Packaging bag

A packaging and bag technology, applied in the field of packaging bags, can solve the problems of taking out the packaged objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

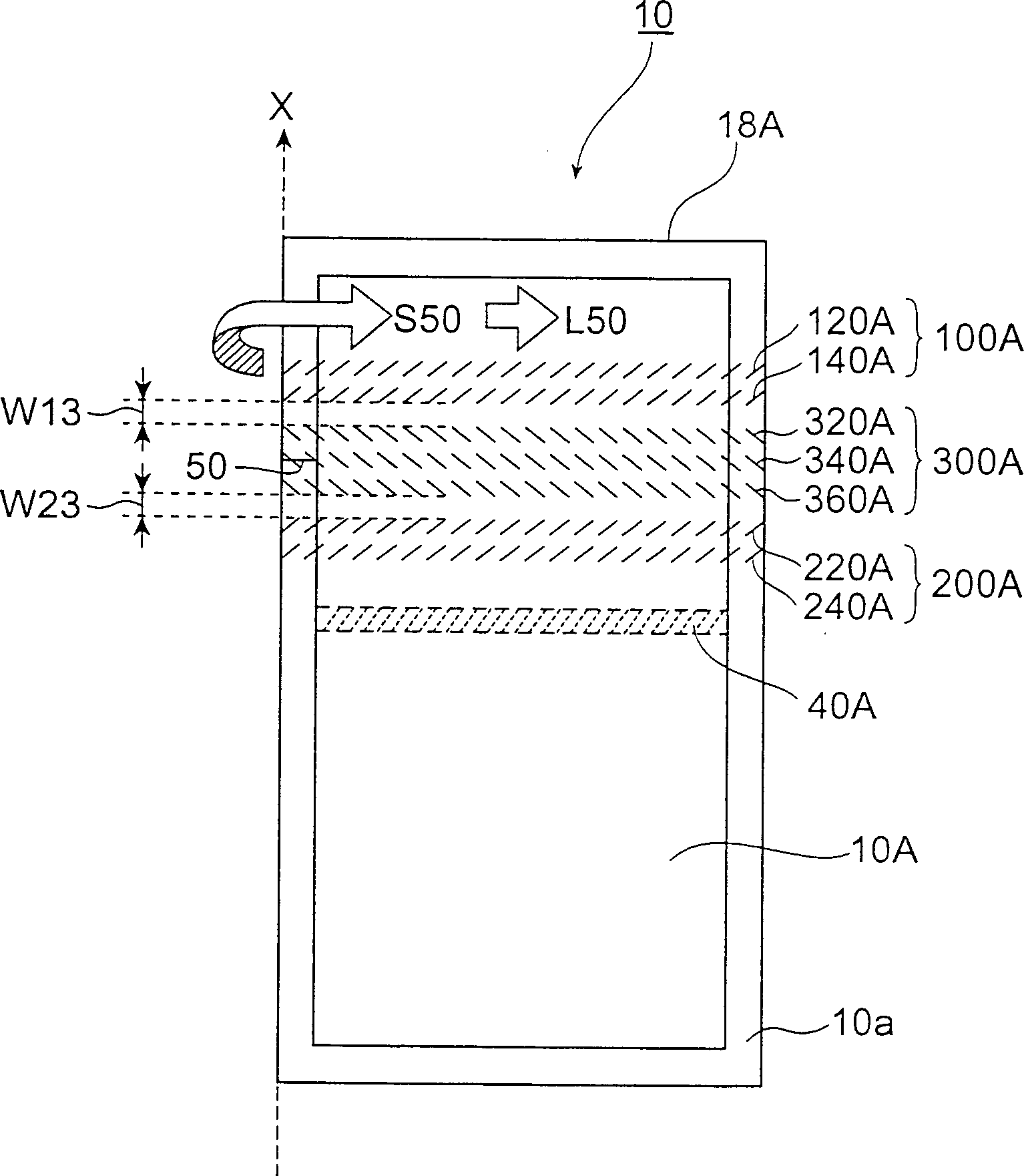

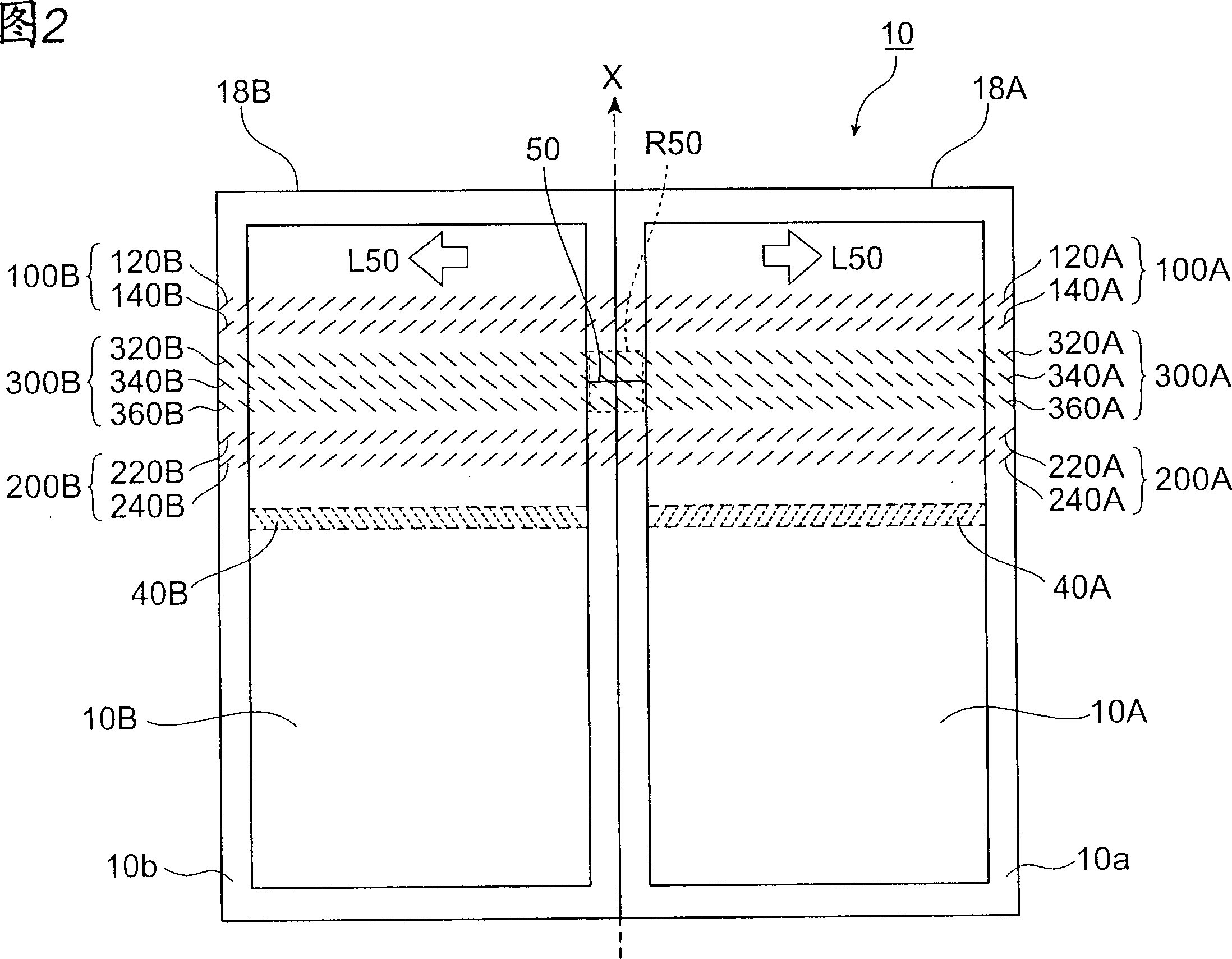

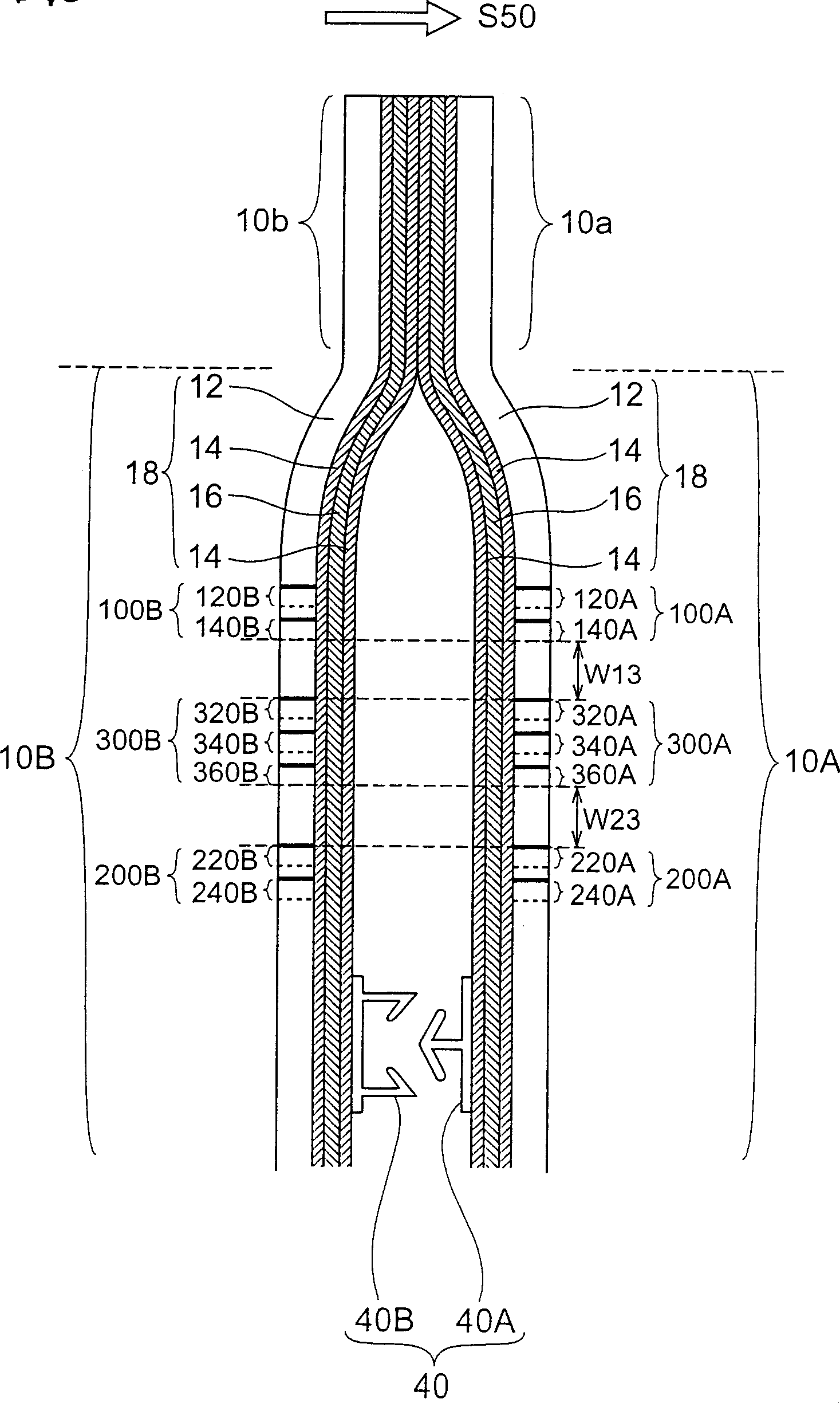

[0147] Rectangular composite laminated film (total thickness of 4 layers: 100μm) is produced by laminating 4 layers of paper, plastic film (polyethylene), aluminum foil, and plastic film from the outside. , as the first surface 10A and the second surface 10B, respectively. Next, a first tear line, a second tear line, and a third tear line are formed on the first surface 10A and the second surface 10B of the packaging bag, and the first tear line, the second tear line and the third tear line by having