Tumble-plating device

A barrel plating and roller technology, applied in the direction of electrodes, cells, electrolysis process, etc., can solve the problems of high thermal expansion rate, low precision of insulating layer formation, difficulty of roller rotation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

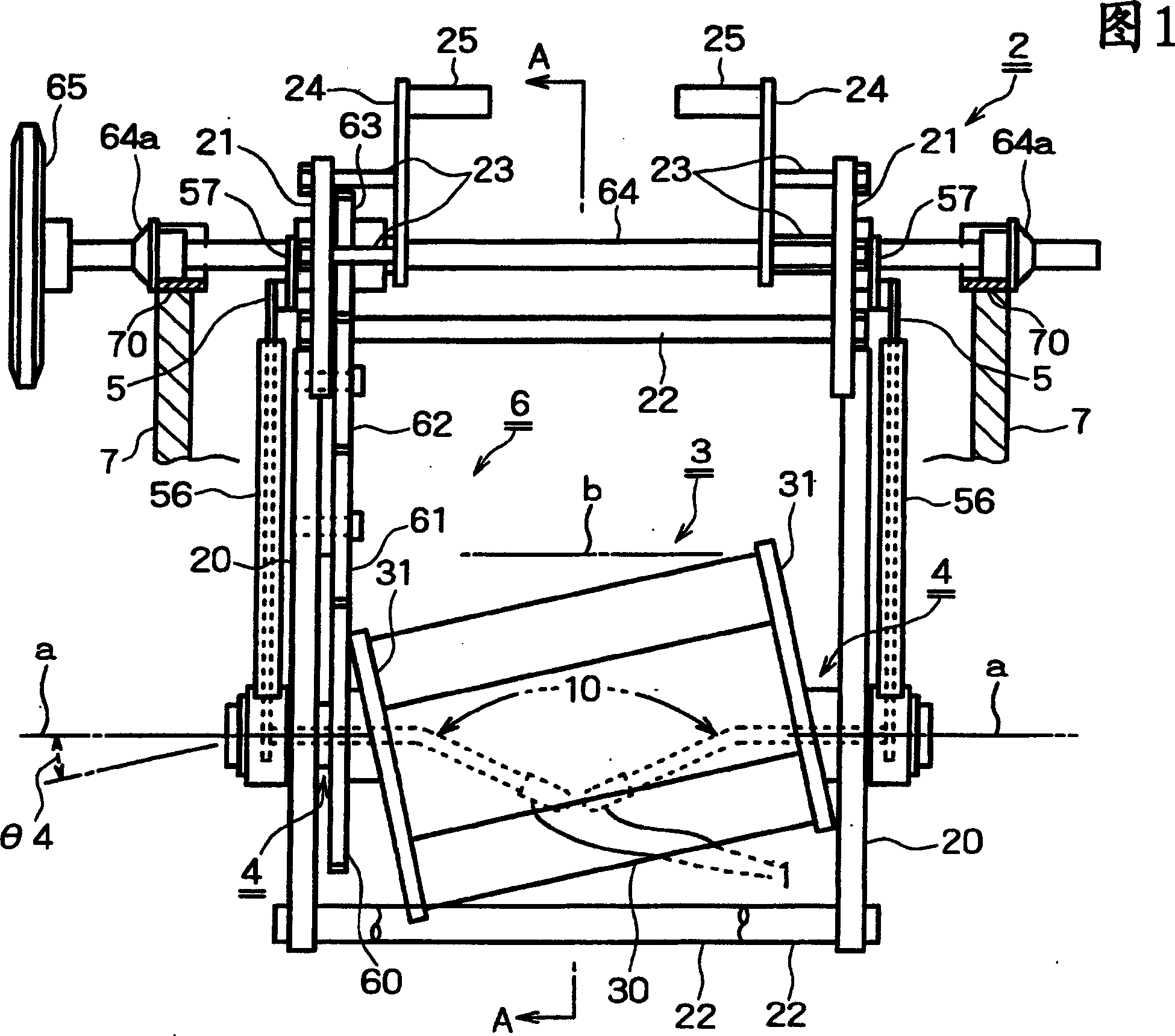

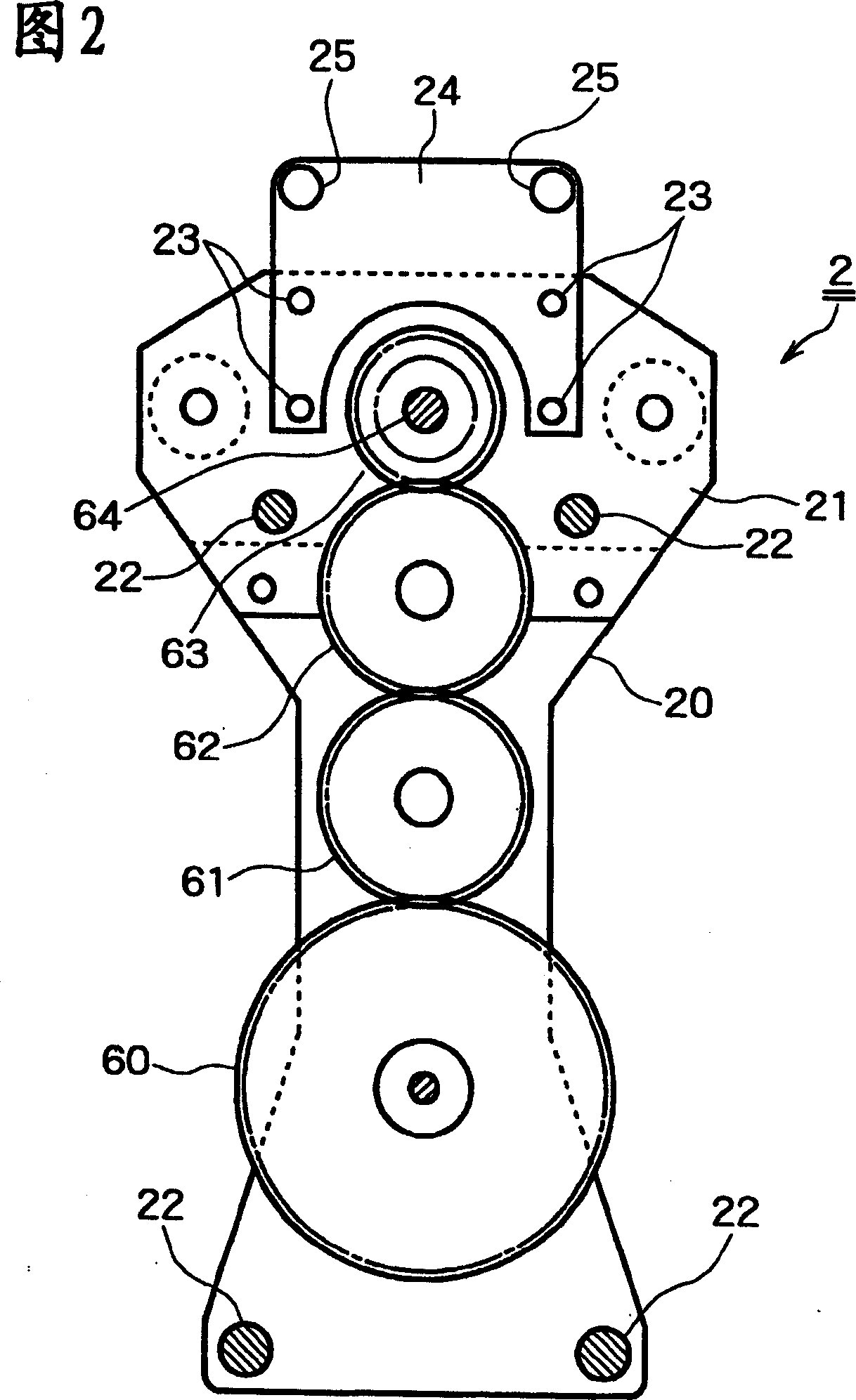

[0031] Hereinafter, first, the outline of the barrel plating apparatus of the present invention will be described with reference to FIGS. 1 and 2 .

[0032] Shown in Fig. 1 and Fig. 2, barrel plating device of the present invention has cylinder support frame 2, and this cylinder support frame 2 is contained in the electroplating bath 7, connects by the support member 20 of predetermined interval opposite by a plurality of connecting rods 22, 20. An upper support plate 21 is attached to the upper portion of each support member 20 .

