Knuckle hub assembly and method for making same

a technology of hub assembly and knuckle, which is applied in the direction of manufacturing tools, brake discs, transportation and packaging, etc., can solve the problems of performance and run-out problems, the approach has not found widespread acceptance, and the manufacturers have faced difficulties in achieving enhanced control over these tolerances. achieve the effect of reducing the lateral run-out of the hub

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

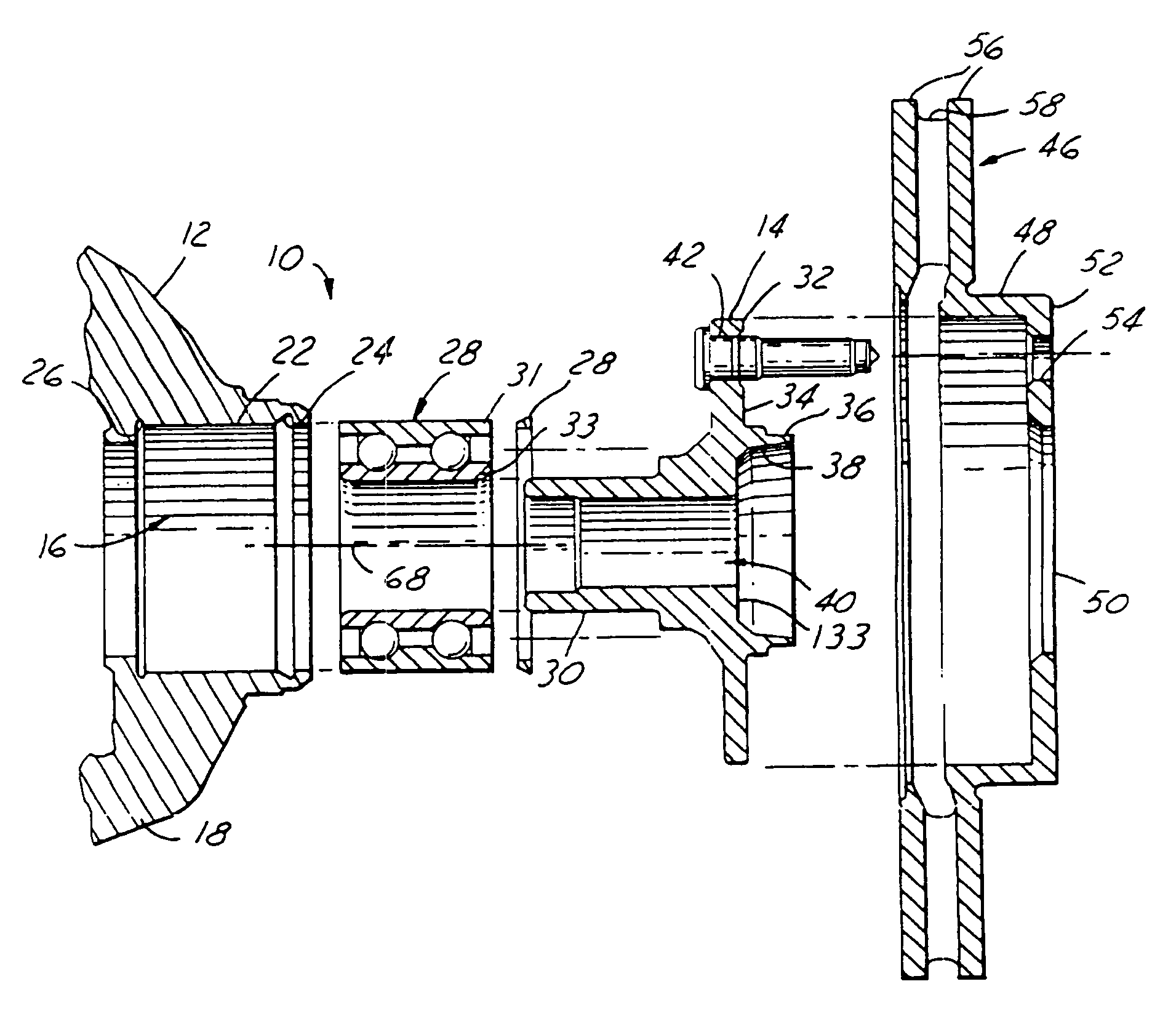

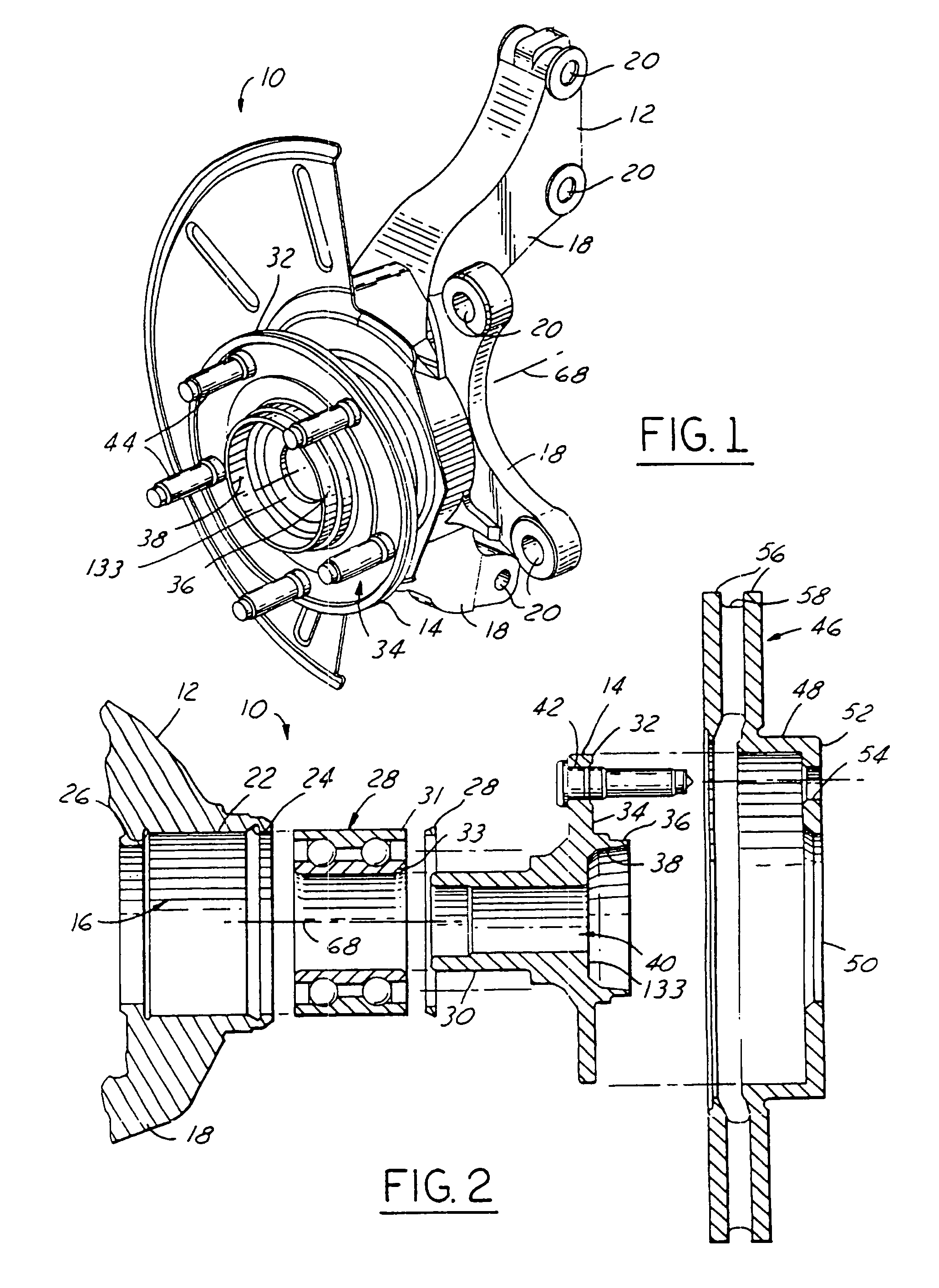