the same Figure 7 and Figure 8 The shown packaging bag body 11 is configured with the same shape of the breaking portion and the same number of tearing lines.

[0148] That is, the third tear line is formed on the first surface 10A and the second surface 10B with Figure 7 and Figure 8 The same 8 tear lines are shown. In addition, for these 8 tear lines, the inclination angle D300 of the breaking portion of each tear line relative to the desired unsealing direction L50 is ...

Embodiment 2

[0154] A packaging bag was manufactured in the same manner as in Example 1 except that the number of tear lines constituting the third tear line was six.

[0155] As a result of forming the third tear line in this way, the overall width of the third tear line in the direction perpendicular to the desired unsealing direction L50 is 2.70mm. The third tear line, the second tear line and the first The total width in the direction perpendicular to the desired unsealing direction L50 of the tear line forming region of the tear line was 4.42 mm.

Embodiment 3

[0157] A packaging bag was produced in the same manner as in Example 1 except that the number of tear lines constituting the third tear line was ten.

[0158] As a result of forming the third tear line in this way, the overall width of the third tear line in the direction perpendicular to the desired unsealing direction L50 is 4.24mm. The third tear line, the second tear line and the first The total width in the direction perpendicular to the desired unsealing direction L50 of the tear line forming region of the tear line was 5.96 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com