Gasifying anxiliary device for high pressure jetting oil and water

A high-pressure fuel injection and auxiliary device technology, applied in the charging system, fuel re-atomization/homogenization, combustion air/combustion-air treatment, etc., can solve the problems of polluting power, loss, poor mixing effect, etc. The effect of output power and emission quality, simple structure, easy maintenance and repair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

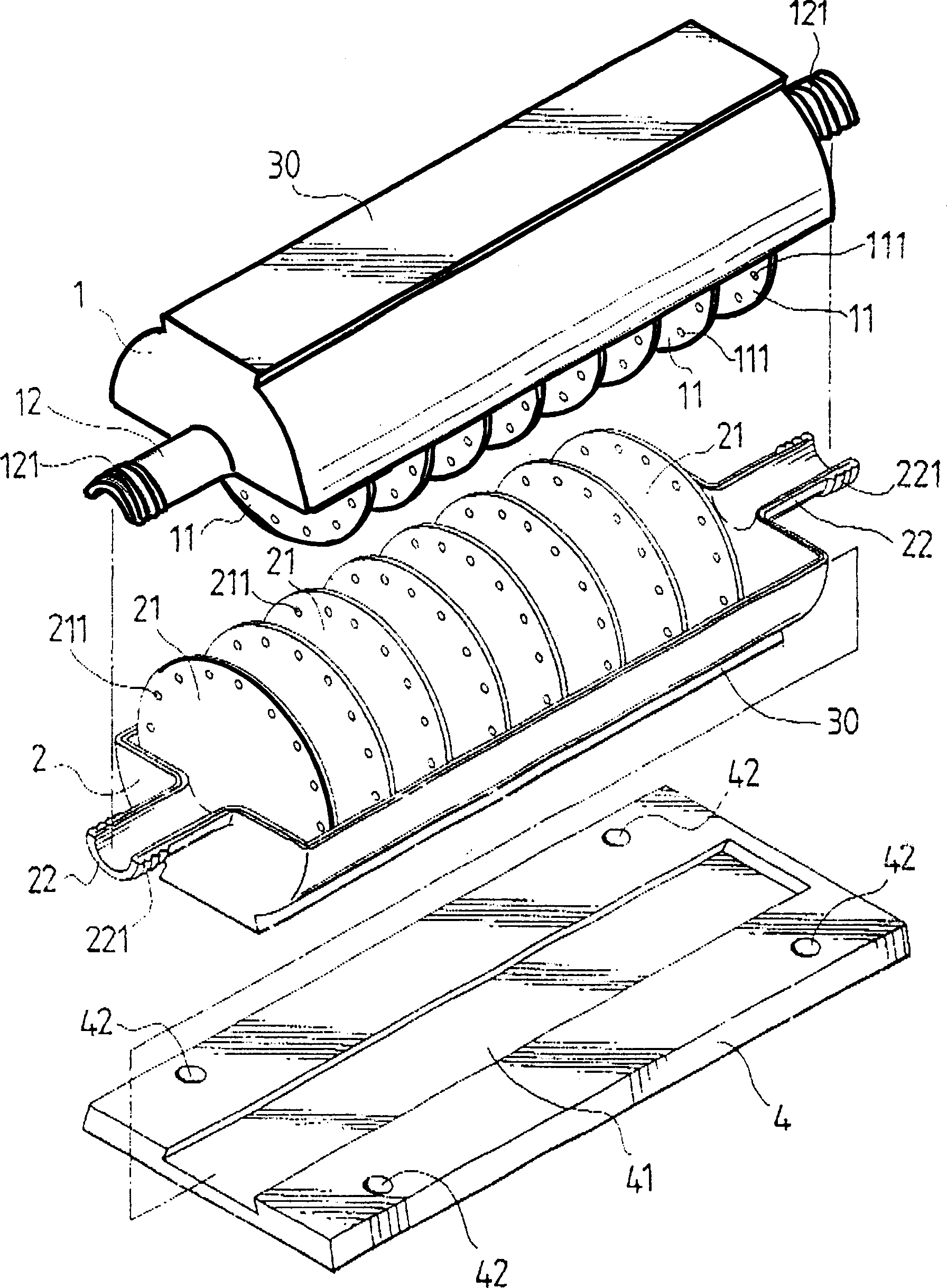

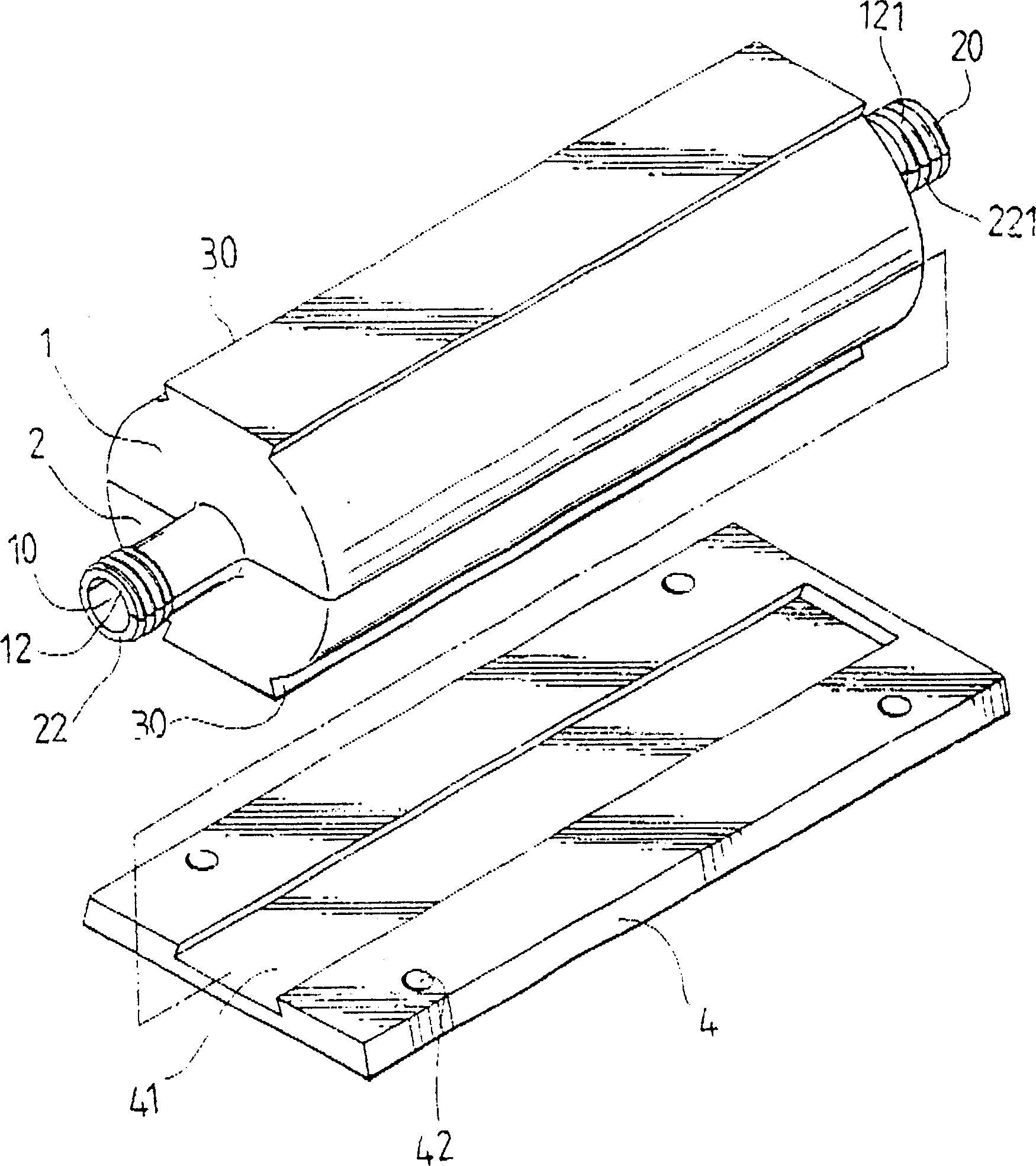

