Method for solidifying frame glue and meethod for making liquid crystal display panel by using sad method

A liquid crystal panel and frame glue technology, applied in identification devices, nonlinear optics, instruments, etc., can solve problems such as complicated process, inability to use ultraviolet curing process, and influence on the effect of ultraviolet curing process, so as to avoid UV absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

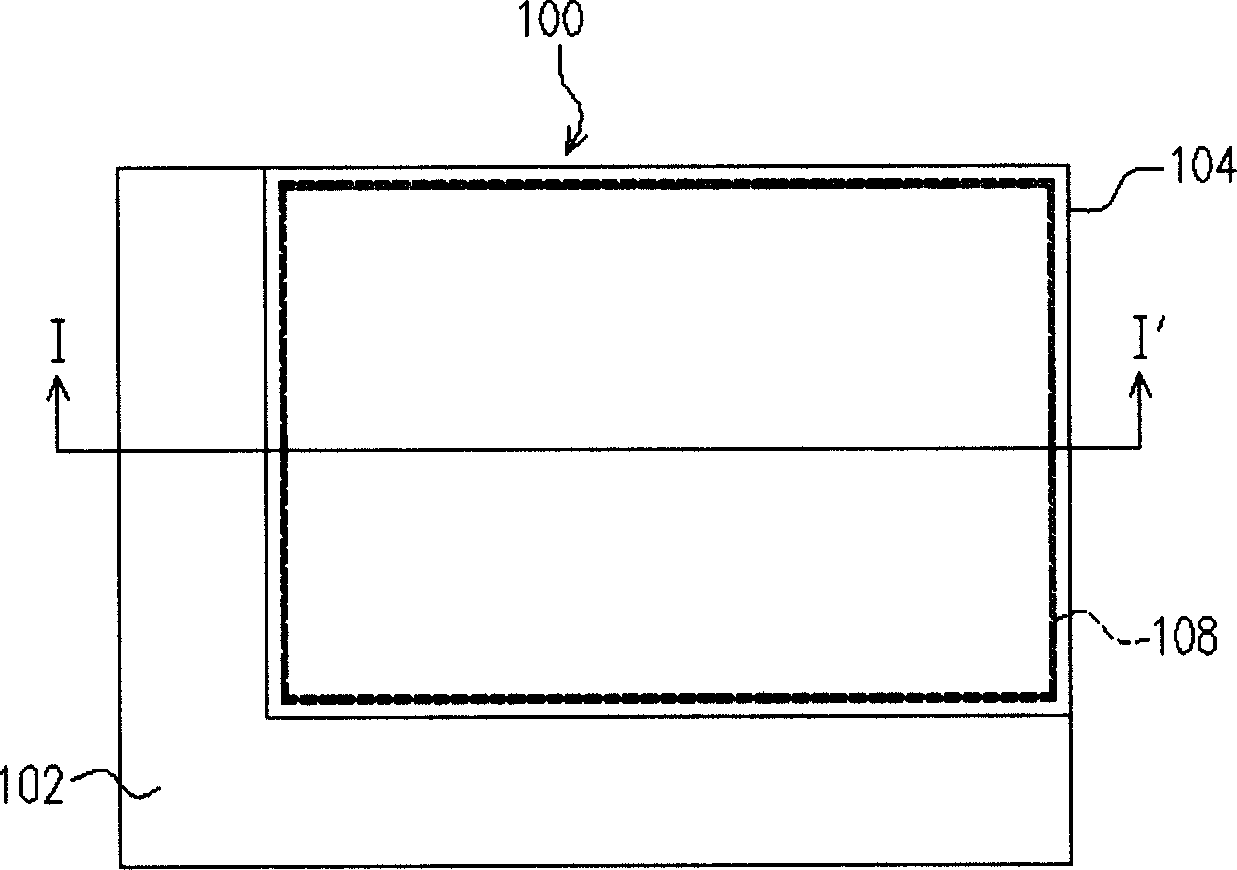

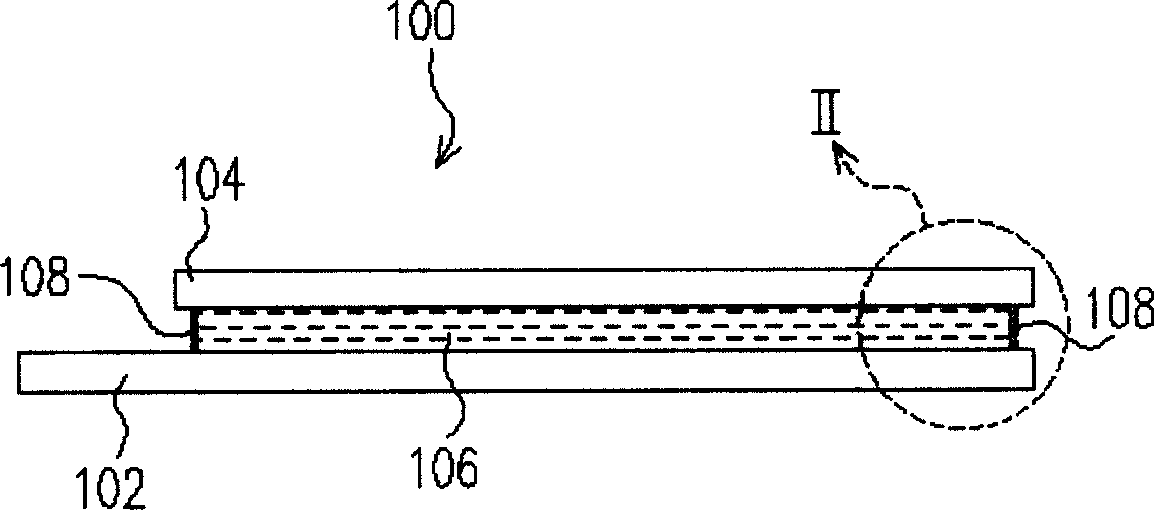

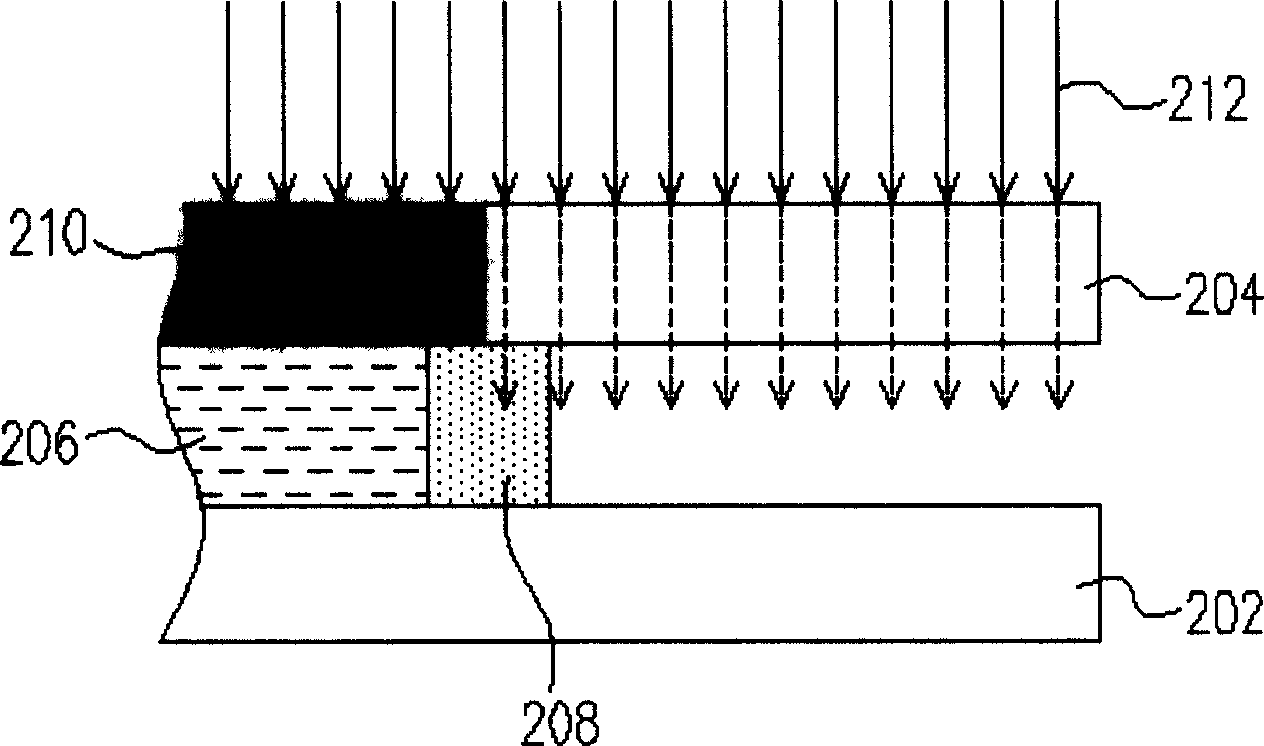

[0040] image 3 It is a schematic cross-sectional view of a liquid crystal panel according to a preferred embodiment of the present invention when curing the frame glue process. Please refer to image 3 , the method proposed by the present invention is suitable for curing the sealant 308 between a first substrate 302 and a second substrate 304, wherein the first substrate 302 and the second substrate 304 both include a front 320 and a back 324 and the side surface 322 , and the front surface 320 of the first substrate 302 and the second substrate 304 are opposite. The material of the frame glue 308 is, for example, UV glue. The width of the frame glue 308 is, for example, between 1000-1200 microns, and the thickness is, for example, about 5 microns. The material of the first substrate 302 and the second substrate 304 is, for example, glass.

[0041] Please continue to refer to image 3 , the curing method of the present embodiment is to use the law of total internal reflec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com