Double wrapper cigarette, and machine and method for manufacturing it

A paper-wrapped, double-layer technology, applied in the manufacture of paper cigarettes, cigars, tobacco, etc., can solve the problems of strong sidestream smoke and reduced sidestream smoke, and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

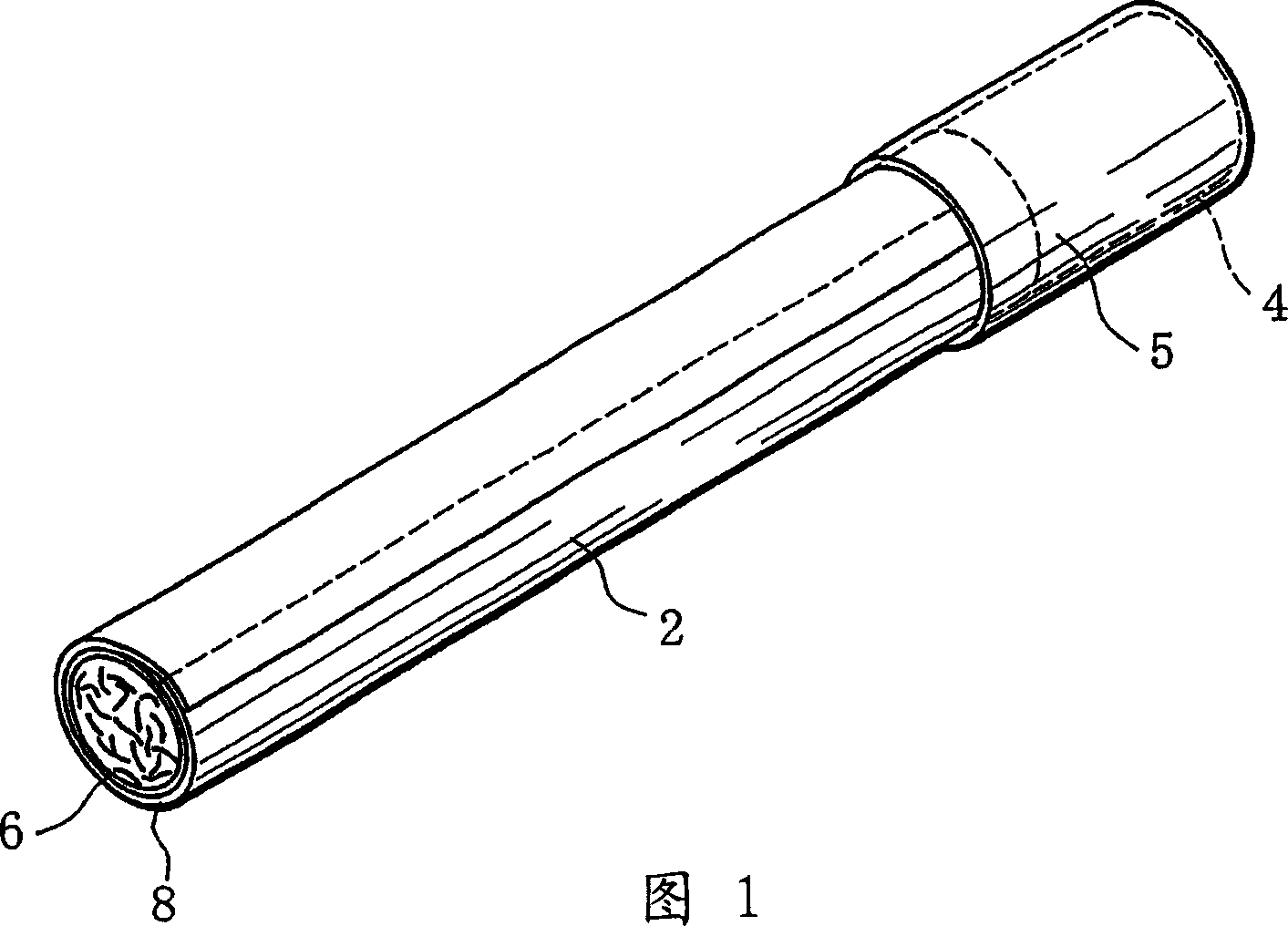

[0027] Figure 1 shows a filter cigarette. The filter cigarette has a double-wrapped cigarette 2, and a filter 4 is connected to one end of the double-wrapped cigarette 2 through a filter paper 5.

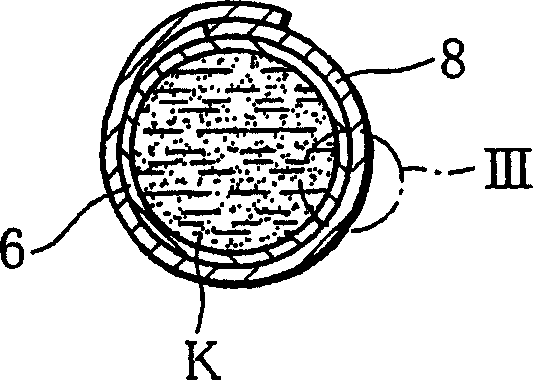

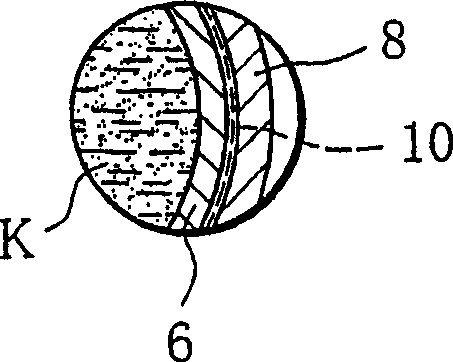

[0028] The double-wrapped cigarette 2 has an inner layer wrapper 6 and an outer layer wrapper 8, the inner layer wrapper 6 is directly wrapped into the filling material K, and the filling material K is formed into a rod shape. On the other hand, the outer layer wrapping paper 8 concentrically surrounds the inner layer wrapping paper 6 from the outer layer.

[0029] from figure 2 It can be seen that the two side edges of the outer wrapping paper 8 are superimposed on each other, and then bonded by seam paste (not shown). But the two side edges of inner wrapping paper 6 are not overlapped. That is, the width of the inner layer wrapper 6 is narrower than the width of the outer layer wrapper 8 when viewed unfolded.

[0030] The filler K is a mixture of shredded tobacco obtained by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com