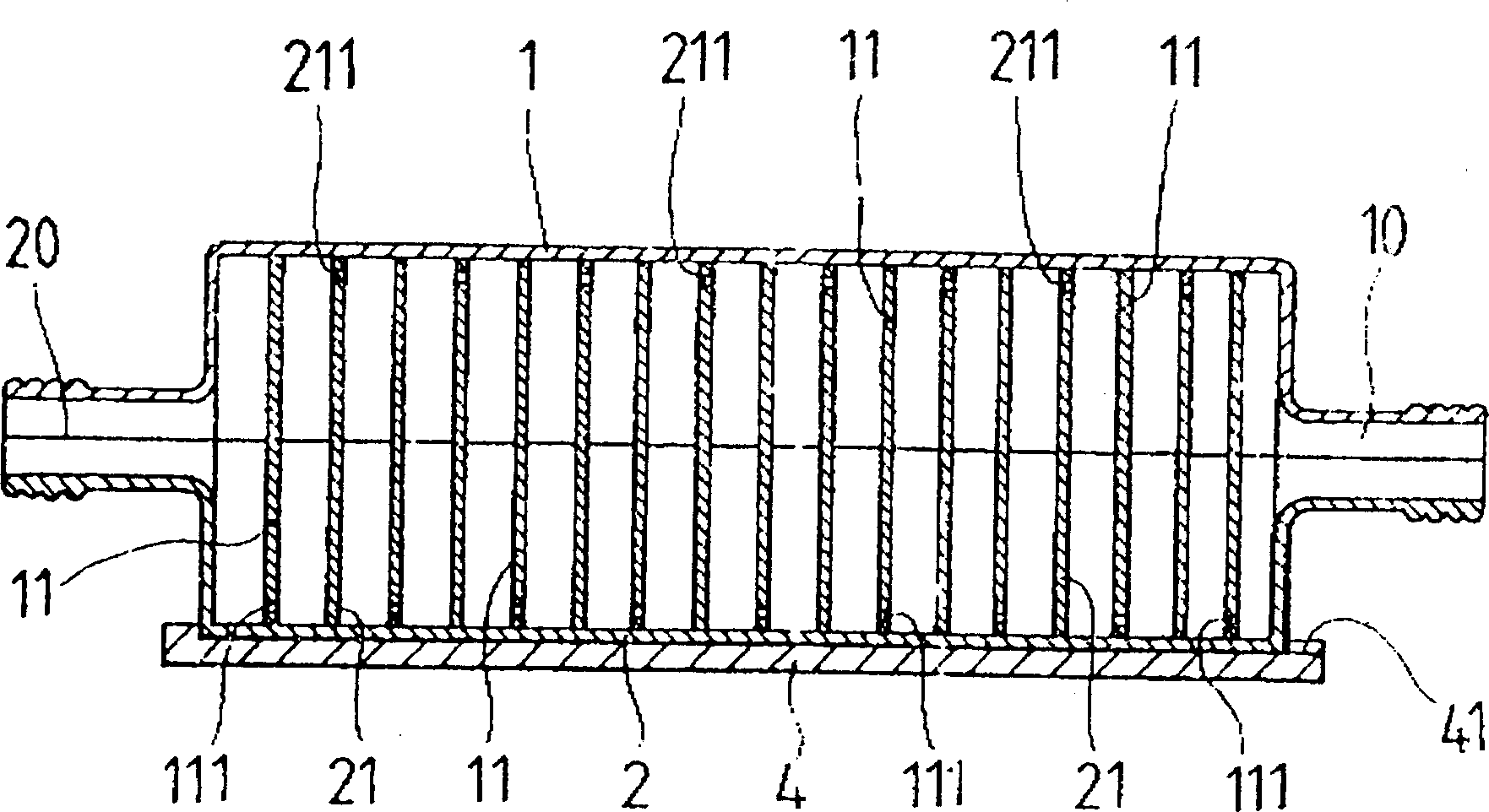

[0021] Depend on Figure 1 to Figure 4 As shown, the present invention includes an upper casing seat 1, a lower casing seat 2, and a plurality of upper gasification blades 11 and lower gasification blades 21, wherein the upper casing seat 1 and the lower casing seat 2 are seats that can be covered correspondingly , the plurality of upper gasification vanes 11 and lower gasification vanes 21 arranged in them are distributed at intervals interlaced with each other. When the upper housing base 1 and the lower housing base 2 are closed, one of the two ends forms an oil inlet joint 10, and the other One is the oil outlet joint 20; a plurality of upper and lower gasification blades 11, 21 are respectively formed on the inner walls of the upper and lower shell seats 1, 2, and are distributed at intervals, and the upper and lower gasification blades 11 , 21 set a plurality of upper blade gasification holes 111 and lower blade gasification holes 211 in the exposed parts of the upper an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com