New disffuser in central air conditioning system

A technology of central air-conditioning system and diffuser, which is applied in the directions of space heating and ventilation details, household heating, piping arrangement, etc., can solve the problems of increasing production cost, time-consuming, and increasing cost, and achieves reduction of production cost and time-consuming assembly. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

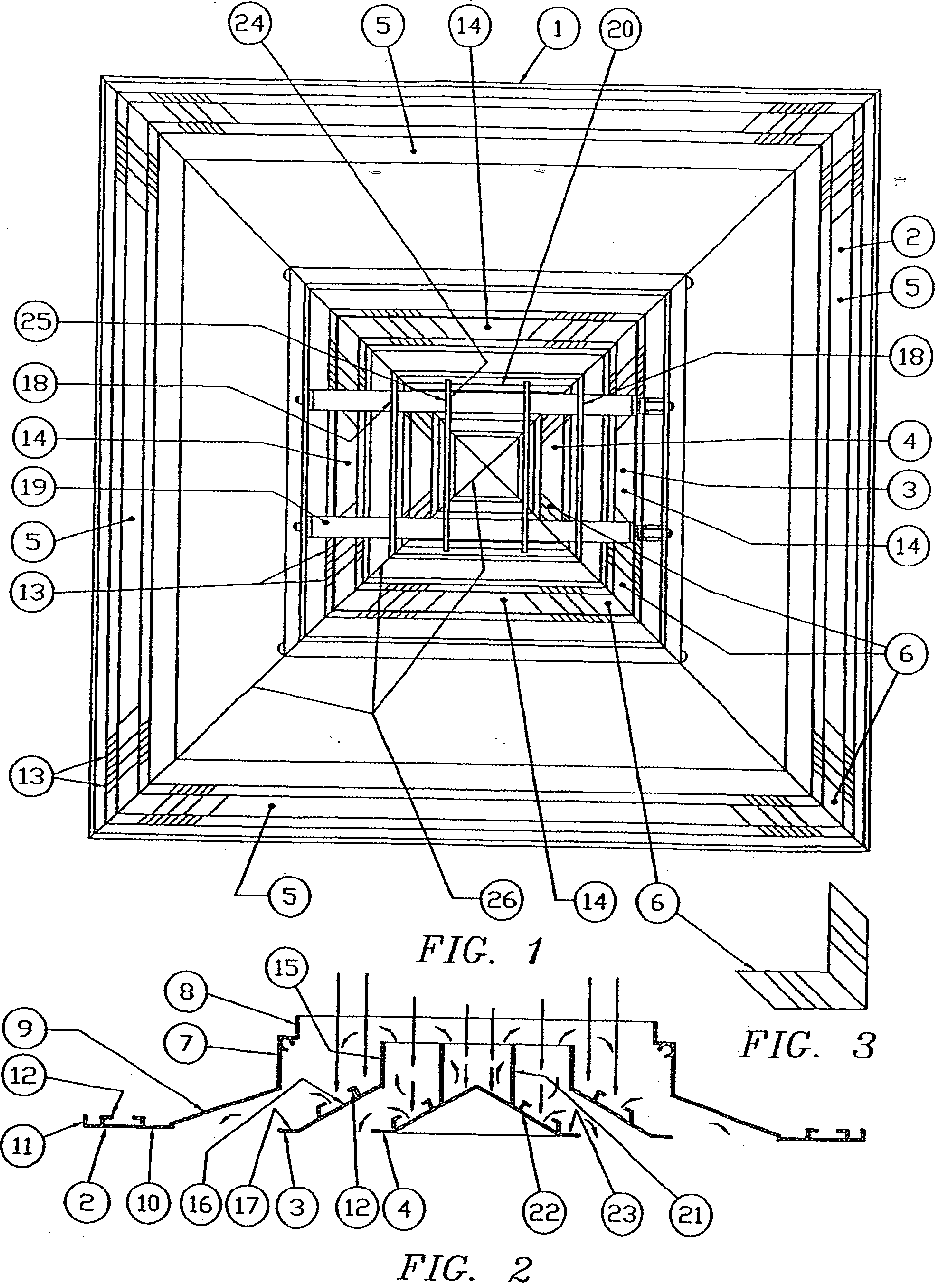

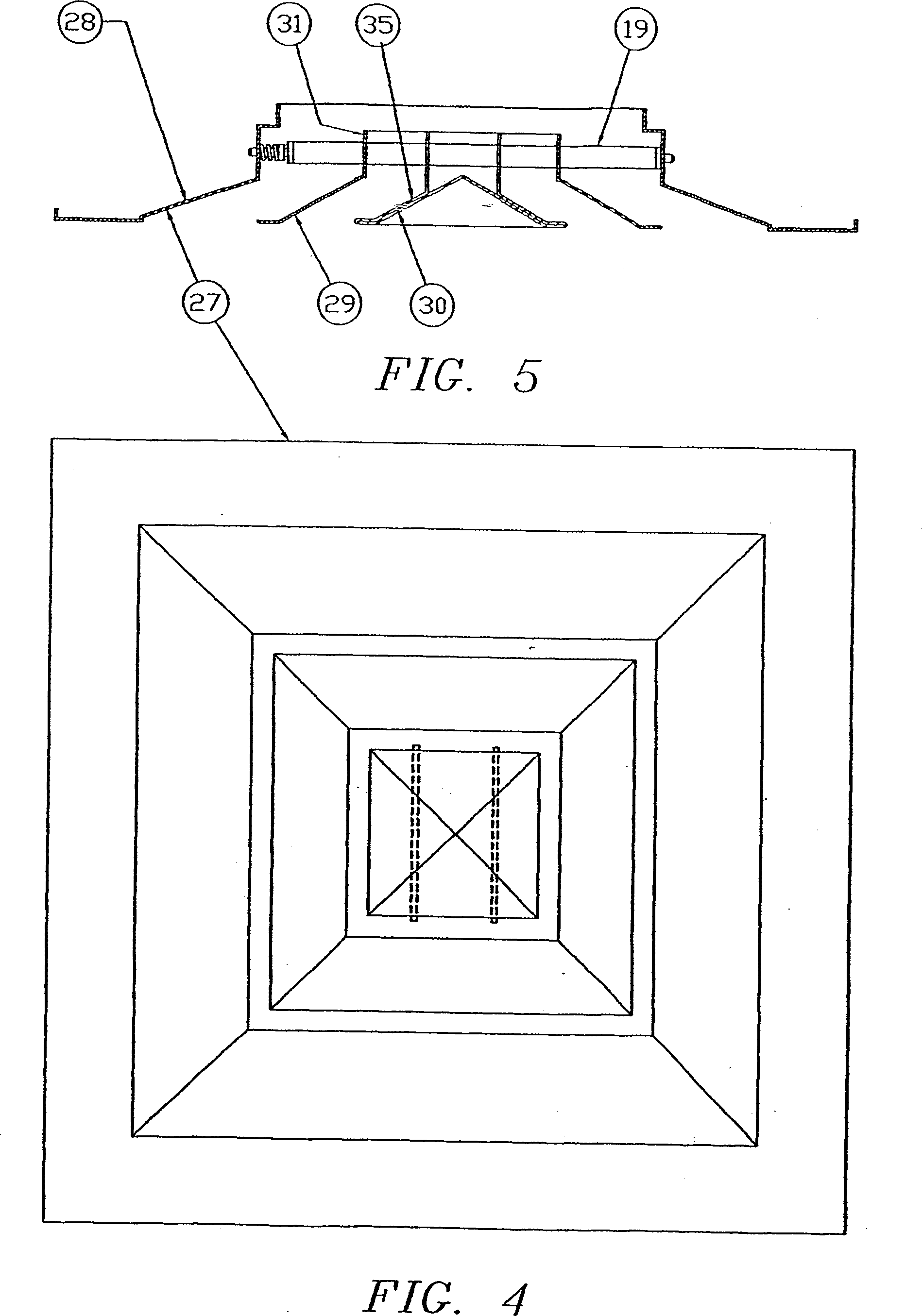

