Hinge apparatus

A hinge device and a technology for installing parts, which are applied in the directions of printing devices, hinges with pins, multi-purpose hand tools, etc., can solve problems such as changes in closing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

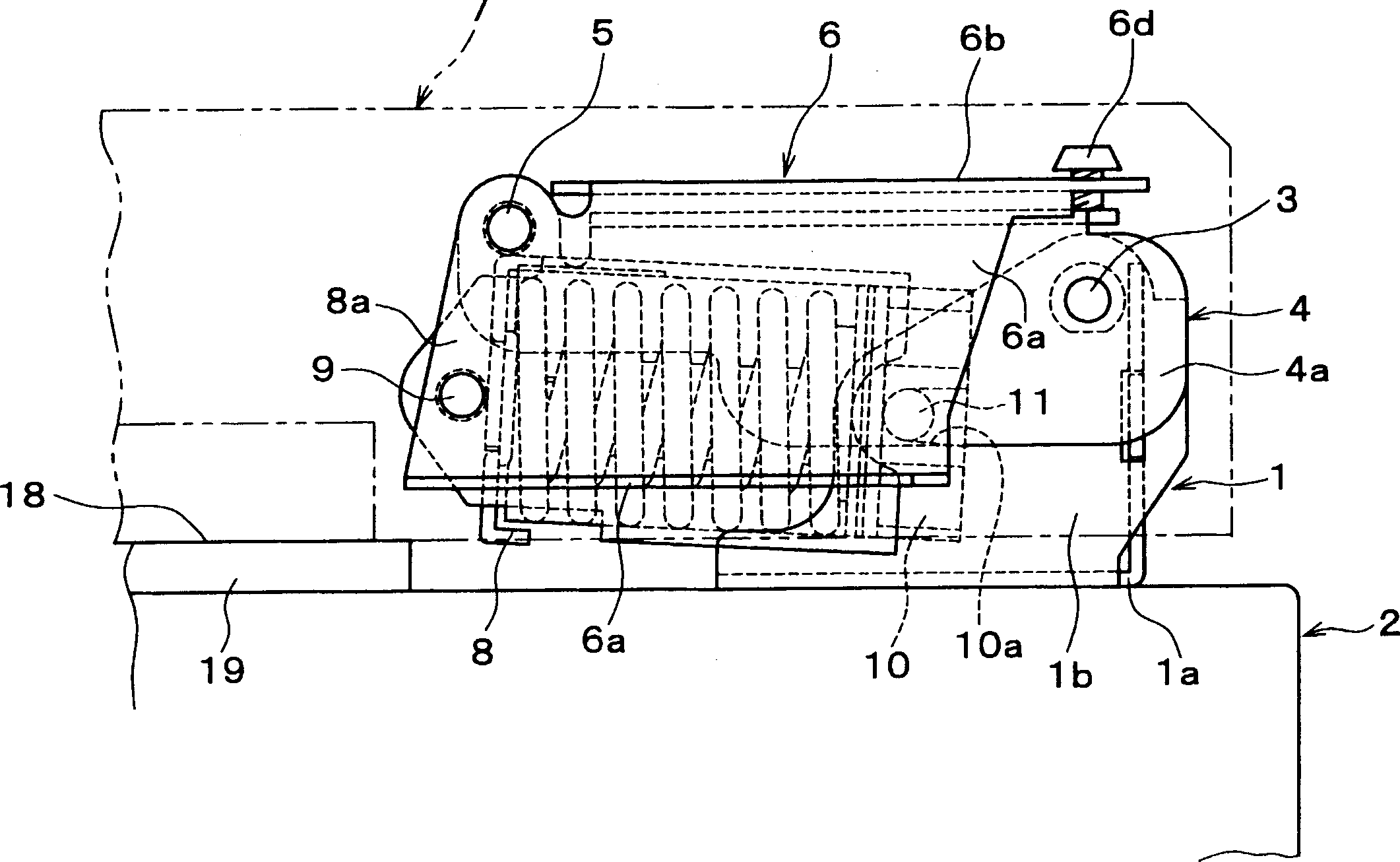

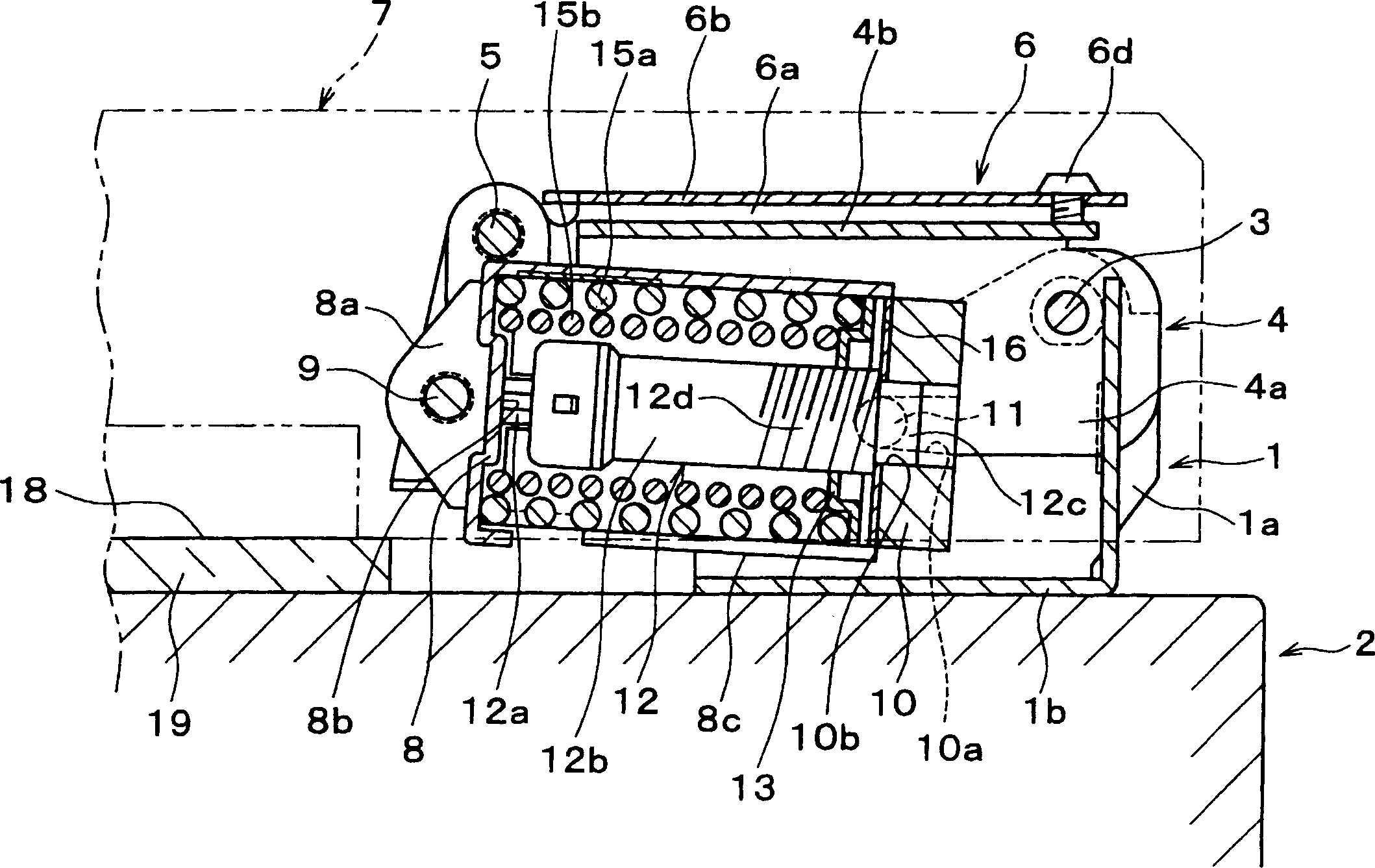

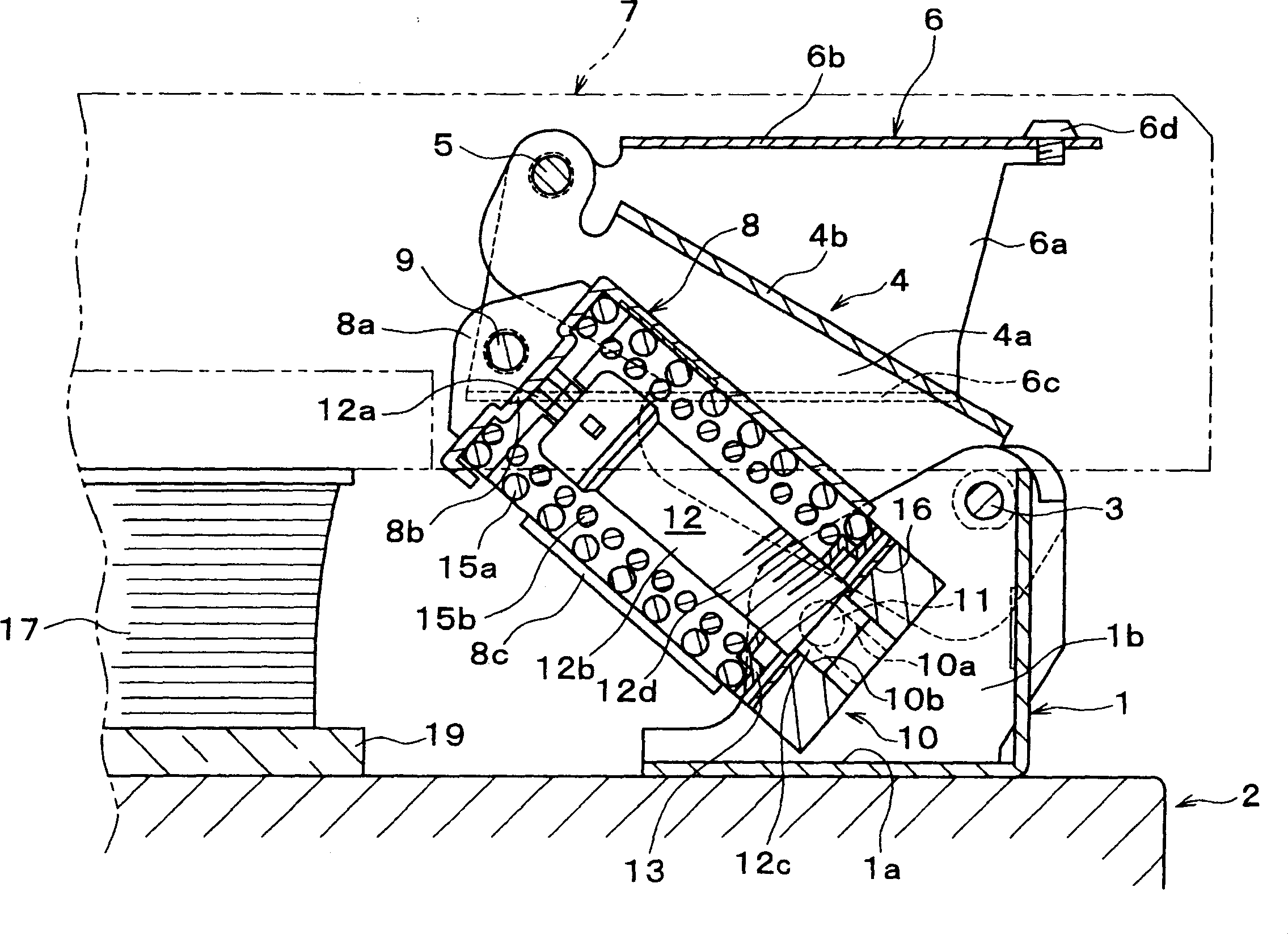

[0021] Hereinafter, an embodiment in which the hinge device of the present invention is applied to a copying machine will be described in detail with reference to the accompanying drawings.

[0022] In the accompanying drawings, reference numeral 1 is the mounting part installed on the upper end of the body 2 rear of copier or printing machine, and the two side plates 4a, 4a of supporting part 4 are supported by the first hinge pin 3 on the installation part from above-mentioned mounting part 1. The two side plates 1b, 1b erected on both sides of the plate 1a can be rotated.

[0023] The two side plates 6a, 6a of the elevating member 6 are supported by the free ends of the two side plates 4a, 4a of the support member 4 via the second hinge pin 5, and are also rotatable. Like this, the direction of rotation of support member 4 is just opposite to the direction of rotation of elevating member 6, so, mounting member 1, support member 4 and elevating member 6 are mutually supporte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com