Suspended insulator

An insulator, hanging type technology, applied in the field of hanging type insulators, can solve the problems of increased surface impedance, conductive surface erosion, etc., to achieve the effect of improving the fouling resistance voltage, preventing fouling corona, and improving the voltage distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

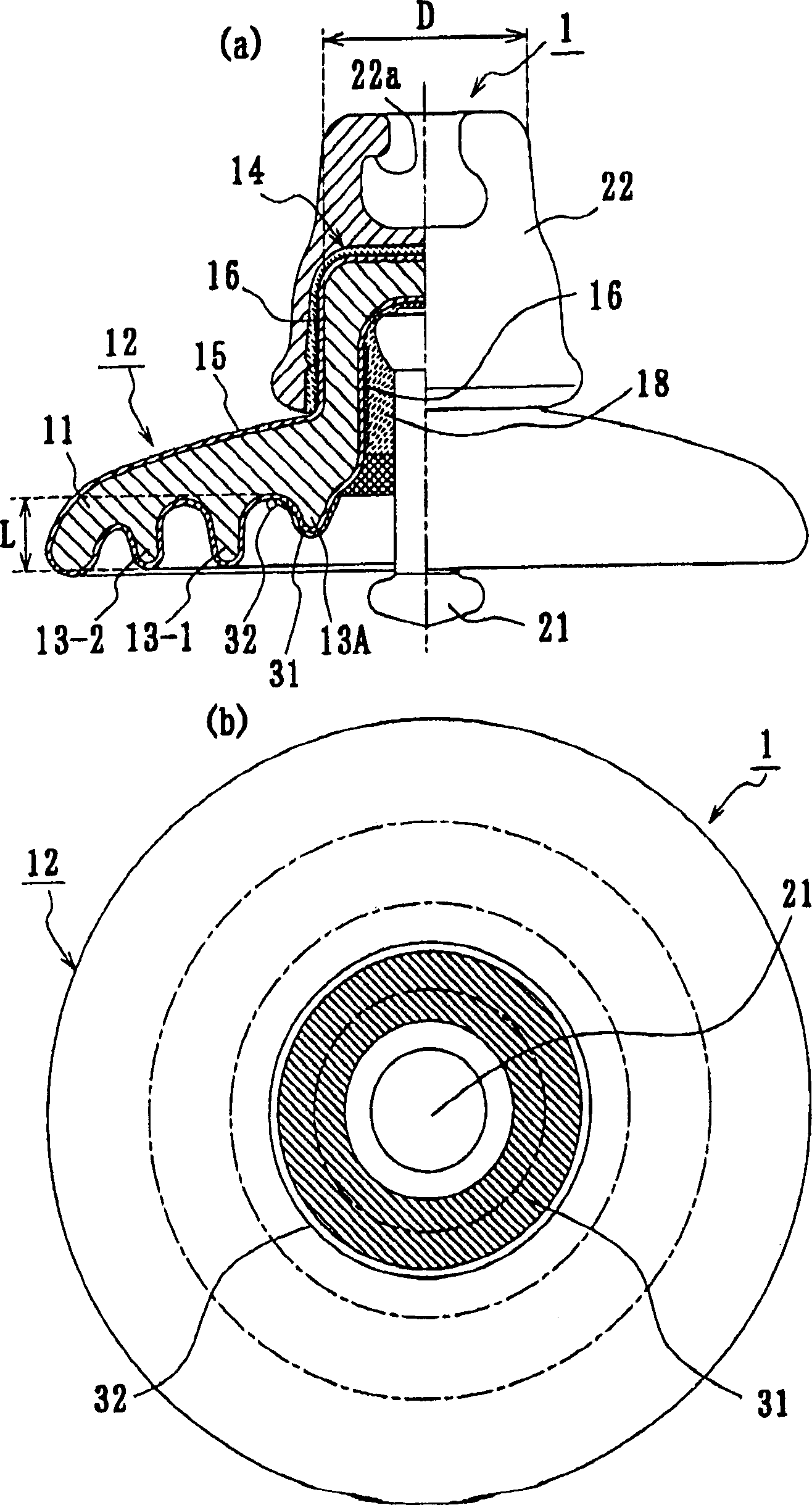

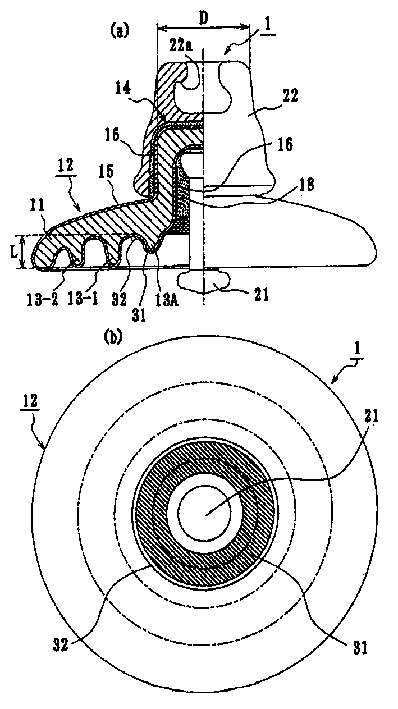

[0024] Example 1 (about the length of the flange)

[0025] In order to obtain an appropriate range of the flange length in the first aspect of the present invention, as shown in Table 1 below, hanging insulators having various shed diameters and leakage distances were prepared. In each suspension type insulator, a conductive glaze layer composed of a resistive band and a ring-shaped conductive band is also formed up to the inner base of the target flange. The shape of each target flange is shown in Table 1 below. CA-500, CA-826, CA-845 have figure 1(a), (b) shows the shape of the annular protrusion 13A, the annular protrusion is shown as the first object flange, and the first annular flange 13-1 is shown as the second object flange. . CA-894 with figure 1 Unlike (a) and (b), the flange has a thin and long flange shape, and is a shape in which the annular protrusion 13A does not exist. Therefore, in CA-894, the first annular flange 13-1 is shown as the first target flange....

