Active driving pixel structure and its checking method

A pixel structure and inspection method technology, applied in the direction of light source, electric light source, electroluminescent light source, etc., can solve problems such as difficult gap adjustment and light-emitting element defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

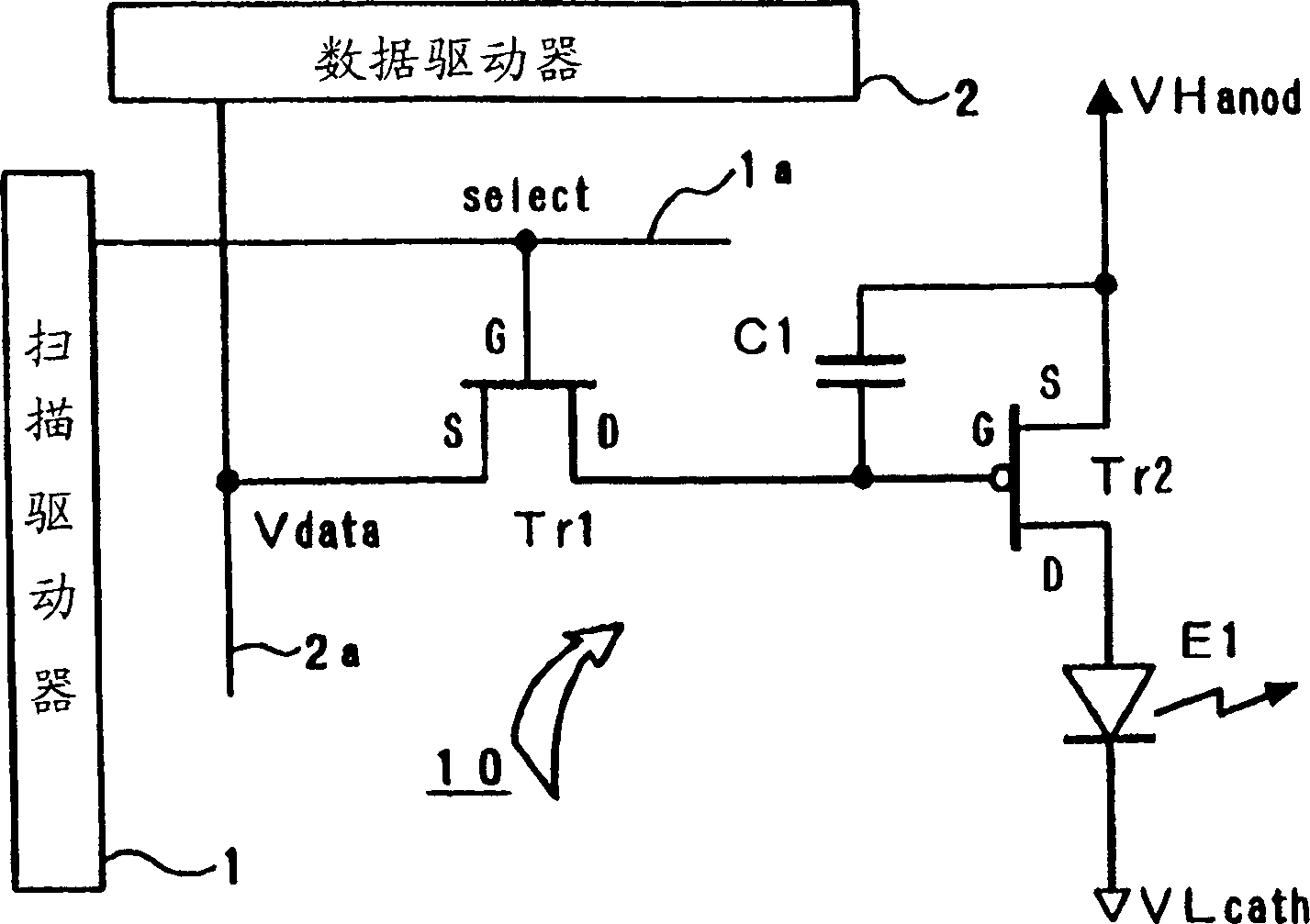

[0035] Hereinafter, the active driving pixel structure and inspection method of the present invention will be described according to the illustrated embodiment. In addition, in the following description, the same symbols are used to indicate the figure 1 The parts shown in 1 are equivalent to each other, so descriptions of various functions and operations are appropriately omitted.