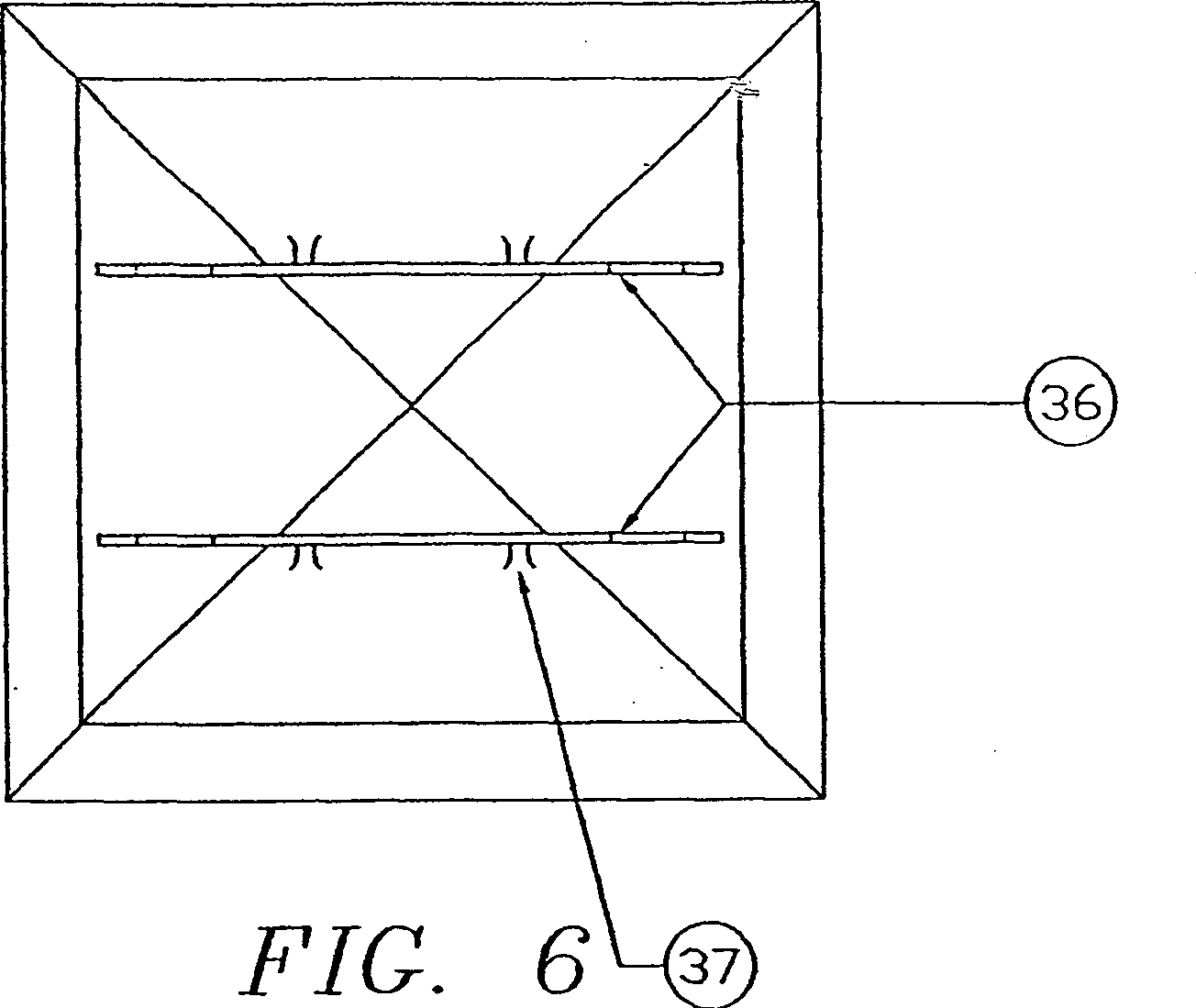

[0045] Referring to FIGS. 1 to 3 , a conventional disperser 1 includes an outer frame 2 , one or more intermediate cores 3 and a central core 4 . The outer frame 2 is made by assembling four side panels 5 with four corner panels 6 comprising vertical sides 7 bent at an angle 8 at the top, an outer bevel 9 at the bottom, and a substantially horizontal The flange 10, the outer free edge of the flange 10 is bent upwards as shown in Figure 11 to increase the strength. A groove 12 is formed on the upper / rear surface of the flange 10 to accommodate the gusset 6 when assembled. As shown at 13, four such side panels 5 are assembled together by means of gusset panels 6 and hemmed to secure the various pieces together. When assembling, the upper vertical sides of the upper square or rectangle of the outer frame depend on the size of the air duct to be assembled with the diffuser.

[0046]The central core 3 is also made of four side panels 14 assembled together by means of four corner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com