Method for detecting clothes weight in washing machine

A detection method and a technology for the amount of clothes, which are applied in the invention field of the detection method of clothes amount, and can solve problems such as the inability to accurately detect the amount of clothes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

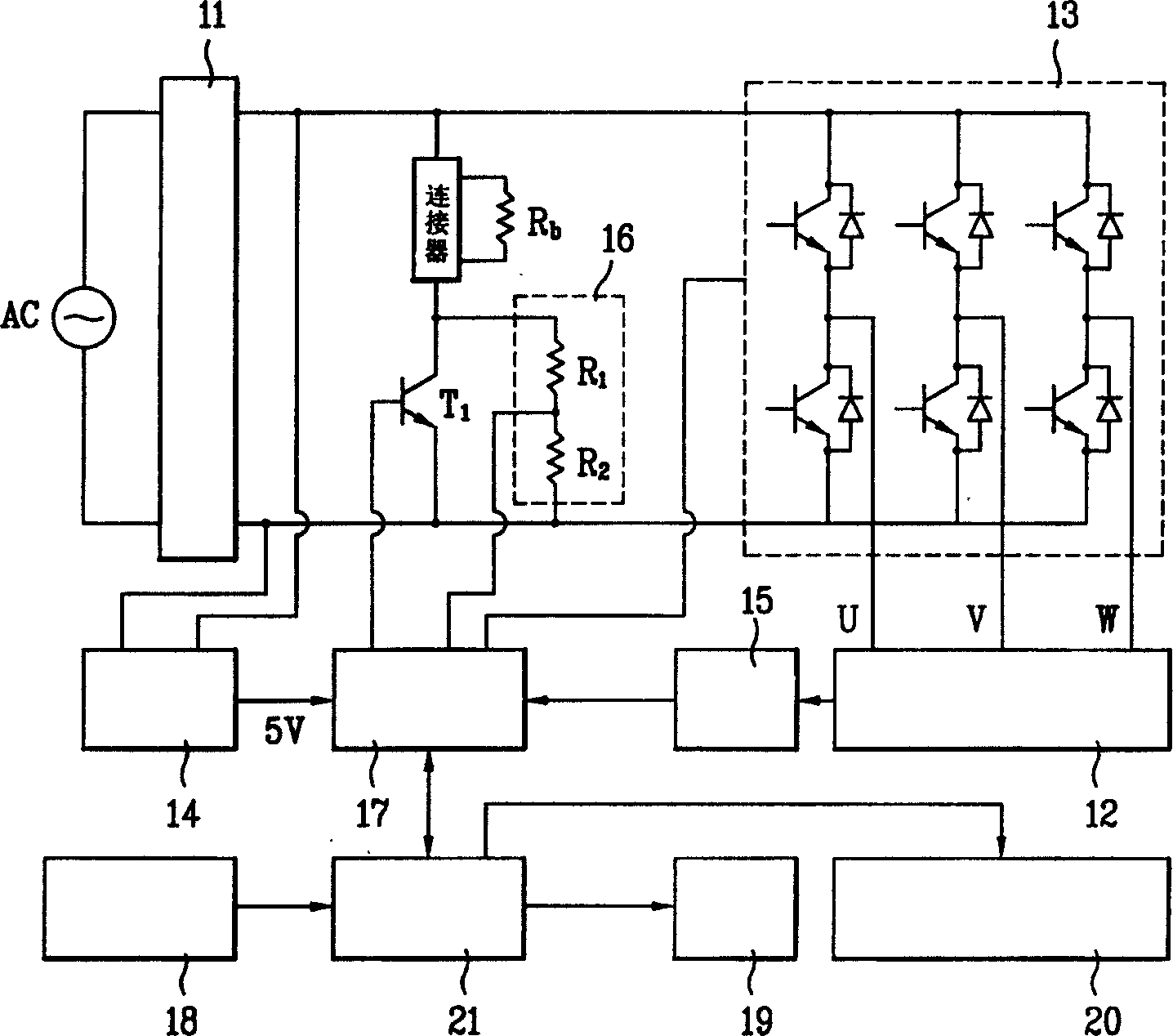

Examples

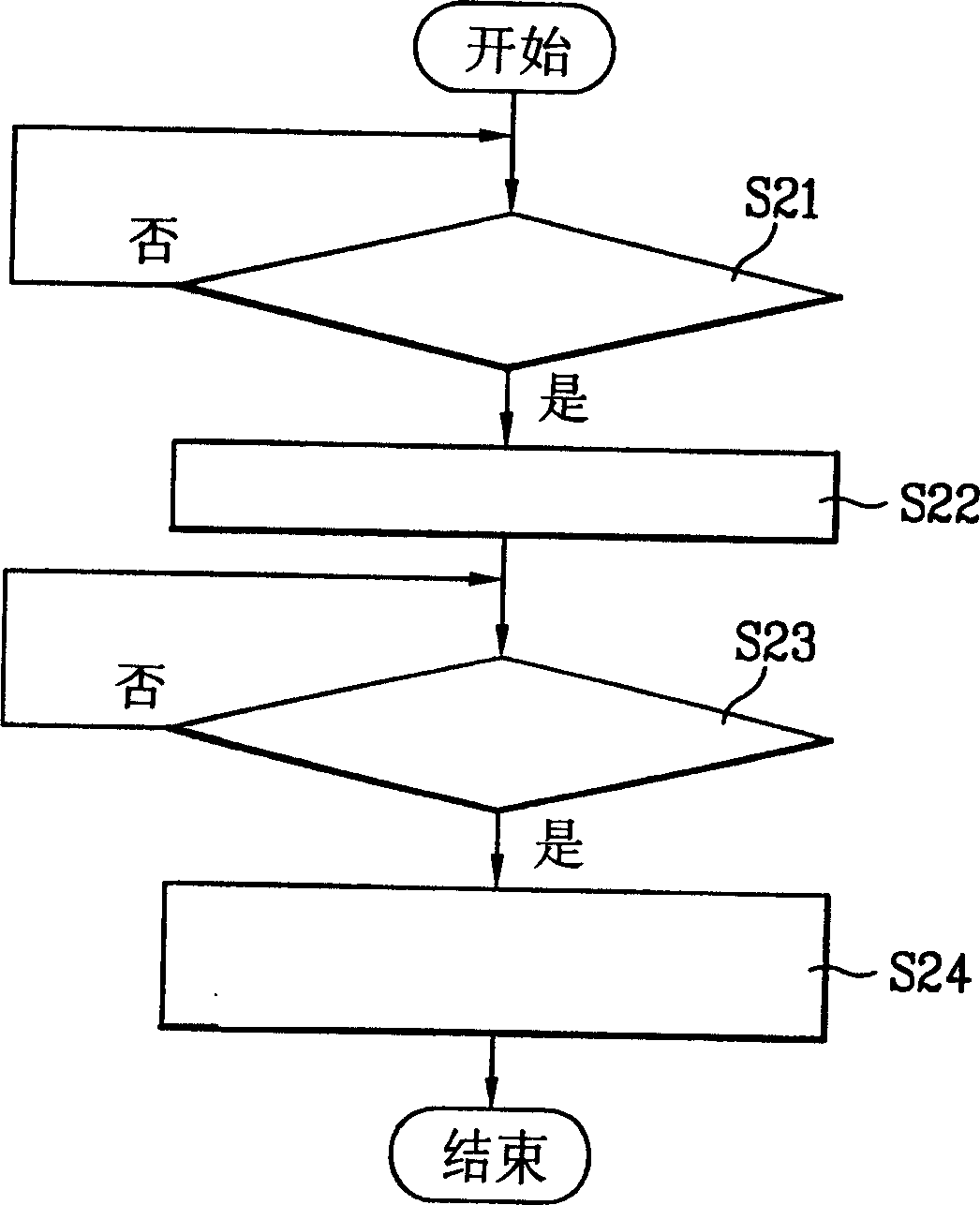

no. 1 Embodiment —

[0039] The first embodiment of the present invention is such as figure 2 As shown, firstly, the main microcomputer 21 will judge S21 whether there is a washing instruction input.

[0040] If the above judgment result S21 is that there is a washing instruction input, then the agitator is accelerated, and the timing S22 is started.

[0041] Here, the main microcomputer 21 instructs the microcomputer 17 to accelerate the stirrer, and if the rotation of the stirrer is detected based on the output of the speed sensor 15, time is started. In addition, the microcomputer 17 controls the drive part 13 according to the instruction|indication of the said main microcomputer 21, and accelerates a stirrer.

[0042] Next, whether the rotation speed of the agitator has reached the set speed (for example, 150rpm) is judged S23, if it has reached the set speed, then the power is cut off, and the amount of clothes is detected by the time so far obtained by counting S24 .

[0043] Here, it is...

