Rotor and electric generator

A generator and rotor technology, applied to wind power generation, synchronous motors with stationary armatures and rotating magnets, electromechanical devices, etc., can solve problems such as not being able to play or provide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

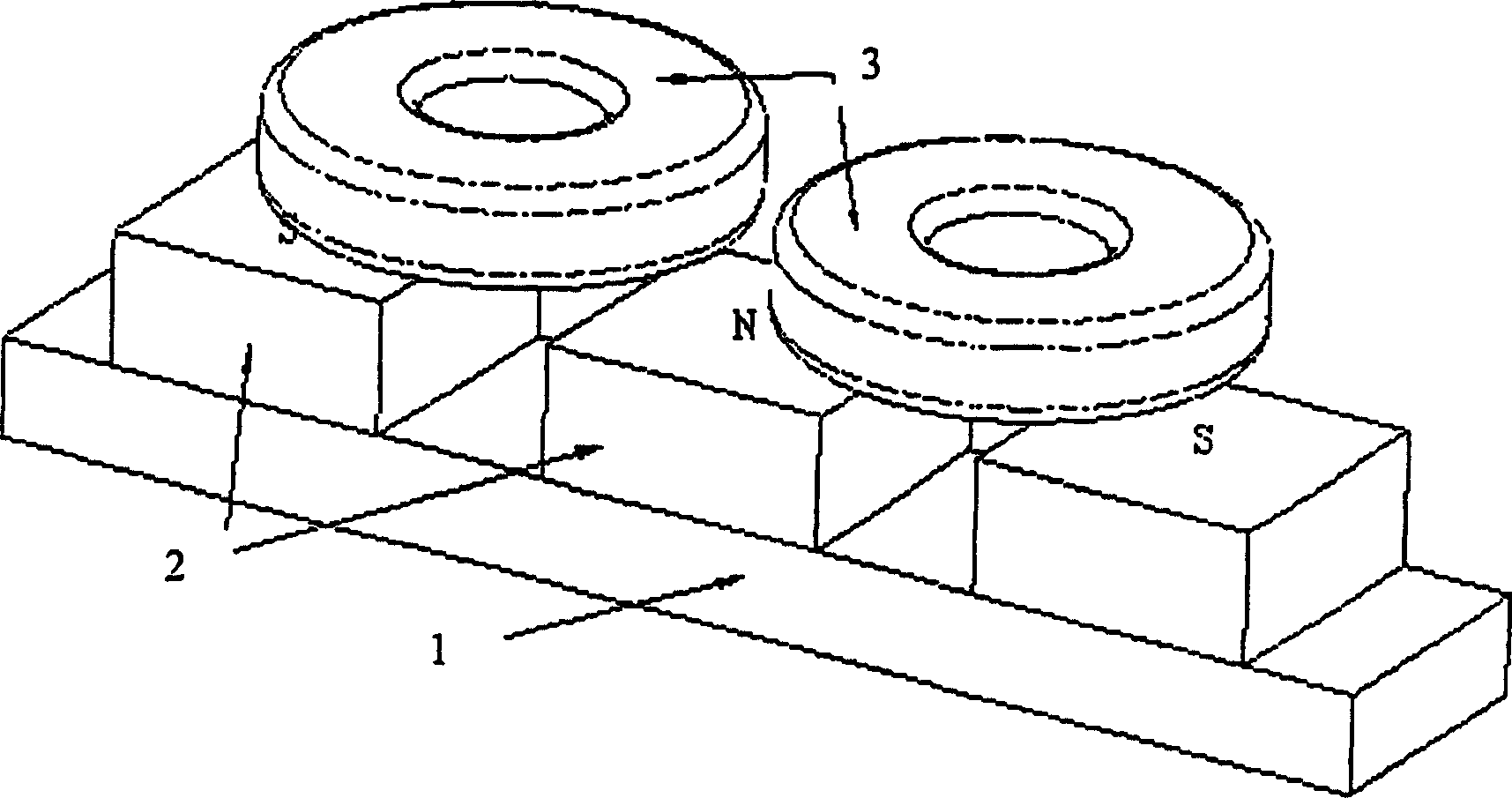

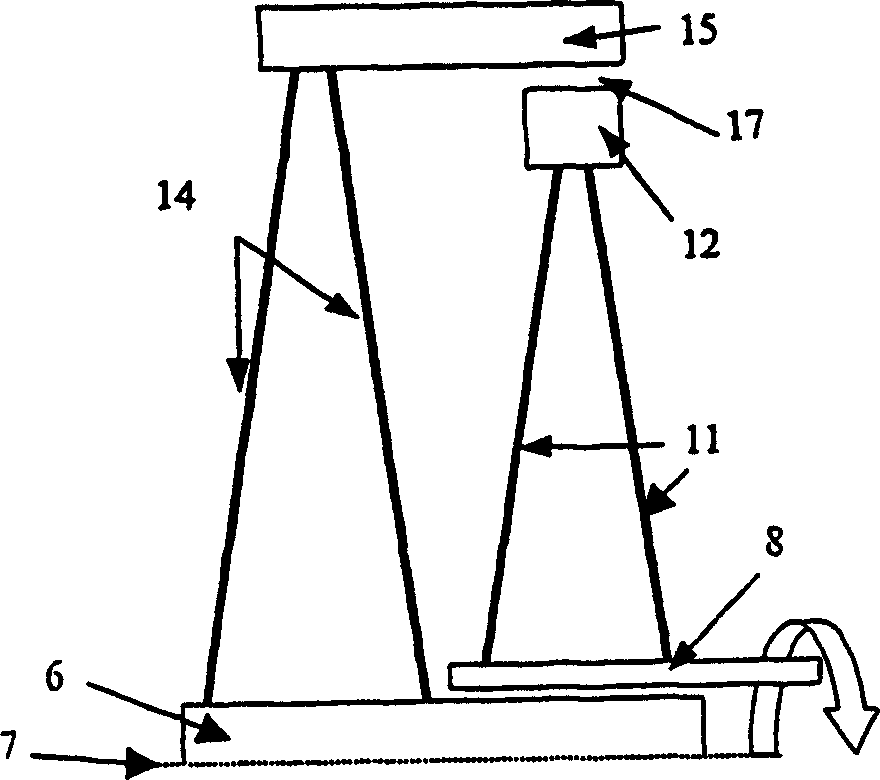

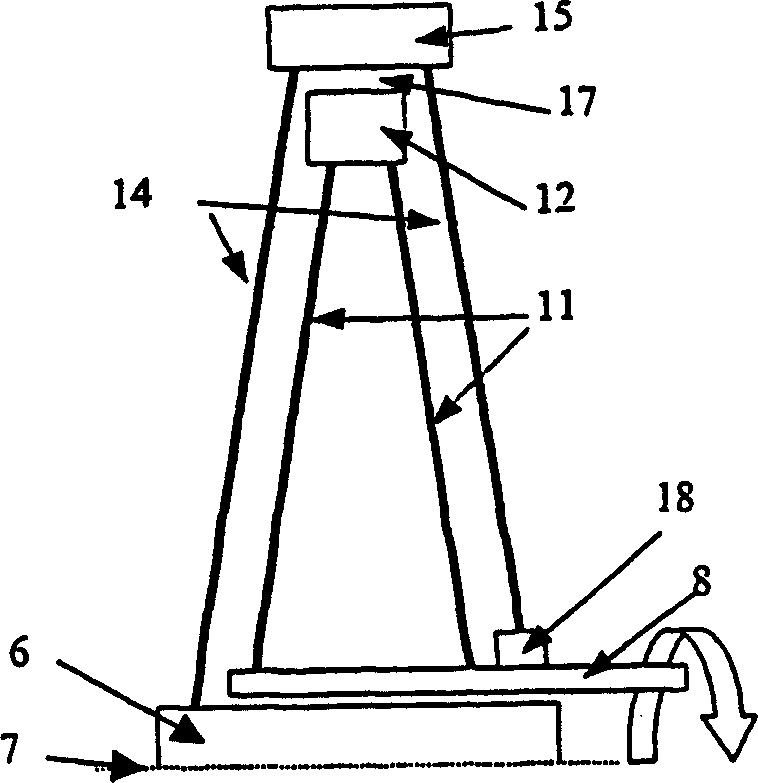

[0058] Various electromagnetic layout techniques may be employed and will be apparent to those skilled in the art. Below, the attached Figure 1 to Figure 3a and Figure 3b , with a specific embodiment, the present invention is described. Specifically, all examples use radially polarized magnets, an iron core that is not used on the stator, and both the rotor and stator use the structure of the present invention. However, it goes without saying that, in principle, the invention is equally applicable to other field geometries and / or iron-core or iron-less stator mechanisms, and that a rotor constructed according to the invention can be combined with any suitable stator, e.g. Used with a circumferentially extending stator on an arc.

[0059] figure 1 The best electromagnetic configuration is shown. In this embodiment, a ferromagnetic cylinder 1 fits a rotor back iron and has NdFeB permanent magnets 2 mounted on its outer surface. They can be fixed in any suitable way, such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com