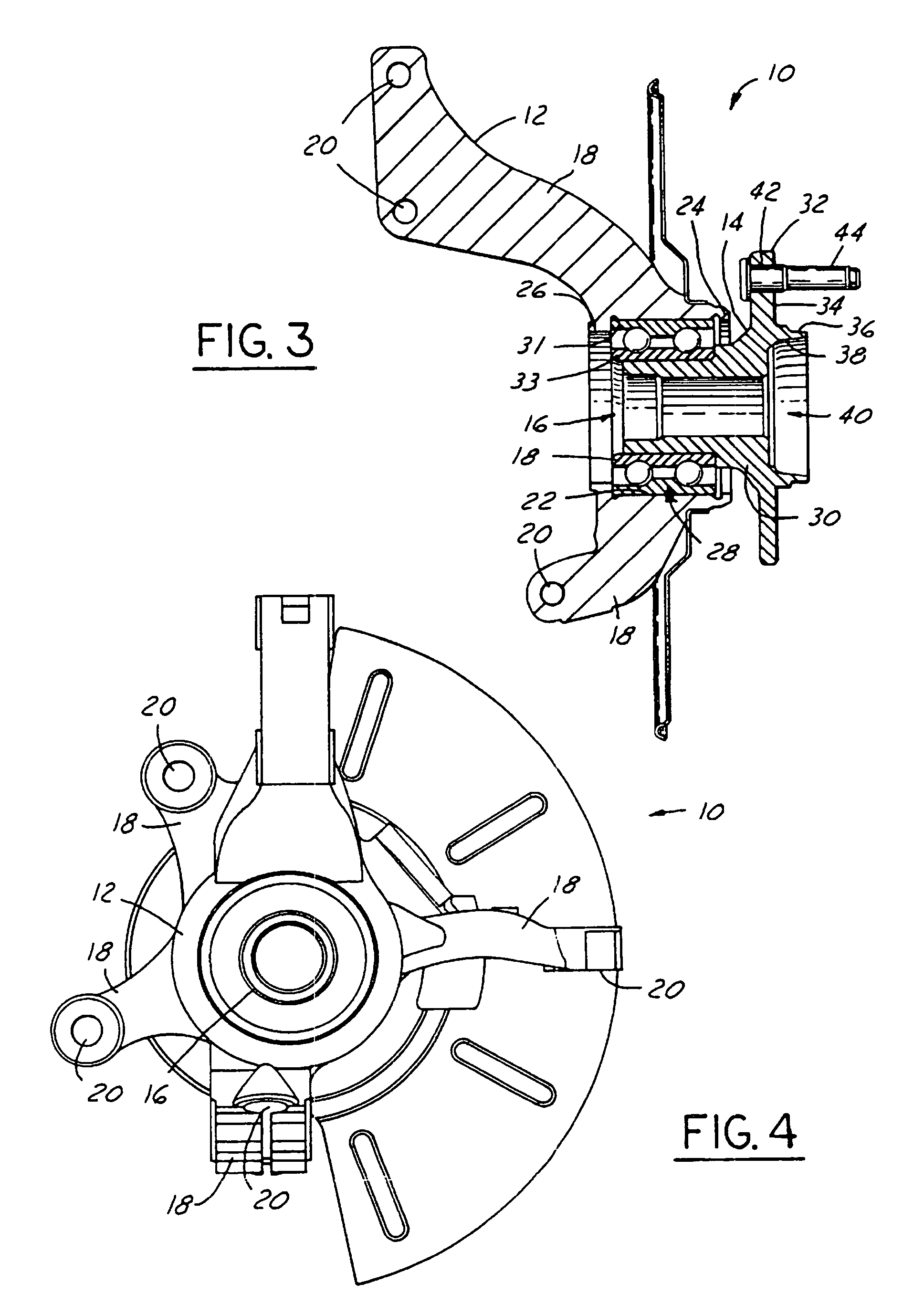

FIGS. 1 through 4 illustrate a preferred knuckle / hub assembly, as generally indicated by reference number 10, in accordance with the present invention. The assembly 10 is comprised of a variety of components, including a knuckle 12 and a wheel hub 14. The knuckle 12 is preferably constructed of metal and is generally formed by casting while the wheel hub 14 is preferably constructed of metal. The knuckle and hub can obviously be formed of other materials. The knuckle 12 preferably has a generally circular bore 16 formed therein and a plurality of outwardly extending appendages 18 that attach to the vehicle through a plurality of apertures 20 formed in the plurality of legs 18, as is well known in the art.

The bore 16 has a recess 22 formed therein bounded by an upper snap ring groove 24 and a lower snap ring 26 or shoulder for receiving a bearing 28 press fit therein. A snap ring 29 is preferably press fit or otherwise secured into the upper snap ring groove 24 prior to engagement of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flatness | aaaaa | aaaaa |

| flatness | aaaaa | aaaaa |

| flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com