Stirring mixer and stirring mixing method

A technology of stirring and mixing and stirring body, which is applied in the field of stirring and mixing devices for powder and liquid and the field of stirring and mixing, which can solve the problems of limited combination of powder and liquid, inability to fully and uniformly mix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

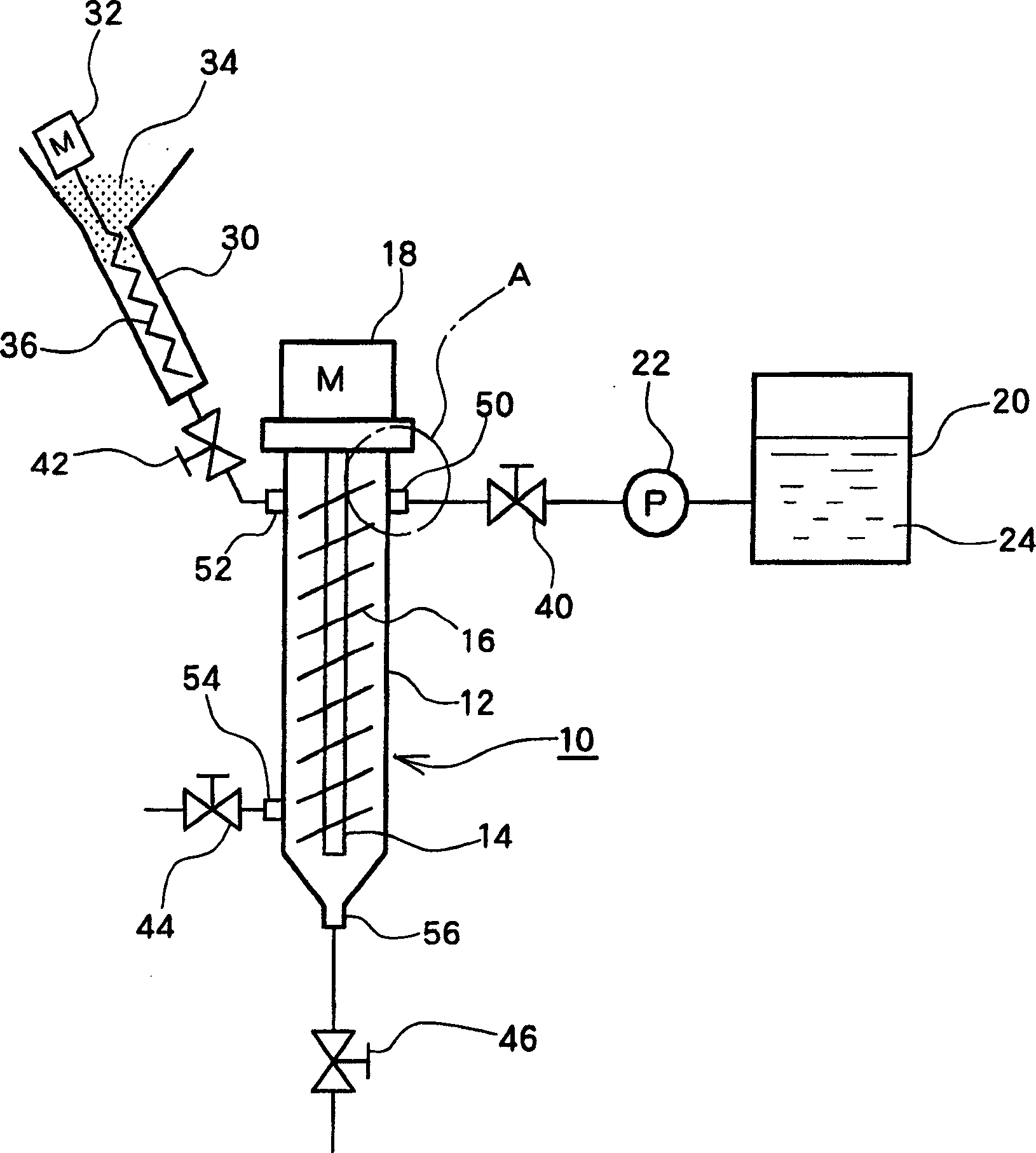

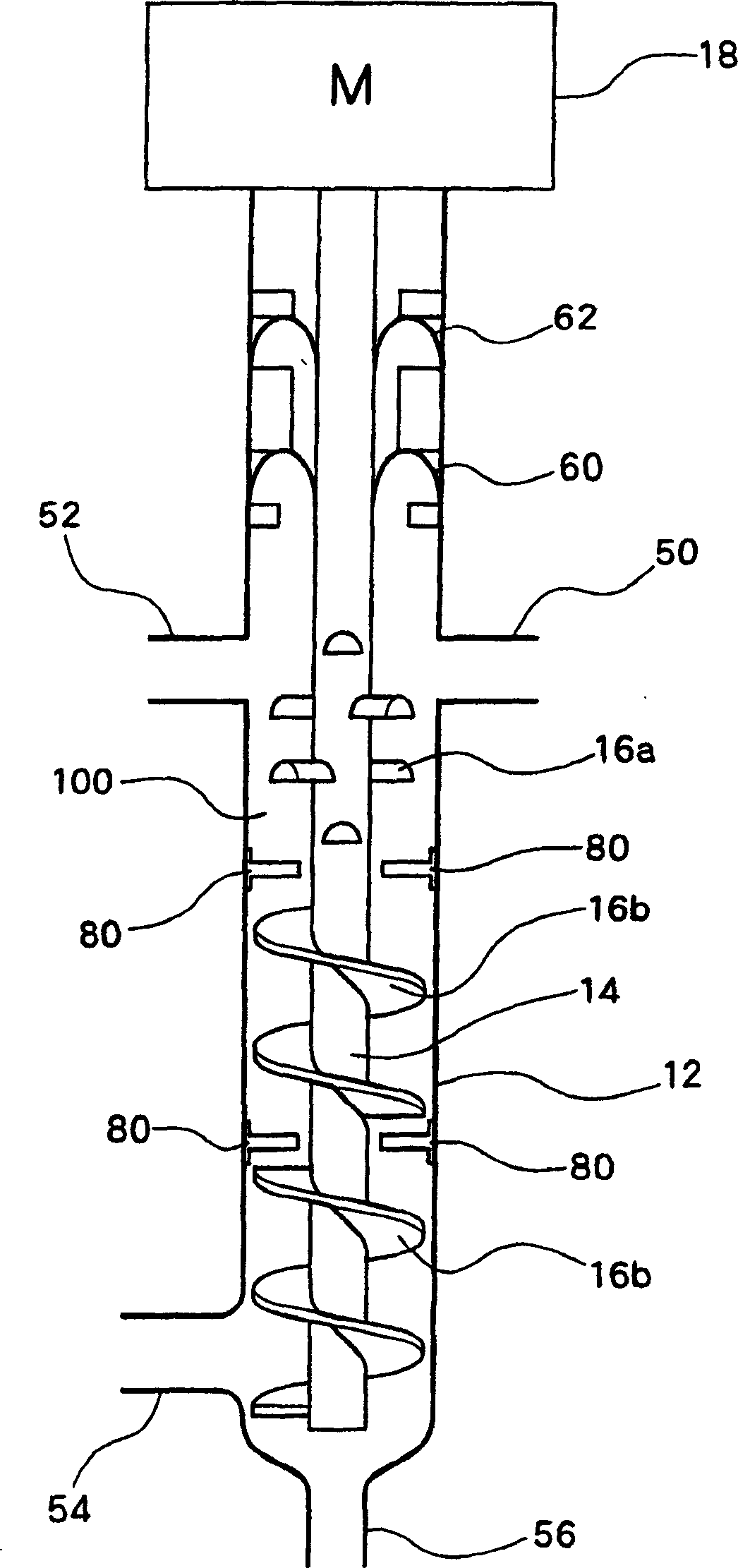

[0059] like figure 1 As shown, the powder and liquid stirring and mixing device 10 of the present embodiment (hereinafter referred to as "stirring and mixing device 10") includes a housing 12 with a flow path for fluid circulation inside, and a stirring body is provided inside the housing 12. , the stirring body is composed of a shaft portion 14 connected to a motor 18 as a vibration source and stirring blades 16 installed around the shaft portion 14 .

[0060] Further, a powder introduction port 52 for introducing powder 34 into the case 12 and a liquid introduction port 50 for introducing liquid 24 into the case near the powder introduction port 52 are provided on the upper portion of the case 12 . In this way, it is possible to further suppress the occurrence of secondary aggregation due to contact between the supplied powder and the liquid.

[0061] Furthermore, the liquid introduction port 50 is connected to the liquid storage tank 20 through the valve 40 and the pump 22...

Embodiment 2

[0067] And, in another embodiment, in figure 1 In the stirring and mixing device shown, the supply port 56 is used to replace the above-mentioned liquid inlet 50, and the pump 22 and the liquid storage tank 20 are connected through the valve 46. The pipe 30 is connected, and then, the liquid inlet 50 of Embodiment 1 is used as a discharge port, so that the mixture of liquid and powder is sent to the outside. Except for the above structure, other structures are the same as those of the above embodiment. For the same structure, same symbols, so their descriptions are omitted.

[0068] As in this embodiment, by introducing the powder 34 and the liquid 24 into the housing 12 from the lower side, vibrating and agitating against gravity, thereby further increasing the amount of turbulence in the housing 12, for example, suitable for uniform stirring of slurry or high viscosity mixtures.

