Full-plane soft circuit board connector

A flexible circuit board, full-plane technology, applied in the direction of circuits, connections, instruments, etc., can solve the problems of inconvenient operation, limited space of the locking cover, laborious operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

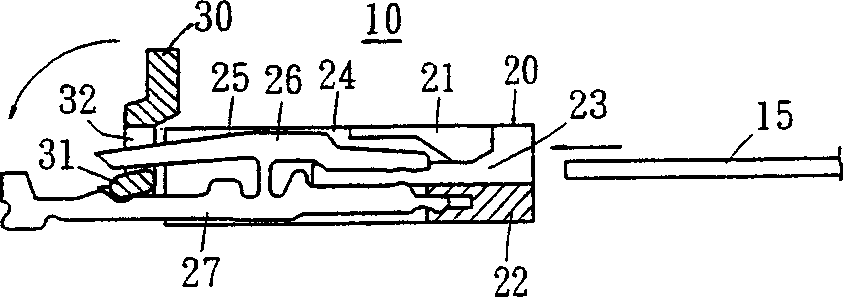

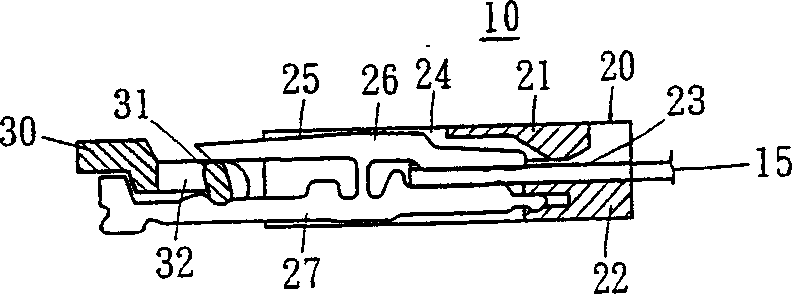

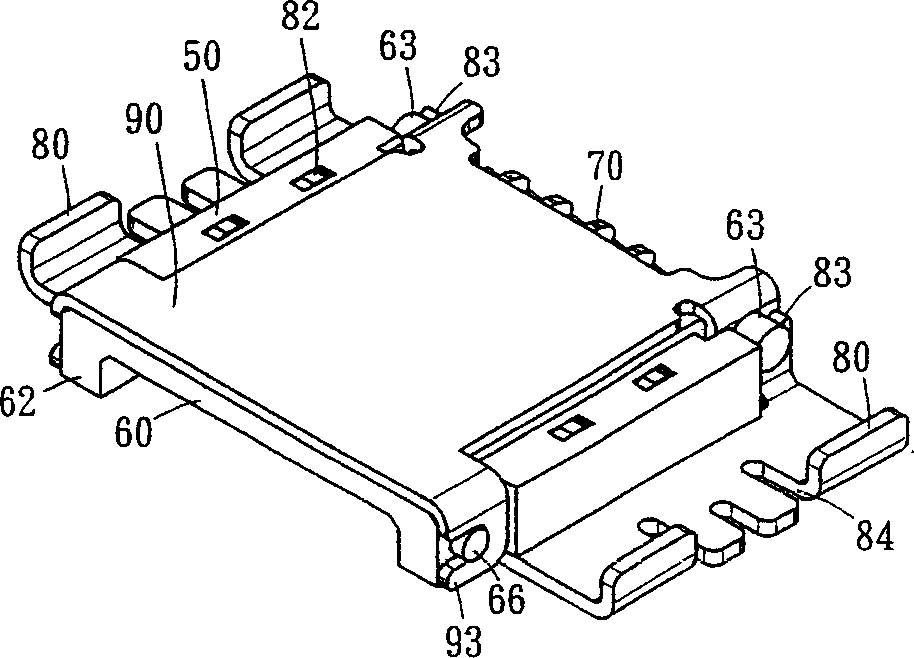

[0045] see Figure 6 to Figure 9 , when the flexible circuit board (15) is to be plugged in, the movable upper cover (60) of the full-plane flexible circuit board connector (40) is lifted to the maximum angle to the rear, and the opening slot of the concave body (50) is (51) fully reveals, to facilitate the flexible circuit board (15) to carry out plug-in operation, at this moment, the upper pin (71) of plug-in terminal (70) is owing to break away from the protruding shaft ( 65), the front portion of the upper pin (71) does not have a tendency to be pressed downwards, so the flexible circuit board (15) follows the sides of the opening groove (51) of the concave body (50) The side rib (52) can be easily plugged into the inserting groove (75) of the plug terminal (70), and forms an electrical connection with the plug terminal (70). Then, the movable upper cover (60) Cover forward in the opening groove (51) of the concave body (50), at this time, the bending part (74) of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com