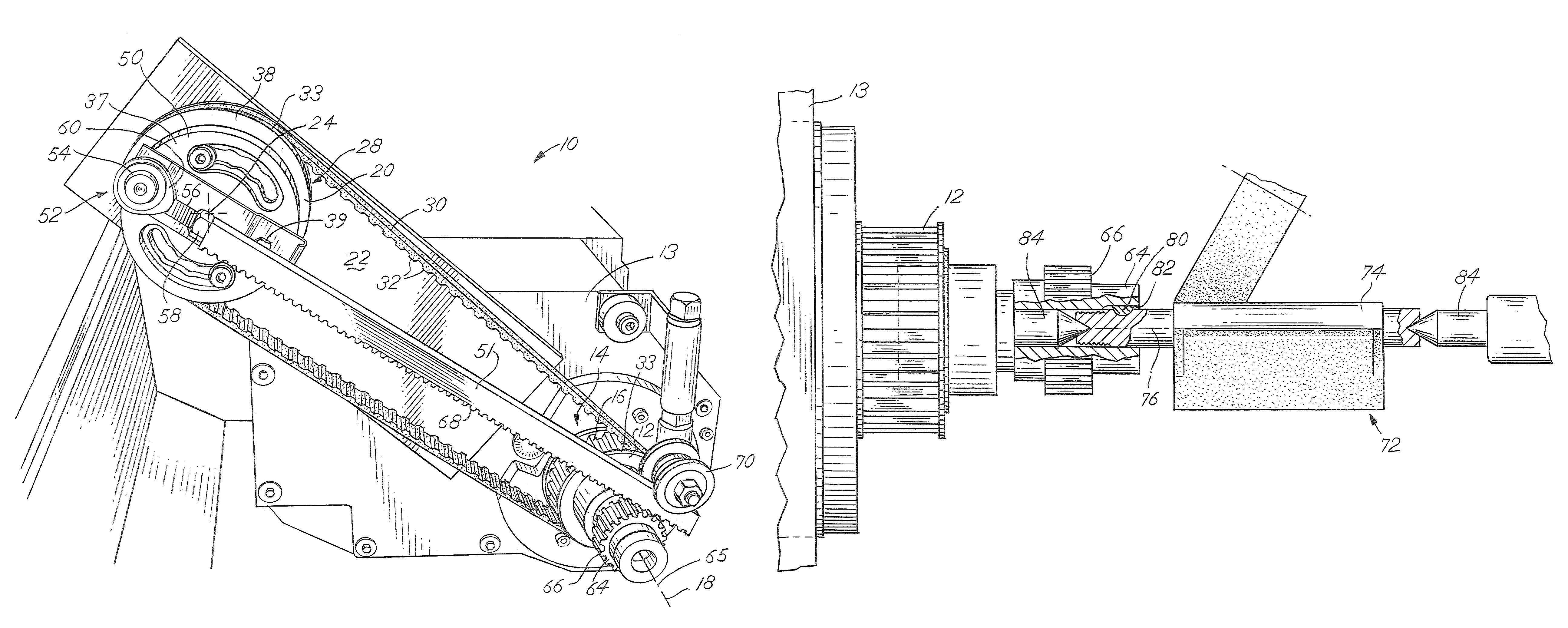

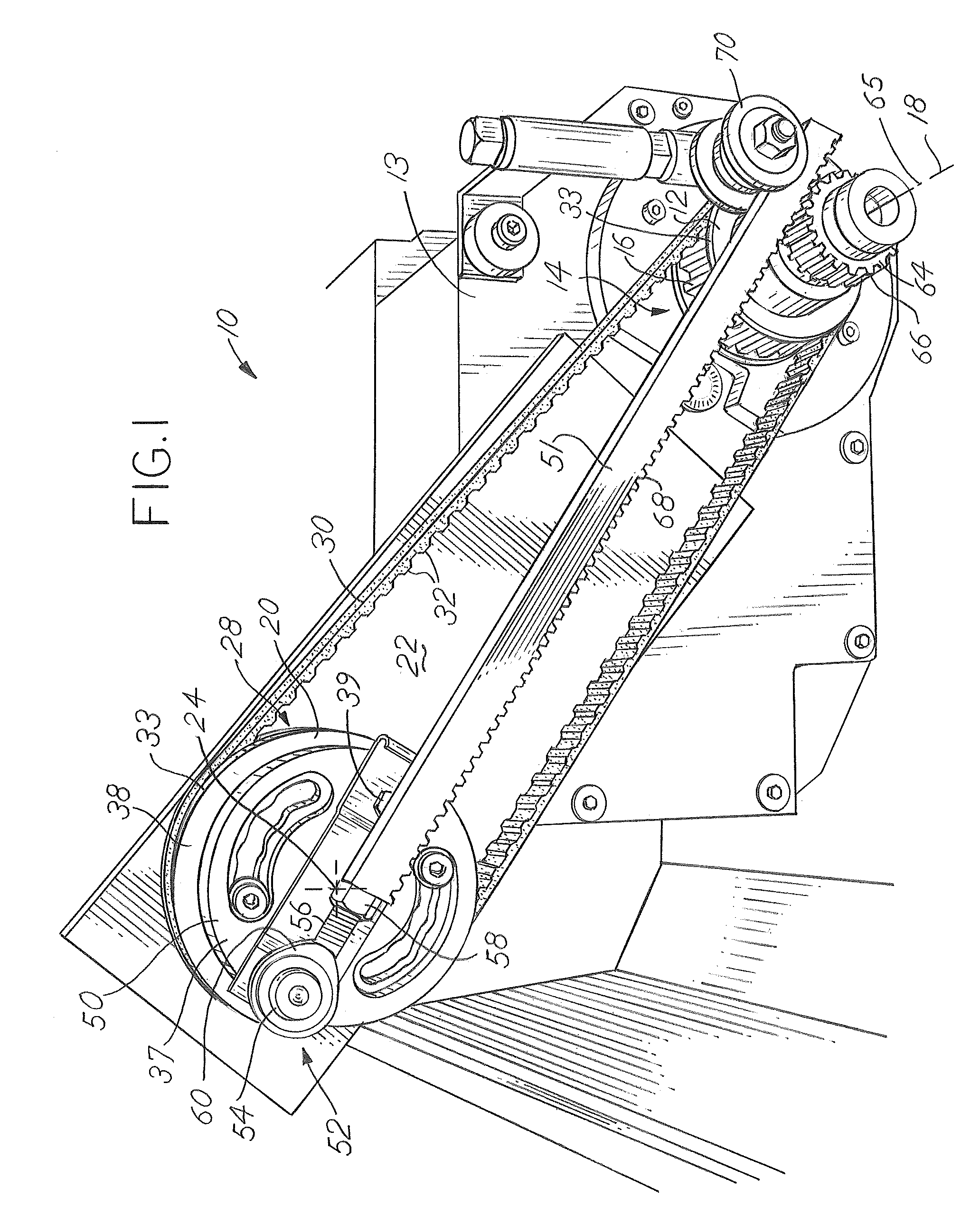

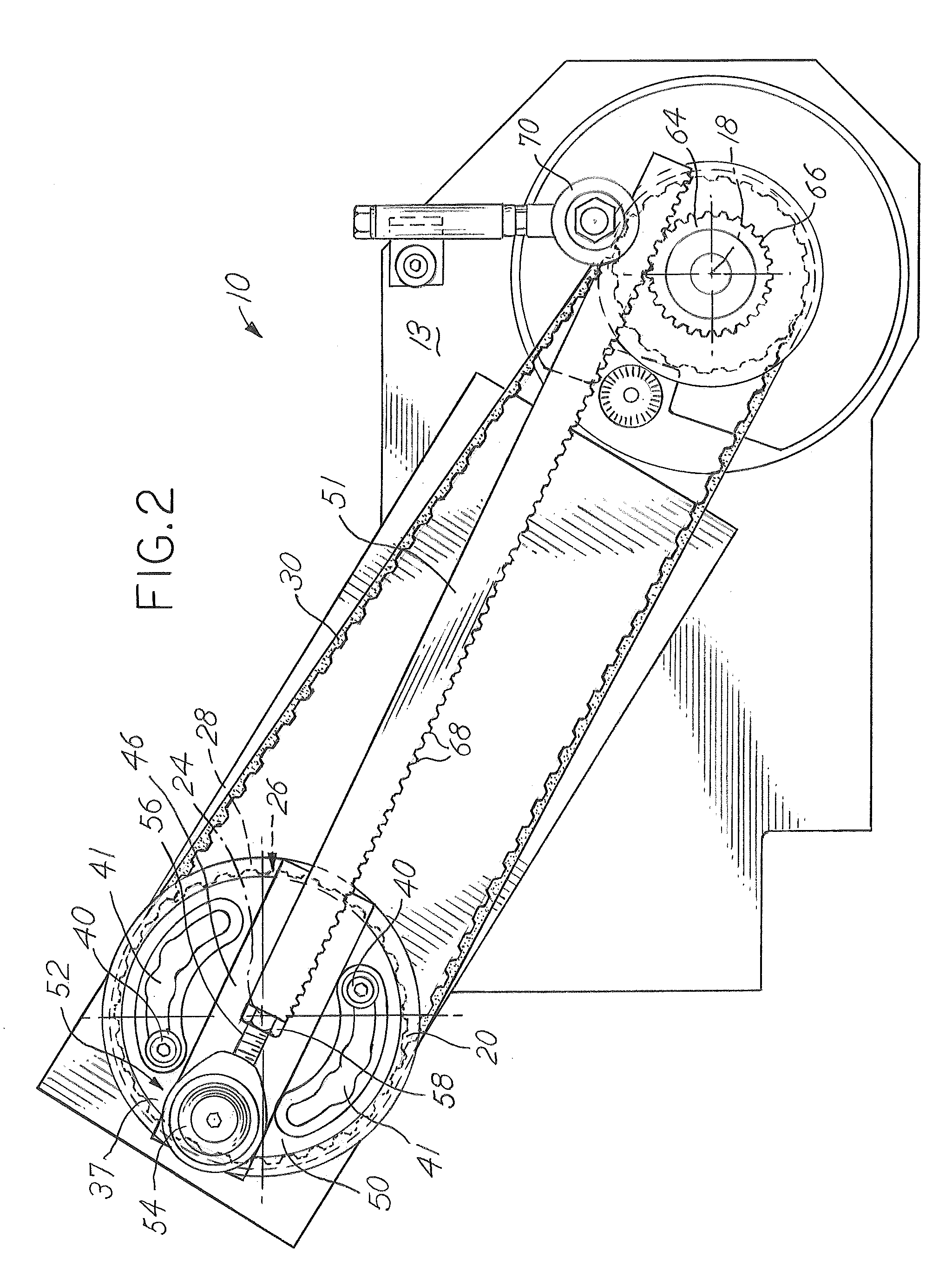

InactiveUS8127645B1Revolution surface grinding machinesGrinding drivesMachine partsReciprocating motion

A machine and method for machining parts of partial revolution. The machine has a driving sheave rotatable about a first axis and a first driven sheave rotatable about a second axis fixed relative to the first axis. An eccentric link is rotatably connected to the first driven sheave at a pivotal connection that is spaced a predetermined distance from the second axis. A belt is wrapped around the driving sheave and the first driven sheave so that rotation of the driving sheave causes the first driven sheave to rotate. A second driven sheave is rotatable about a third axis fixed relative to the second axis. A second driven sheave contacts with the eccentric link. The eccentric link moves in a reciprocating motion when said first driven sheave is caused to rotate and causes reciprocating rotary motion in the second driven sheave, which is transferred to a part being machined.

