Camera module and mfg. method thereof

A manufacturing method and camera technology, which are applied in multilayer circuit manufacturing, semiconductor/solid-state device manufacturing, image communication, etc., can solve the problems of complex installation structure and increased cost of camera modules.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] (A first embodiment for explaining the structure of the camera module 10)

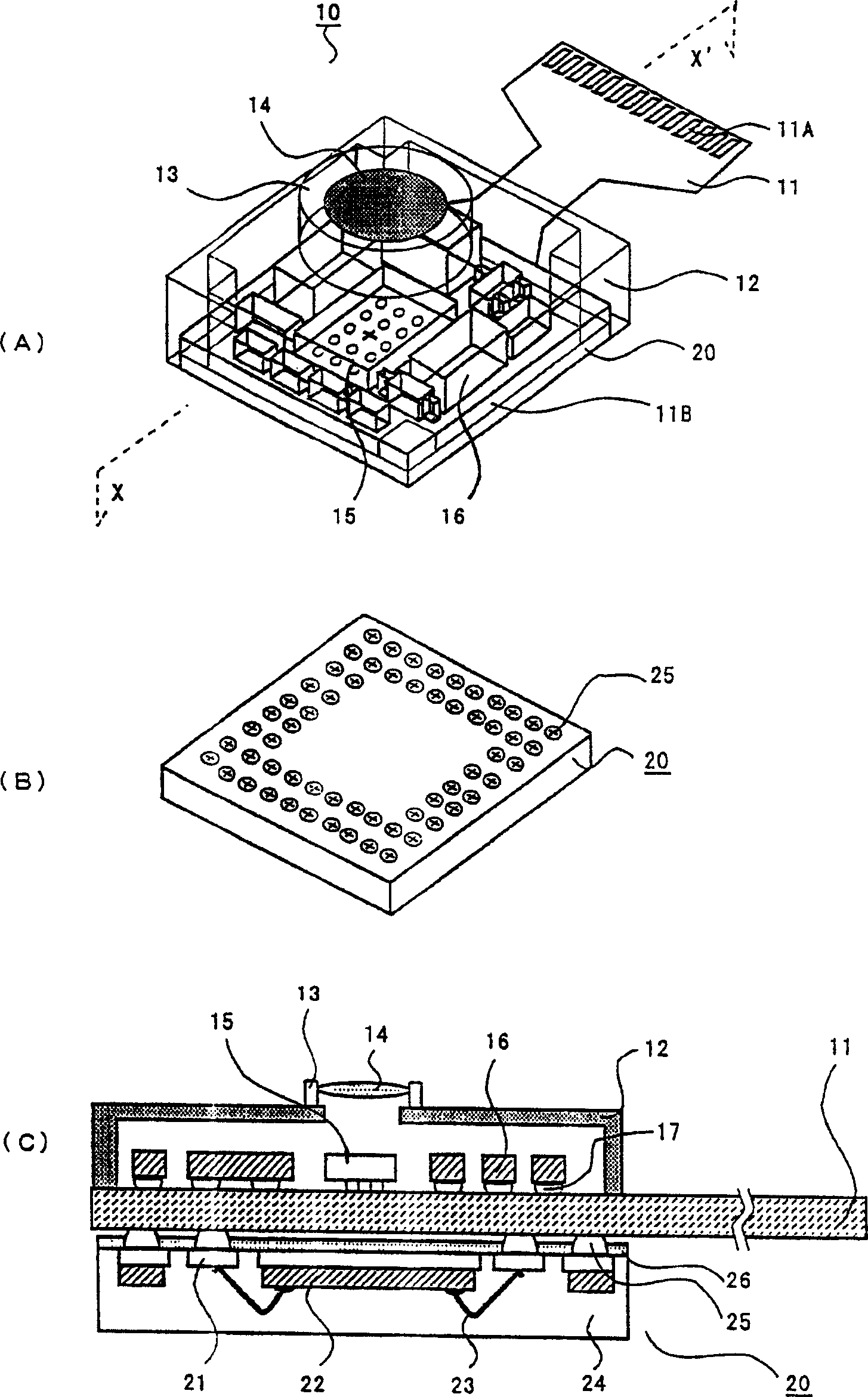

[0047] refer to figure 1 The configuration and the like of the circuit device 10 of the present invention will be described. figure 1 (A) is a perspective view of the camera module 10, figure 1 (B) is a perspective view of the circuit device 10, figure 1 (C) is figure 1 (A) X-X' section view.

[0048] refer to figure 1A. The camera module 10 has the following structure. Namely comprising: the flexible board 11 of the resin sheet that has conductive circuit on both sides; The lens holder 12 that is arranged on the surface of flexible board 11; The circuit device 20 that is installed on the back side of flexible board 11; ; The lens 14 fixedly installed on the top of the lens holder 12, the circuit device 20 is equipped with a structure of semiconductor elements and passive elements electrically connected to the CCD. Such constituent elements will be described below.

[0049] refer t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com