Heavy and medium plate mill non-retraction precision variation quick-speed roll seam initialization method

A roll gap and rolling mill technology is applied in the field of fast roll gap setting without retraction and variable precision in medium and heavy plate rolling mills, which can solve the problems of low setting precision and more time required.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

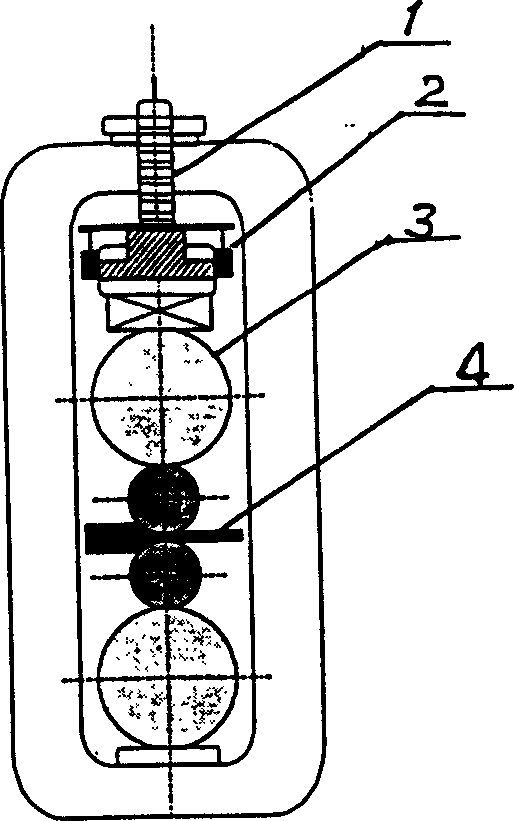

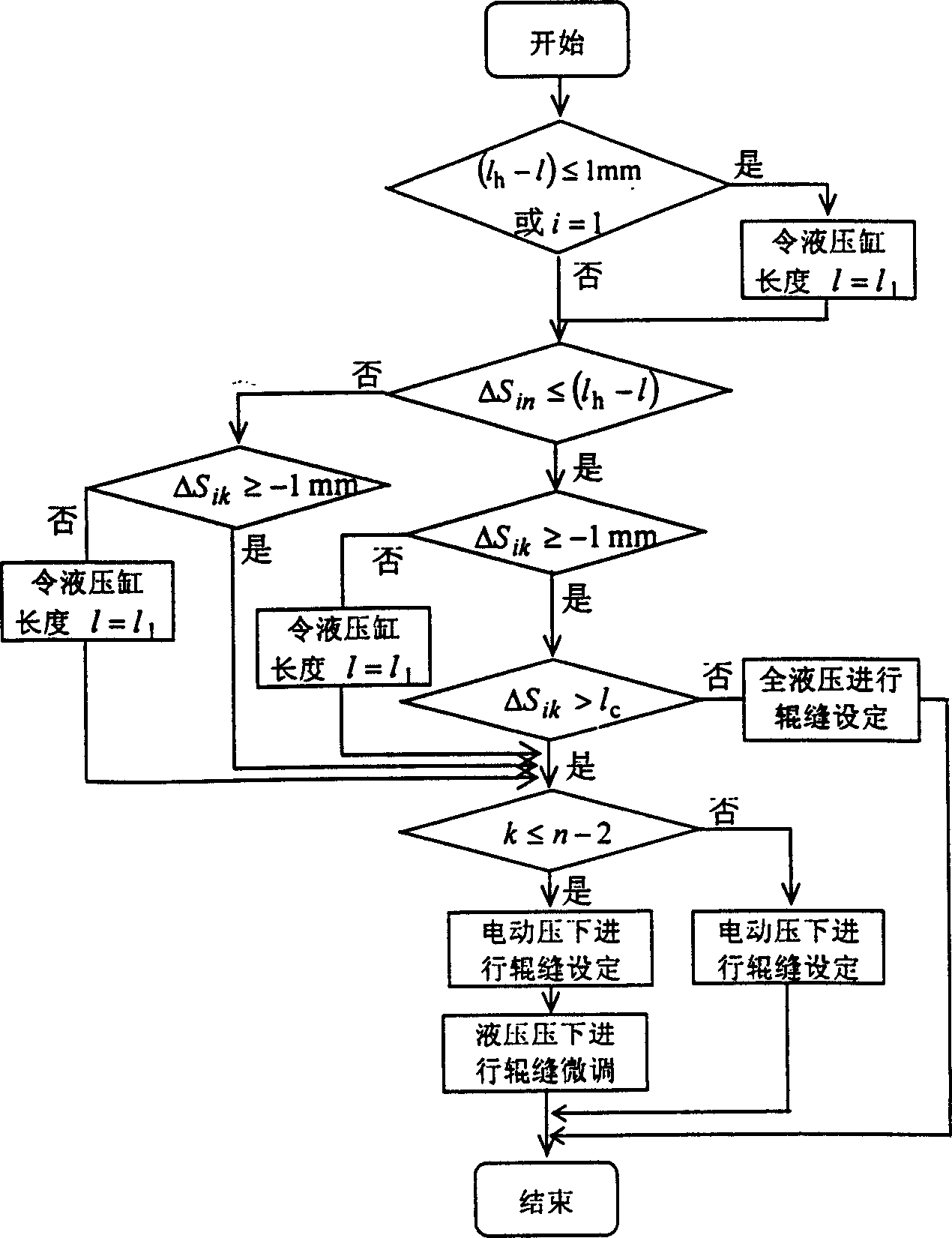

Image

Examples

Embodiment Construction

[0039] A steel plate is selected, and its rolling procedure is shown in Table 1. The total number of rolling passes is 14.

[0040] Table 1 Rolling Regulations

[0041] Blank size: 220*1600*2950 Finished size: 12.0*2350*36823

road

Second-rate

thickness

mm

Roll Gap

mm

Pressdown

mm

width

mm

Convexity

mm

temperature

Rolling force

MN

Deformation resistance

MPa

torque

kNm

speed

rpm

state

1

2

3

4

5

6

7

8

9

10

11

12

13

14

200.4

180.9

161.4

142.0

117.0

92.1

68.2

50.6

37.5

27.9

20.7

16.0

13.5

12

199.9

180.3

160.7

141.1

115.7

90.2

65.8

48.1

35.2

25.7

18.6

14.3

12.8

11.7

19.5

19.5

19.5

19.5

24.9

24.9

23.9

17.7

13.1

9.7

7.2

4.7

2.6

1.4

2977

2977

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com