Embodiment 2

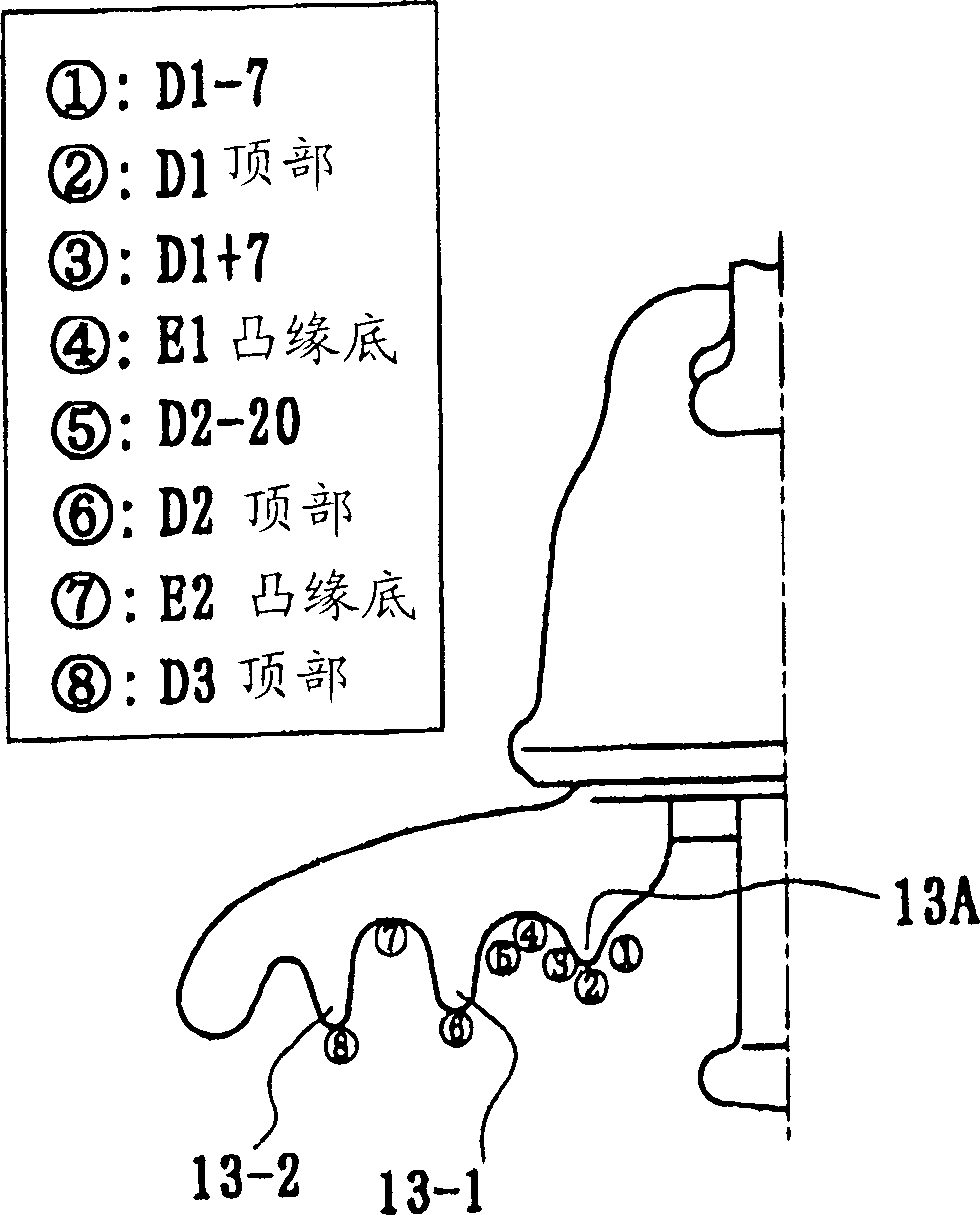

[0030] Example 2 (about the diameter of the ring electrode)

[0031] In order to obtain the appropriate range of the diameter of the conductive glaze layer (meaning the same as the diameter of the annular electrode (conductive band)) of the second aspect of the present invention, prepared figure 2 The ring-shaped electrode (conductive band) is installed at the position shown in ①~⑧, and the ring-shaped electrode and the impedance band are installed from the pin to the position shown in ①~⑧. For the prepared suspension insulator, find the length of the target flange with respect to the electrode diameter at each position, electrode diameter / cover magnet diameter (= 82mm) and the position where the ring electrode exists on the inner side of the flange with flange / leakage distance. Connect 5 prepared hanging insulators, and the adhesion density in salt: 0.25mg / cm 2 , Additional voltage: Under the condition of 55kV, according to the fog test method determined above, investigate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface resistance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com