Advanced pressure type flow control device

A flow control device and flow control technology, applied in the direction of flow control, flow control of electrical devices, measuring devices, etc., can solve the problems of slow response speed, high cost, and many troubles of mass flow regulators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

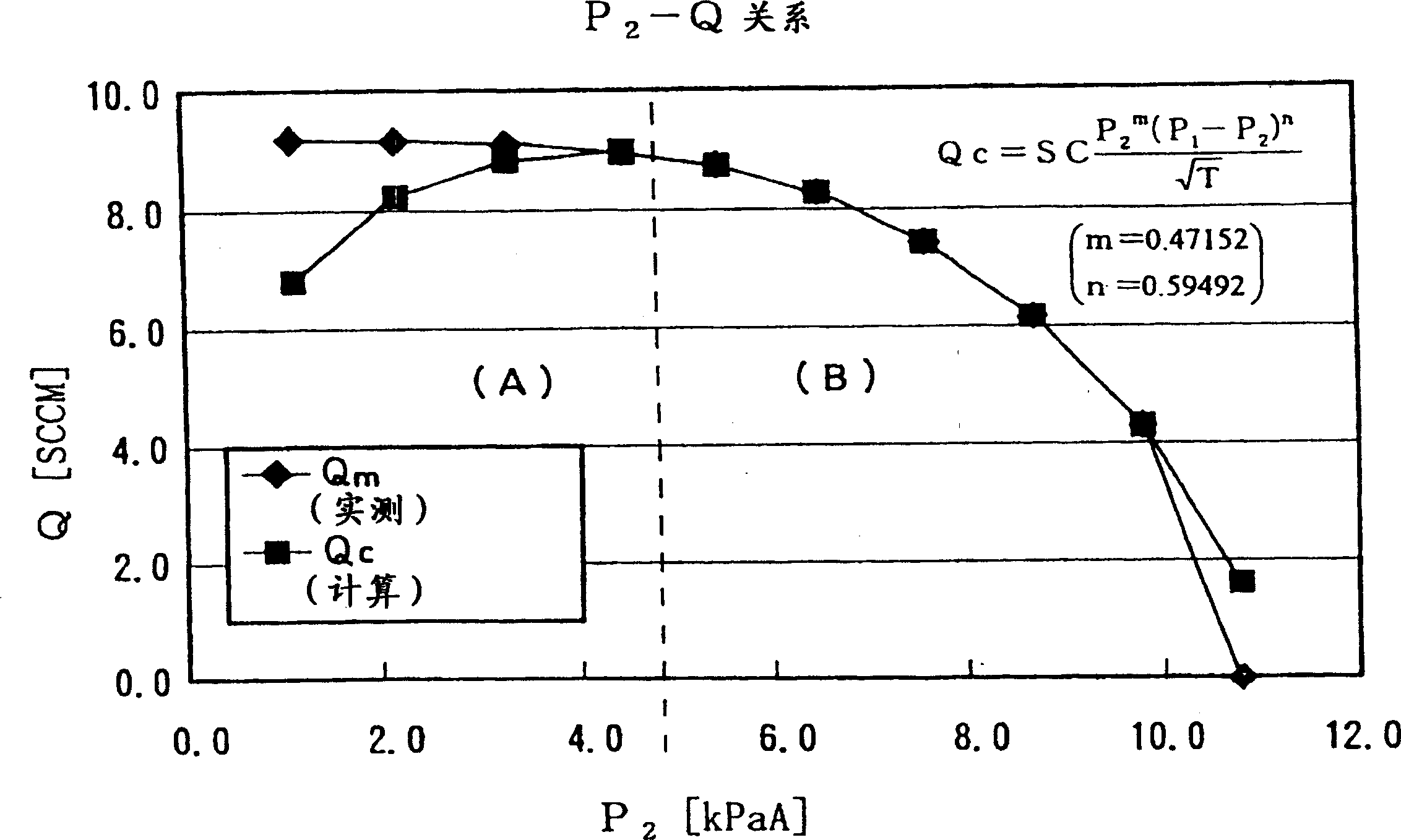

[0029] figure 1 It is a comparison diagram of the flow experimental formula and the flow measurement side under the non-critical condition of the present invention. The present inventors reviewed conventional theoretical flow formulas for non-critical conditions. The conventional flow formula derived by Bernoulli's theorem is Qc=K(P 2 (P 1 -P 2 )) 1 / 2 . Rewrite it as Qc=KP 2 1 / 2 (P 1 -P 2 )) 1 / 2 .

[0030] This known flow formula is correct for incompressible fluids. For example, it is a flow type with sufficient accuracy for fluids such as incompressible liquids. In order to make this flow formula suitable for compressive fluids such as gas, it is necessary to establish an experimental flow formula that does not change the structure as much as possible and has complex parameters.

[0031] Therefore, the present inventors propose to use Qc=KP 2 m (P 1 -P 2 ) n As an experimental flow formula, import m and n parameters for matching. Here, the constant of pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com