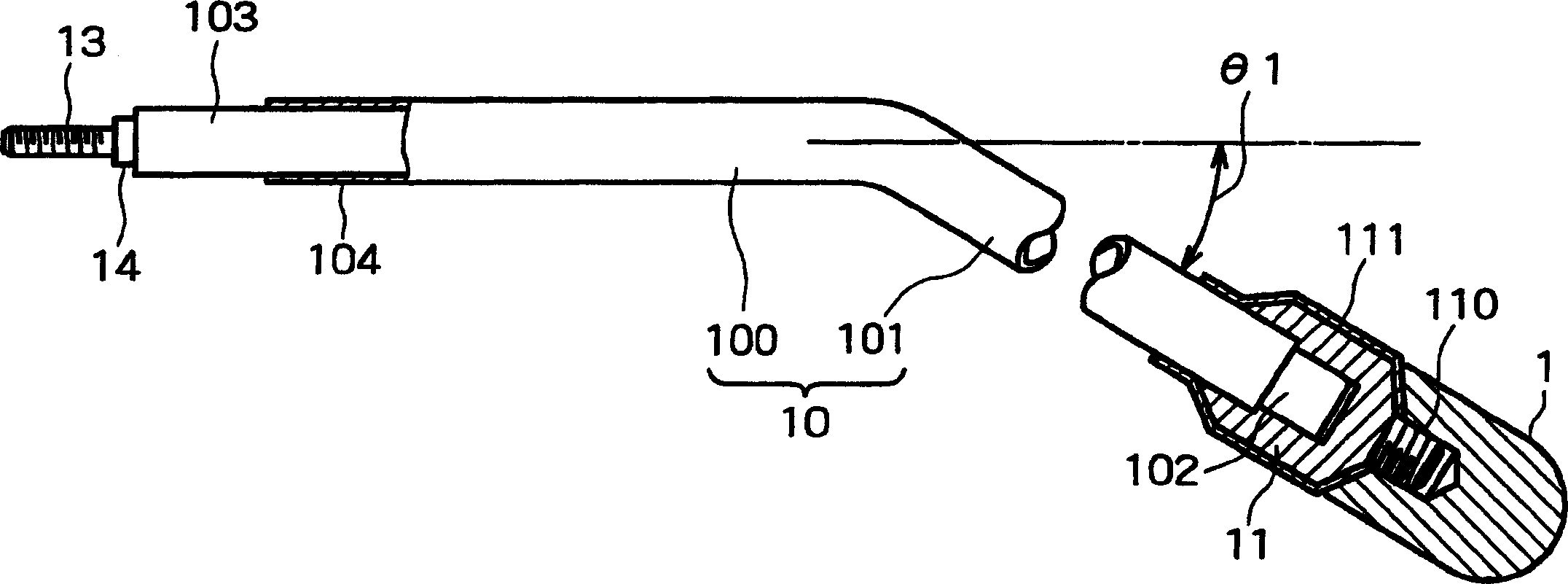

[0033] The hollow support shafts 4 are respectively attached to penetrate from the outside at the same height of the lower part of each support member 20 . Except that both ends of the drum 3 are rotatably mounted on the support shaft 4, the lead wires 10 of the electrode (cathode) 1 are inserted through the interior in a non-rotatable and waterproof state.

[0034] The drum 3 is composed of a hollow cylinder 30 and end plates 31 , 31 . The holl...

no. 2 Embodiment approach

[0090] Fig. 10 is a partial sectional view showing a second embodiment of the electrode lead mounting structure of the present invention.

[0091] In this embodiment, the lead wire 10 and the current-carrying member 5 in the first embodiment are integrally formed, and the support shaft 4 is integrally formed without providing the cover portion 42 .

[0092] The other configurations and effects are substantially the same as those of the first embodiment, and description thereof will be omitted.

Embodiment approach

[0094] In each of the above-mentioned embodiments, the bushing 32 is installed in the insertion hole 312 on the end plate 31 of the drum 3, but the bushing 32 may be omitted. When the drum 3 rotates, the inner peripheral surface of the insertion hole 312 is relatively The outer peripheral surface of the sleeve 12 slides.

[0095] In the first embodiment, the adjustment plate 46 for adjusting the posture of the lead wire 10 is fixed to the current-carrying member 5 with the screw 47, but the adjustment plate 46 is fixed to the support shaft 4 (connecting part cover 41) with the same screw 47, and has the same Effect.

[0096] In the above embodiment, the bent portion 101 of the lead wire 10 is formed in an oblique linear shape, but the bent portion 101 may be formed in an arc shape or a polygonal shape, and may be formed in a convex shape obliquely upward or downward.

[0097] As adopt barrel plating device of the present invention, lead wire 10 runs through the bearing part o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap