Angular position pick up for measuring high linear flux density

A technology for measuring sensors and magnetic flux density, which is applied in the direction of using electric/magnetic devices to transfer sensing components, measuring devices, and converting sensor outputs, etc., which can solve problems such as large computing burdens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

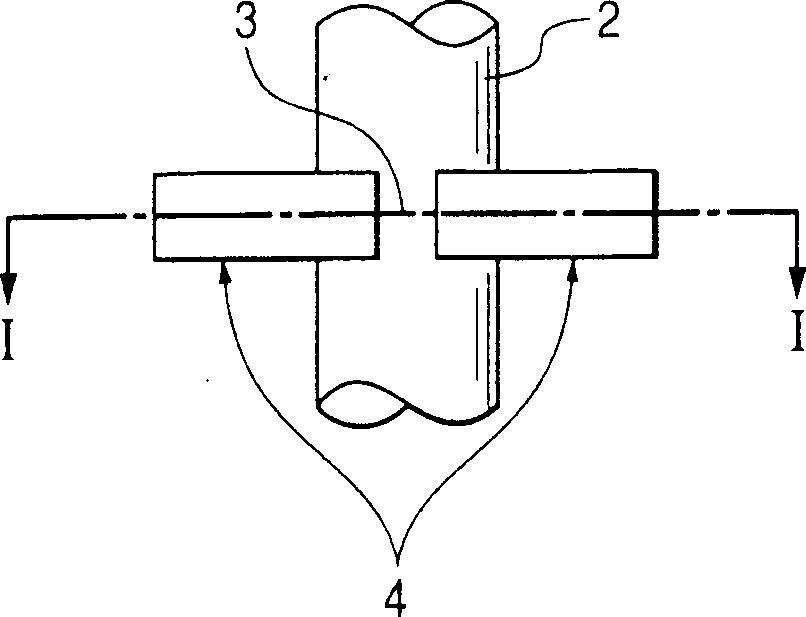

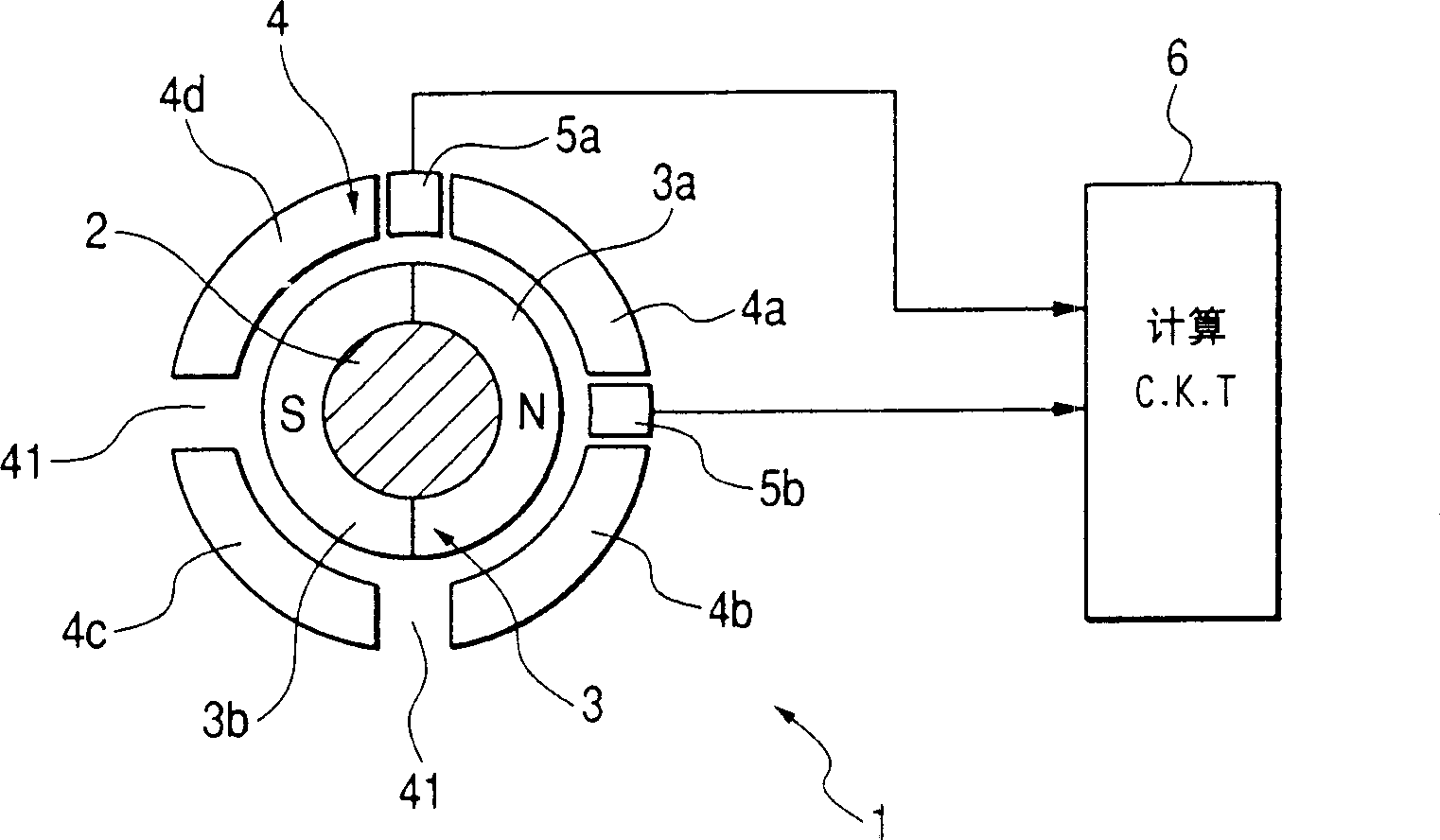

[0068] Referring to the accompanying drawings, wherein the same reference numerals refer to the same parts in the accompanying drawings, especially Fig. 1 (a) and Fig. 1 (b), they represent the angular position detector 1 according to the first embodiment of the present invention .

[0069] The angular position detector 1 mainly includes an angular position sensor installed on the periphery of the rotating shaft 2 and an angular position calculation circuit 6 . The angular position calculation circuit 6 is designed to determine the angular position of the rotary shaft 2 using the output of the angular position sensor.

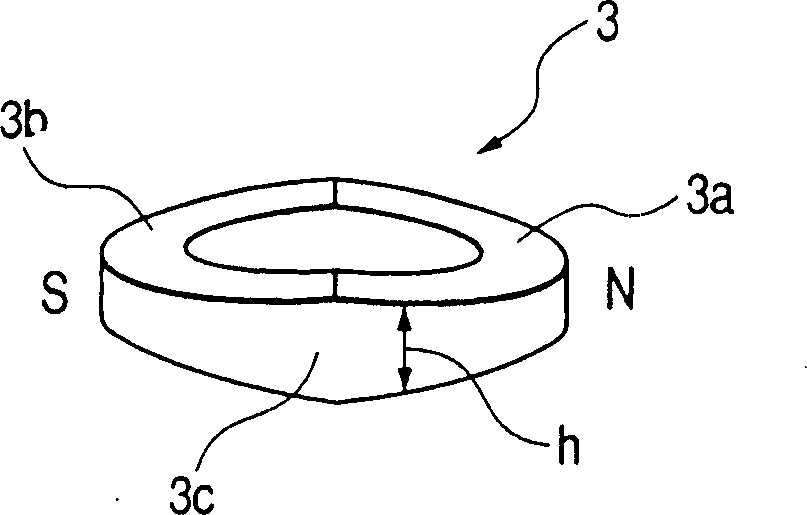

[0070] The angular position sensor includes a magnet 3 made of hard magnetic material, a yoke 4 made of soft magnetic material, and a magnetic sensor 5 for measuring magnetic flux density.

[0071] The magnet 3 is annular and fixed on the periphery of the rotating shaft 2 . The magnet 3 is composed of two semicircular parts: one has an N pole 3a, and the othe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com