Method for producing personalized doll

A manufacturing method and technology of dolls, which are applied in the field of manufacturing individual dolls, can solve problems such as the lack of methods for manufacturing individual dolls, and achieve realistic modeling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

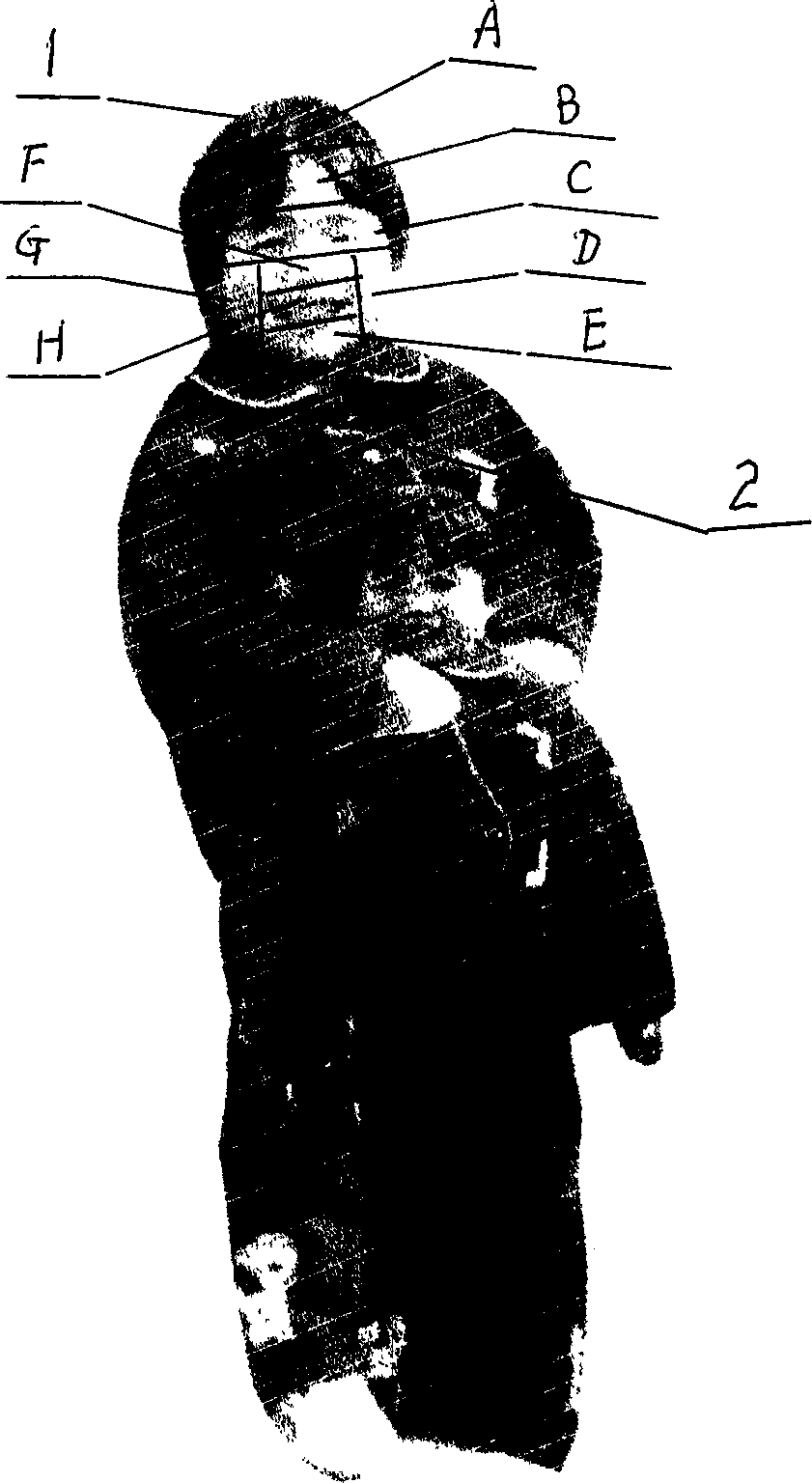

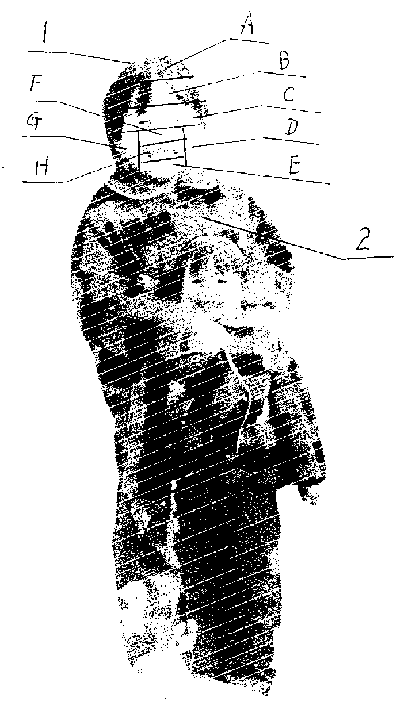

[0014] A preferred embodiment of the present invention is: the manufacturing process steps of this character doll are: (1) head portrait production: 1. child three-dimensional video recording; 2. three-dimensional video recording is input into computer, and computer matching skull mold and head portrait mask mold; 3. make with glass fiber reinforced plastics The hard shell of the skull is filled with foamed plastic; ④ A mask made of plastic is put on the hard shell of the skull; ⑤ A wig is attached to the head; ⑥ The eyes are pasted with colored self-adhesive paper; ⑦ Cheeks and lips are colored; ( 2) Body production: matching with prefabricated body models; (3) matching with clothing; (4) installing a pronunciation device containing a language chip on the personality doll. Referring to the accompanying drawings, the method for matching skull molds and head mask molds by computer is as follows: ① Divide the head into skull A, forehead B, eyes C, two cheeks D, G, nose F, and mou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com