A LED structure and method for manufacturing same

A technology for light-emitting diodes and a manufacturing method, which is applied in the directions of electrical components, circuits, semiconductor devices, etc., can solve problems such as the inability to effectively improve the luminous efficiency of light-emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

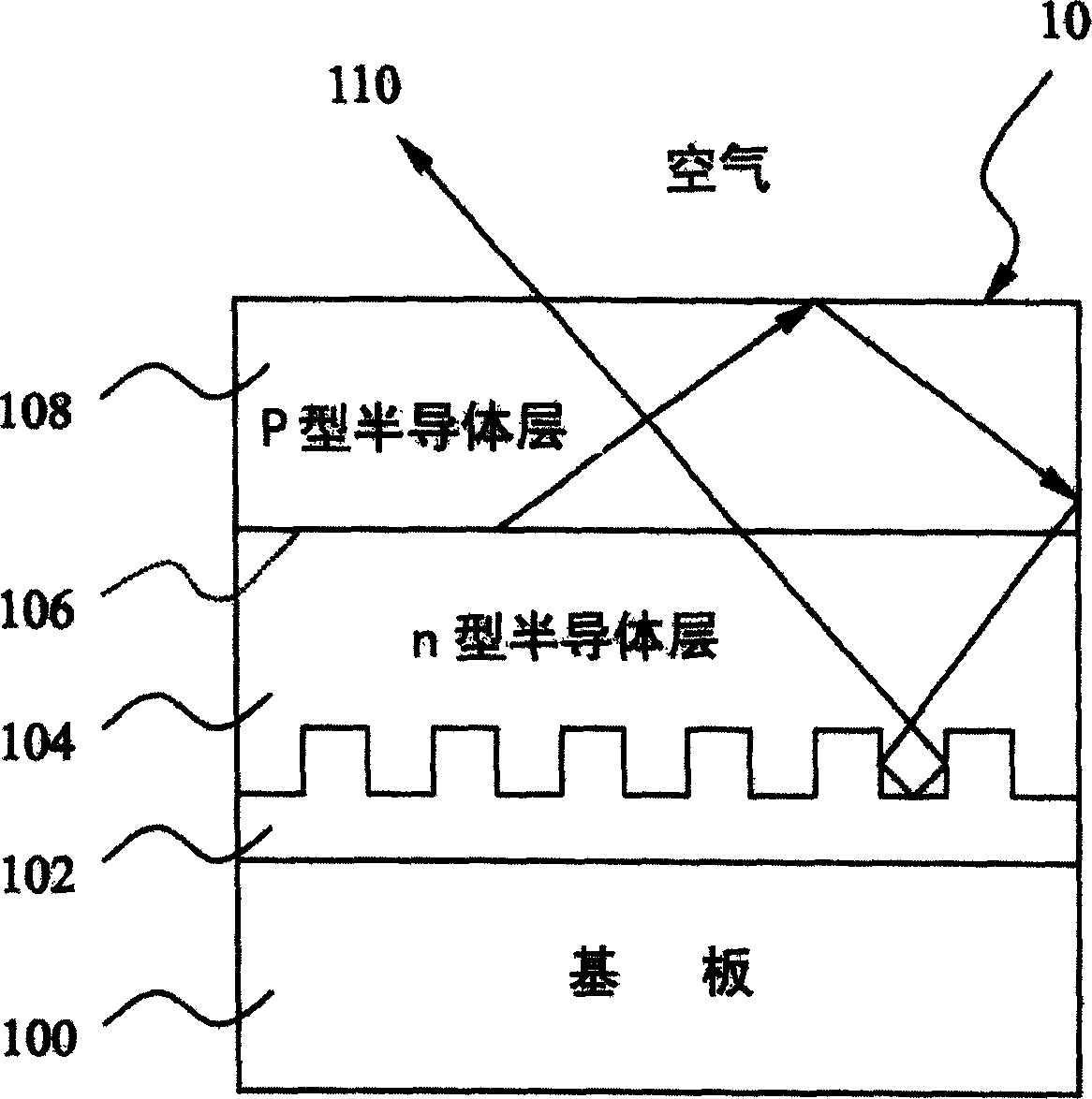

[0030] The spirit of the present invention is to grow a grid layer during the epitaxial process of the LED assembly, which can make the light emitted toward the inside of the LED assembly reflect back and travel toward the outside, so that all the light will not be continuously It travels inside the light-emitting diode assembly so that it is absorbed by the internal active layer, electrodes, and substrates, thereby improving the luminous efficiency of the light-emitting diode assembly. Such as figure 1 Shown is a basic LED assembly 10 having a mesh layer 102 . A light beam 110 generated by the p-n junction 106 in the figure is totally reflected at the interface between the LED component 10 and the air and returns to the inside of the LED component 10. When the light beam 110 reaches the grid layer 102, it is received by the grid layer. The light beam 110 is not absorbed by the substrate 100 due to the influence of the pattern on the substrate 102 and is reflected back and tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com