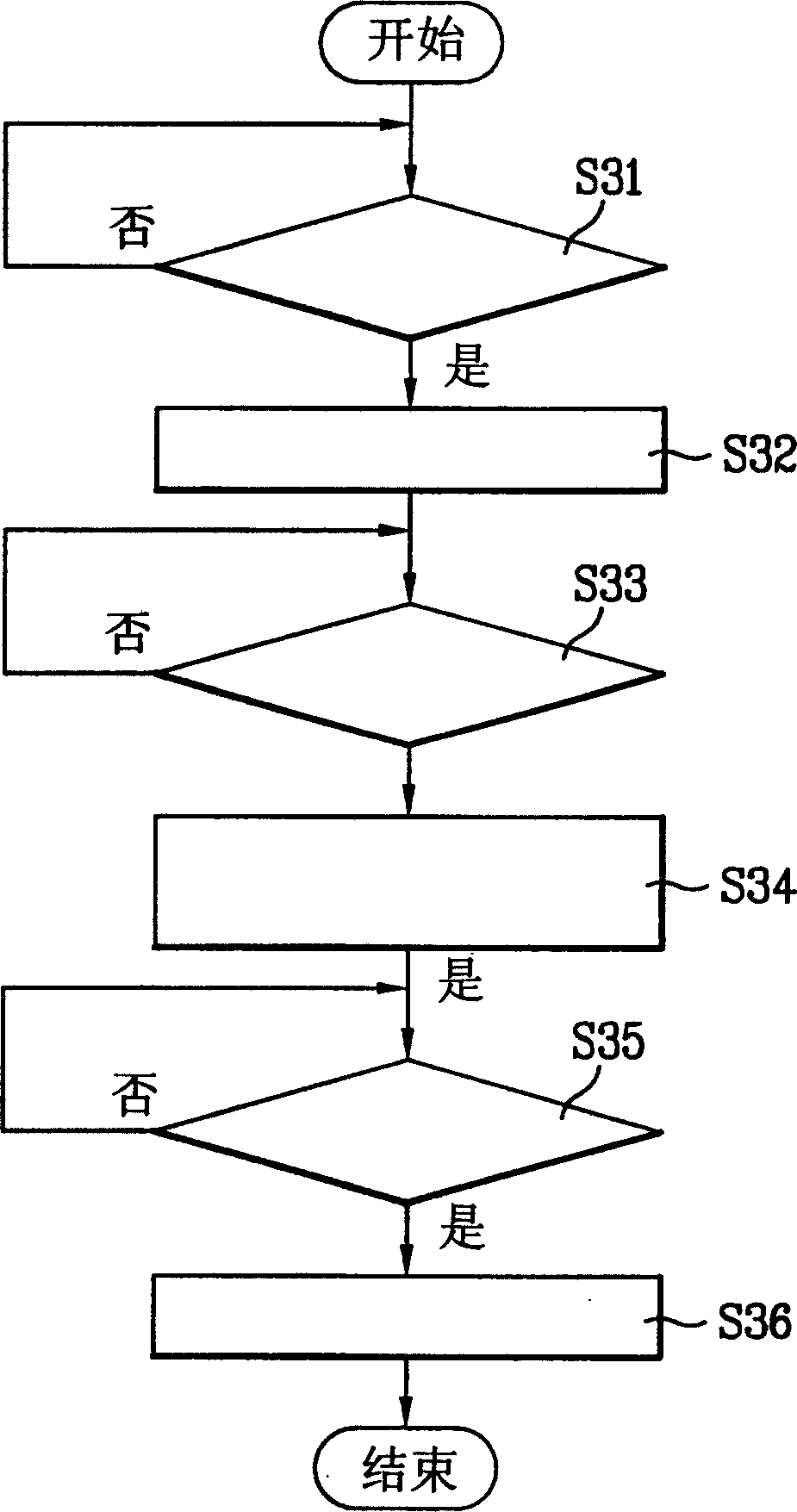

no. 2 Embodiment —

[0046] The second embodiment of the present invention is such as image 3 As shown, first, the main microcomputer 21 judges whether there is a washing instruction input S31.

[0047] Here, the washing instruction is input by the user through the user interface 18 .

[0048] If the above judgment result S31 is that there is a washing instruction input, then the agitator is accelerated S32, and whether the agitator has reached the set speed (eg 150 rpm) is judged S33.

[0049] Next, if the set speed is reached, the power is cut off to cause the agitator to rotate by inertia, and the number of pulses generated with the inertia rotation, that is, the output of the speed sensor 15, is counted S34.

[0050] Here, the main microcomputer 21 issues the agitator acceleration command to the microcomputer 17, and if it is judged that the rotational speed of the agitator has reached the set speed according to the output of the speed sensor 15, then the power is cut off, and then the outpu...

no. 3 Embodiment —

[0055] The third embodiment of the present invention is a method of combining the above-mentioned first embodiment and the second embodiment. The clothes quantity detection method in the above-mentioned first embodiment is more reliable when there is a large amount of clothes. The second embodiment The laundry amount detection method is more reliable when the amount of laundry is small.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com