Embodiment 3

[0070] In another embodiment, in figure 1 In the stirring and mixing device shown, the figure 2 supply port 58 shown in place of figure 1 The illustrated liquid introduction port 50 has the same structure as that of the above-mentioned device except that, and therefore, the same symbols are used for the same structures, and their descriptions are omitted.

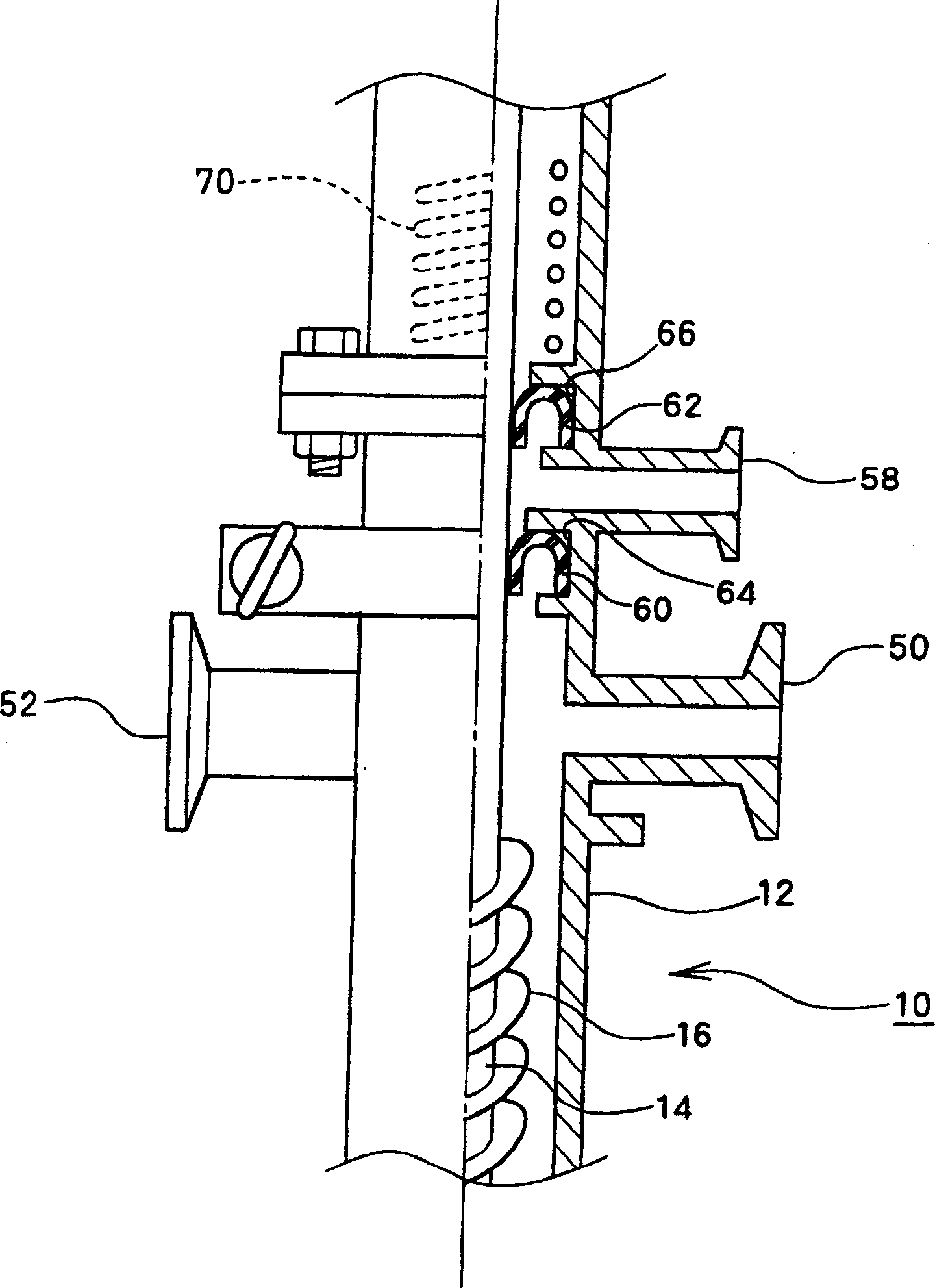

[0071] In order to prevent fluid from intruding into the motor as a vibration source for vibrating the stirring body from the internal stirring and mixing part, the housing 12 forms a double sealing structure. That is, if figure 2 As shown, an inverted U-shaped sealing member 60 is installed near the stirring and mixing part by a sealing fastener 64. On the other hand, an inverted U-shaped sealing member 62 is installed near the coil near the motor by using a sealing fastener 66. Form a double sealing structure. One end of the inverted U-shaped seals 60 and 62 is fixed by the above-mentioned seal fasteners 64 and 66 ,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com