Owner:C M GRINDING

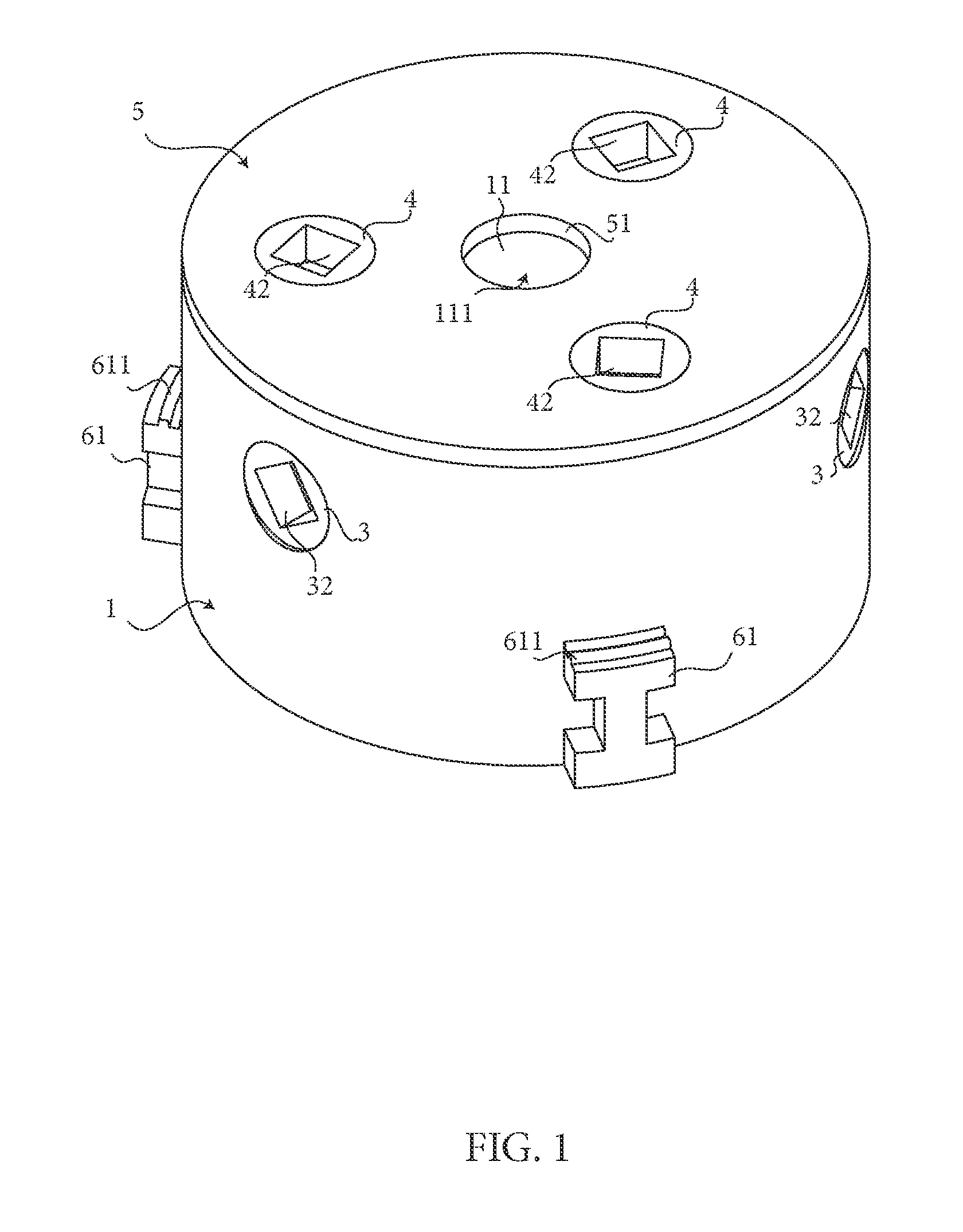

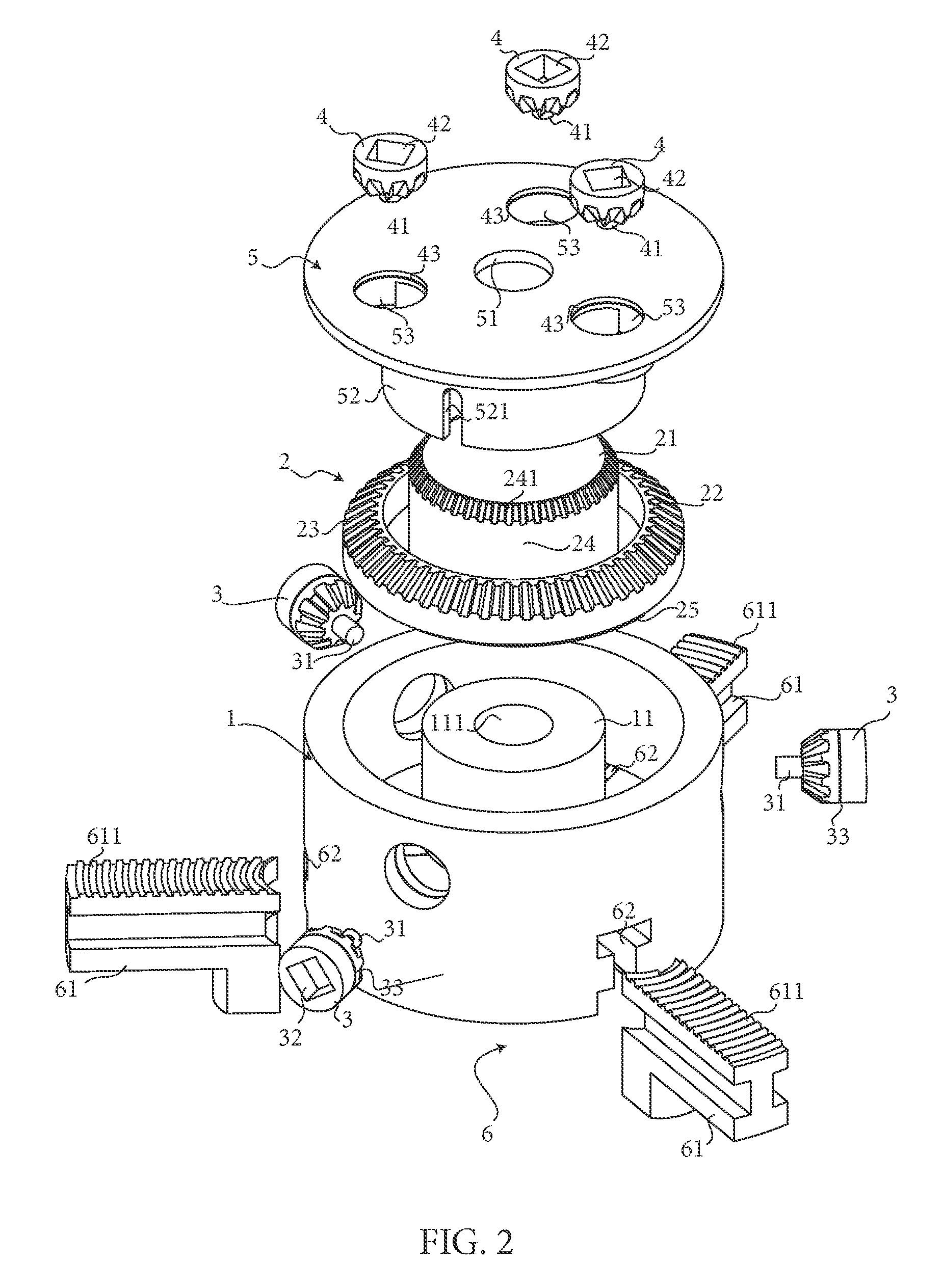

Dual lock brake lathe chuck

A dual lock brake lathe chuck comprises of at least one primary drive gear with keyhole along with at least one secondary drive gear with keyhole. The keyhole is rotated through the side of the chuck whereas the secondary keyhole is rotated through the back of the chuck. Rotation of either the primary keyhole or the secondary keyhole extends a plurality of jaws to secure a brake rotor on a brake lathe. The secondary keyhole positioned on the back of the chuck allows easier access of the keyhole when a brake rotor is attached to the chuck allowing the user to ensure that the brake rotor is securely tightened onto the brake lathe chuck.

Owner:DOLE LONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com