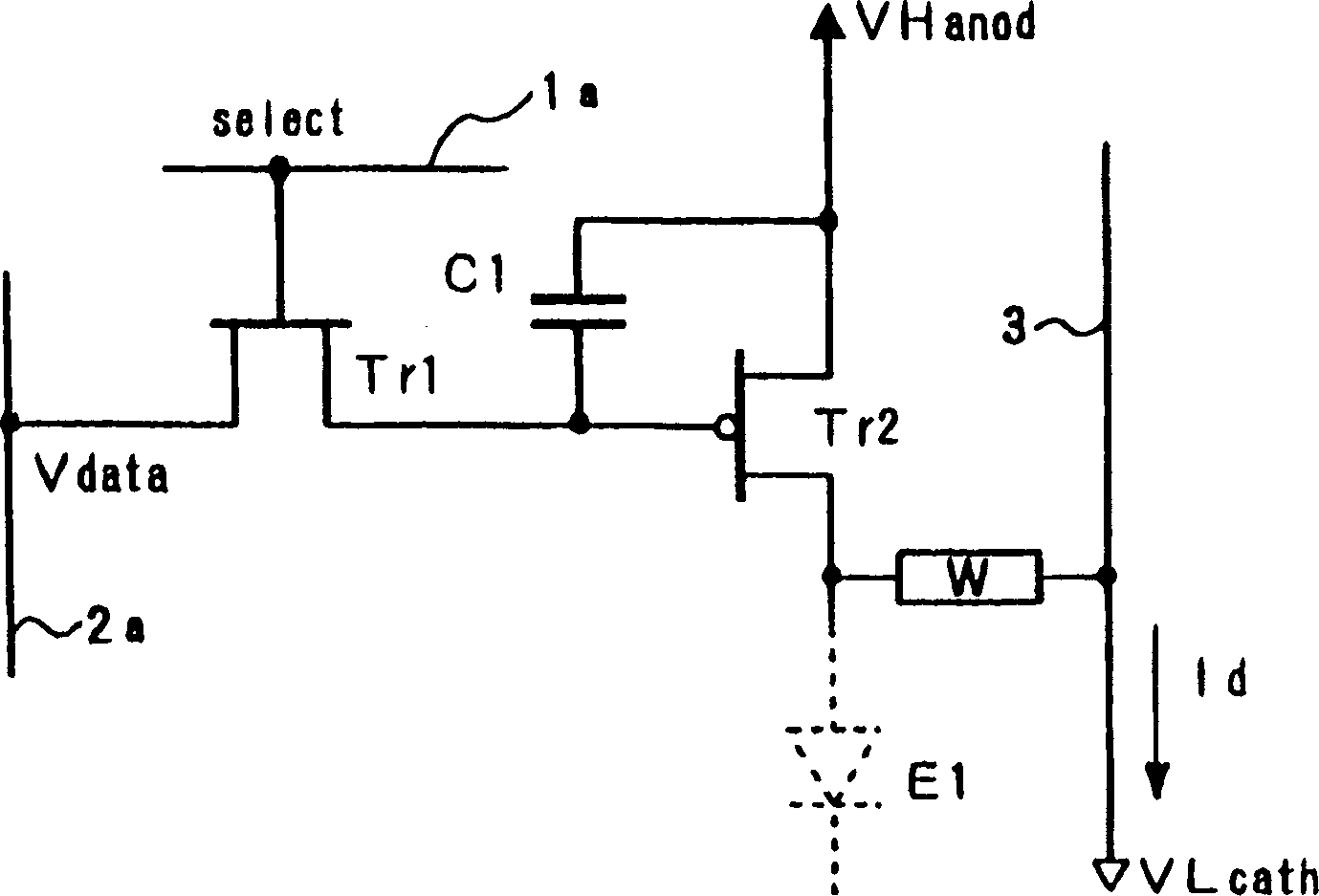

[0036] first, figure 2 It is a diagram showing the first embodiment of the active driving type pixel structure of the present invention. in the figure 2 The morphology shown shows the figure 1 The example shown is likewise referred to as a conductance-controlled circuit configuration. and, figure 2 The state shown shows the state of the semi-finished product before the film formation of the organic EL element E1.

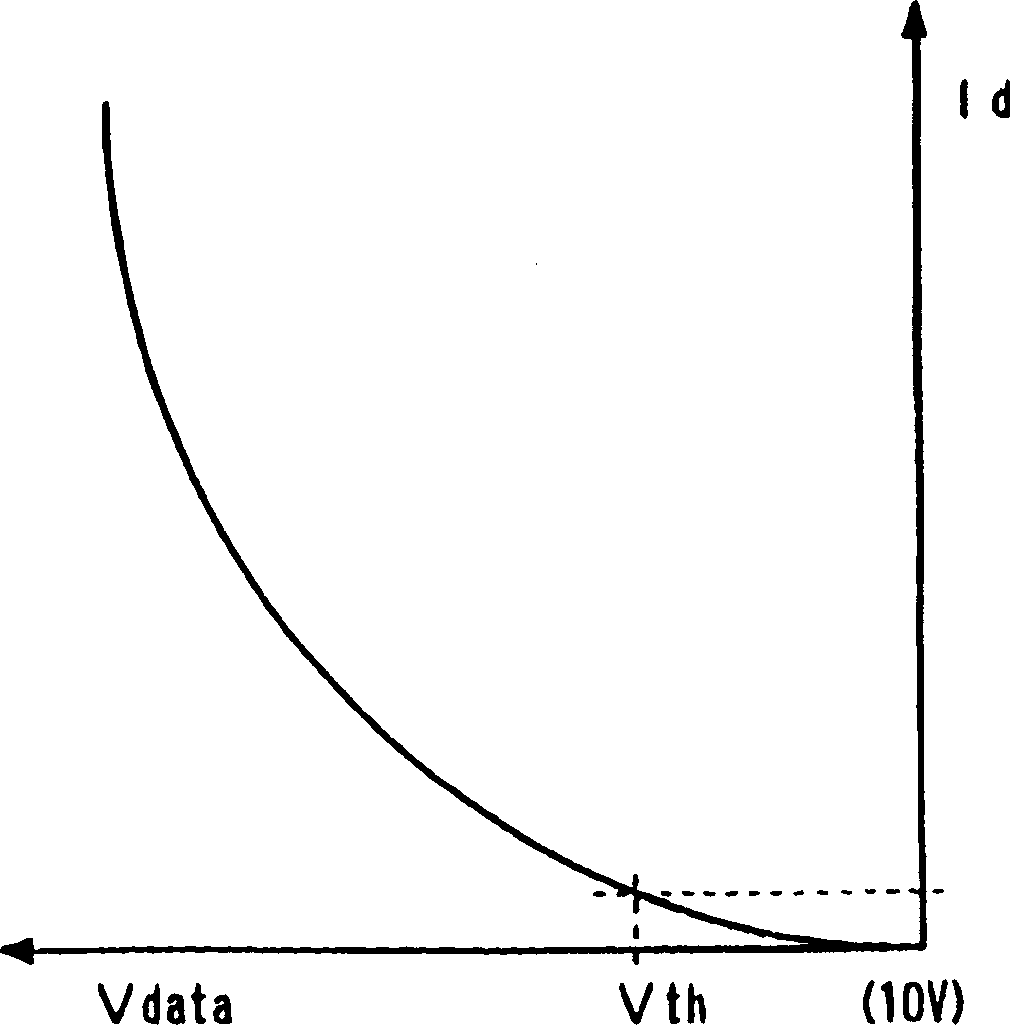

[0037] exist figure 2 In the shown first embodiment, such a structure is formed that one end of the dummy load W for inspection is connected to the drain of the current outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com